Grinding device capable of performing bilateral rotation

A crushing device and two-way rotation technology, which is applied in grain processing and other directions, can solve the problems of large space for crushed objects, excessive crushing, waste of motor power and raw materials for crushed objects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

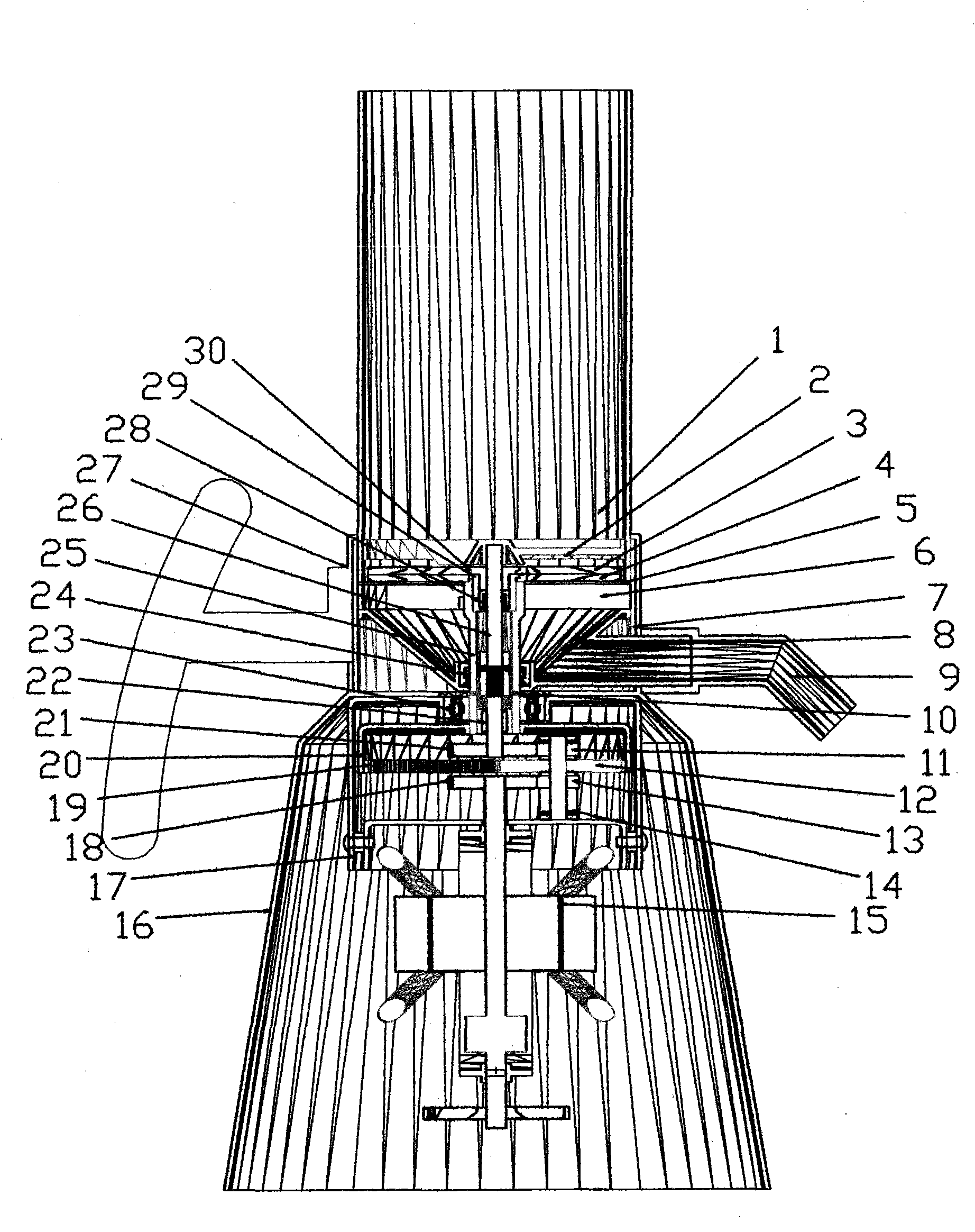

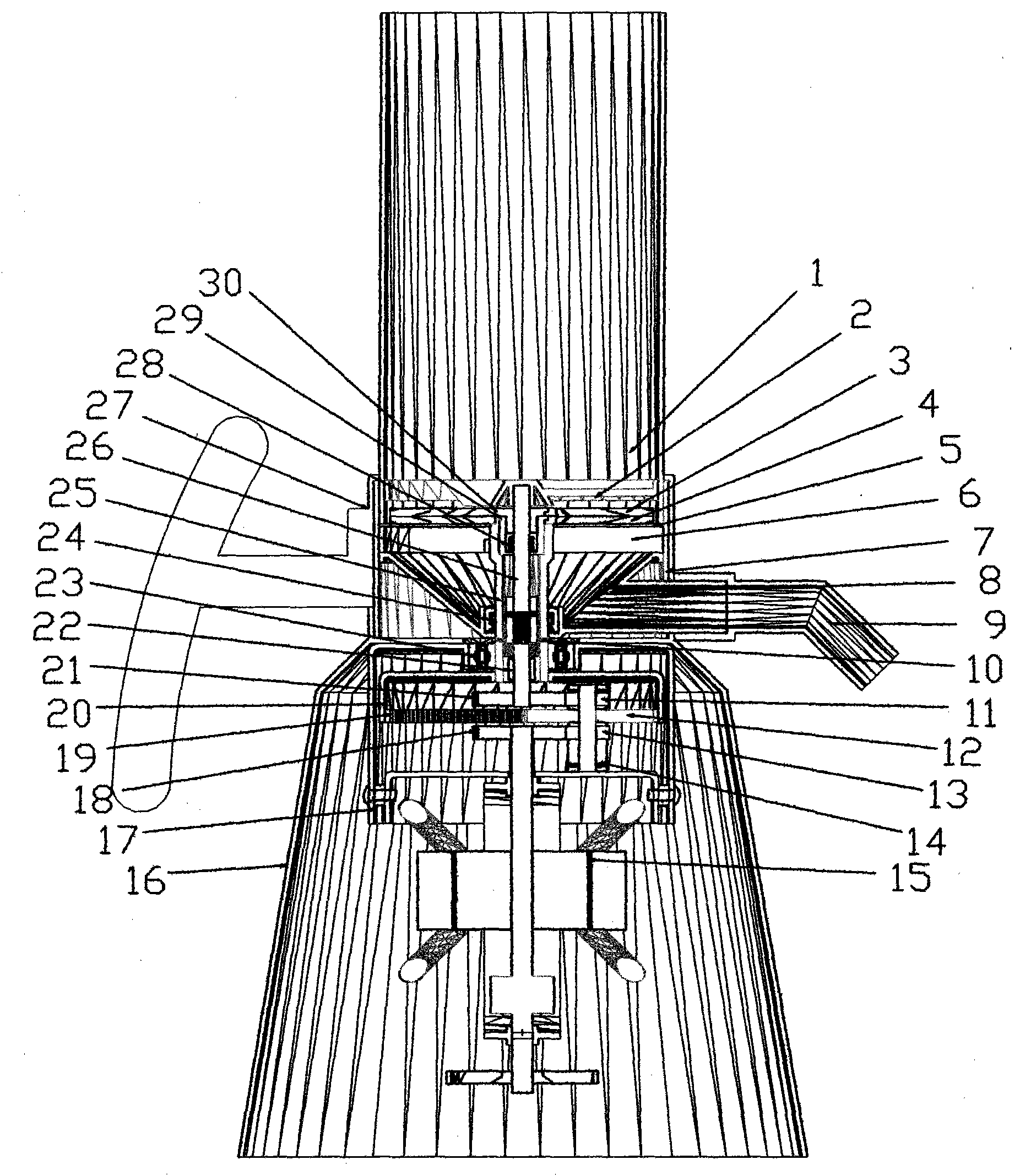

[0024] The following is combined figure 1 and figure 2 To implement this pulverizing device, do a more specific description:

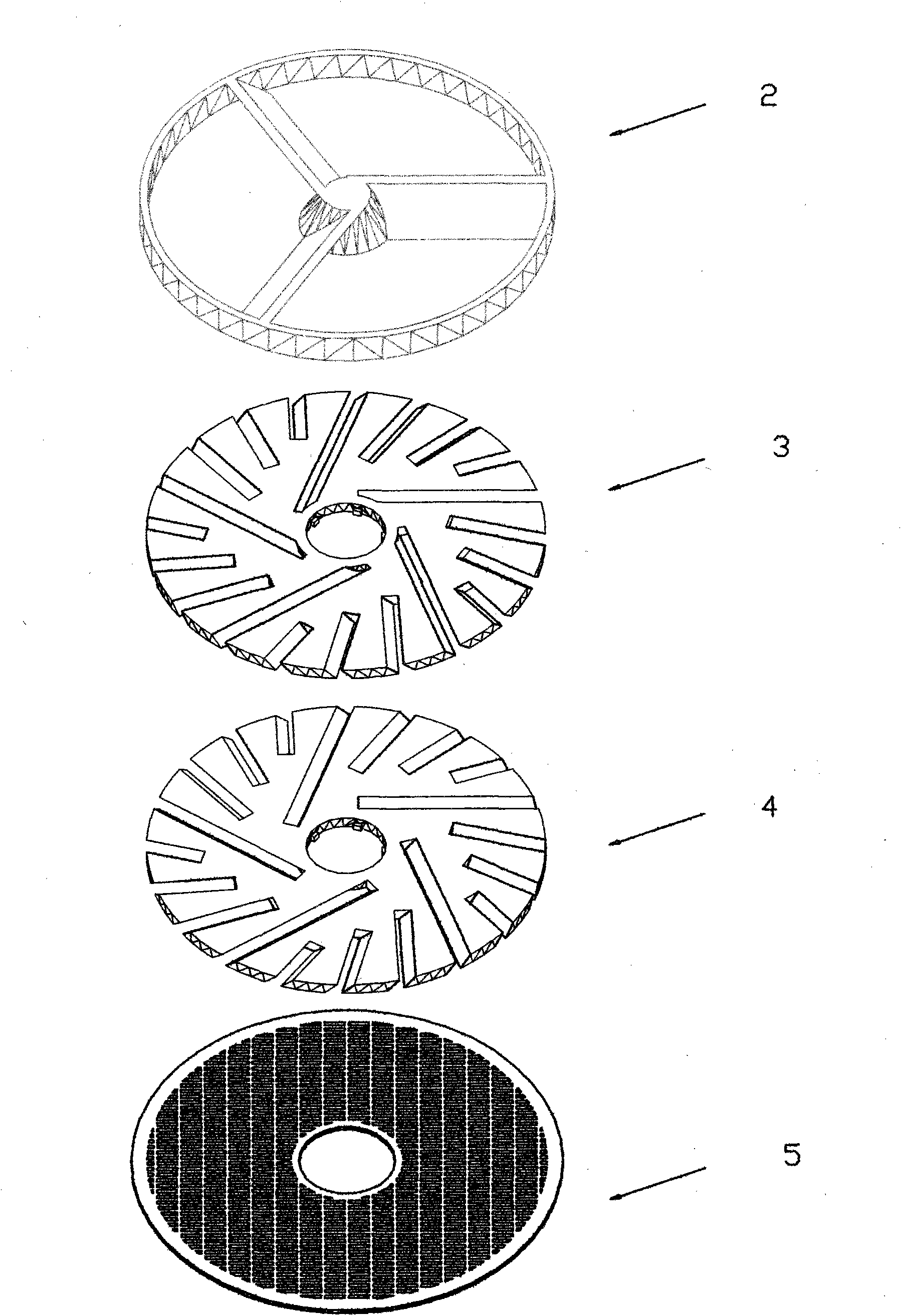

[0025] Such as figure 1 The pulverizer structure provided is a way to implement the pulverizing device, in which the motor, internal gear and five gears, double driving shafts (inner driving shaft and outer driving shaft), double connecting parts (in the cutter wheel A and the inner driving shaft The connecting piece between the shafts and the connecting piece between the cutter wheel B and the external driving shaft) are the driving parts of the pulverizer, which can be installed at the end of the pulverizing device that enters the pulverized material or the end that discharges the pulverized material, so as to apply For horizontal or inverted pulverizers; among them, the fixed material rack, cutter wheel A, cutter wheel B, sieve, sieve support seat, funnel, etc. are the parts that the crushed materials need to pass through, and the installation se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com