Oil-gas mixed gas recovery control method and system and master controller

A technology of gas recovery and oil-gas mixing, which is applied to the charging system, machines/engines, and adding non-fuel substances to fuel, etc., can solve problems such as oil circuit blockage, improve reliability, improve recovery quality, and reduce excessive emissions risk effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

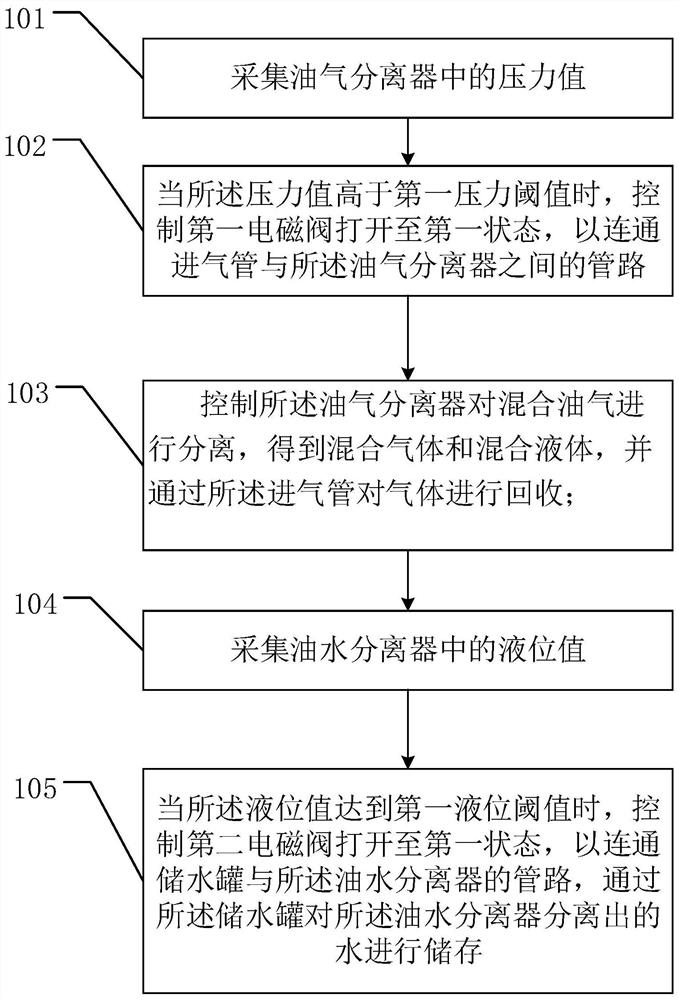

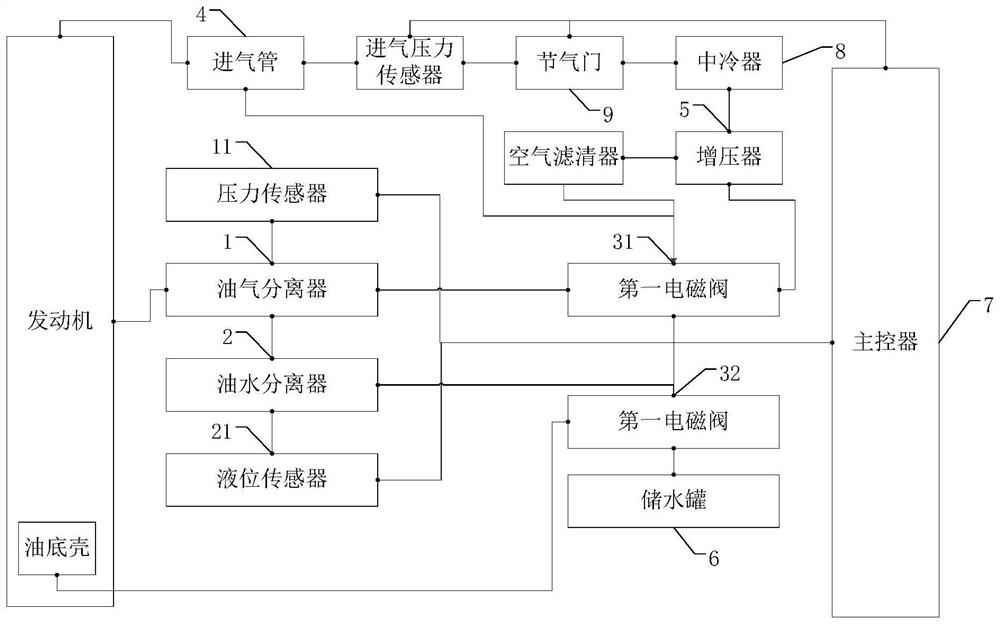

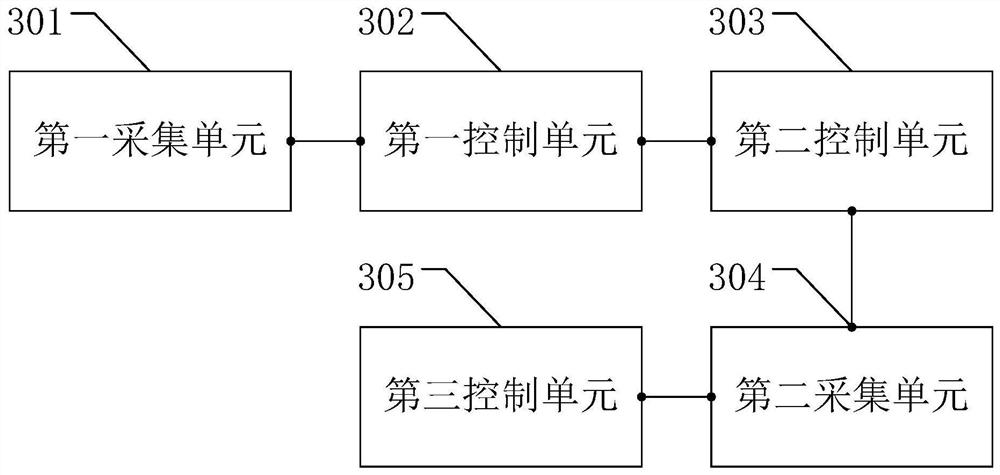

Method used

Image

Examples

Embodiment Construction

[0039] As an important part of the vehicle, the crankcase in the vehicle engine can not only effectively prevent the crankcase pressure from being too high, but also effectively extend the service life of the engine oil and reduce wear and corrosion of parts. With the implementation of the National VI regulations, the importance of the engine crankcase of the vehicle has become more prominent. Among them, 6.5 of the "Heavy-duty Diesel Vehicle Pollutant Emission Limits and Test Methods (China Phase VI)" (GB 17691-2018) clearly states that "engine Any gas in the crankcase is not allowed to be discharged into the atmosphere", and "crankcase exhaust shall be tested in accordance with the open crankcase pollutant evaluation method, crankcase emissions and exhaust emissions shall not exceed the emission limit".

[0040] In the solution provided by the prior art, the blow-by gas in the engine crankcase (which may contain unburned oil gas, water vapor and exhaust gas, etc.) enters the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com