Components of high-erosion-resistance zirconia corundum brick, melting process, and melting device

A zirconium corundum brick and high-resistance technology, which is applied to the components of high-erosion-resistance zirconium corundum brick and the field of melting process and device, can solve the problems of difficulty in achieving melting effect, glass solution pollution, product inclusion lumps, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

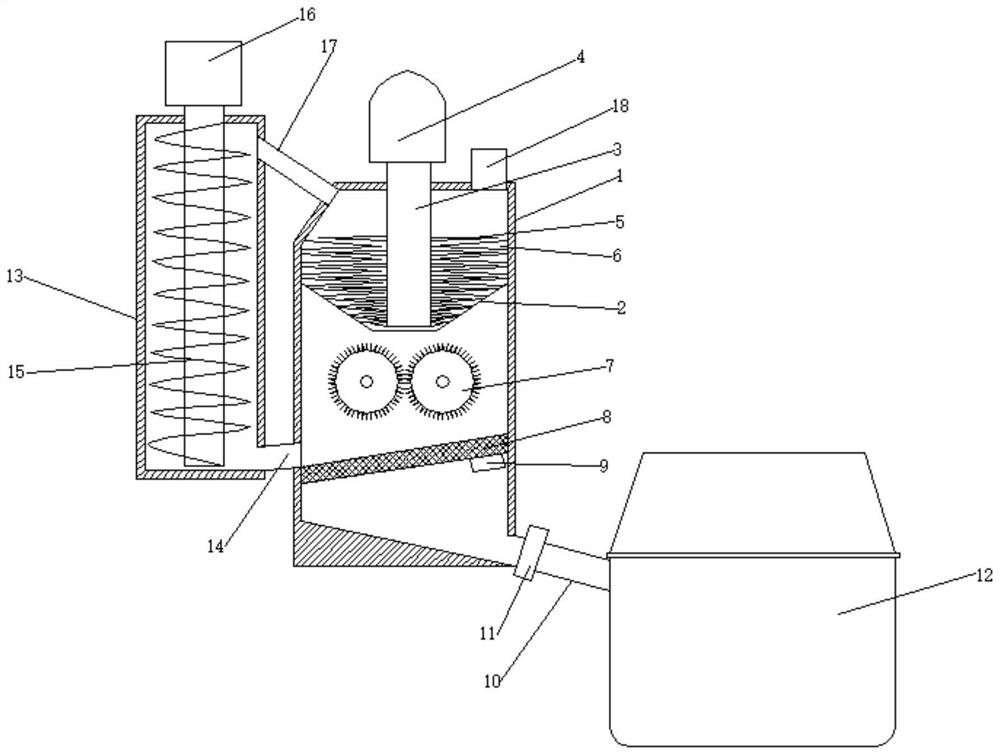

Image

Examples

Embodiment 1

[0019] Embodiment 1: The present invention provides a technical solution: a component of a high-corrosion-resistant zirconium corundum brick, according to its component mass percentage: 68% zirconium dioxide, 3% silicon dioxide, and 27% aluminum oxide , 0.3% sodium oxide, 1% boron trioxide.

[0020] In this embodiment, the compressive strength is ≥400MP, the erosion resistance is ≤0.5mm / 24h, and the amount of exudation of the glass phase is ≤0.5%.

Embodiment 2

[0021] Embodiment 2: The present invention provides a kind of technical scheme: the component of a kind of high anti-corrosion zirconium corundum brick is: zirconium dioxide 65%, silicon dioxide 6%, aluminum oxide 27% according to its component mass percentage , 0.6% sodium oxide, 0.8% boron trioxide.

[0022] In this embodiment, the compressive strength is ≥390MP, the erosion resistance is ≤0.6mm / 24h, and the exudation of glass phase is ≤0.7%.

Embodiment 3

[0023] Embodiment 3: The present invention provides a technical solution: a component of a high-corrosion-resistant zirconium corundum brick, according to its component mass percentage: 68% zirconium dioxide, 10% silicon dioxide, and 20% aluminum oxide , sodium oxide 1%, boron trioxide 0.5%.

[0024] In this embodiment, the compressive strength is ≥400MP, the erosion resistance is ≤0.6mm / 24h, and the amount of exudation of the glass phase is ≤1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com