Light diffusion plate and lighting device

A technology of light diffusion plate and diffusion plate, which is applied in the field of diffusion plate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] The preparation method of the above-mentioned light diffusion plate in one embodiment is as follows:

[0049] 1. Mix and granulate the slices and additives used to prepare the diffusion plate body, the first microstructure layer and the second microstructure layer respectively in a twin-screw extruder to prepare masterbatches respectively. The temperature of each section of the twin-screw extruder is as follows: the temperature of the first zone is 160-220°C, the temperature of the second zone is 200-280°C, the temperature of the third zone is 195-275°C, the temperature of the fourth zone is 195-275°C, and the temperature of the fifth zone is 190-270°C °C, the temperature in the six zones is 190-270 °C, and the temperature of the machine head is 185-265 °C.

[0050] 2. Mix the above-mentioned masterbatch with the slices used to prepare the diffusion plate body, the first microstructure layer and the second microstructure layer in a certain proportion, and then put them ...

Embodiment 1

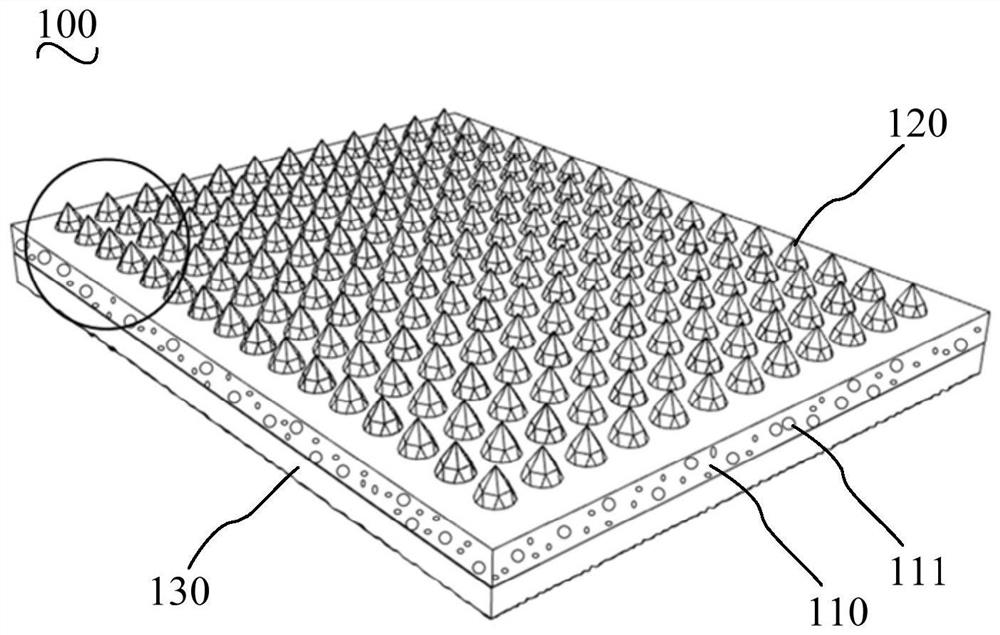

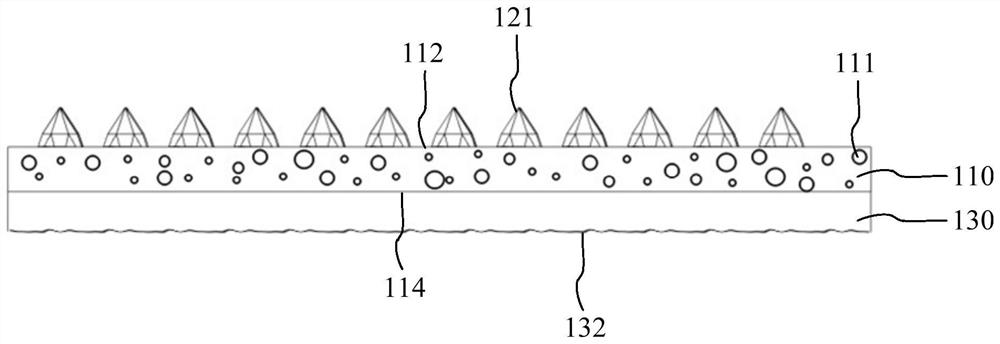

[0057] The light diffusion plate of embodiment 1 includes a diffusion plate body, a first microstructure layer and a second microstructure layer.

