Integrated continuous discharging mobile mixing plant

An all-in-one, mixing station technology, applied in the field of mixing stations, can solve the problems affecting the safety of construction and equipment use, poor coordination of functional equipment, poor stability of the main body of the mixing station, etc. Transportation risk, the effect of convenient transportation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples.

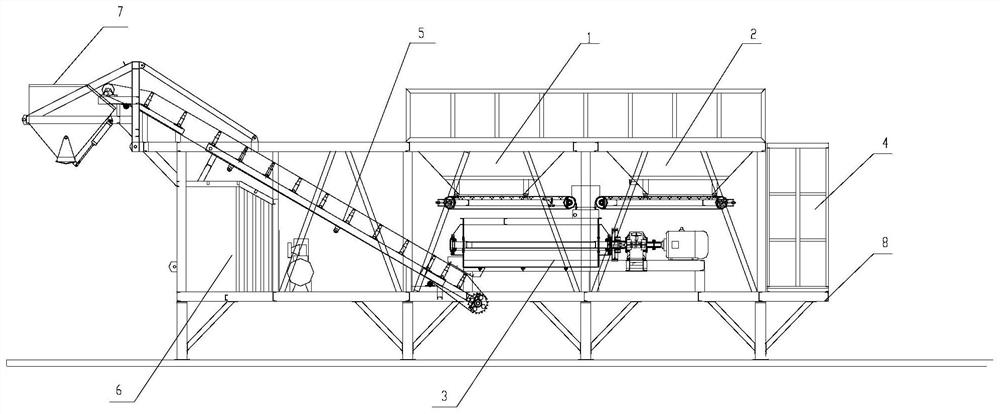

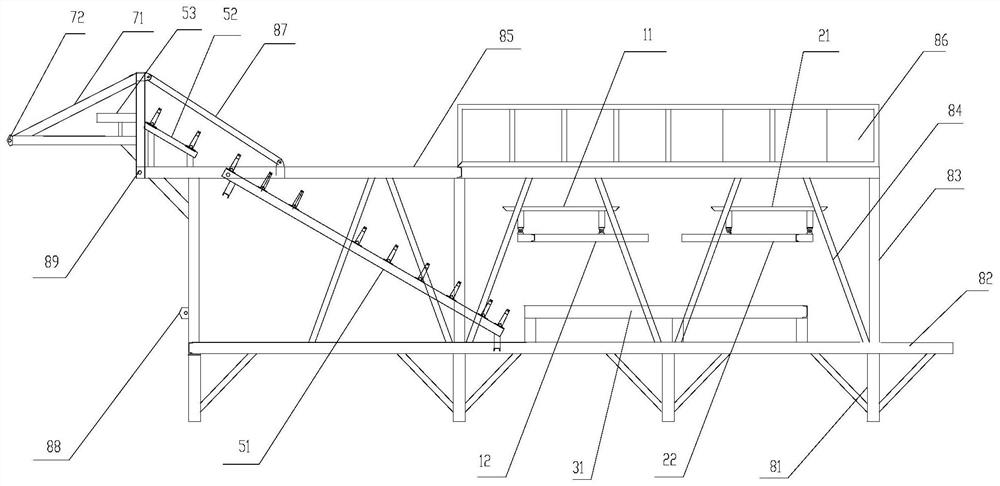

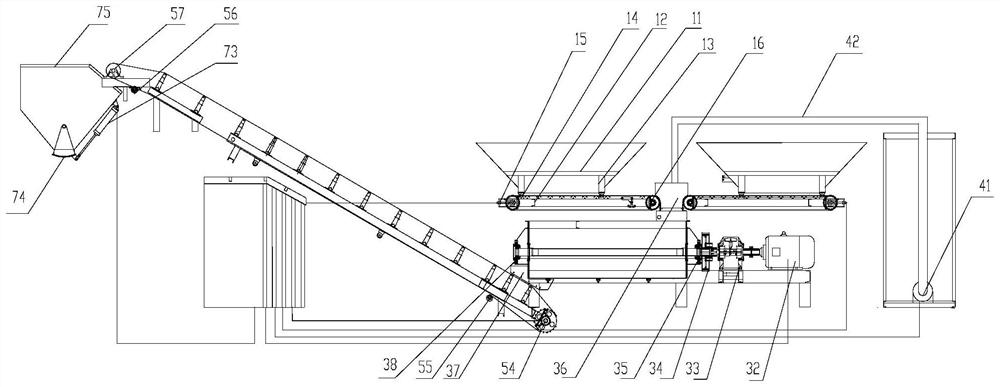

[0030] Such as figure 1 As shown, the integrated continuous discharge mobile mixing station includes a first batching mechanism 1, a second batching mechanism 2, a stirring mechanism 3, an admixture device 4, a transmission mechanism 5, a control room 6, a transfer warehouse mechanism 7, and a frame body 8 Connect the above-mentioned various functional devices into an integrated device structure.

[0031] In the present invention, each functional equipment is controlled by the control room 6. The connection relationship between them is as follows: the first batching mechanism 1 and the second batching mechanism 2 have the same structure, and they are horizontally arranged, and the materials are erected at their respective discharge ports. The conveyor belt is transferred t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com