Patents

Literature

52results about How to "Meet crushing requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

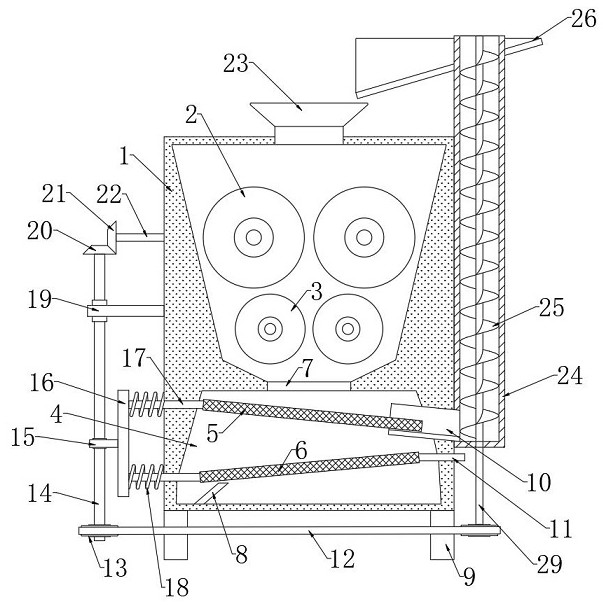

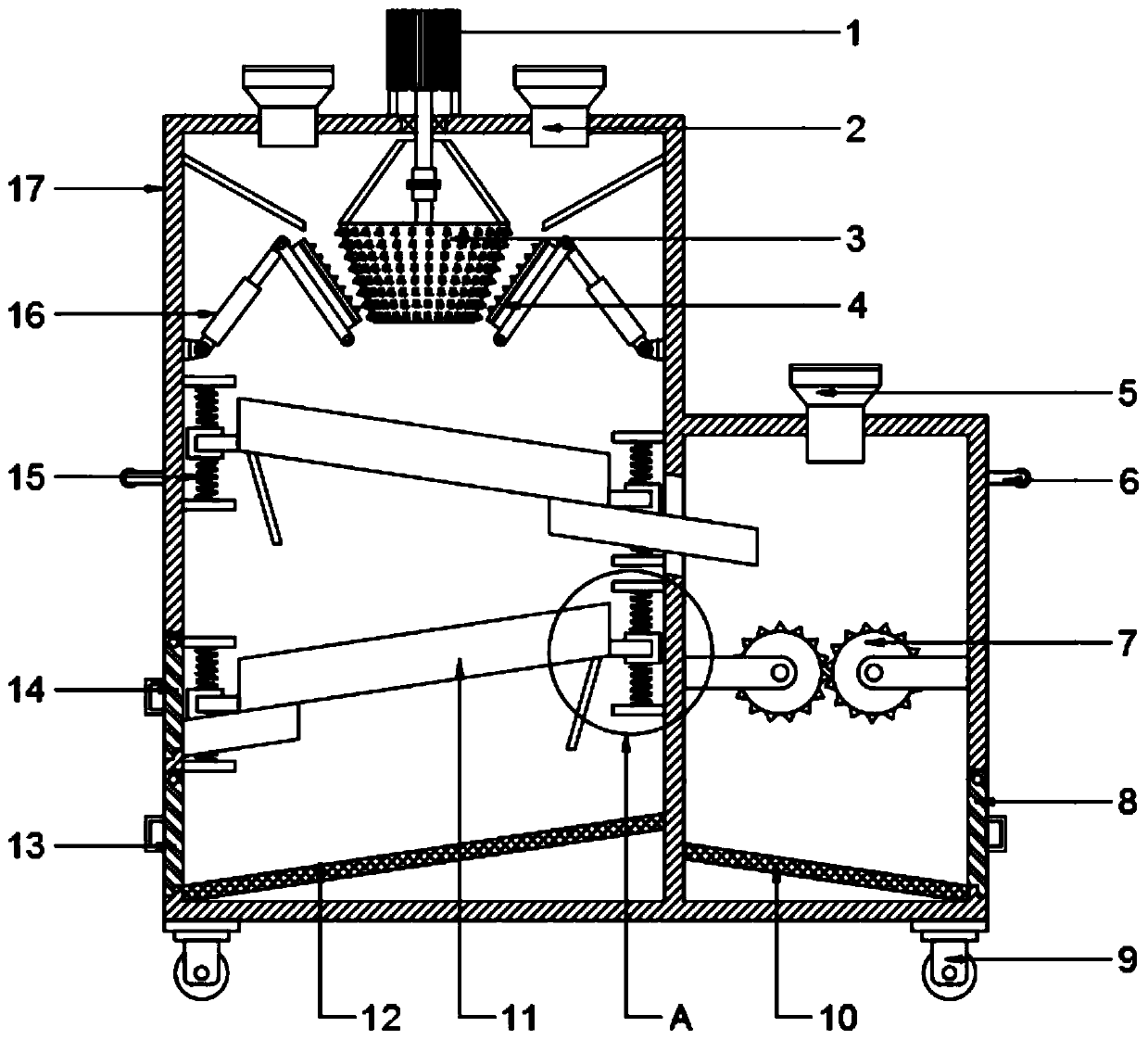

