Method and device for transporting thin-wall equipment in nuclear power plant

A technology for transportation devices and nuclear power plants, applied in the field of transportation, can solve problems such as no reinforcement measures, large dimensions, and fragile structures, and achieve the effects of improving transportation stability, reducing transportation risks, and solving adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

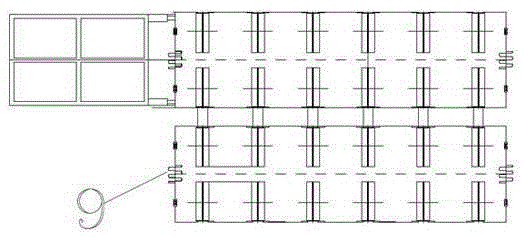

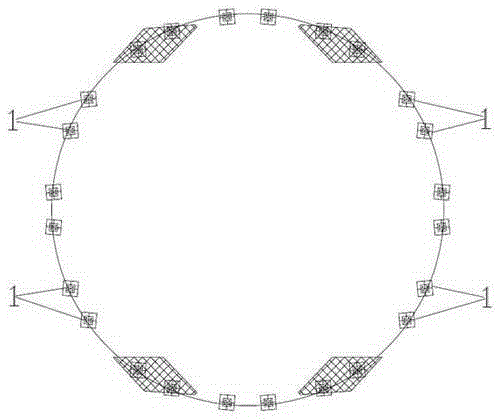

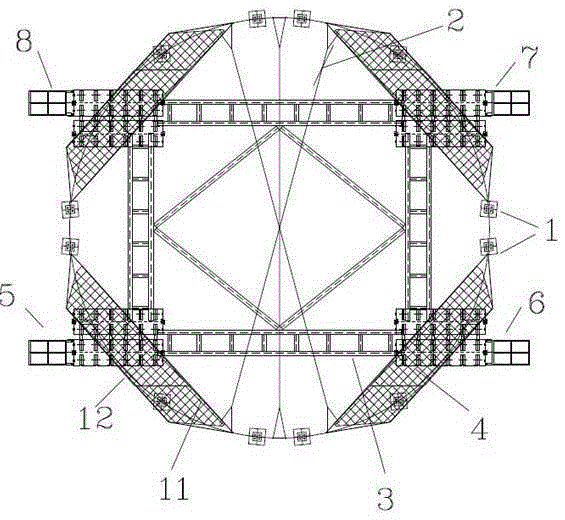

[0029] Such as Figure 1 to Figure 3 As shown, the present invention discloses a transport device for nuclear power plant thin-walled equipment, including a power module transporter (SPMT), a plurality of cement buttresses 1, and thin-walled equipment. The power module transporter (SPMT) is four groups, and the The power module transport vehicle (SPMT) is composed of a square arrangement, and the power module transport vehicle (SPMT) group is connected by a connecting frame 3. The power module transport vehicle (SPMT) is fixed with a steel plate, and the steel plate is laid with welded and formed The bracket 4, the bracket 4 is provided with a base, the steel plate and the bracket base are fixed by spot welding, and the power module transport vehicle (SPMT) is provided with an inner block frame 11, an outer block frame 12. The multiple cement piers 1 are arranged in a ring, and the thin-walled equipment is arranged on the multiple cement piers 1 .

[0030] Two 8000mm×2400mm×3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com