Method for recovering metal conductor from enameled wire

A technology of metal conductors and enameled wires, applied in recycling technology, electronic waste recycling, electrical components, etc., can solve problems such as insufficient purity of recycled products, environmental pollution sources, etc., to improve recovery rate and recycling quality, reduce pollution, and low consumption The effect that can be recycled

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

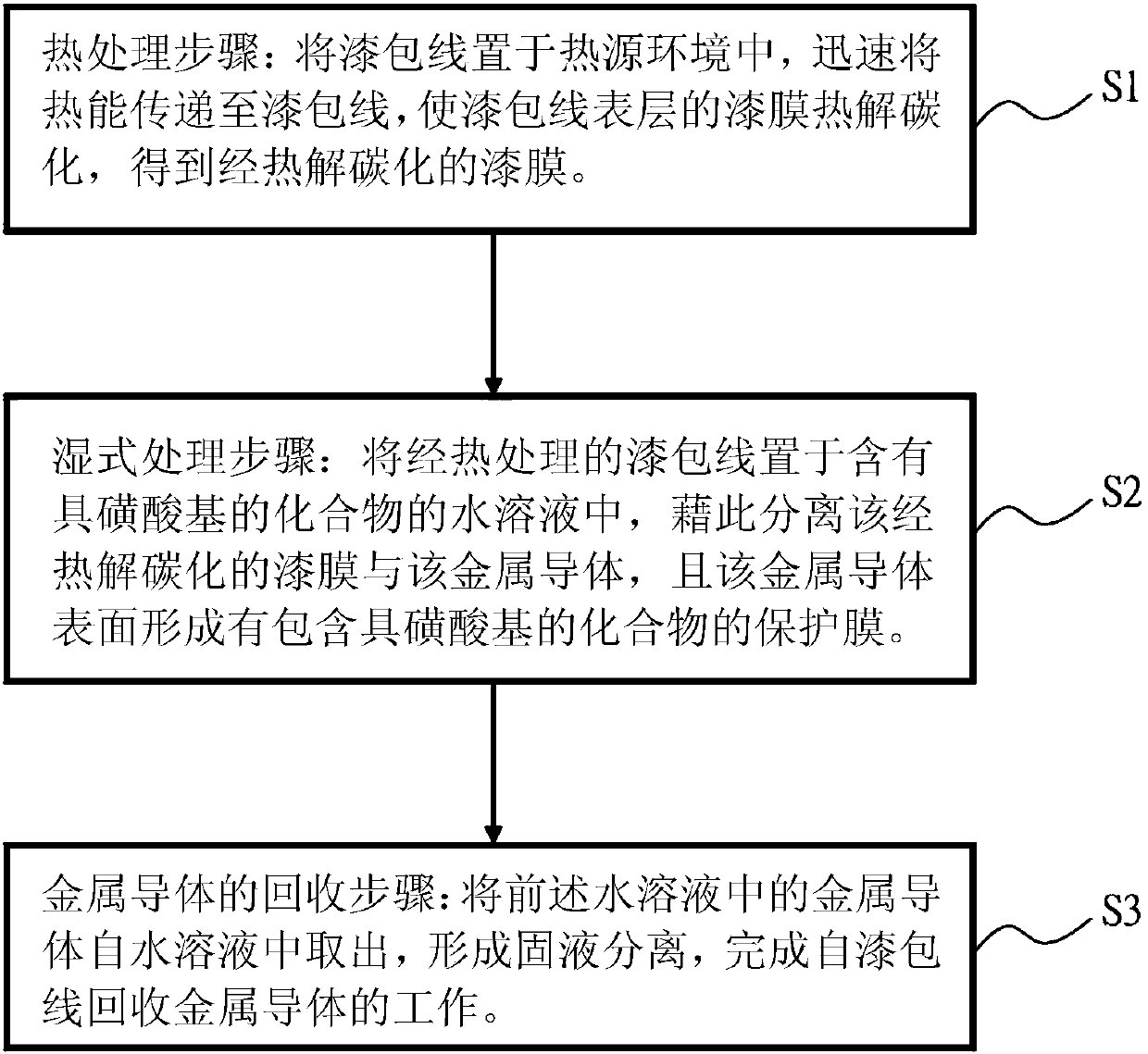

[0039] Step S1 is a heat treatment step: the enameled wire is placed in a heat source environment, and the heat energy in the heat source environment is quickly transferred to the enameled wire through the heat source environment through heat conduction, heat radiation, etc., so that the paint film on the surface of the enameled wire is pyrolyzed and carbonized to obtain a heated Decarbonized paint film. The temperature of the heat source environment is 500°C, so that the paint film is pyrolyzed and carbonized after being heated, and the metal conductor material will not be melted due to heat, so as to avoid the melting of the metal conductor material due to the high temperature of the heat source environment. The decarburized paint films are melted and mixed with each other, causing subsequent troubles in the recovery of metal conductors.

[0040] In addition, the present invention places the enameled wire in a heat source environment for pyrolytic carbonization for 20 minute...

Embodiment 2

[0047] The method for recovering metal conductors from enameled wires in Example 2 is similar to the steps in Example 1, the difference being that the time for pyrolytic carbonization in the heat source environment is 25 minutes. In this embodiment, the immersion time of the heat-treated enameled wire placed in the aqueous solution containing the compound with sulfonic acid groups is 5 minutes, 10 minutes, and 15 minutes in sequence, and the peeling area of the carbonized paint film at each stage 85%, 99% and 99.5%, respectively. The pyrolytic carbonized paint film on the surface of the metal conductor becomes less and less, and the surface of the metal conductor becomes cleaner. After soaking in the aqueous solution containing the compound with sulfonic acid groups for 15 minutes, the remaining carbonized paint film on the metal conductor is hardly visible to the naked eye, and the recovery rate of the recovered metal conductor is greater than 99.5% by weight.

Embodiment 3

[0049] The method for recovering metal conductors from enameled wires in Example 3 is similar to the steps in Example 1, the difference being that the time for pyrolytic carbonization in the heat source environment is 30 minutes. In this embodiment, the immersion time of the heat-treated enameled wire placed in the aqueous solution containing the compound with sulfonic acid groups is 5 minutes, 10 minutes, and 15 minutes in sequence, and the peeling area of the carbonized paint film at each stage 95%, 100%, and 100%, respectively. The pyrolytic carbonized paint film on the surface of the metal conductor becomes less and less, and the surface of the metal conductor becomes cleaner. After soaking in the aqueous solution containing the compound with sulfonic acid group for 10 minutes, the residual carbonized paint film on the metal conductor is almost invisible to the naked eye; after soaking for 15 minutes, the surface of the metal conductor is brighter . The metal conductor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com