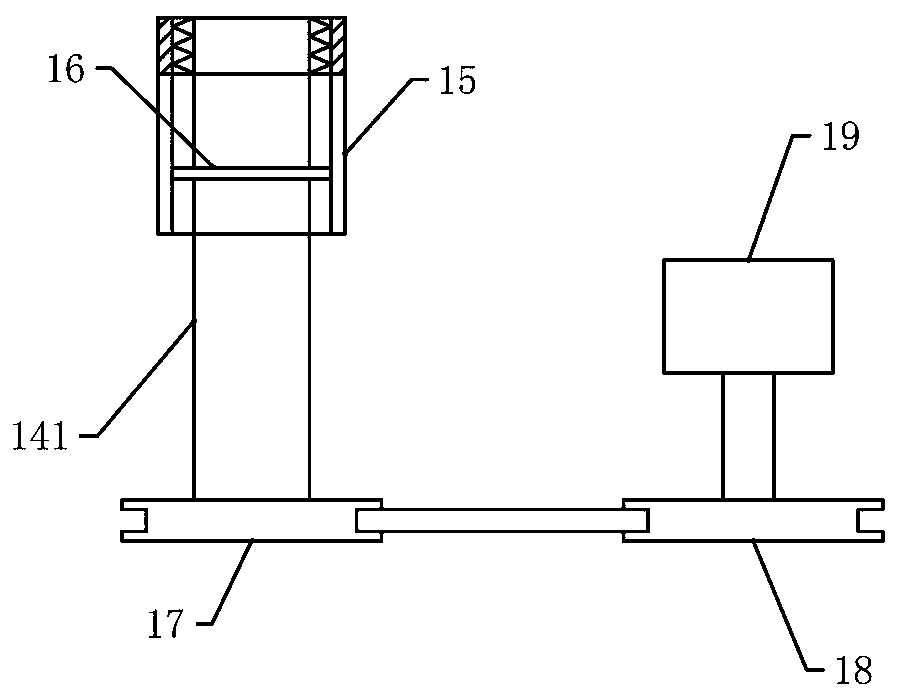

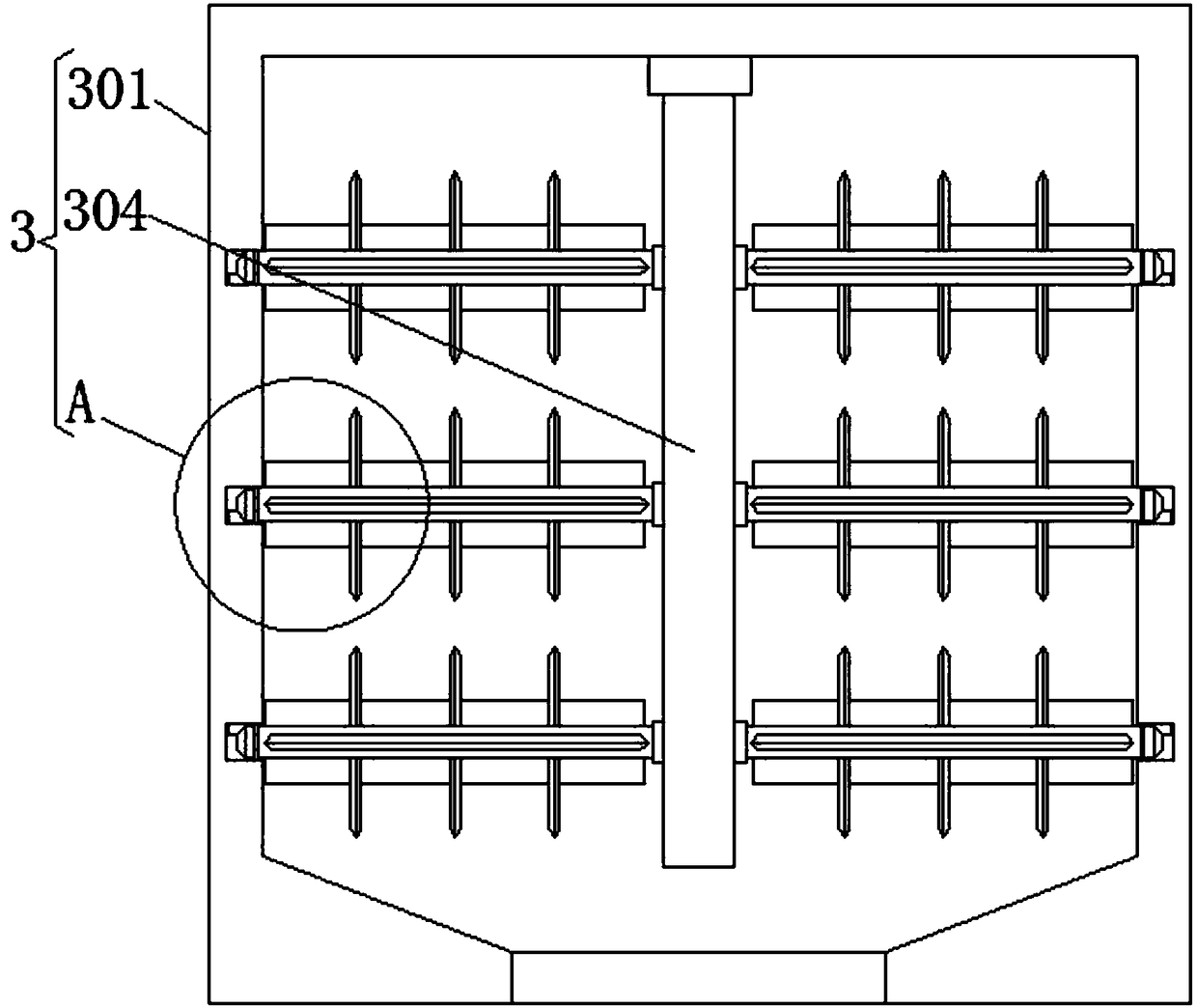

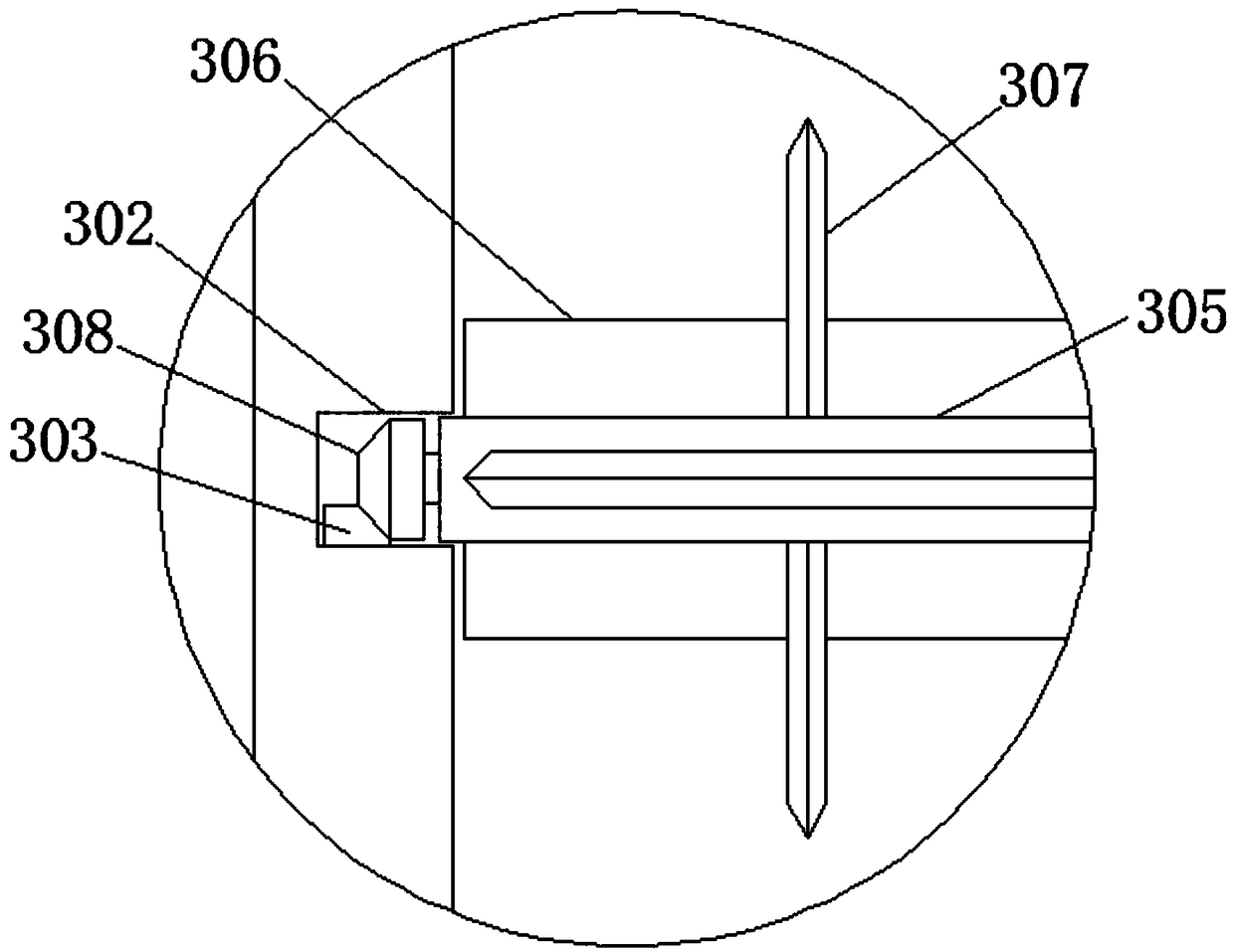

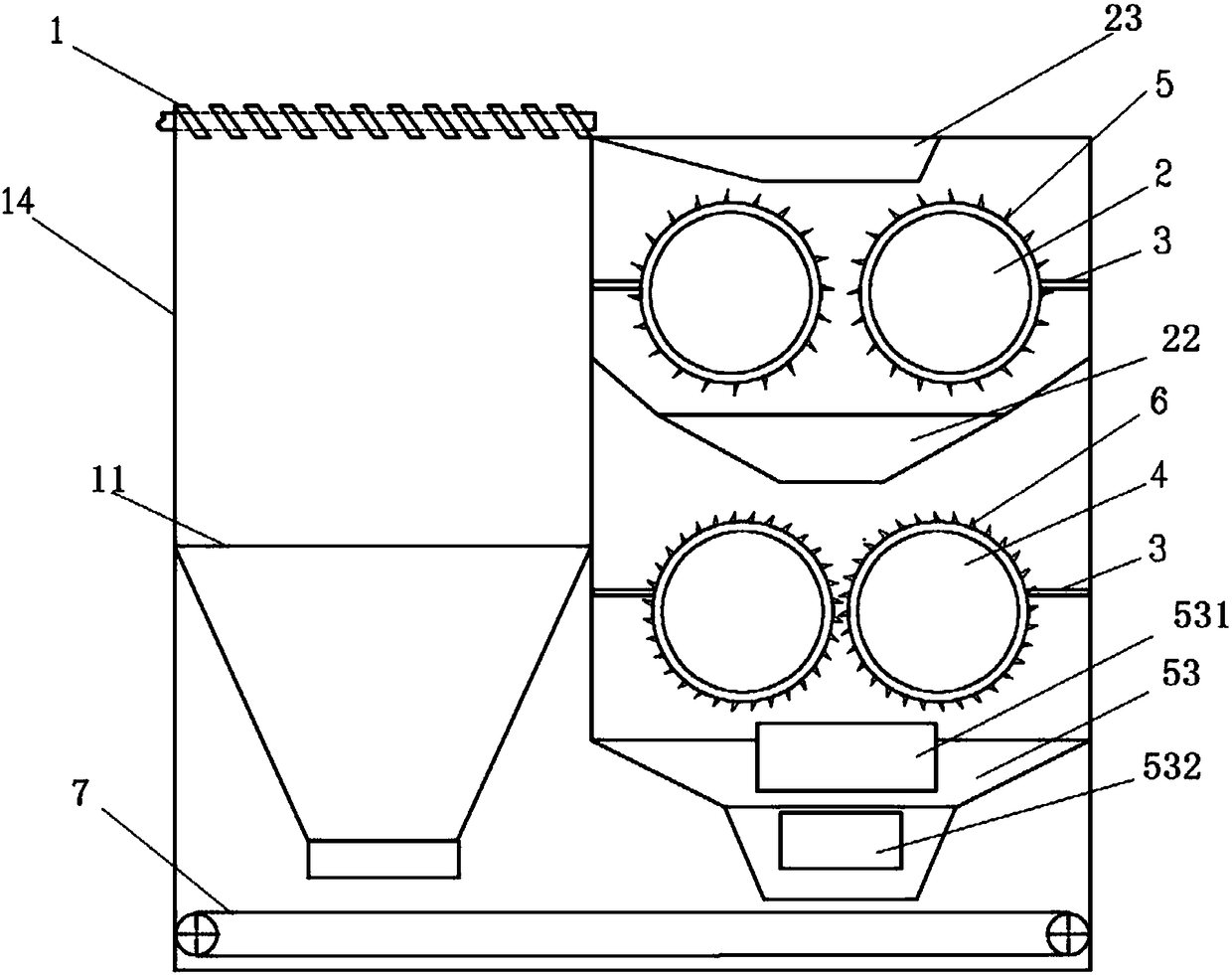

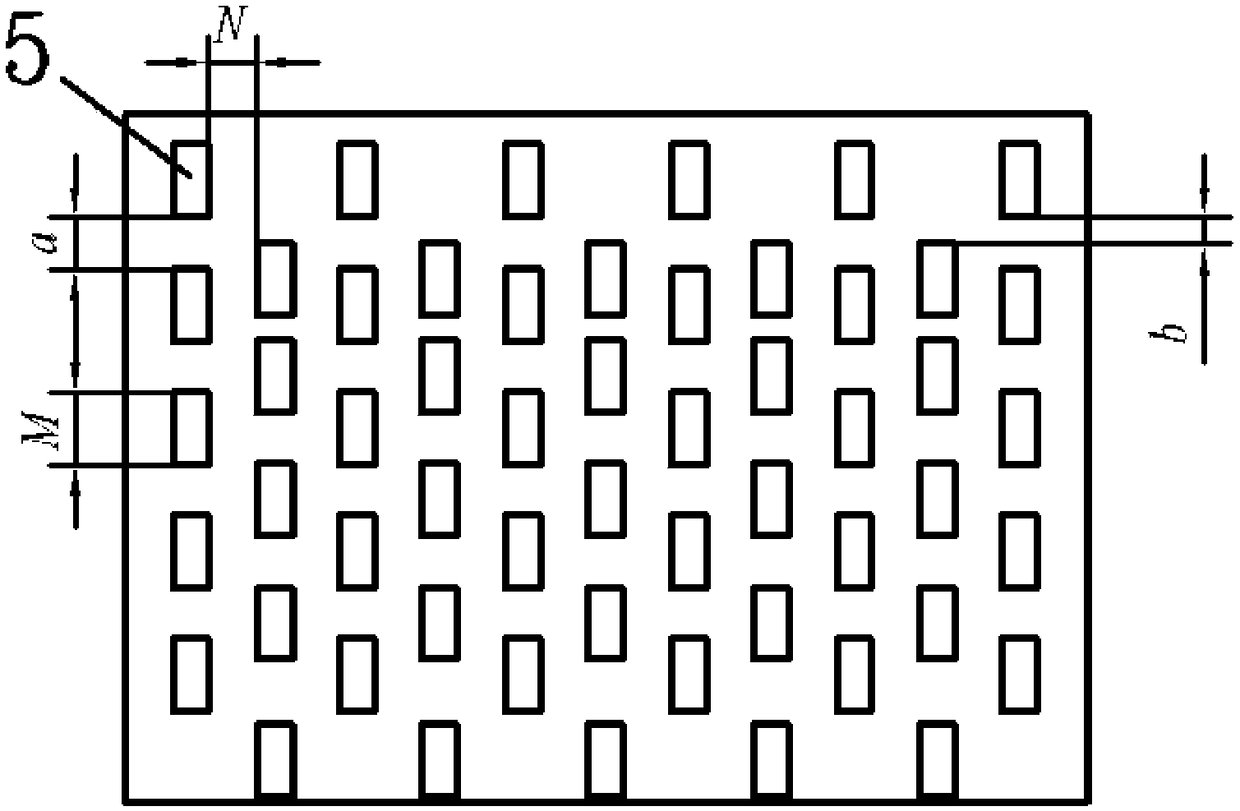

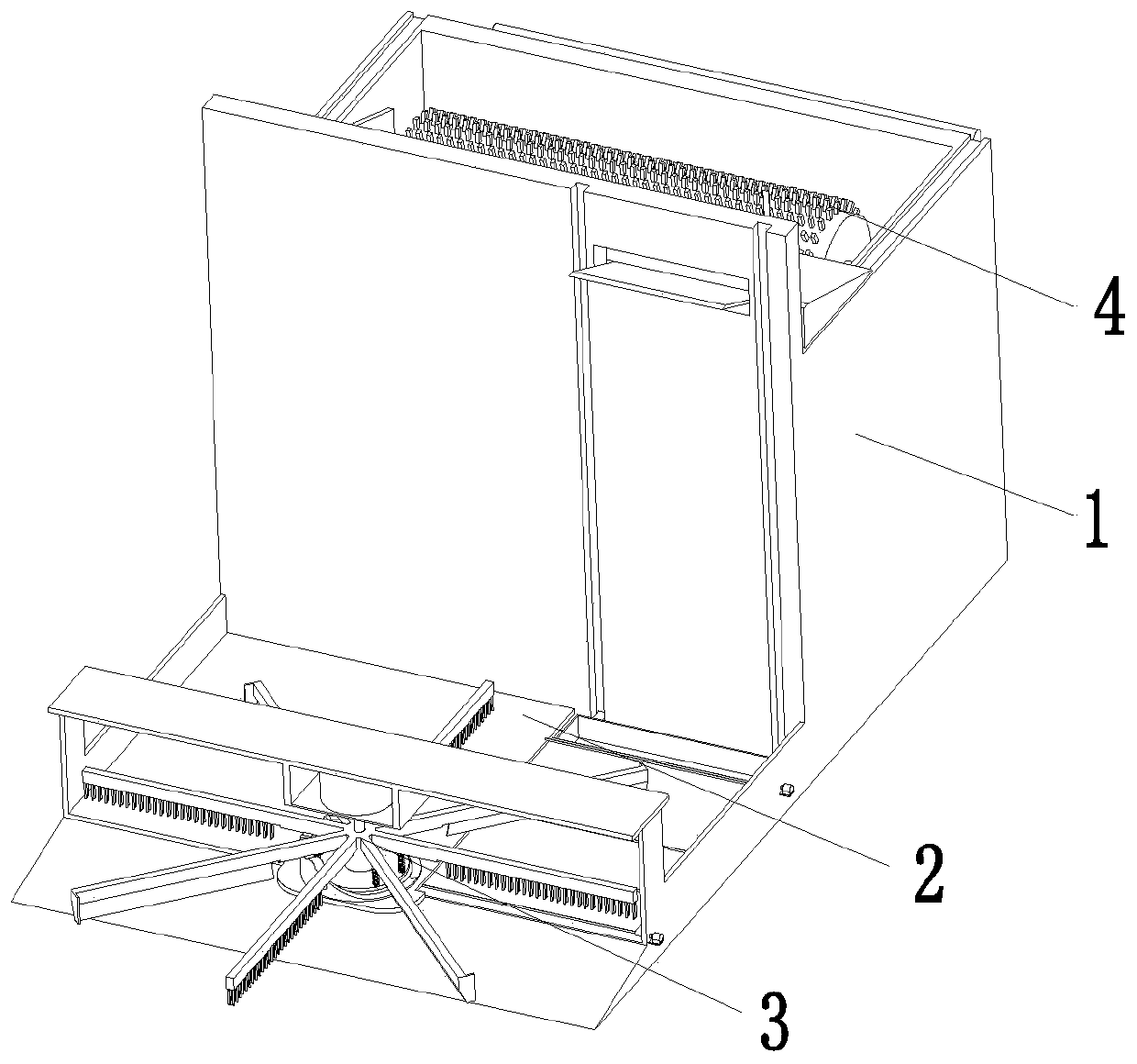

