Effectively fix the structure of the fuel cell stack

A fuel cell stack and support plate technology, which is applied to battery pack components, structural parts, circuits, etc., can solve problems such as unstable performance of fuel cell stacks, hydrogen leakage, and performance degradation of stacks, so as to increase service life and ensure safety Reliability, safe and reliable use, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

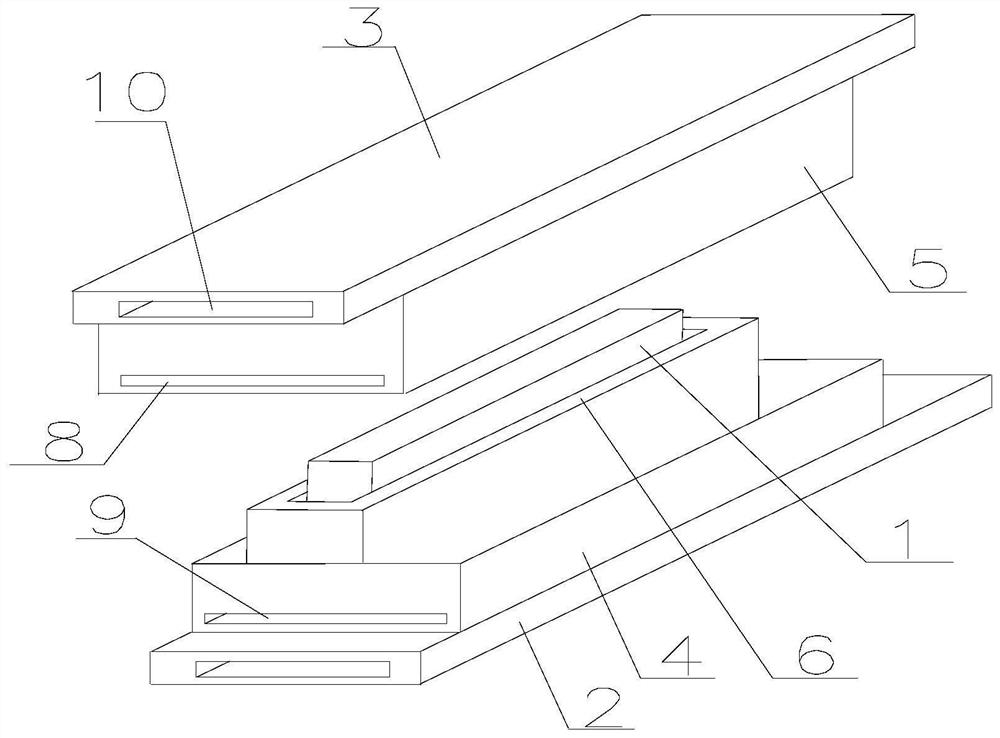

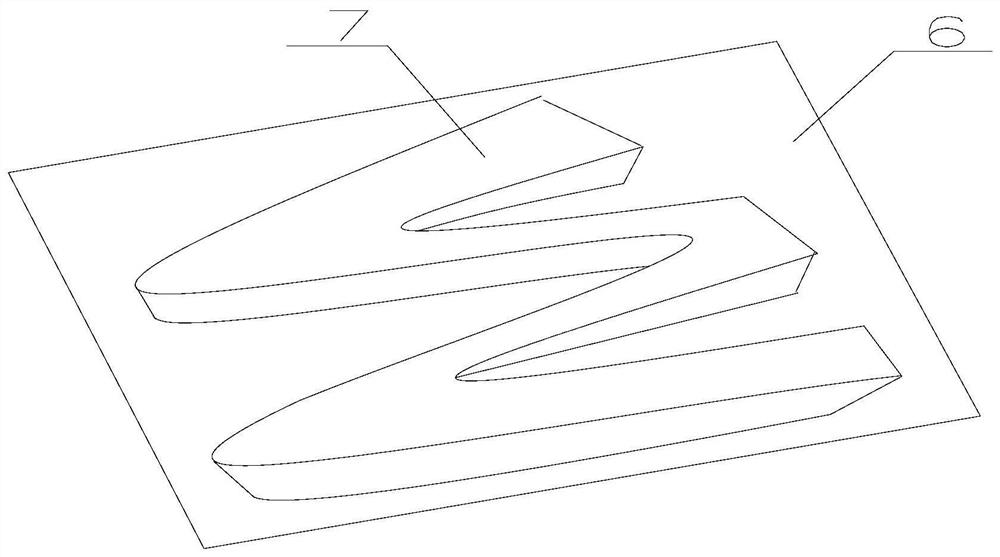

[0028] Such as figure 1 and figure 2 As shown, the structure of the present invention to effectively fix the fuel cell stack includes a fuel cell stack 1, a lower support plate 2 and an upper support plate 3 for fixing the fuel cell stack 1, and the lower support plate 2 and the upper support plate 3 are both There is a groove A for placing the fuel cell stack 1, the lower support plate 2 is connected with a placement groove 4 surrounding the fuel cell stack 1, and there is a buffer plate 6 between the placement groove 4 and the fuel cell stack 1 , the buffer plate 6 includes a pressure dispersion plate and a wave-shaped elastic buffer plate 7 located on the pressure dispersion plate, the buffer plate 7 is in contact with the side of the fuel cell stack 1, and there are several small holes on the buffer plate 7 hole, the upper support plate 3 has a groove B for clamping the buffer plate 6, and the upper support plate 3 is connected with a connecting plate 5 set in the placem...

Embodiment 2

[0030] The structure for effectively fixing the fuel cell stack includes a fuel cell stack 1, a lower support plate 2 and an upper support plate 3 for fixing the fuel cell stack 1, and the lower support plate 2 and the upper support plate 3 are provided with The groove A for placing the fuel cell stack 1, the lower support plate 2 is connected with a placement groove 4 surrounding the fuel cell stack 1, and there is a buffer plate 6 between the placement groove 4 and the fuel cell stack 1, so The buffer plate 6 includes a pressure dispersion plate and a wave-shaped elastic buffer plate 7 located on the pressure dispersion plate. The buffer plate 7 is in contact with the side of the fuel cell stack 1. There are a number of small through holes on the buffer plate 7. The upper support plate 3 has a groove B for clamping the buffer plate 6, and the upper support plate 3 is connected with a connection plate 5 set in the placement groove 4. When the connection plate 5 is set in the p...

Embodiment 3

[0032] The structure for effectively fixing the fuel cell stack includes a fuel cell stack 1, a lower support plate 2 and an upper support plate 3 for fixing the fuel cell stack 1, and the lower support plate 2 and the upper support plate 3 are provided with The groove A for placing the fuel cell stack 1, the lower support plate 2 is connected with a placement groove 4 surrounding the fuel cell stack 1, and there is a buffer plate 6 between the placement groove 4 and the fuel cell stack 1, so The buffer plate 6 includes a pressure dispersion plate and a wave-shaped elastic buffer plate 7 located on the pressure dispersion plate. The buffer plate 7 is in contact with the side of the fuel cell stack 1. There are a number of small through holes on the buffer plate 7. The upper support plate 3 has a groove B for clamping the buffer plate 6, and the upper support plate 3 is connected with a connection plate 5 set in the placement groove 4. When the connection plate 5 is set in the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com