Improved color-changing flexible neon tube lamp

A neon tube lamp, flexible technology, applied in special patterns, parts of lighting devices, patterns characterized by light projection effects, etc., can solve the problems of time-consuming production process, easy to break LED legs, short service life, etc., to achieve Uniform and soft light, increase product brightness, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

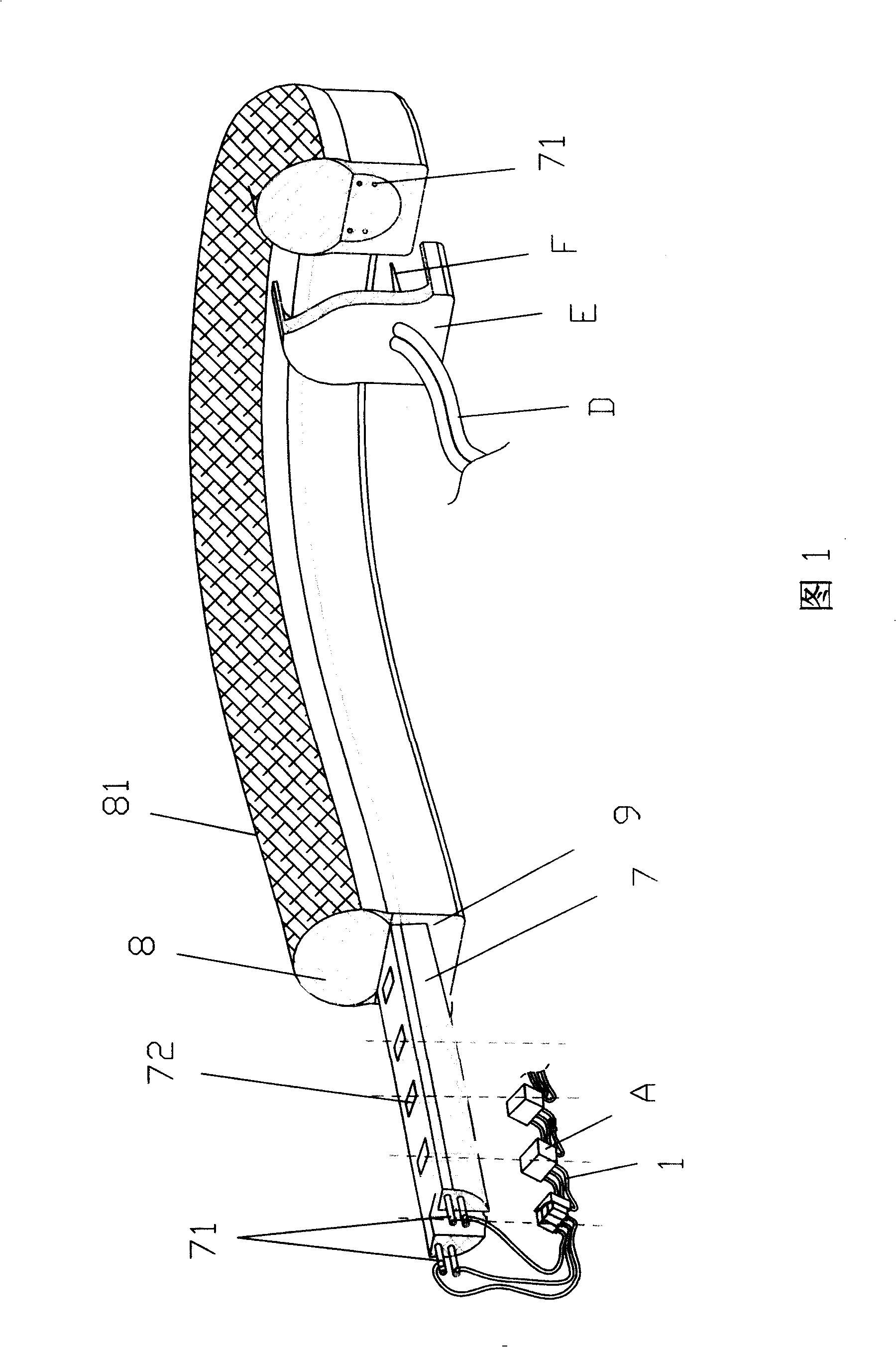

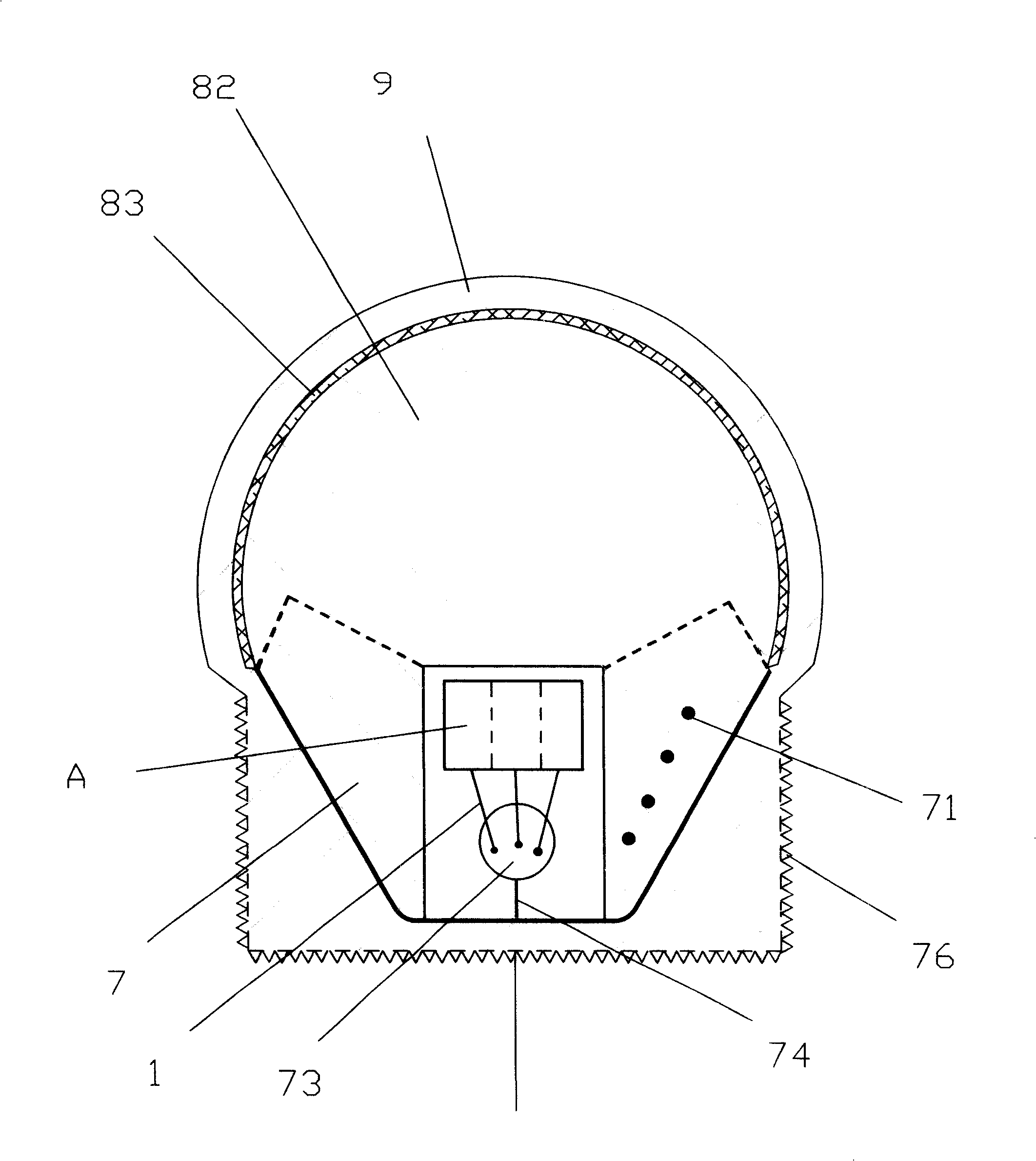