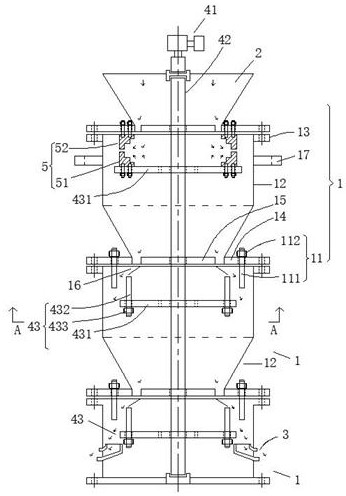

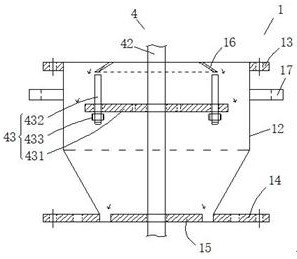

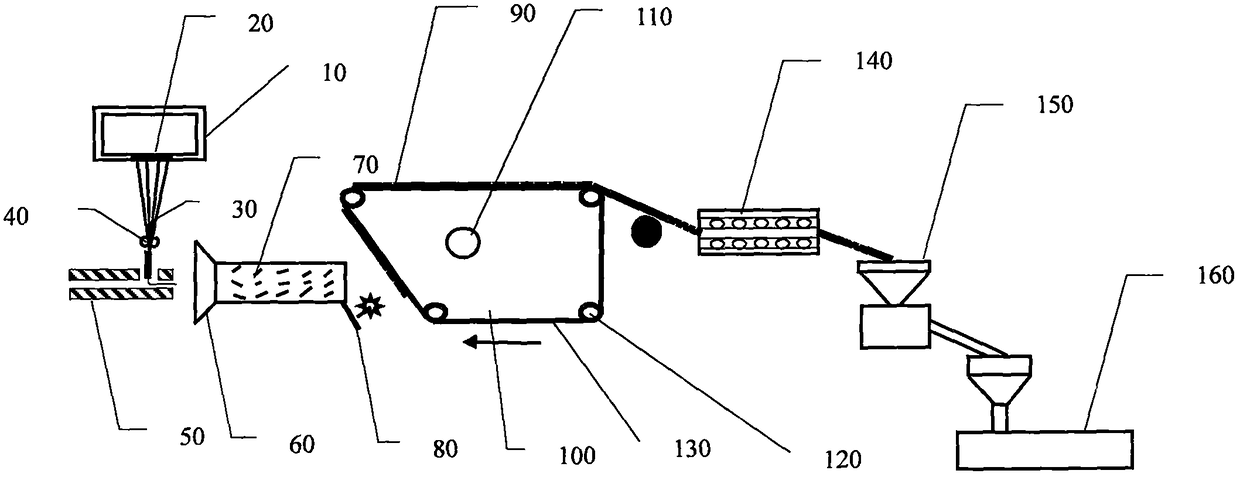

Soil remediation filtration system and soil filtration and separation repair method

