Disassembly-convenient large triangular 3D printer

A 3D printer, triangular technology, applied in the direction of additive processing, etc., can solve the problems affecting the overall performance, deformation of equipment parts, large transportation volume, etc., achieve the effect of simple assembly and connection, reduce packaging requirements, and reduce packaging and transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] A large triangular 3D printer that is easy to assemble and disassemble according to the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

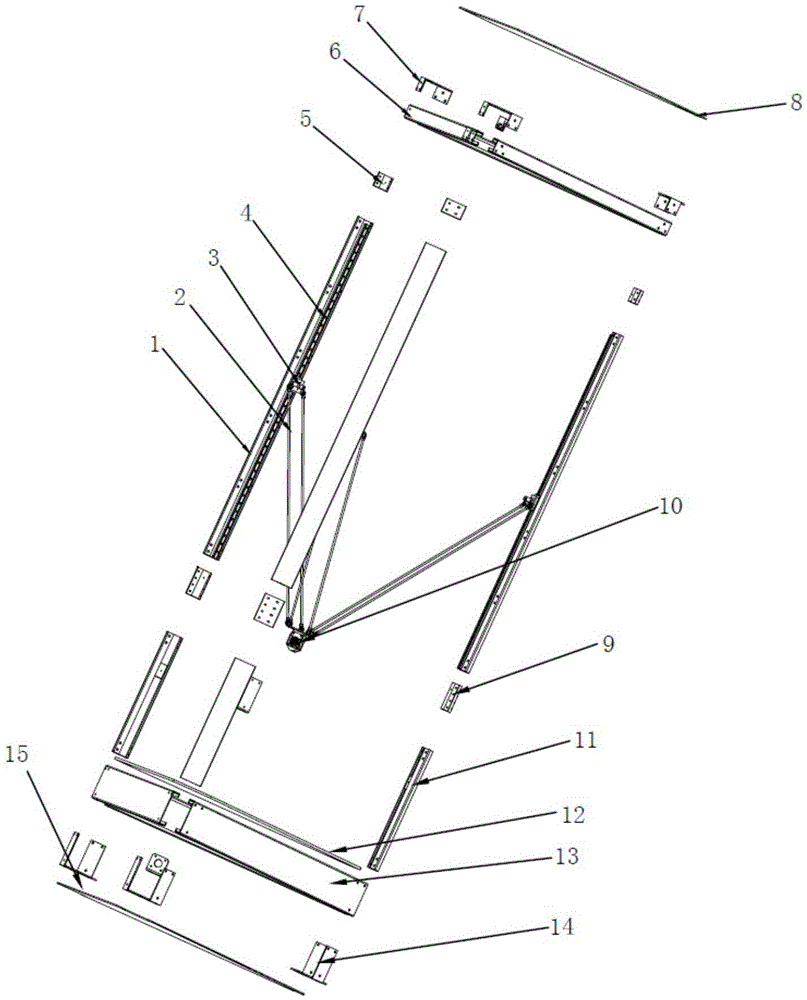

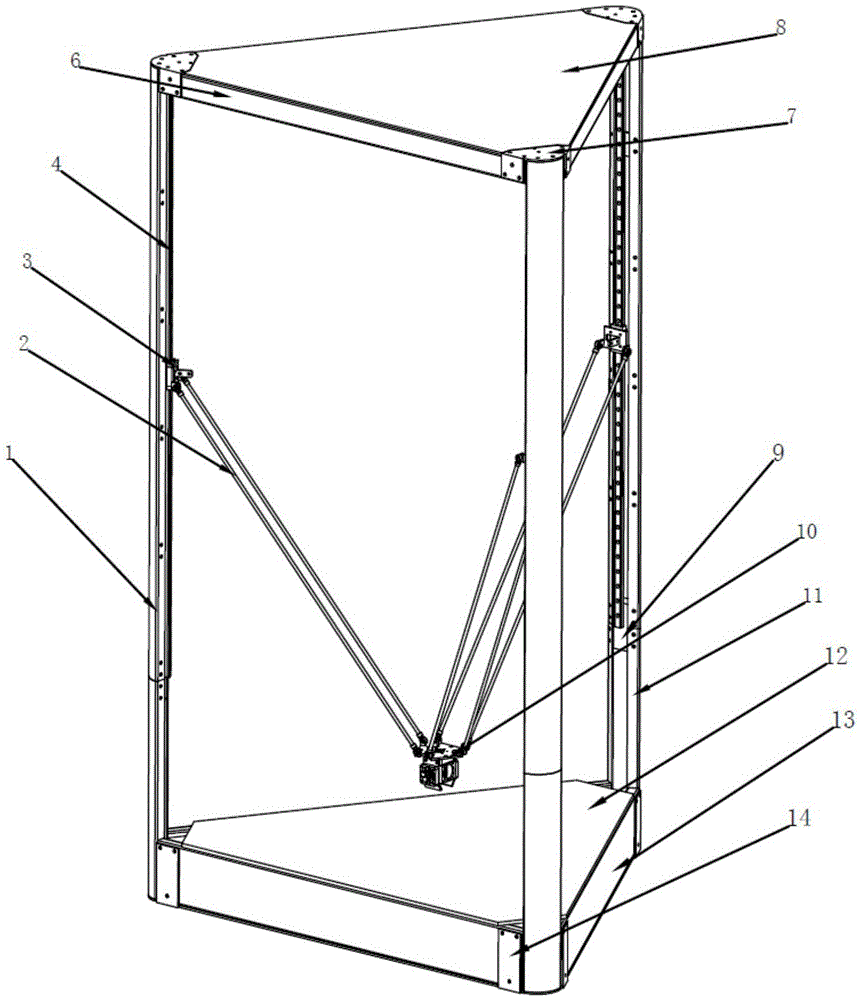

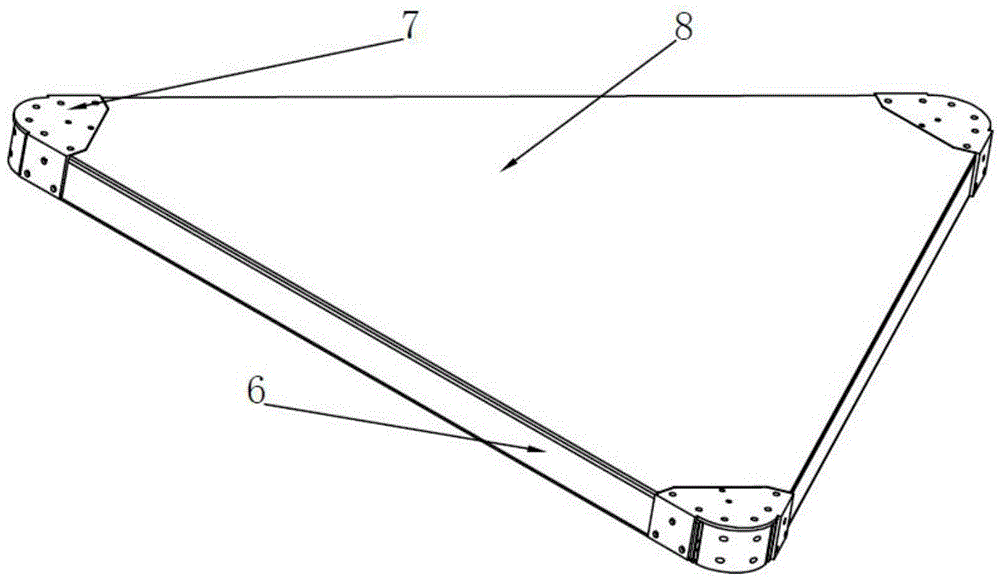

[0018] See Figure 1-2 As shown in the schematic diagram of the embodiment, a large triangular 3D printer that is easy to disassemble is mainly composed of an upper triangular cover module, a detachable support rod guide rail module, a triangular base module and a nozzle mechanism module. See image 3 As shown, the upper triangular cover module is composed of the upper cover bracket 6 , the upper cover lock block 7 and the upper cover plate 8 . During assembly, the three upper cover brackets are first connected into 6 triangular frames through the three upper cover locking blocks 7, and then the upper cover plate 8 is locked on the triangular frame. The modules are connected by screws to ensure structural strength and stability. See Figure 5 As sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com