Treatment process for chemical nickel plating waste liquid in circuit board industry

A treatment process, chemical nickel technology, applied in the field of chemical nickel waste liquid treatment in the circuit board industry, can solve water eutrophication pollution, environmental pollution and other problems, achieve the effects of reducing pollution, considerable economic benefits, and reducing treatment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

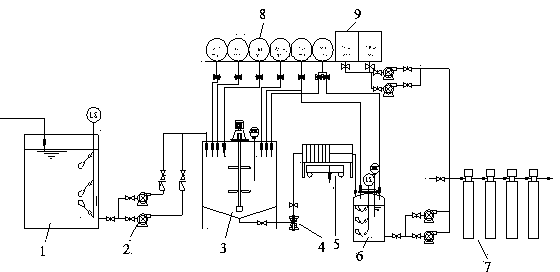

Image

Examples

Embodiment 1

[0038] Use waste liquid delivery pump 2 to extract 3000L containing Nickel waste liquid In the reaction tank 3, add sulfuric acid through the dispensing tank and the dosing metering pump 8 to adjust the pH to 3~4, then add ferrous sulfate 15KG, slowly add 27.5% hydrogen peroxide 100L at a speed of 2~3L / min to carry out the Fenton reaction to break the complex and Oxidize hypophosphite, after reacting for 2Hr, add 25KG ferrous sulfate solid to reduce excess hydrogen peroxide and increase flocculation effect. Add sodium hydroxide to adjust the pH to 9~10, add 3KG Na 2 Continue to adjust the pH to 11 after the S reaction for 30 min. After stirring and reacting for 20 minutes, add 250~300L of 0.2% PAM to precipitate and form obvious alum flocs. Close the agitator of the reaction tank 3, open the plate and frame filter press 5 and the pneumatic diaphragm pump 4 for solid-liquid separation, the filtrate flows into the pH callback intermediate tank 6, and then add sulfuric acid to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com