ActiveCN109158156AReduce labor intensityEasy to operateContaminated soil reclamationMagnetic separationParticulatesSoil remediation

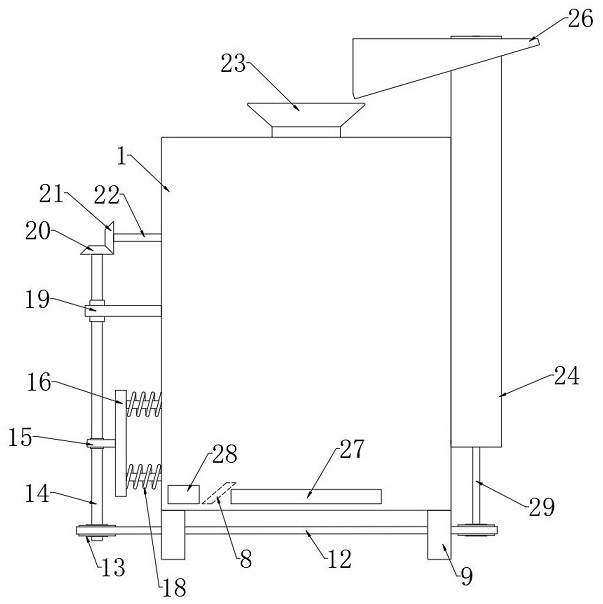

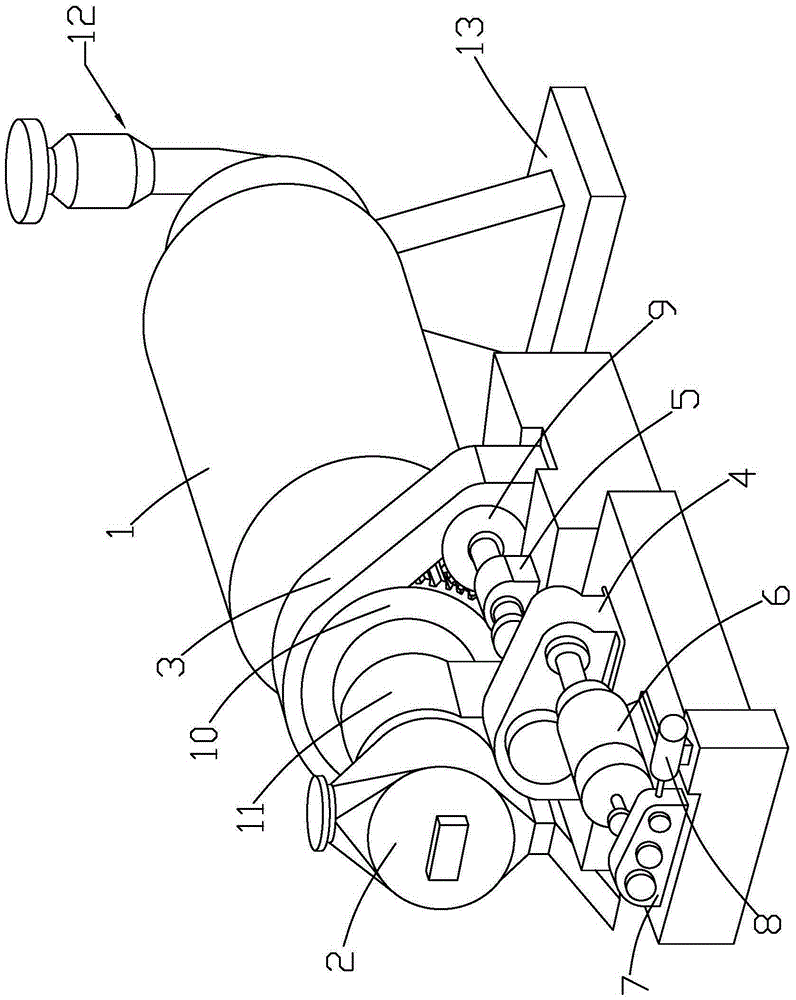

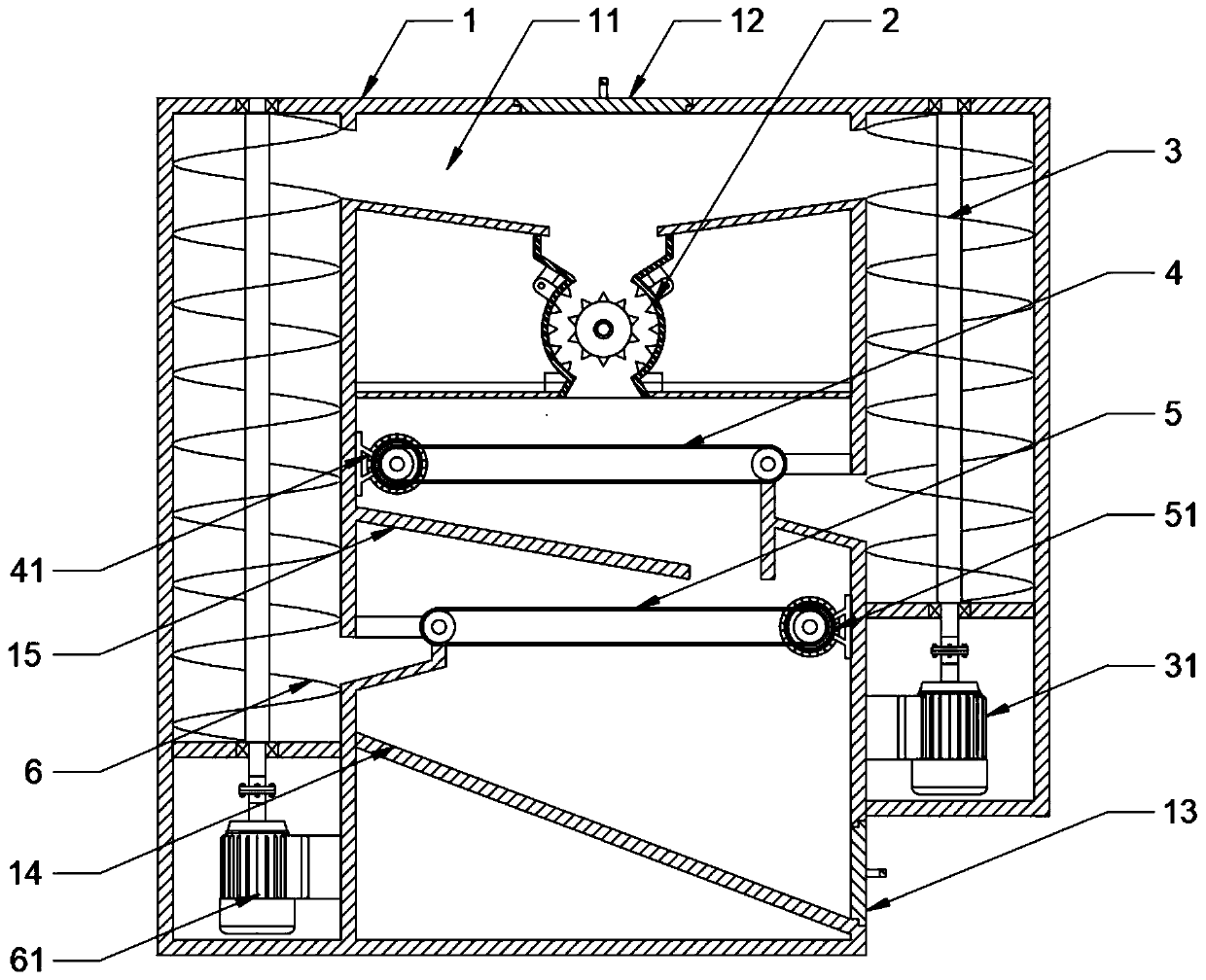

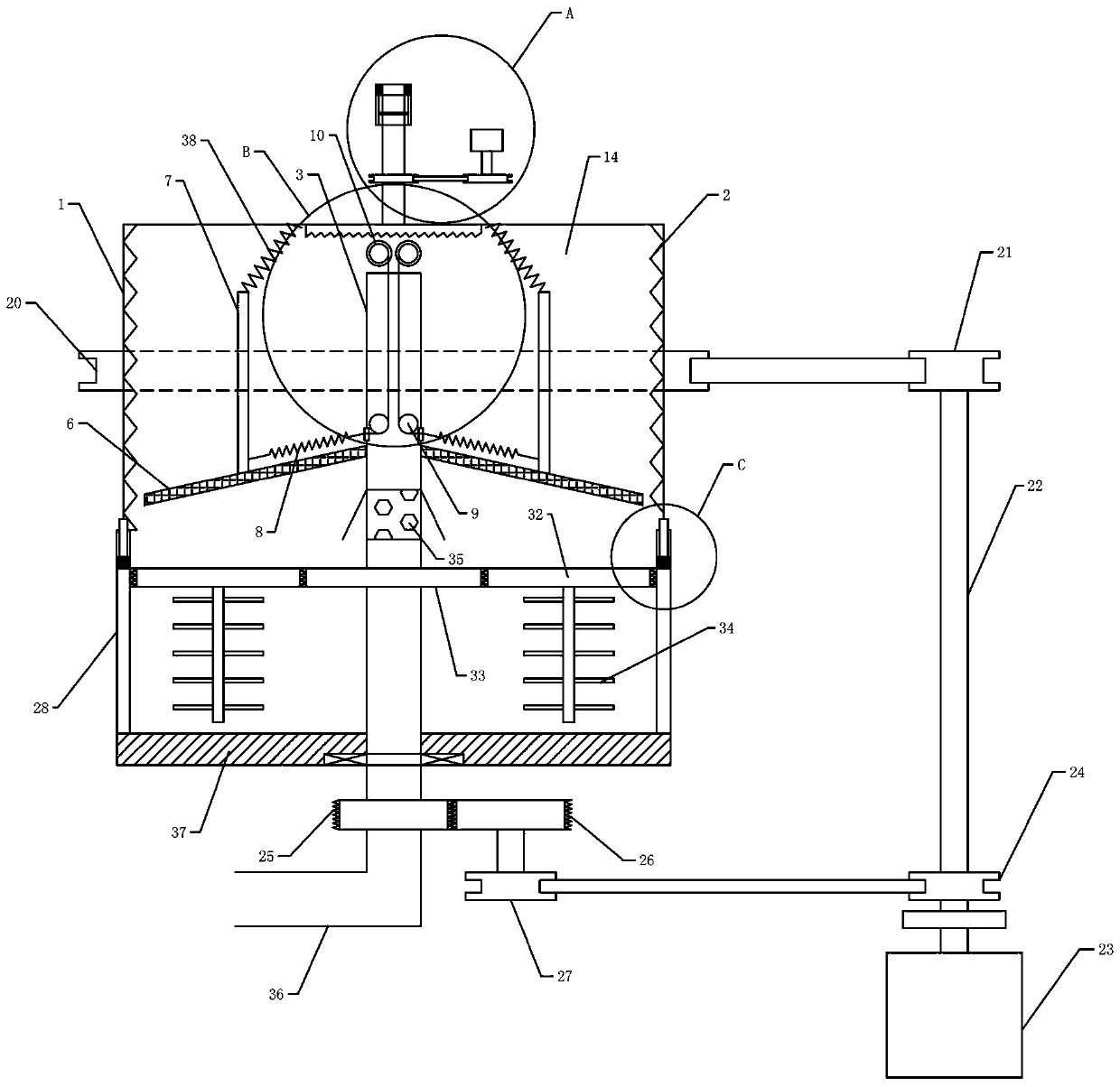

The invention relates to a soil remediation filtration system and a soil filtration and separation repair method. The system comprises a bottom plate, a box, a rolling mechanism, a screening mechanism, two electromagnetic separation mechanisms and a conveying mechanism, wherein the box is mounted on the bottom plate, the box is of a structure with a top opening, conveying grooves are formed in left and right ends of the lower side of the box, the rolling mechanism, the screening mechanism and the electromagnetic separation mechanisms are sequentially mounted on the box from top to bottom, thetwo electromagnetic separation mechanisms are symmetrically mounted on the box, the conveying mechanism is mounted on the bottom plate and mounted in the conveying roves, polluted soil is crushed by the rolling mechanism and screened by the screening mechanism, large particulate matter is filtered out, the electromagnetic separation mechanism adsorbs heavy metals in the screened soil, and the problems that hardened soil is not easy to crush thoroughly, heavy metals in hardened blocks are not easy to separate, collected metal elements contain a large quantity of soil and impurities and the likeare solved.

