Low-E glass high-efficiency transport damping device

A shock absorbing device, high-efficiency technology, applied in transportation and packaging, spring/shock absorber, vehicles for freight, etc., can solve the problems of LOW-E glass shattering, increasing cost and risk, difficult to fix, etc. The effect of preventing slipping, strong toughness and preventing bumps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

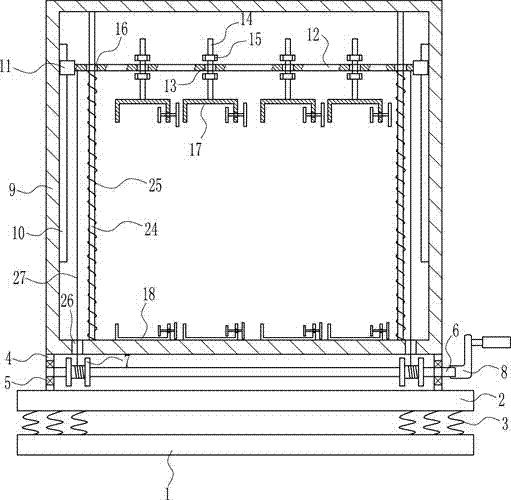

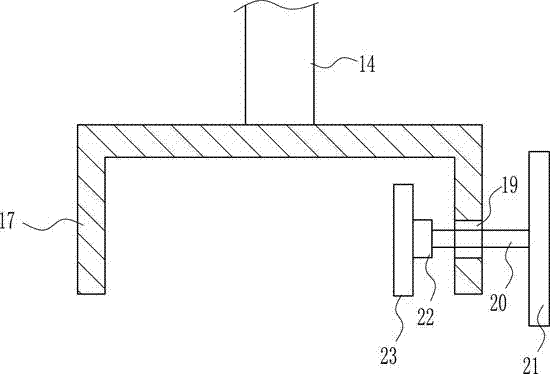

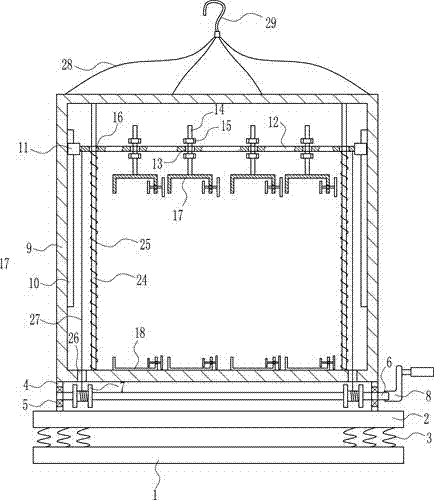

[0038] A kind of LOW-E glass high-efficiency transportation shock absorption device, such as Figure 1-8 As shown, it includes a base 1, a base plate 2, a buffer spring 3, a vertical plate 4, a first bearing seat 5, a rotating shaft 6, a winding reel 7, a rocker 8, a return frame 9, a slide rail 10, a slider 11, Horizontal plate 12, first threaded rod 14, first nut 15, upper u-shaped holder 17, lower u-shaped holder 18, second threaded rod 20, rotating rod 21, second bearing seat 22, fixed plate 23, sliding rod 24, the first spring 25 and stay cord 27, the top of the base 1 is provided with a base plate 2, the left and right sides of the top of the base 1 and the left and right sides of the bottom of the base plate 2 are connected with buffer springs 3, and the left and right sides of the base plate 2 top are provided with Riser 4, the middle part of the vertical plate 4 on the left and right sides is all embedded with the first bearing seat 5, the first bearing seat 5 on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com