Energy-saving type grain crushing air dryer

An energy-saving, air-drying machine technology, which is applied in grain drying, dryers, grain processing, etc., can solve the problems that grain crumbs cannot be dried quickly, it is not conducive to the rapid drying of grain crumbs, and the effect of grain crushing is not thorough enough. Achieve the effect of accelerating drying, improving drying efficiency and promoting crushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with specific embodiment, the technical scheme of this patent is described in further detail:

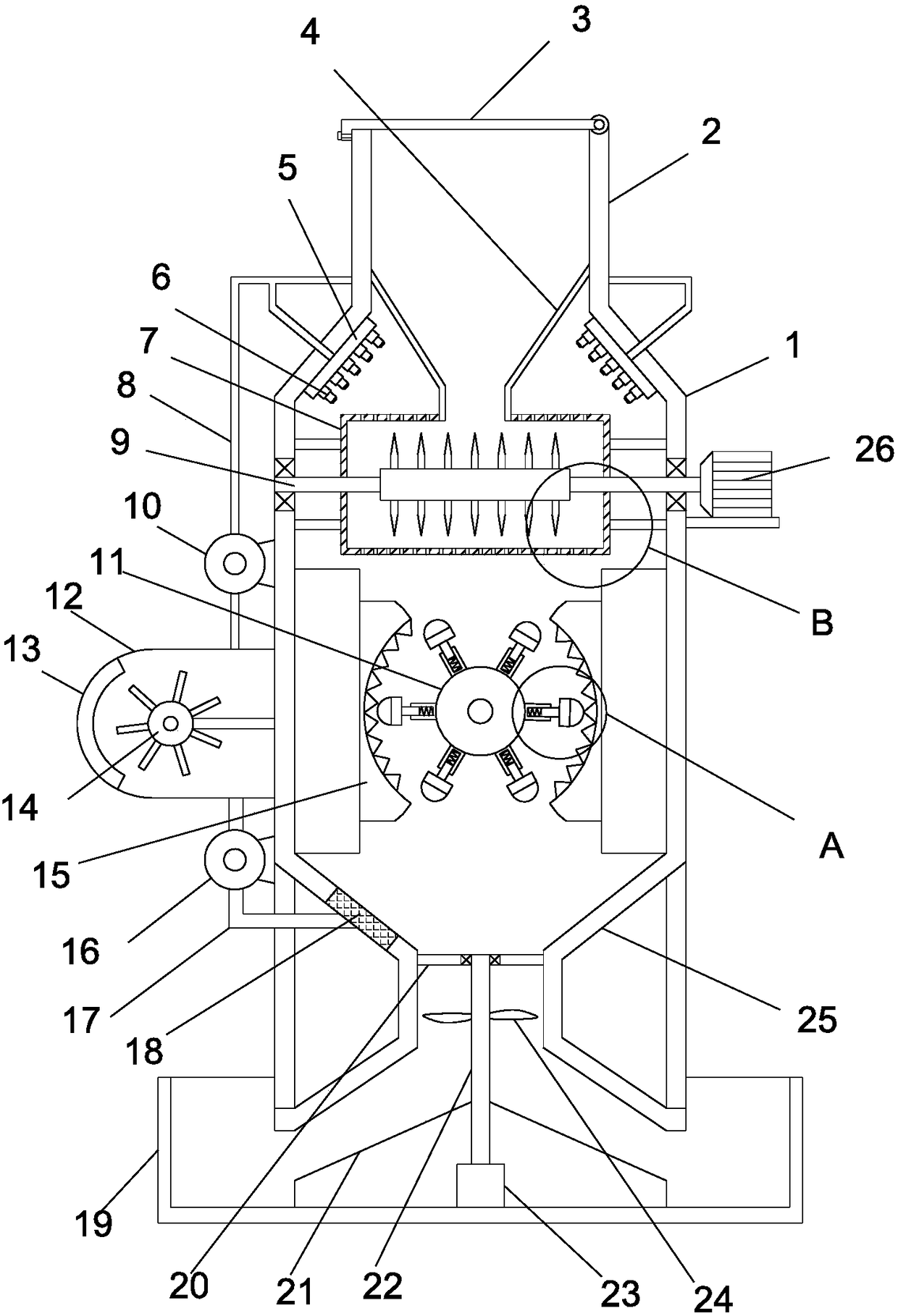

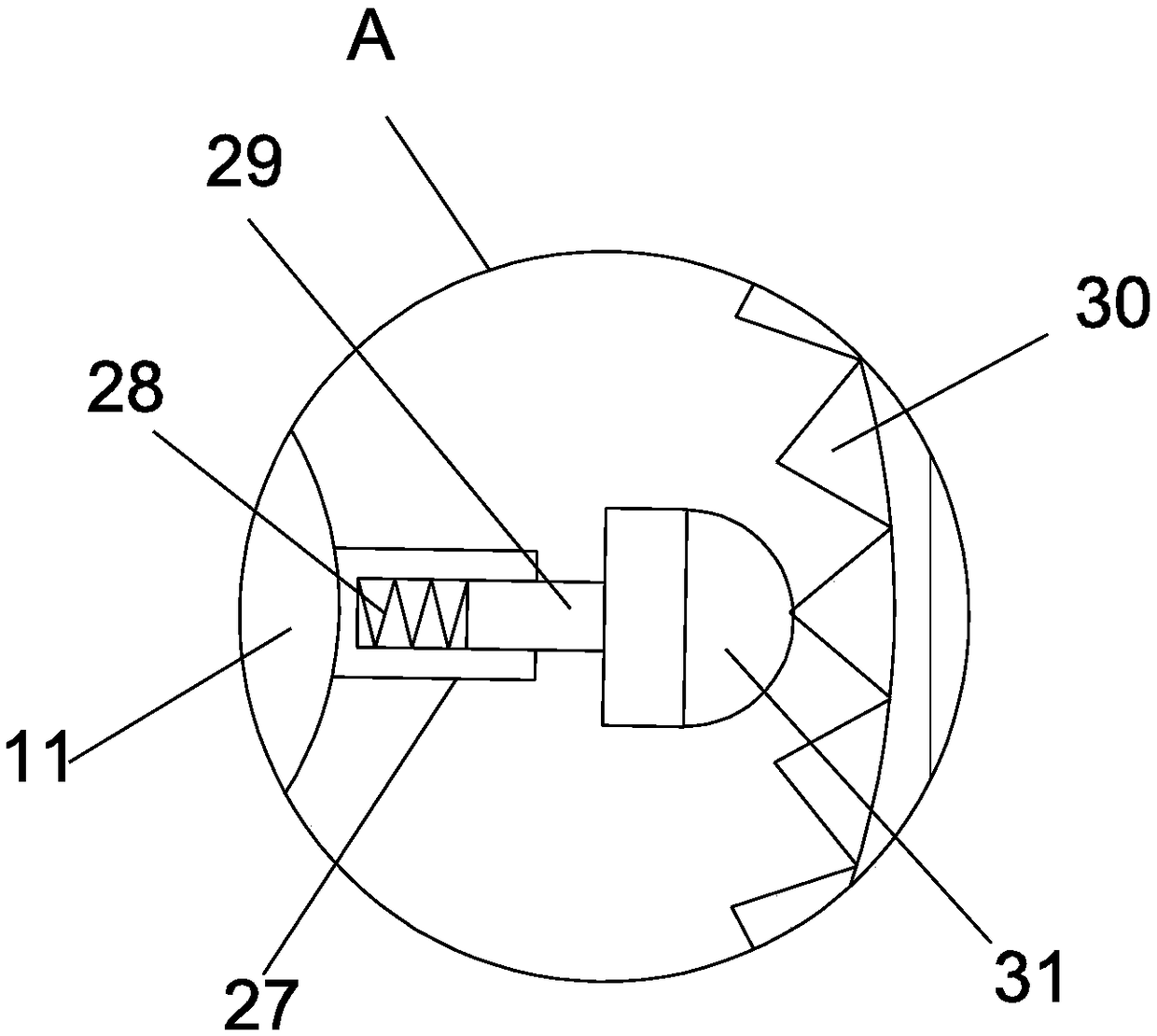

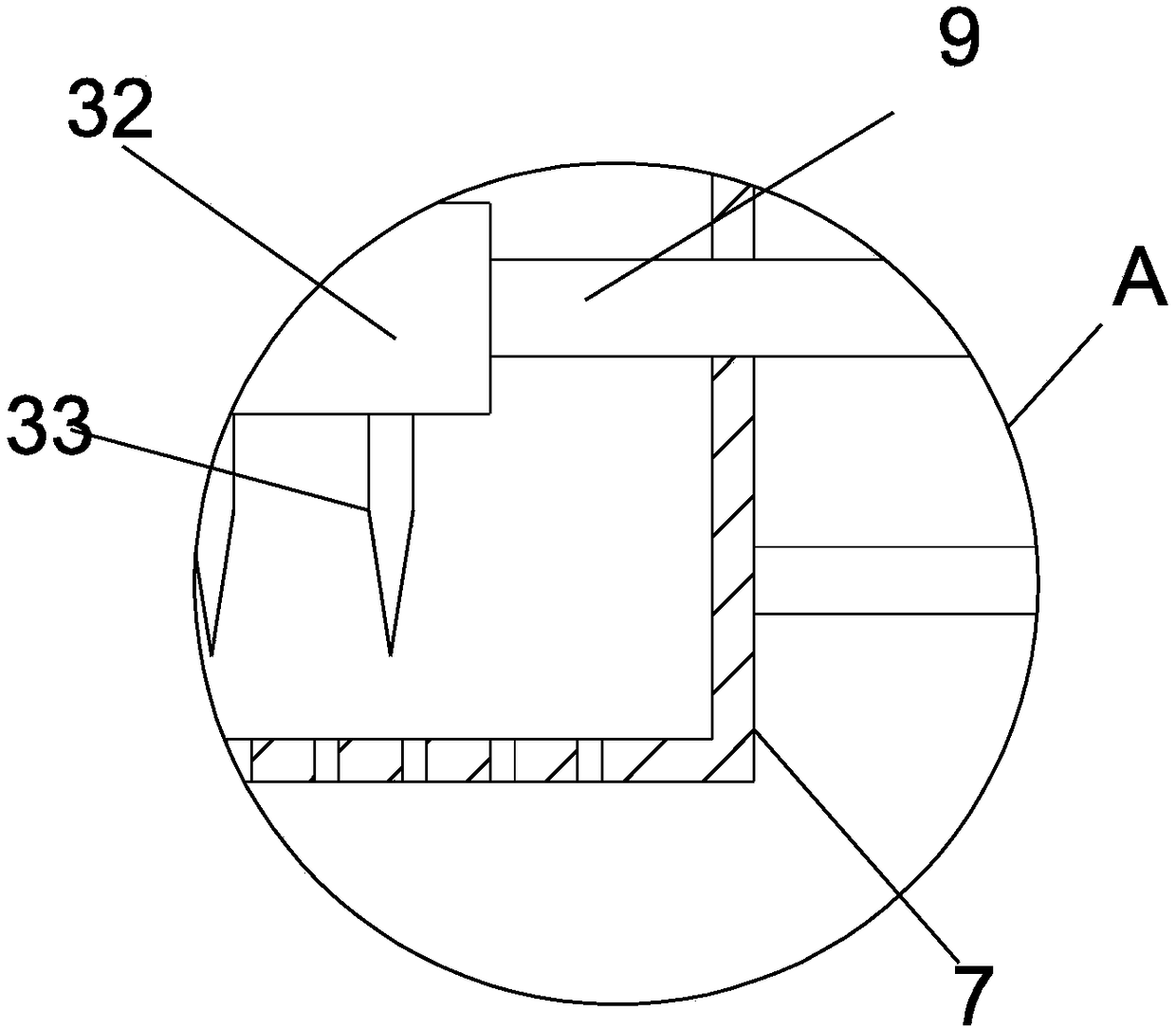

[0020] see Figure 1-3 , an energy-saving grain crushing air dryer, comprising a body 1, a feed pipe 2 is vertically fixedly installed on the body 1, a movable cover 3 is rotatably arranged on the feed pipe 2, and a fixed cover is fixed on the right side wall of the body 1. A second motor 26 is installed, the output shaft of the second motor 26 is coaxially fixed with a drive shaft 9, and the drive shaft 9 is sleeved and fixed with a crushing blade 33, and the surface of the crushing blade 33 is fixedly mounted with several crushing blades. The blade 33, the outer cover of the crushing roller 32 is provided with a crushing net cylinder 7 fixedly installed, the upper part of the crushing net cylinder 7 is connected with a guide hopper 4, and an air heater 12 is fixedly installed on the left side wall of the body 1, and the air heater 12 The inner rotary t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com