Vertical pulse type electric vibrating and screening machine and use method thereof

An oscillating sieve and pulsed technology, which is used in shaking/oscillating/vibrating mixers, chemical instruments and methods, sieves, etc., can solve the problems of short relative displacement distance, low sieving efficiency, easy clogging of sieves, etc. Variety, improve efficiency and effect, improve the effect of screening efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

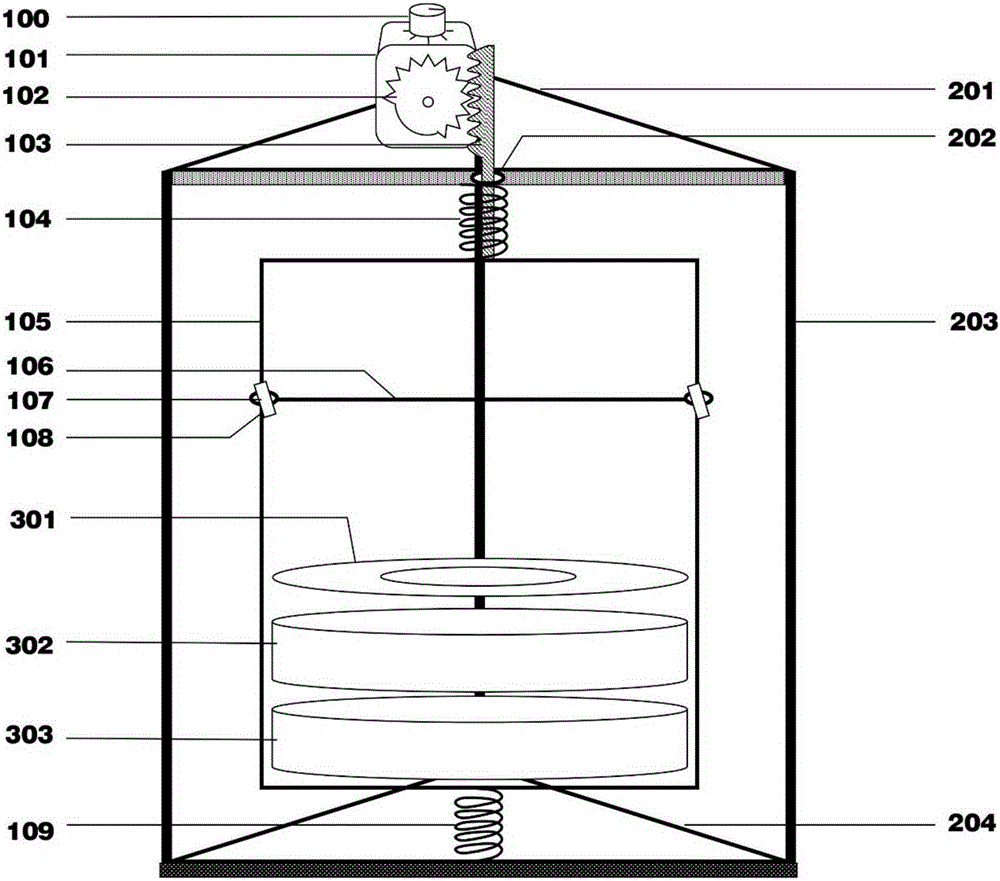

[0070] Each elastic member is a vertical support spring, one end of each vertical support spring is fixedly connected with the top or bottom edge of the fixed square frame 105, and the other end of each vertical support spring is fixedly connected with the top plate 201 or the bottom plate 204 .

[0071] The quantity of vertical support spring is preferably two, is respectively upper vertical support spring 104 and lower vertical support spring 109, wherein, the bottom of upper vertical support spring 104 is fixedly connected with the top center of fixed square frame 105, and upper vertical support spring The top of the support spring 104 is fixedly connected to the bottom center of the triangular long side of the top plate 201; The bottom center of the box 105 is fixedly connected.

[0072] Since the distance between the left and right sides of the fixed frame 105 and the support 203 is small, the vertical support spring is generally 10mm.

[0073] Alternatively, the number...

Embodiment 2

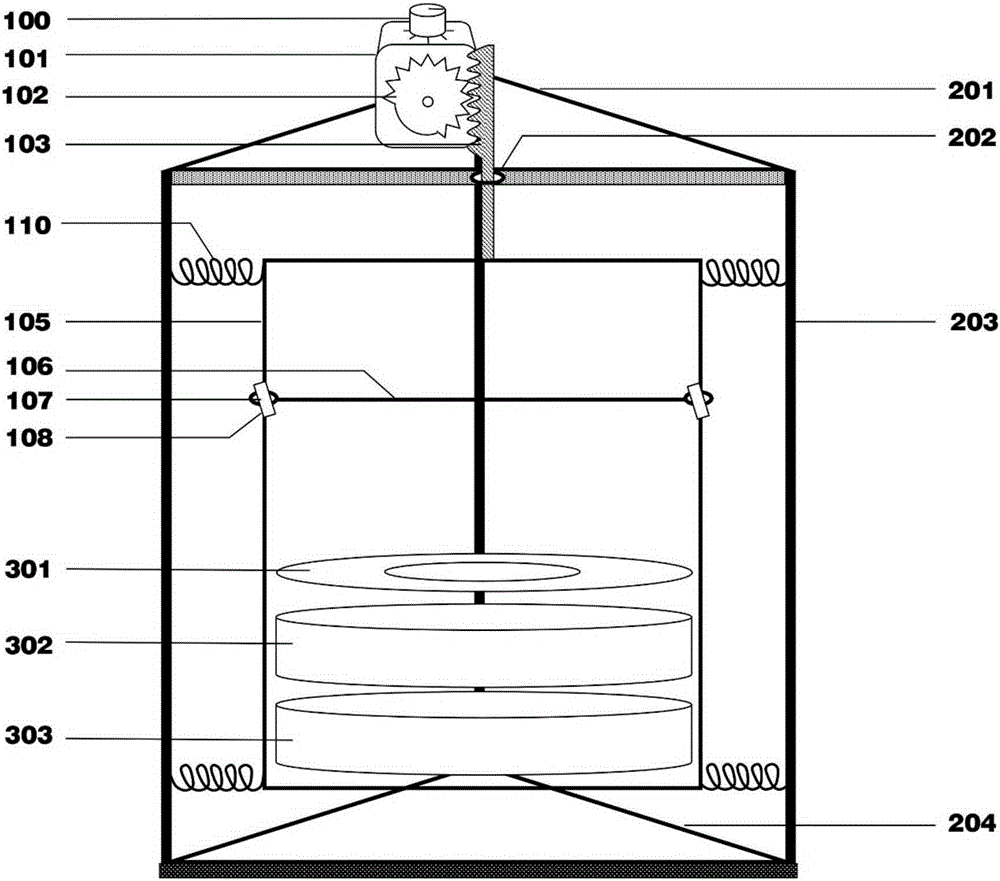

[0075] Each elastic component is a side tension spring 110 , one end of each side tension spring 110 is fixedly connected to the side of the fixed frame 105 , and the other end of each side tension spring 110 is fixedly connected to the corresponding bracket 203 .

[0076] The number of side tension springs 110 is preferably two or four, which are arranged symmetrically around the longitudinal central axis of the fixed frame 105 .

[0077] Because the distance between the left and right sides of the fixed frame 105 and the support 203 is large, the elastic properties of the side tension spring 110 or the side tension rubber band are different, and the length of the side tension spring 110 or the side tension rubber band is generally 40-80 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com