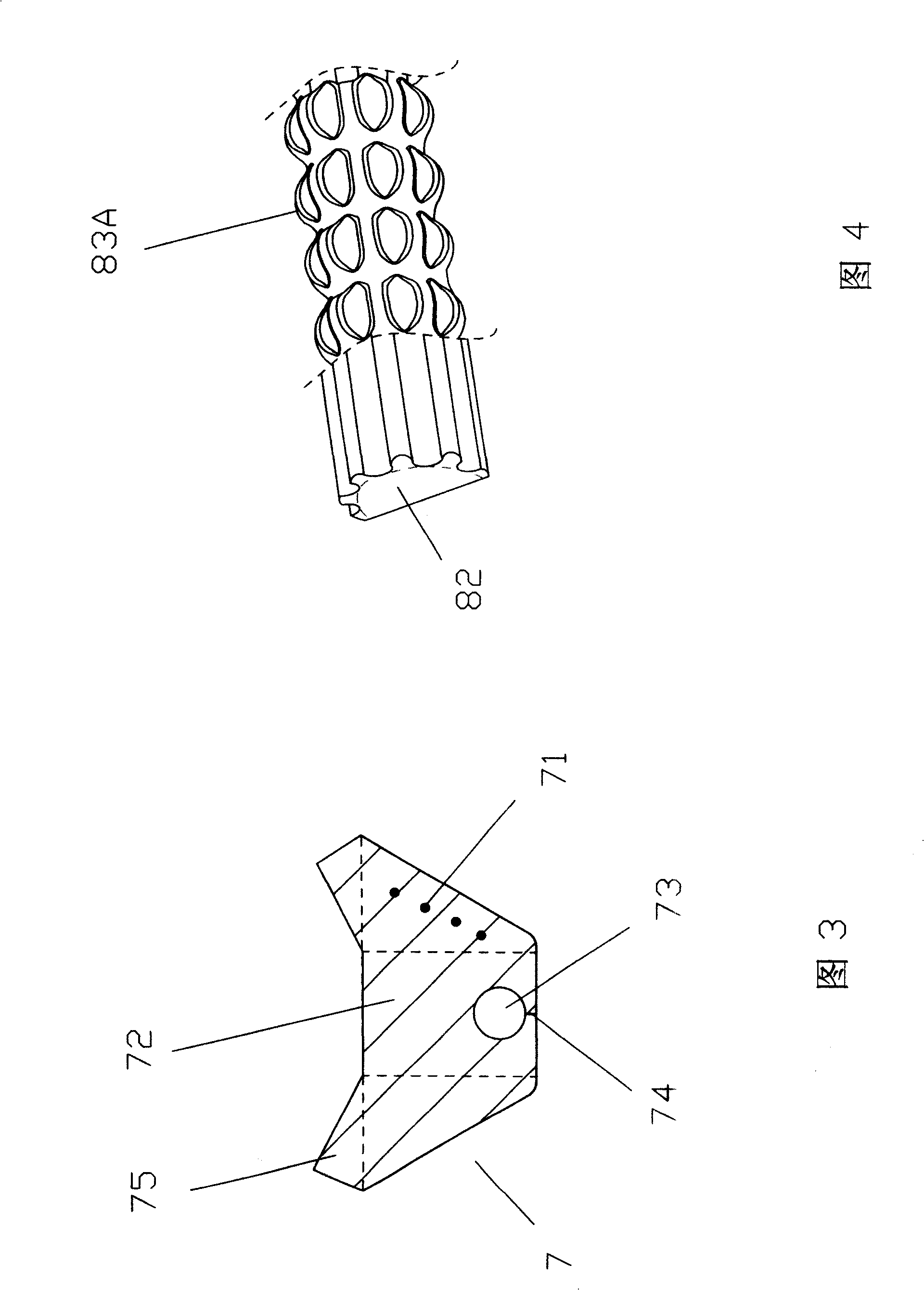

[0045] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0046] Referring to Figures 1 to 4, the present invention includes a flexible lamp body core wire 7, in which there are at least two wires 71 that can be electrically connected to a power supply or a signal controller along the longitudinal direction, the lamp body core wire 7 is The flexible plastic material is provided with a lamp body hole 72 for accommodating the illuminant in the core wire. The illuminant A is arranged in the lamp body hole. An astigmatism layer 8 is arranged above the core wire of the lamp body. The astigmatism layer is a light-transmitting body. The astigmatism layer is arranged on the top of the core wire along the longitudinal direction of the lamp body core wire. Shape, a fixed layer 9 is coated on the periphery of the core wire of the lamp body and the light-scattering layer, and the lateral direction of the fixed la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com