Discharging device for flour packaging machine

A packaging machine and cutting technology, which is applied in the directions of packaging, transportation and packaging, and types of packaging items, can solve the problems of low uniformity of flour, and achieve the effects of uniform flour, convenient use and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

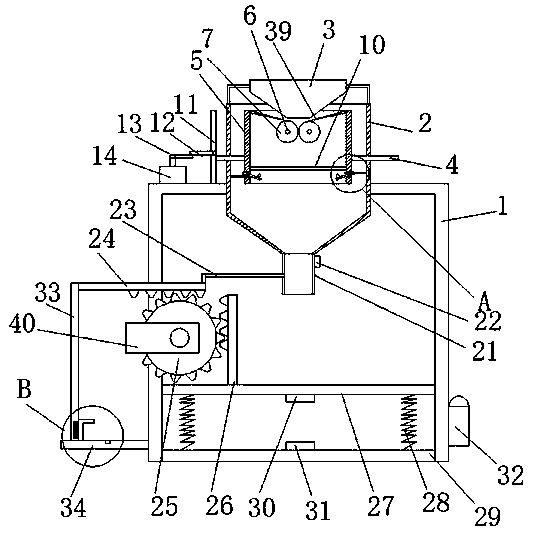

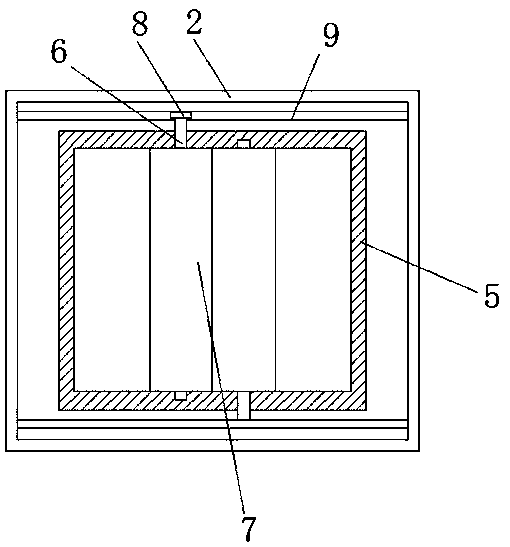

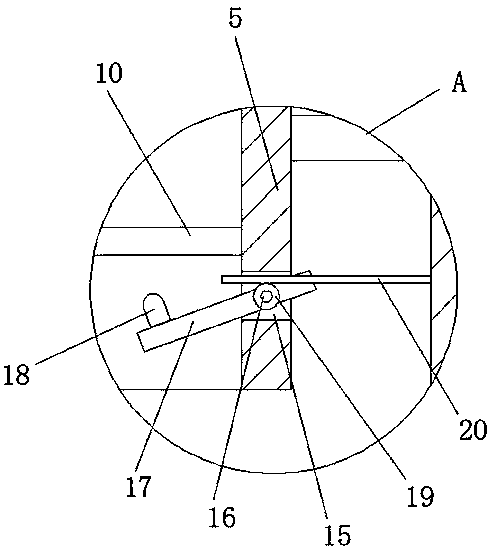

[0029] refer to Figure 1-5 , a blanking device for a flour packaging machine, comprising a bracket 1, a material box 2 with an opening at the top is fixedly installed on the bracket 1, a screening box 5 is arranged in the material box 2, and a rectangular box is fixedly installed on both sides of the screening box 5 The plate 4 and the two rectangular plates 4 are all slidingly connected with the material box 2, and two rotating shafts 6 are installed in the screening box 5, and the outer sides of the two rotating shafts 6 are fixedly set with rolling rollers located in the screening box 5 7. The first gear 8 is fixedly installed on one end of the two rotating shafts 6, and the first rack 9 is fixedly installed in the material box 2, and the two first gears 8 are meshed with the two first racks 9 respectively, and the screening A screen cloth 10 positioned at the bottom of the two rolling rollers 7 is fixedly installed in the box 5, one side of a rectangular plate 4 in the tw...

Embodiment 2

[0040] refer to Figure 1-5 , a blanking device for a flour packaging machine, comprising a bracket 1, a material box 2 with an opening at the top is fixed on the bracket 1 by bolts, a screening box 5 is arranged in the material box 2, and both sides of the screening box 5 are bolted A rectangular plate 4 is fixedly installed, and the two rectangular plates 4 are slidingly connected with the material box 2. There are two rotating shafts 6 installed in the screening box 5, and the outer sides of the two rotating shafts 6 are fixedly set in the screening box 5. The first gear 8 is fixedly installed on one end of the two rotating shafts 6 by bolts, the first rack 9 is fixed by bolts in the material box 2, and the two first gears 8 are respectively connected with the two second gears. A toothed rack 9 meshes with each other, and a screen 10 located below the two rolling rollers 7 is installed in the screening box 5 by bolts, and a push-pull plate is installed on one side of one of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com