Owner:玉环市几偶孵化器有限公司

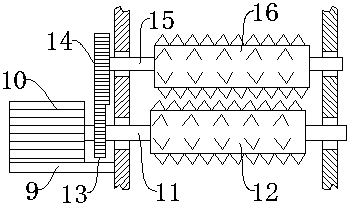

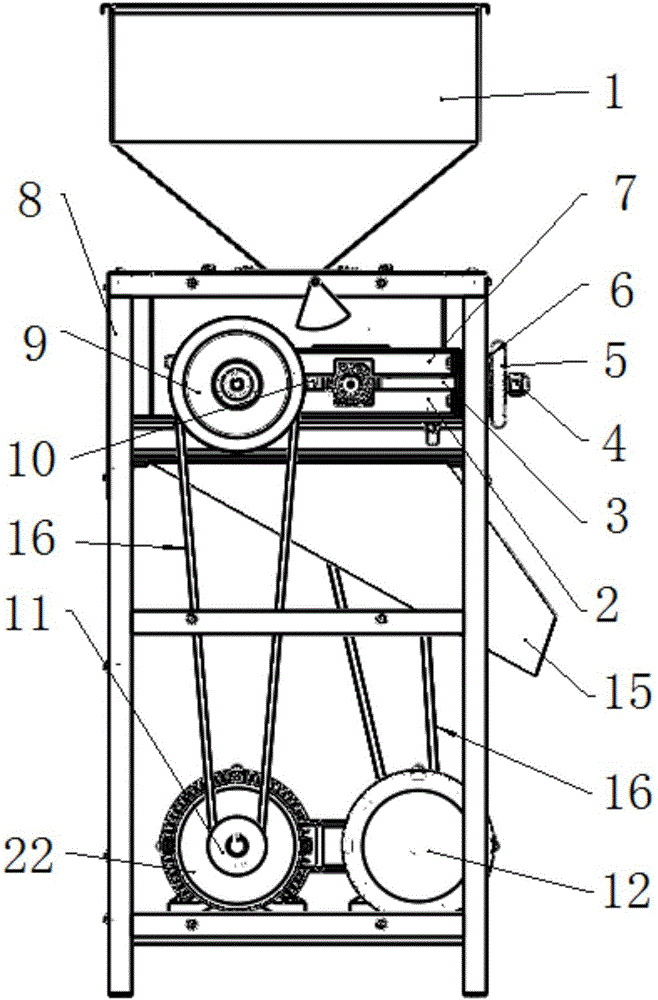

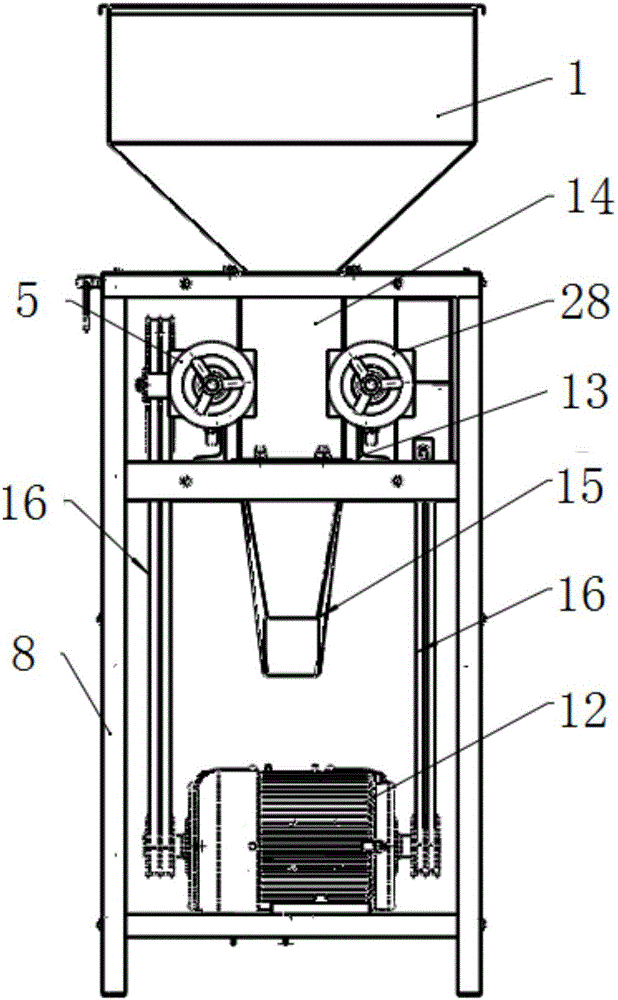

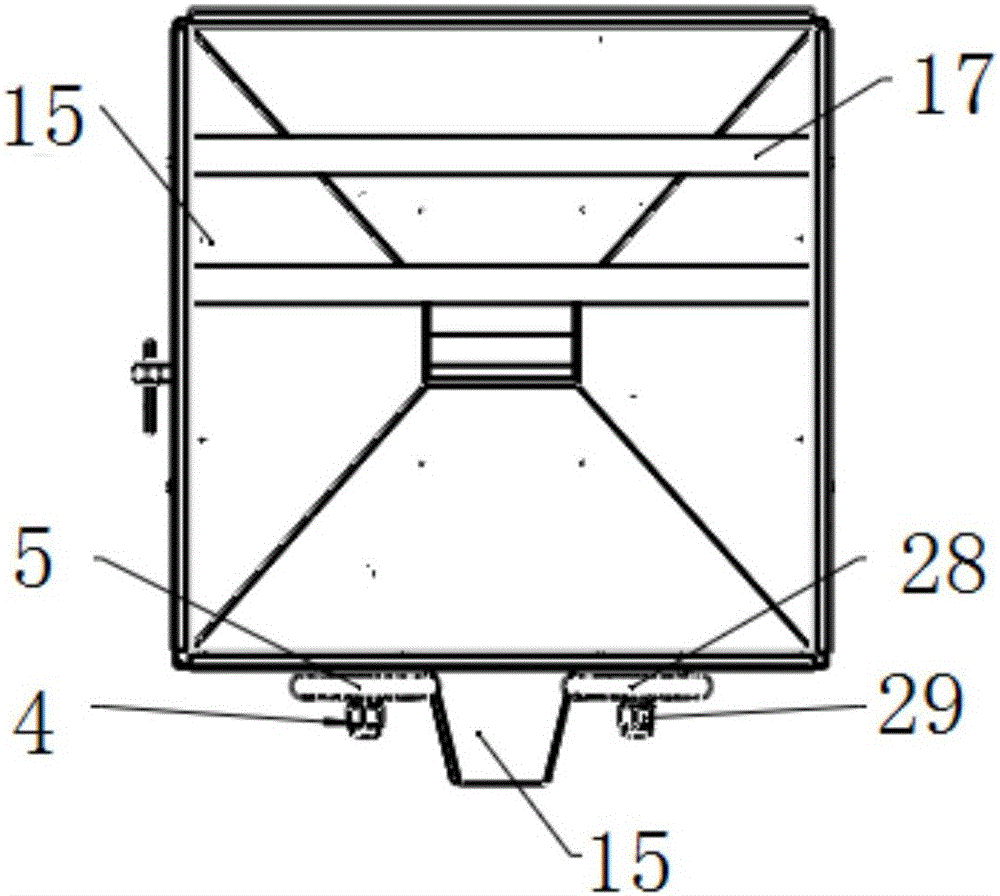

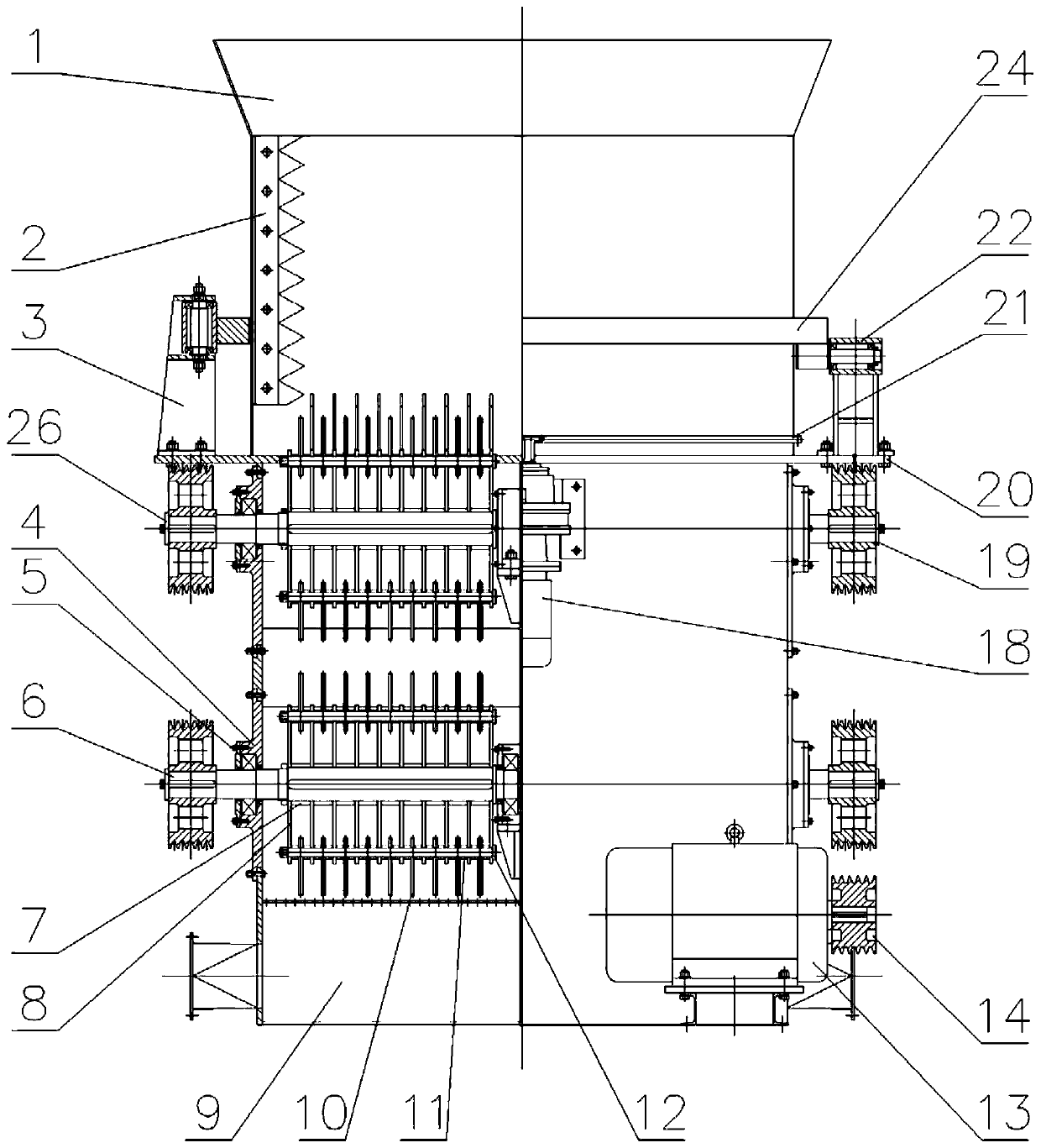

Concrete test block crusher and use method thereof

InactiveCN111841718ARealize two-stage crushingMeet crushing requirementsSievingScreeningElectric machineryStructural engineering

