Gravel crushing device for building construction

A technology for building construction and crushing devices, which is applied in the direction of solid separation, filter screens, grilles, etc., can solve the problems of uneven particle size, high labor intensity, and low work efficiency, and achieve high work efficiency, enhanced crushing effect, and practical strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

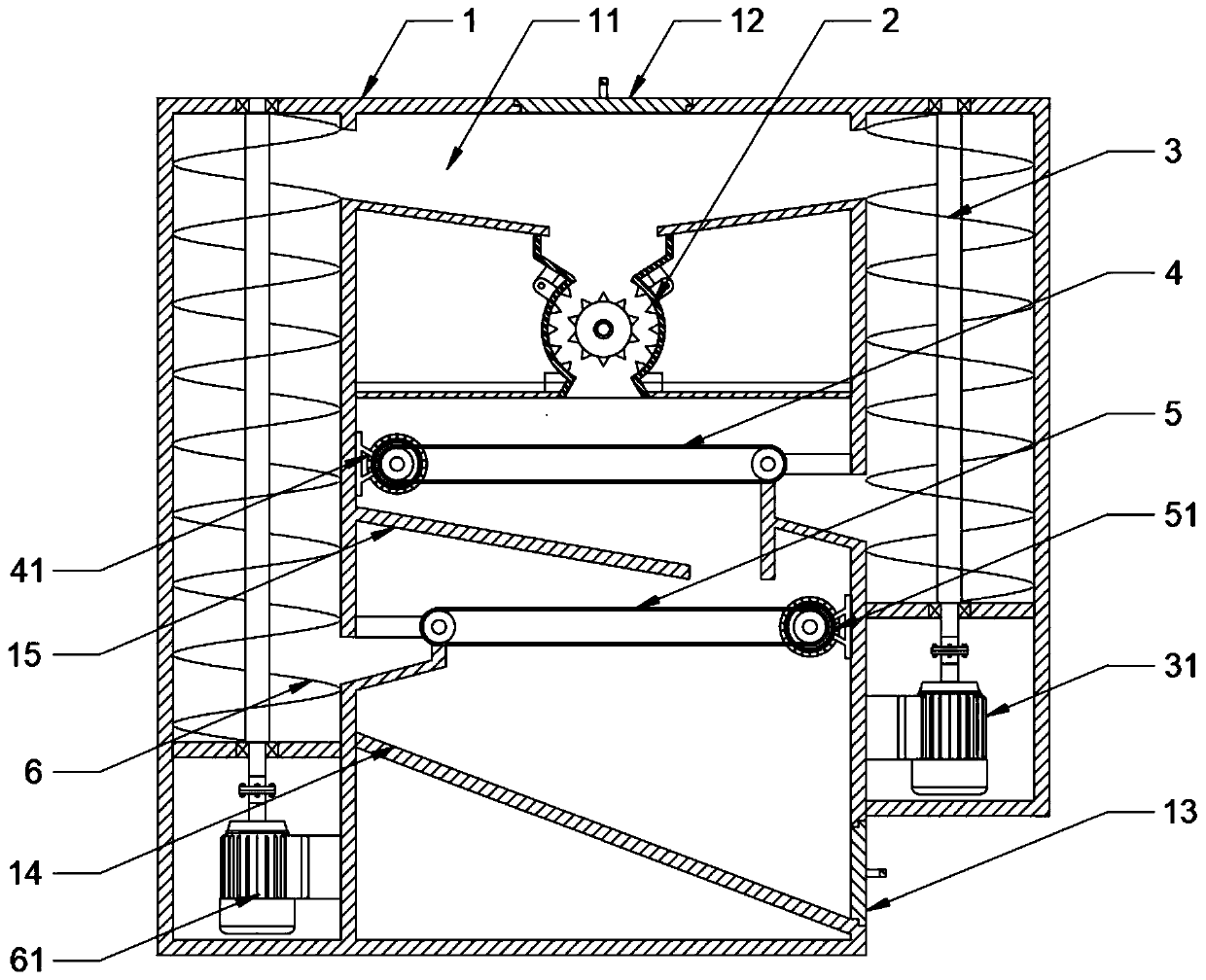

[0022] see Figure 1~4 , in an embodiment of the present invention, a sand and gravel crushing device for building construction includes a frame 1 and a crushing assembly 2 installed on the frame 1. The bottom of the crushing assembly 2 is provided with a dovetail slider and a The dovetail chute on the top is slidingly connected, and a feeding hopper 11 is arranged above the crushing assembly 2, and the material is fed into the crushing assembly 2 through the feeding hopper 11; a screening device and a screening device are also provided in the frame 1 The conveying device provided by Unicom, the screening device is located below the crushing assembly 2, and is used to screen out the incompletely broken sand and gravel, and the conveying device is arranged on the side wall of the frame 1, and is used to displace the screening device The unsatisfactory sand and gravel screened out are conveyed into the feed hopper 11, and crushed again by the crushing assembly 2, and the materia...

Embodiment 2

[0029] see figure 1 , in the embodiment of the present invention, a sandstone crushing device for building construction, in order to ensure the screening quality of the second conveyor belt 5, on the basis of embodiment 1, the frame 1 is also provided with a feeding plate 15 and Located below the first conveyor belt 4, it is used to introduce the gravel sieved by the first conveyor belt 4 to the feeding end of the second conveyor belt 5, so that the gravel is fully in contact with the sieve holes on the second conveyor belt 5 and screened, effectively The gravel screened by the first conveyor belt 4 is prevented from directly entering the second screw blade 6 from the discharge end of the second conveyor belt 5 .

[0030] The working principle of the present invention is:

