Integrated workshop of laser repairing system

A system integration and laser repair technology, applied in the field of parts processing, can solve the problems of low production efficiency in transportation and hoisting, inconvenient transportation and hoisting, and low efficiency, and achieve the effect of reducing hoisting time, ensuring safety, and reducing risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

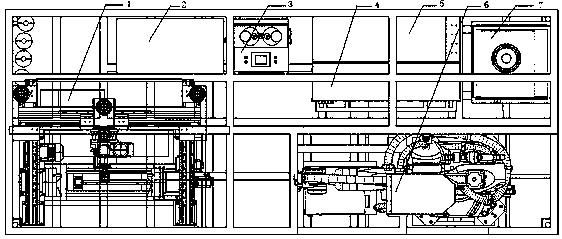

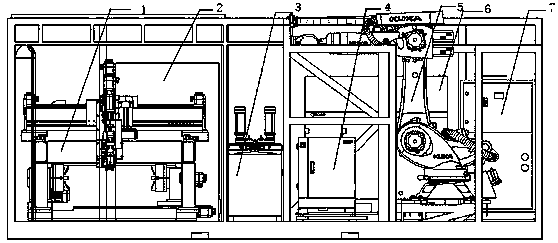

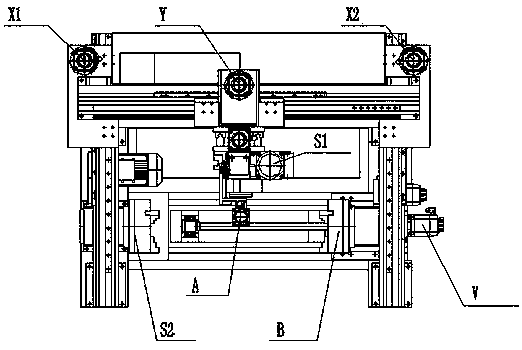

[0032] The laser repair system integration workshop provided by the present invention includes a base on which lasers, robots, robot control cabinets, powder feeders, power supply control cabinets and 6-axis special machines are installed; wherein, all devices in the workshop are installed in two rows, The 6-axis special plane and the robot are arranged side by side, and the power control cabinet, powder feeder, and robot control cabinet are installed side by side;

[0033] The laser is connected with the 6-axis special plane for controlling the operation of the 6-axis special plane; the robot control cabinet is connected with the robot for controlling the operation of the robot;

[0034] The equipment in the workshop also includes a protective wall installed around the base to form a protective room. The power control cabinet is connected to the rest of the equipment, and an external power connection interface is provided on the power control cabinet;

[0035] The powder feed...

Embodiment 2

[0038] A lighting system is also provided in the workshop, and the lighting system is connected with the power control cabinet.

Embodiment 3

[0040] As an integrated workshop as a whole, in order to further achieve a reasonable layout and facilitate the design of the external structure, the edge of the robot is aligned with the 6-axis special machine, the edge of the chiller is aligned with the edge of the robot, and the outer edge of the equipment in the same row is aligned, so that the base A rectangular outer shape is formed, and moving rollers are installed under the base.

[0041] Installing the casing and rollers can further facilitate the movement and placement of the entire workshop, and the interior of the workshop is an independent working environment, which ensures the stability and safety of the working environment.

[0042] All equipment is completed by an integrated monitoring system, and other controllers can be connected externally to monitor the working conditions in the workshop.

[0043] Container Design Scheme:

[0044] 1. According to the current hardware equipment, fix the laser control cabine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com