Building construction concrete block crushing device

A technology of concrete block and crushing device, applied in the direction of grain processing, etc., can solve the problems of insufficient and comprehensive crushing of construction waste, and achieve the effect of full and efficient crushing, improving crushing efficiency, and speeding up screening.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

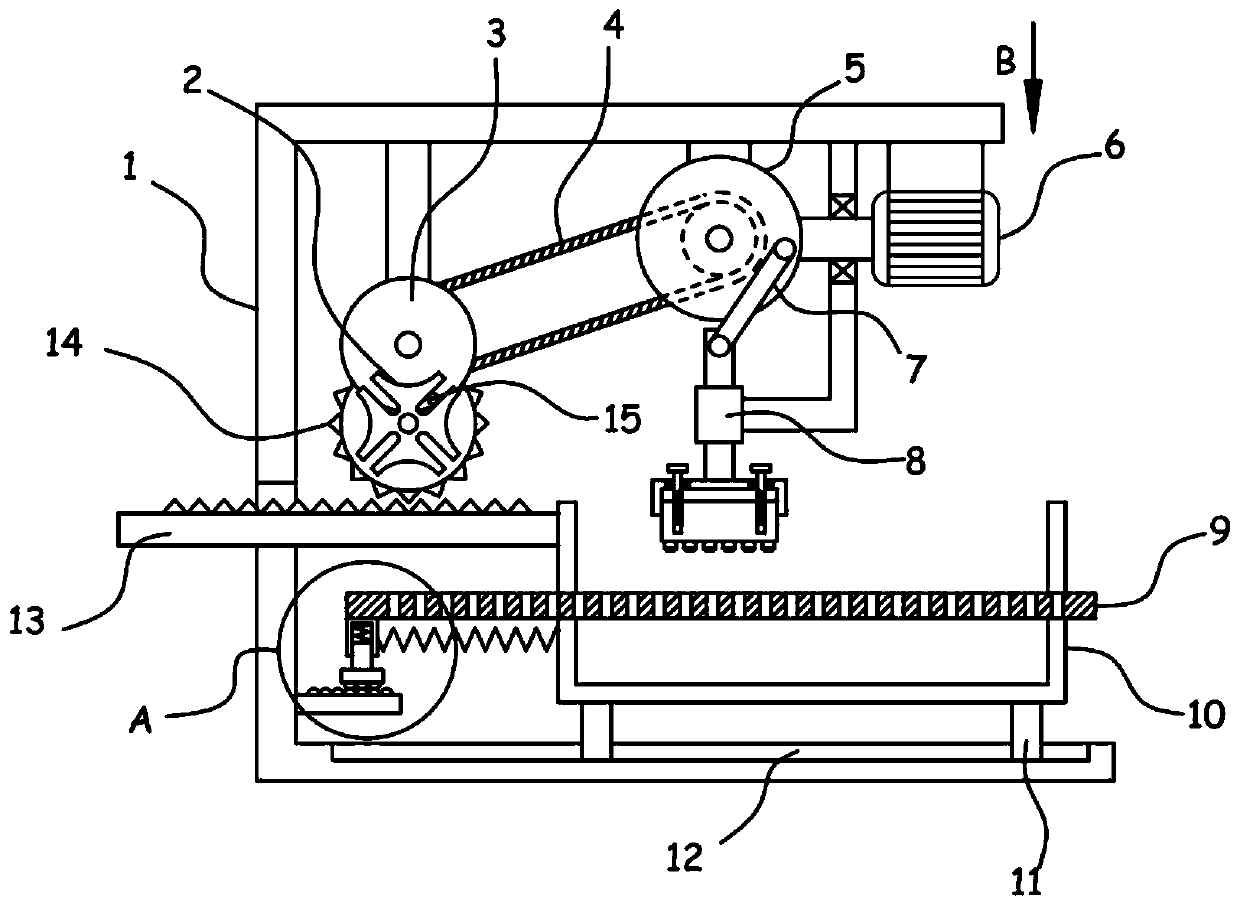

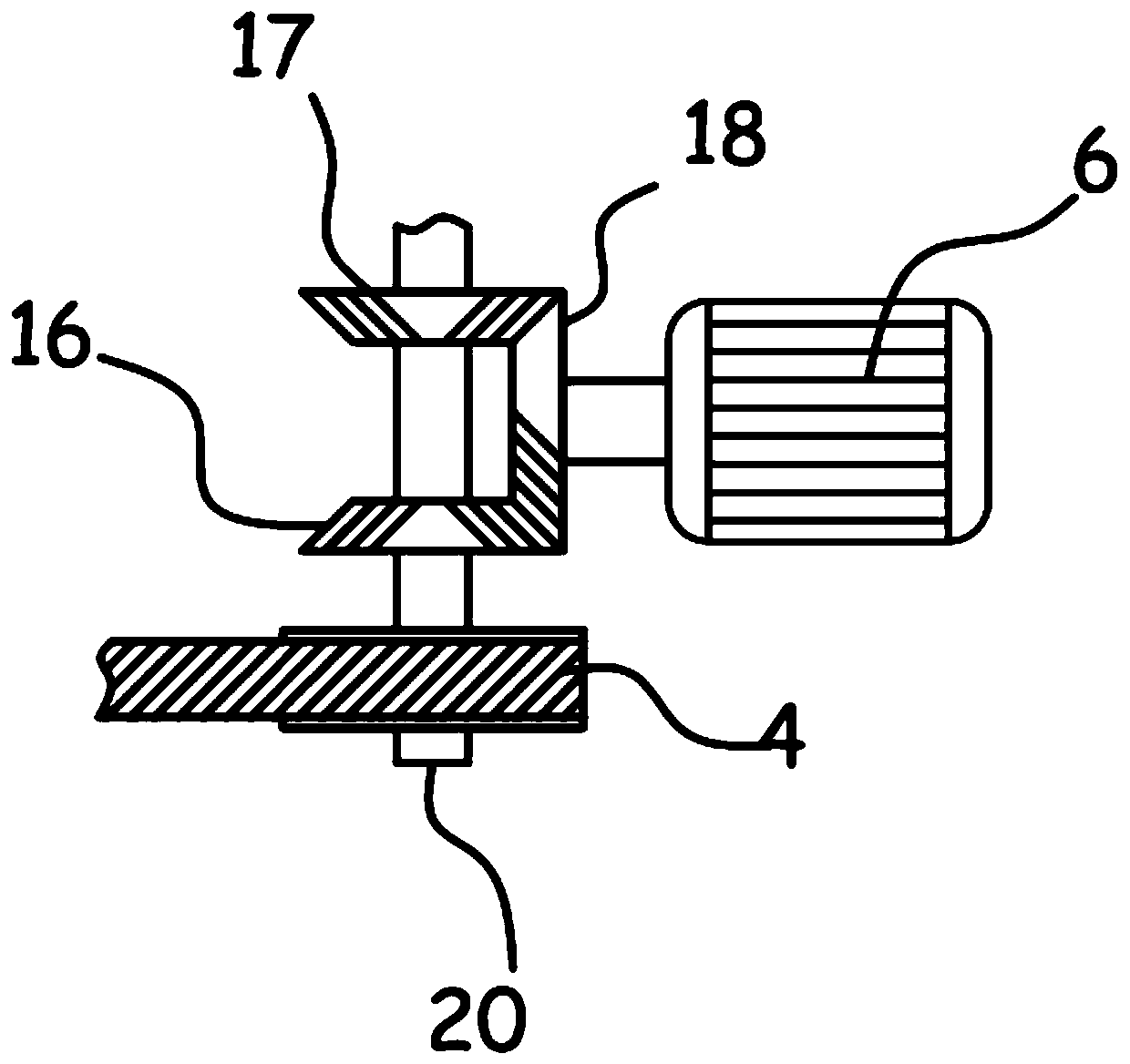

[0024] See Figure 1-5 , A building construction concrete block crushing device, including a fixed frame 1, a collection tank 10 is slidably installed on the fixed frame 1 through a guide mechanism, a net plate 9 is provided in the collection tank 10, and the collection tank 10 is connected by a lifting reciprocating mechanism to drive For the impact crushing mechanism for crushing concrete blocks, the lifting and reciprocating mechanism includes a rotating disc 5, and a sheave mechanism is connected to the sheave mechanism for driving, a rotating transmission gear 14 is drivingly connected to the sheave mechanism, and the transmission gear 14 meshes below A rack 13 fixedly connected with the collecting tank 10 is connected.

[0025] When the concrete block is crushed, the concrete block is placed on the net plate 9 of the collecting tank 10, and the impact crushing mechanism is driven to reciprocate up and down through the set up and down reciprocating mechanism, thereby realizi...