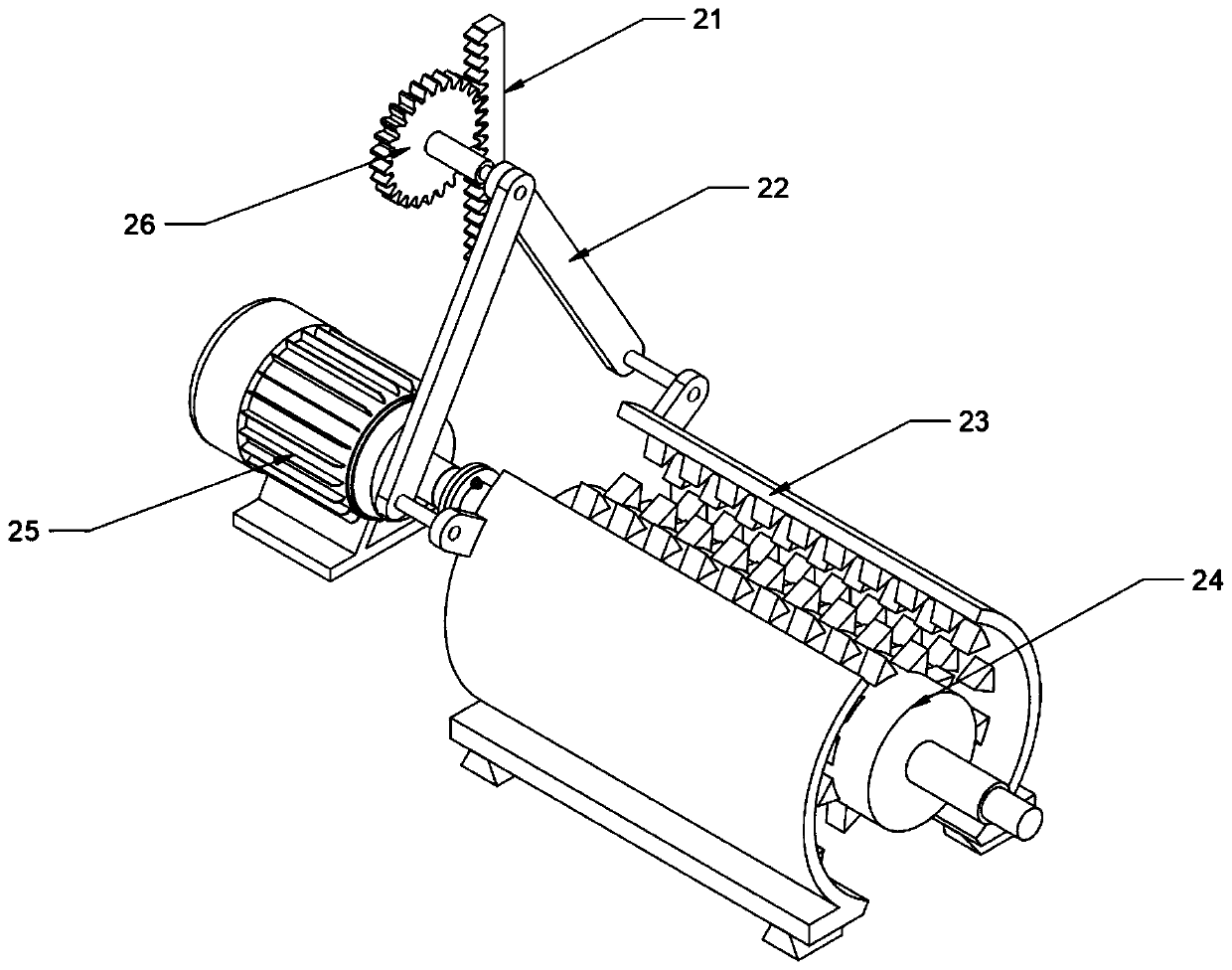

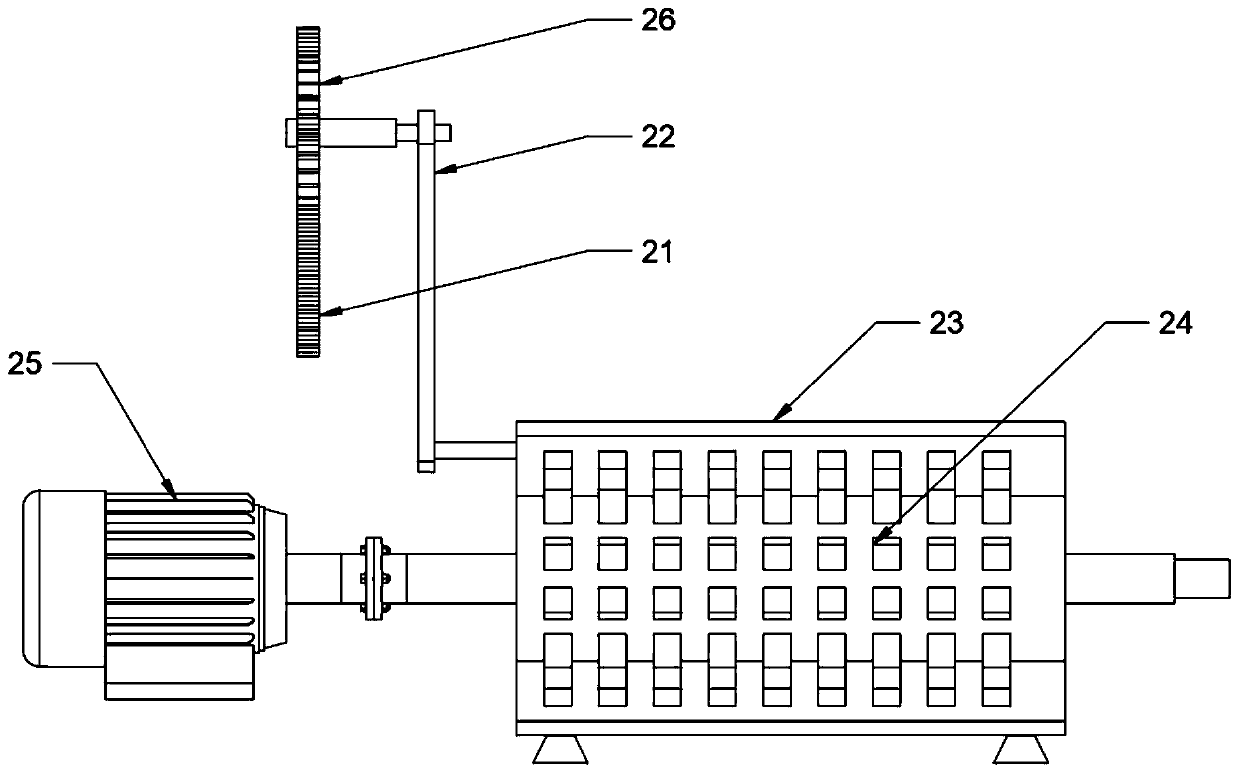

[0031]When working, open the feeding door 12, feed materials into the crushing assembly 2 through the feeding hopper 11, close the feeding door 12; start the crushing motor 25, and the crushing motor 25 dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com