Waste dust-free recovery device for building energy conservation and environmental protection

A technology of building energy saving and recycling devices, which is applied in the direction of smoke removal, solid waste management, sustainable waste treatment, etc. It can solve the problems that affect the crushing efficiency, a large amount of dust, easy to pollute the environment, etc., and achieve the effect of ensuring crushing efficiency and reducing dust.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

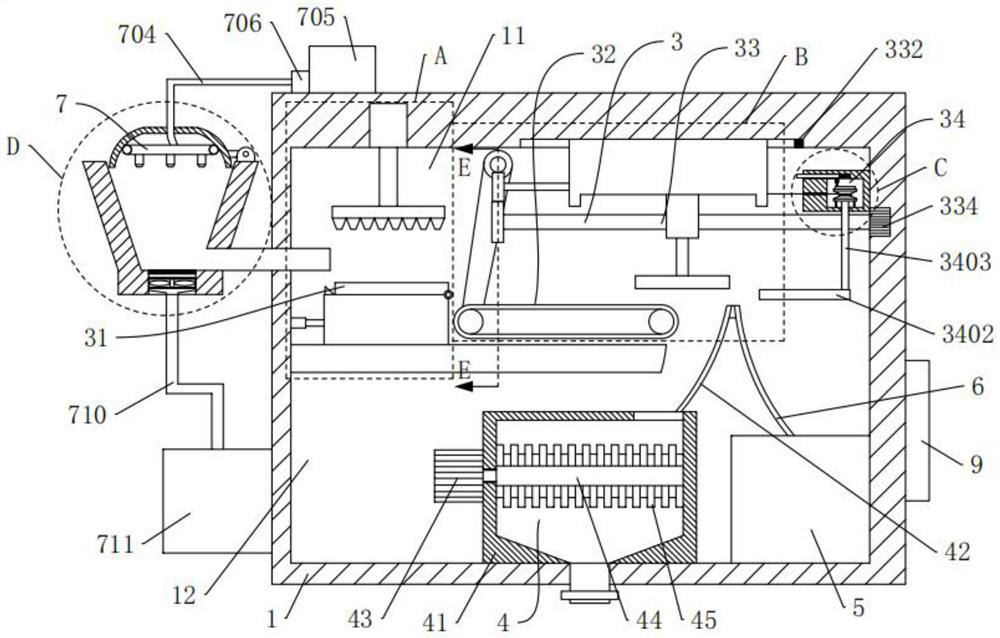

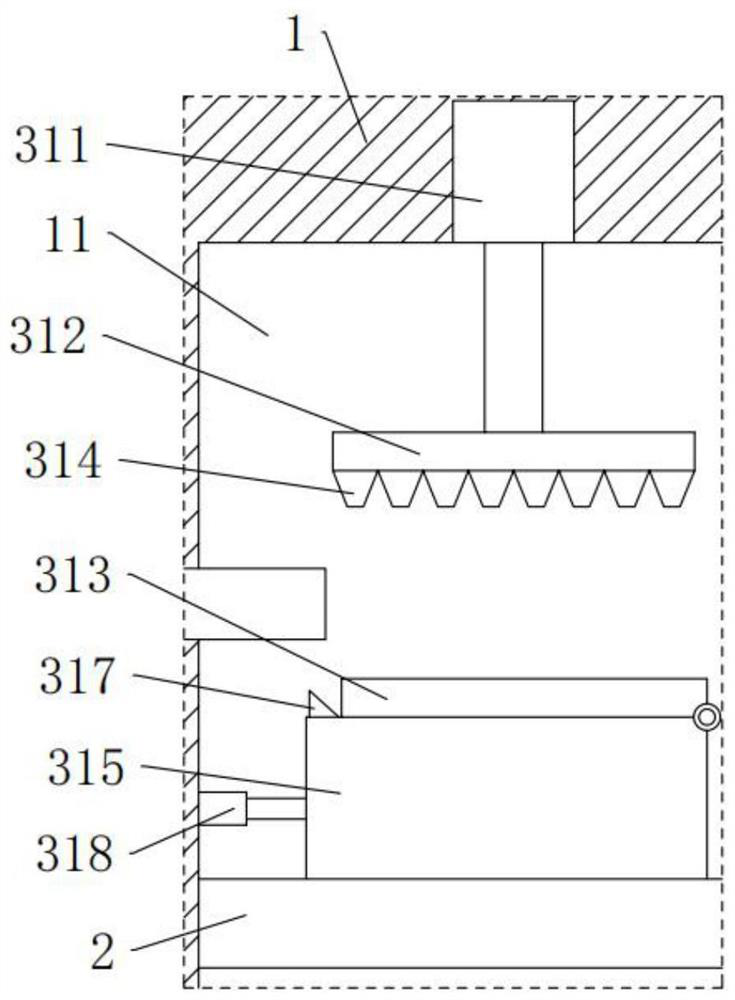

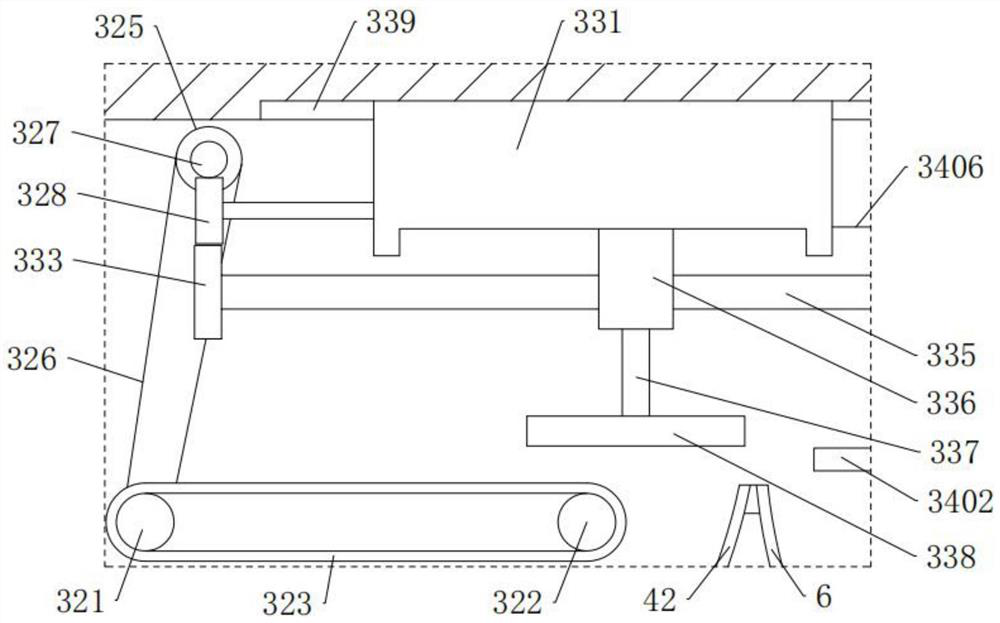

[0026] Such as Figure 1-7 As shown, the embodiment provides a dust-free recovery device for building energy-saving and environmental protection waste materials, including a housing 1, a partition 2, an electromagnetic screening mechanism 3, a crushing mechanism 4, a collection box 5, a second arc-shaped plate 6, The dust suppression mechanism 7, the feed hopper 8 and the main control box 9, a partition 2 is fixed horizontally in the housing 1, and the partition 2 divides the interior of the housing 1 into an upper chamber 11 and a lower chamber 12, and the upper chamber 11 communicates with the lower chamber 12, and the upper chamber 11 is fixed with an electromagnetic screening mechanism 3. The electromagnetic screening mechanism 3 includes a crushing assembly 31, a conveying assembly 32 and a sor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com