[0058] There are a number of diffusion particles in the diffuser body, and the diffuser body includes a light-incoming surface and a light-emitting surface. Wherein, the diffusion particles are organic silicon particles with a diameter of 1 μm. The thickness of the diffusion plate body is 0.6mm.

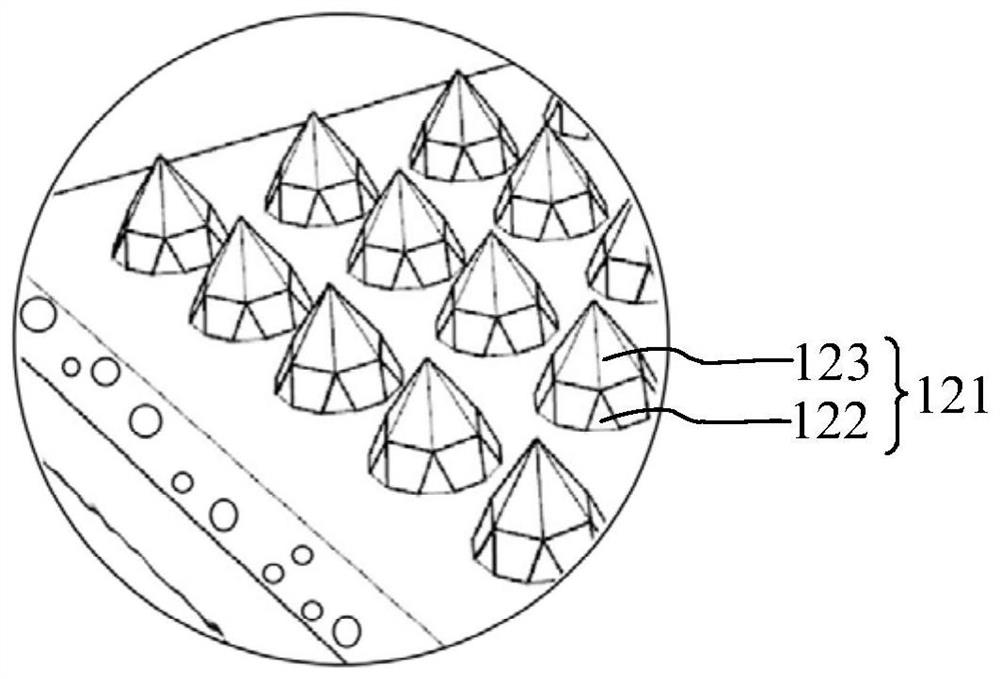

[0059] The first microstructure layer is located on the side of the light-incoming surface of the diffusion plate body, and the first microstructure layer includes several microstructures. The microstructures include prisms on the light-incoming surface and pyramids on the prisms; The bottom surface coincides with the bottom surface of the pyramid, and the sides of the prism are arranged alternately by triangles and trapezoids. The apex of the triangle away from the diffusion plate body coincides with the apex of the bottom surface of th...

Embodiment 2

[0062] The light diffusion plate in embodiment 2 includes a diffusion plate body, a first microstructure layer and a second microstructure layer.

[0063] There are a number of diffusion particles in the diffuser body, and the diffuser body includes a light-incoming surface and a light-emitting surface. Wherein, the diffusion particles are organic silicon particles with a diameter of 1 μm. The thickness of the diffusion plate body is 0.6 mm.

[0064] The first microstructure layer is located on the side of the light-incoming surface of the diffusion plate body, and the first microstructure layer includes several microstructures. The microstructures include prisms on the light-incoming surface and pyramids on the prisms; The bottom surface coincides with the bottom surface of the pyramid, and the sides of the prism are arranged alternately by triangles and trapezoids. The apex of the triangle away from the diffusion plate body coincides with the apex of the bottom surface of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bottom side length | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com