Biological composting processing method of oil-based drilling wastes

An oil-based drilling and treatment method technology, which is applied in the direction of bio-organic part treatment, organic fertilizer, fertilization device, etc., can solve the problems of high safety risk of oil-based drilling waste transportation, unutilized resources, and high treatment cost, and achieve The effect of reducing transportation risk, high economic applicability, and high degradation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

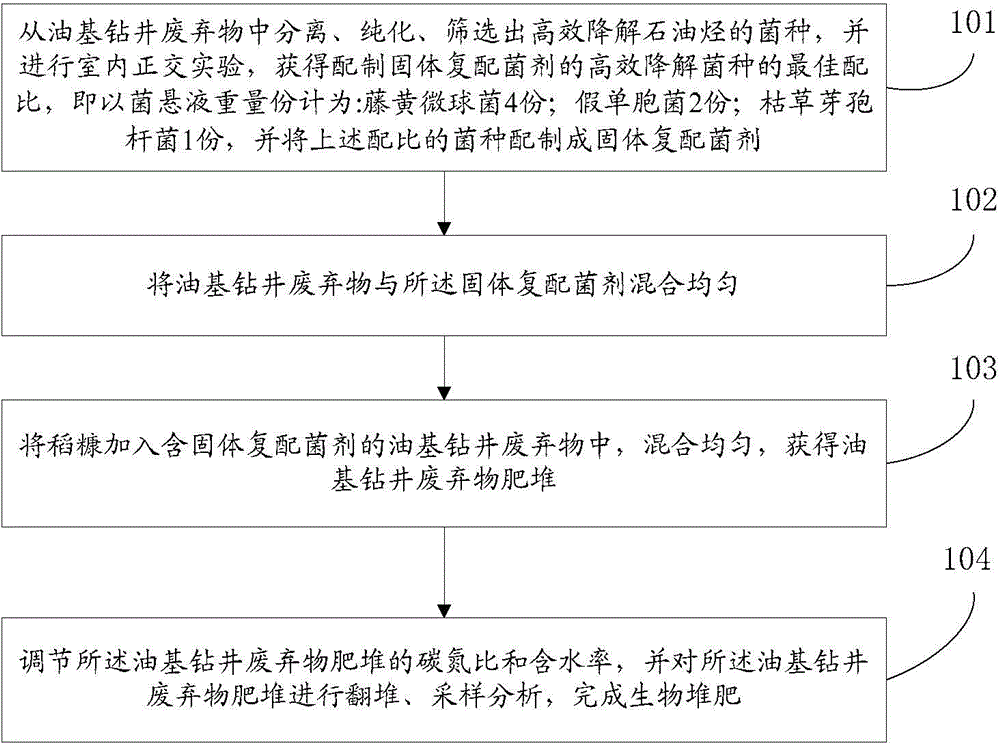

[0046] as attached figure 1 As shown, the embodiment of the present invention provides a biocomposting method of oil-based drilling waste, the method is:

[0047]Step 101. Separating, purifying, and screening strains that efficiently degrade petroleum hydrocarbons from oil-based drilling waste, and conducting indoor orthogonal experiments to obtain the optimal ratio of strains that can efficiently degrade the solid compound bacterial agent, namely Calculated in parts by weight of the bacterial suspension: 4 parts of Micrococcus luteus; 2 parts of Pseudomonas;

[0048] Step 102, mixing the oil-based drilling waste and the solid compound bacterial agent evenly.

[0049] Step 103, adding rice bran to the oil-based drilling waste containing the solid compound bacterial agent, and mixing evenly to obtain an oil-based drilling waste compost heap.

[0050] Step 104 , adjusting the carbon-to-nitrogen ratio and water content of the oil-based drilling waste compost heap, turning over ...

Embodiment 2

[0054] An embodiment of the present invention provides a biological composting treatment method for oil-based drilling waste, the method comprising:

[0055] Step 201: Separating and obtaining bacteria that can degrade petroleum hydrocarbons from oil-based drilling waste, isolating, purifying, and screening highly efficient degrading bacteria using oil-based drilling waste as the only carbon source, and conducting indoor orthogonal experiments, Obtain the optimal proportioning ratio of the highly efficient degrading bacterial classification of preparation solid compound bacterial agent, count 4 parts of Micrococcus luteus in terms of the weight part of bacterial suspension; 2 parts of Pseudomonas; 1 part of Bacillus subtilis, and above-mentioned formula The specific strains are formulated into solid compound bacterial agents.

[0056] Wherein, the preparation method of the solid compound bacterial agent is specifically: mixing the bacterial suspensions of Micrococcus luteus, P...

Embodiment 3

[0075] Preparation of solid compound bacterial agent:

[0076] 1: Isolation and purification of oil total hydrocarbon degrading bacteria

[0077] (1) Preparation of soil suspension

[0078] Collect different oil-based drilling waste samples, weigh 10g under sterile conditions, put them into a 250ml triangular flask filled with 90ml sterile water to make a sample suspension, the concentration is 10- 1 . Shake for 30 minutes on a constant temperature shaker, and then dilute with a 10-fold dilution method.

[0079] (2) Preparation of diluent

[0080]Under sterile conditions, use a sterile pipette to draw 1.0ml from the soil suspension and pour it into a test tube filled with 9.0ml sterile water, blow and suck three times, and mix well to obtain a concentration of 10 -2 diluent. Then use another 1ml sterile pipette to draw 1.0ml of the solution from the test tube and inject it into another test tube filled with 9.0ml sterile water, and so on to make 10 -3 , 10 -4 , 10 -5 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com