Embodiment 2

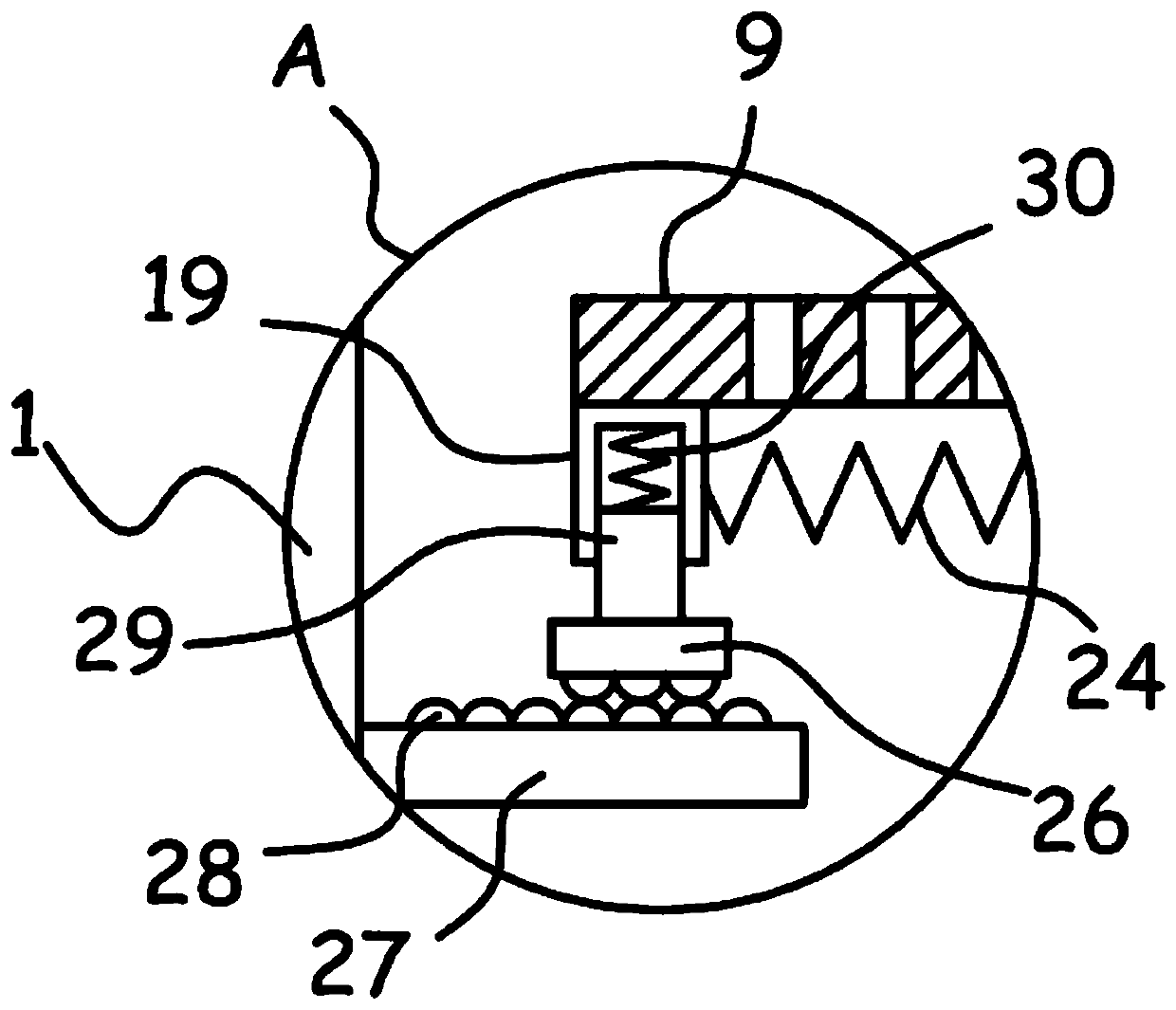

[0032] In order to improve the impact crushing effect on the concrete block, on the basis of embodiment 1, in addition, the impact crushing mechanism includes a connecting frame 22 fixed at the bottom of the guide rod 21, the connecting frame 22 is slidably mounted with an impact block 23, and the connecting frame 22 A threaded rod 25 is pivotally connected with the impact block 23 in threaded connection.

[0033] The impact block 23 in the impact crushing device is used to contact and crush the concrete, and by rotating the threaded rod 25, the impact block 23 can be driven to move in the vertical direction relative to the connecting frame 22, so that the impact block 23 is driven by the lifting reciprocating mechanism The adjustment of the distance between the lowest point of the downward movement and the mesh plate 9 can be adaptively adjusted according to the actual size of the crushed concrete, which effectively improves the crushing effect.

[0034] In addition, a guide sleev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com