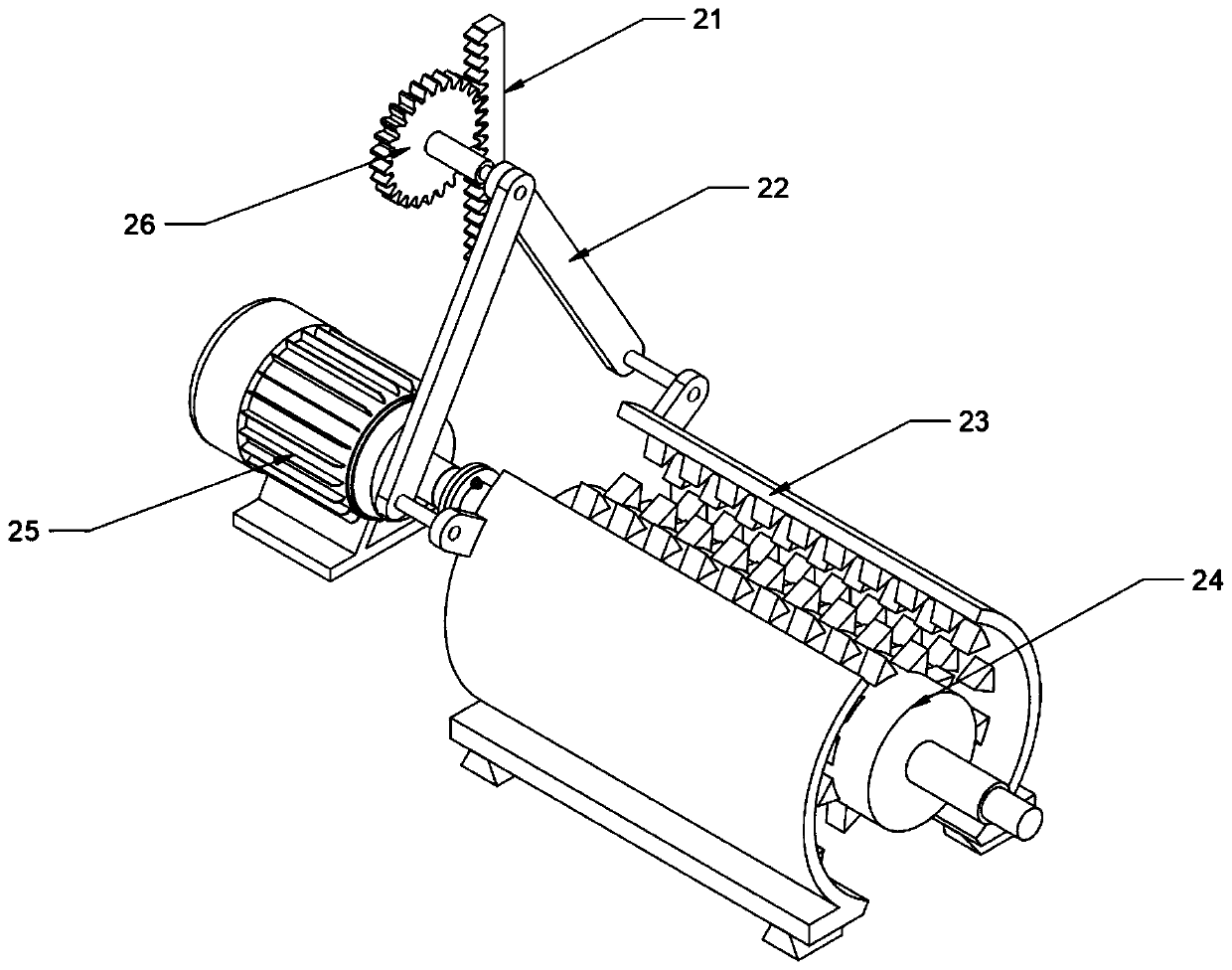

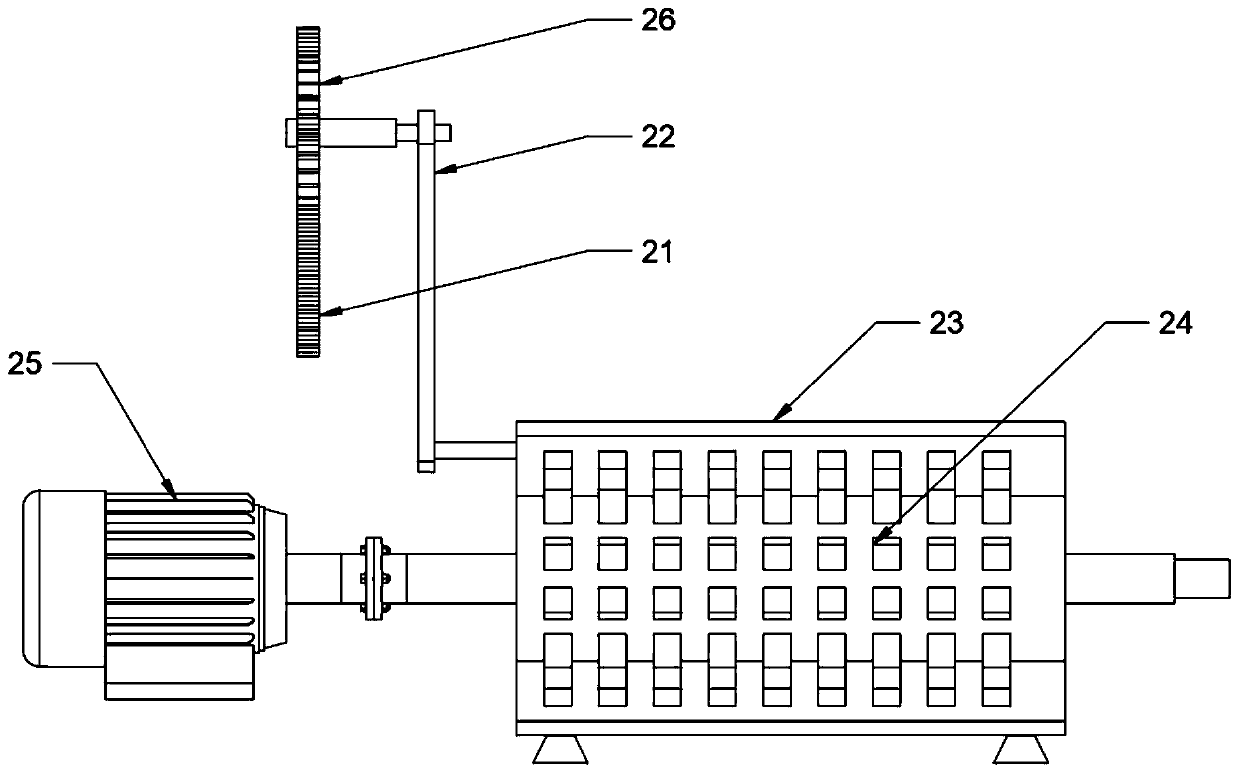

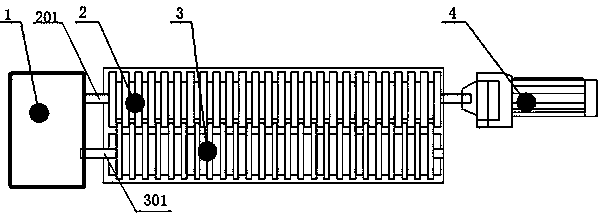

The invention discloses a concrete test block crusher and a use method thereof. The concrete test block crusher comprises a crushing box, a crushing cavity is formed in the crushing box, two first crushing rollers and two second crushing rollers which are rotationally connected with the crushing cavity are installed in the crushing cavity, the two first crushing rollers are located above the two second crushing rollers, and power mechanisms are arranged between the two first crushing rollers and a square crushing box and between the two second crushing rollers and the square crushing box; anda feeding port is formed in the upper end of the crushing box, a discharging cavity is formed below the crushing box, the discharging cavity communicates with the crushing cavity through the discharging port, and a first screen and a second screen which are distributed up and down are arranged in the discharging cavity; and rectangular cross rods are fixedly connected with the left ends of the first screen and the second screen. According to the concrete test block crusher and the use method thereof, the structure is reasonable, concrete blocks can be crushed and screened and large-particle concrete blocks can be crushed in a reciprocating mode through one driving motor, and the crushing quality is improved.

Owner:路顺

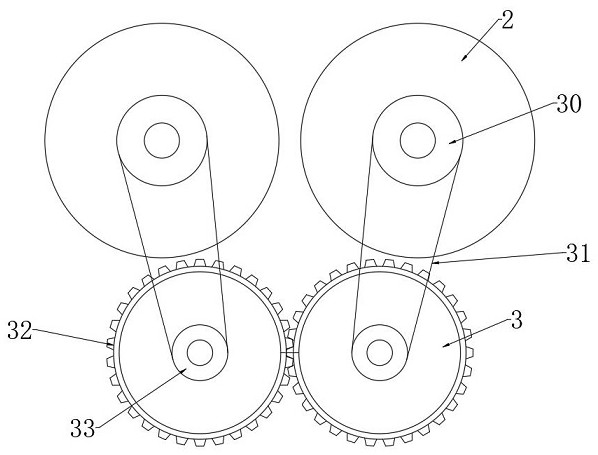

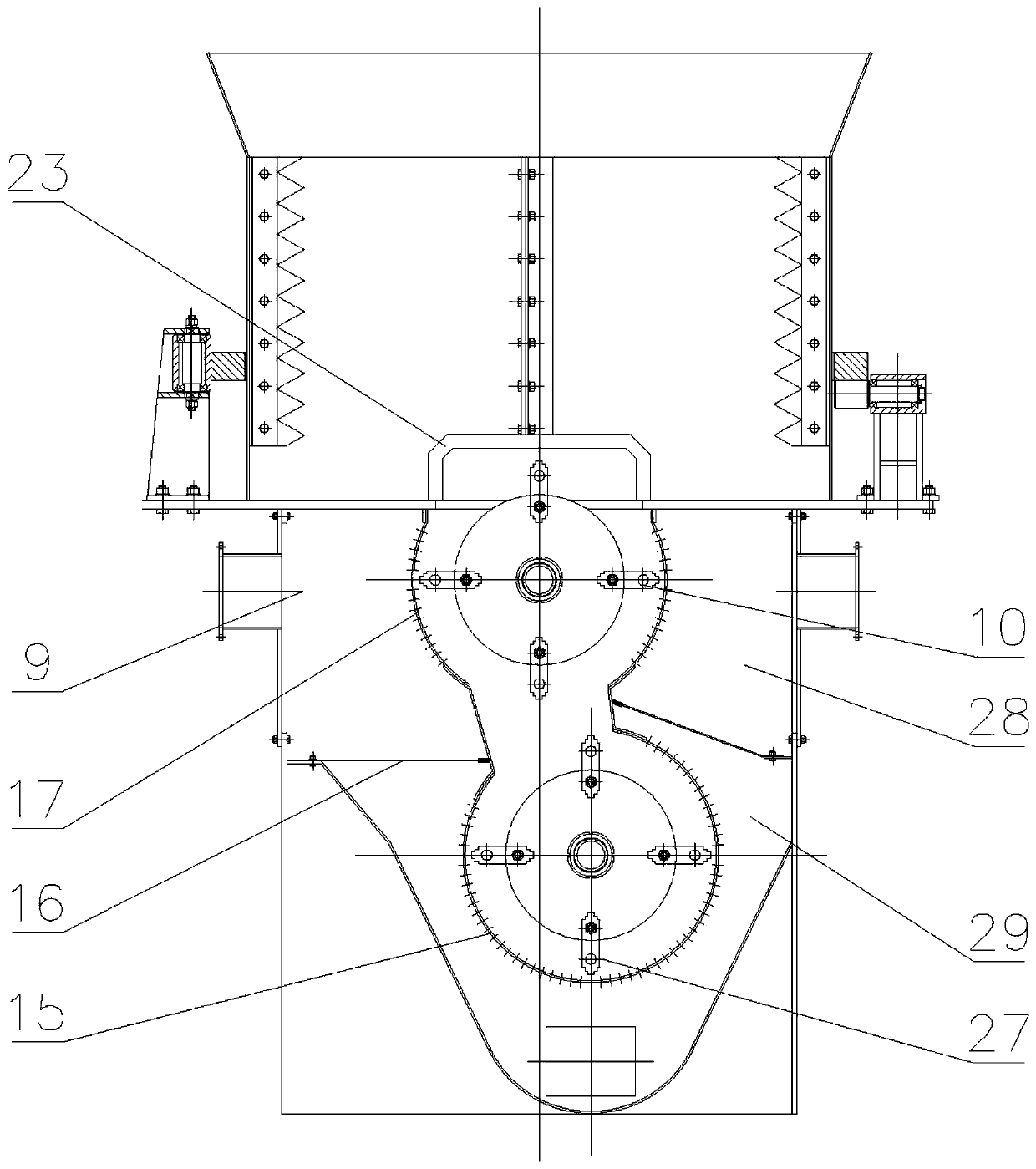

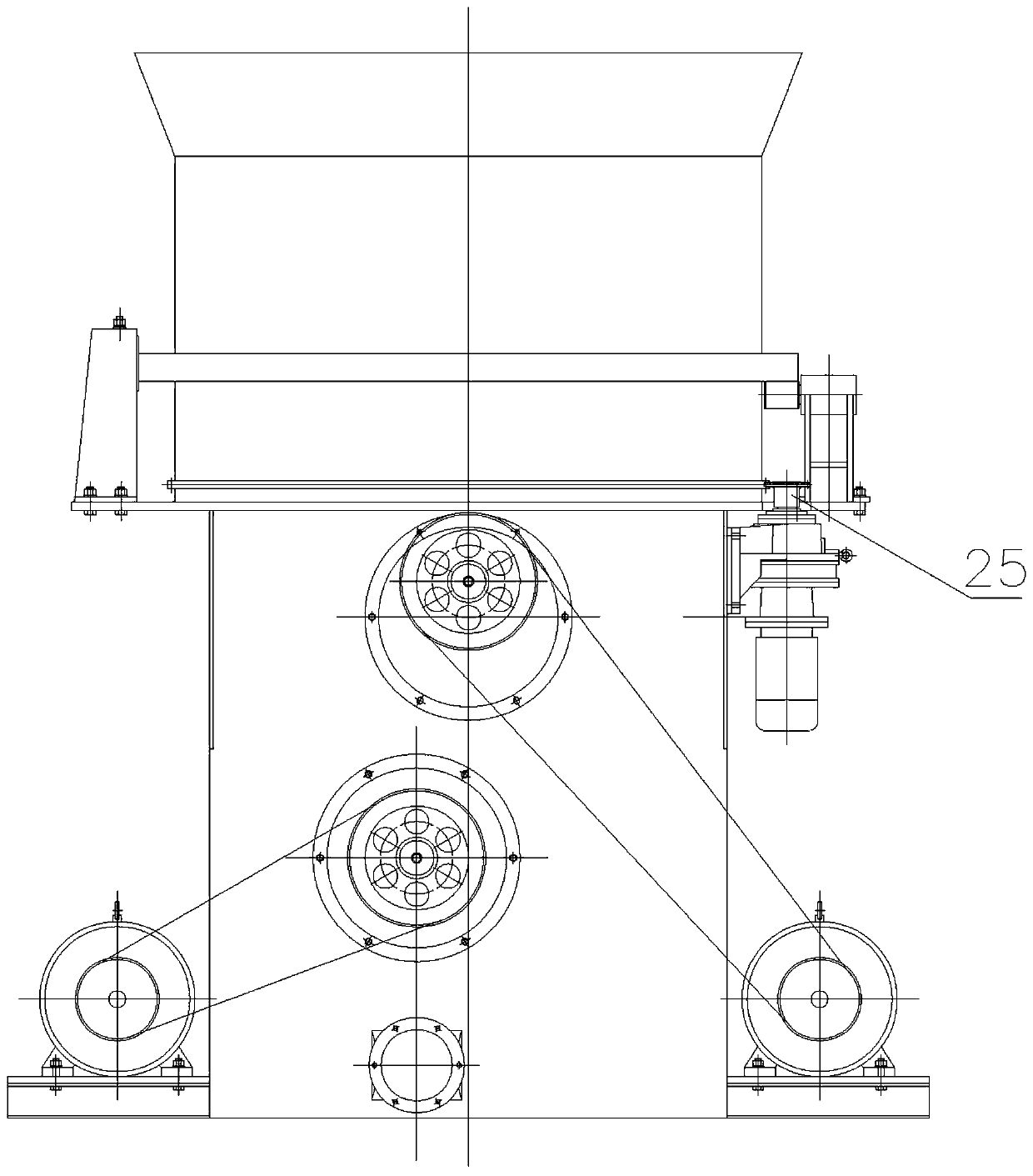

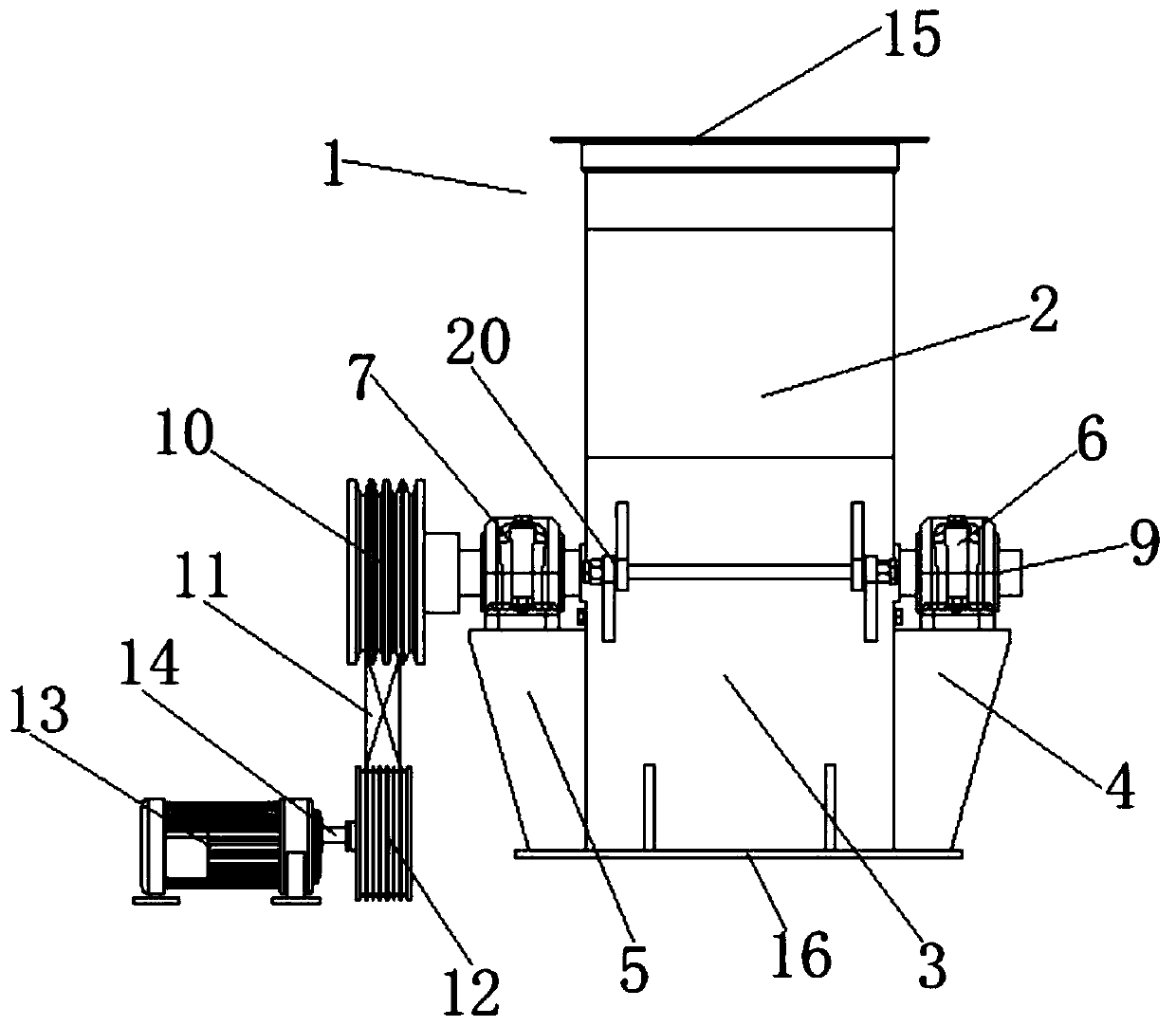

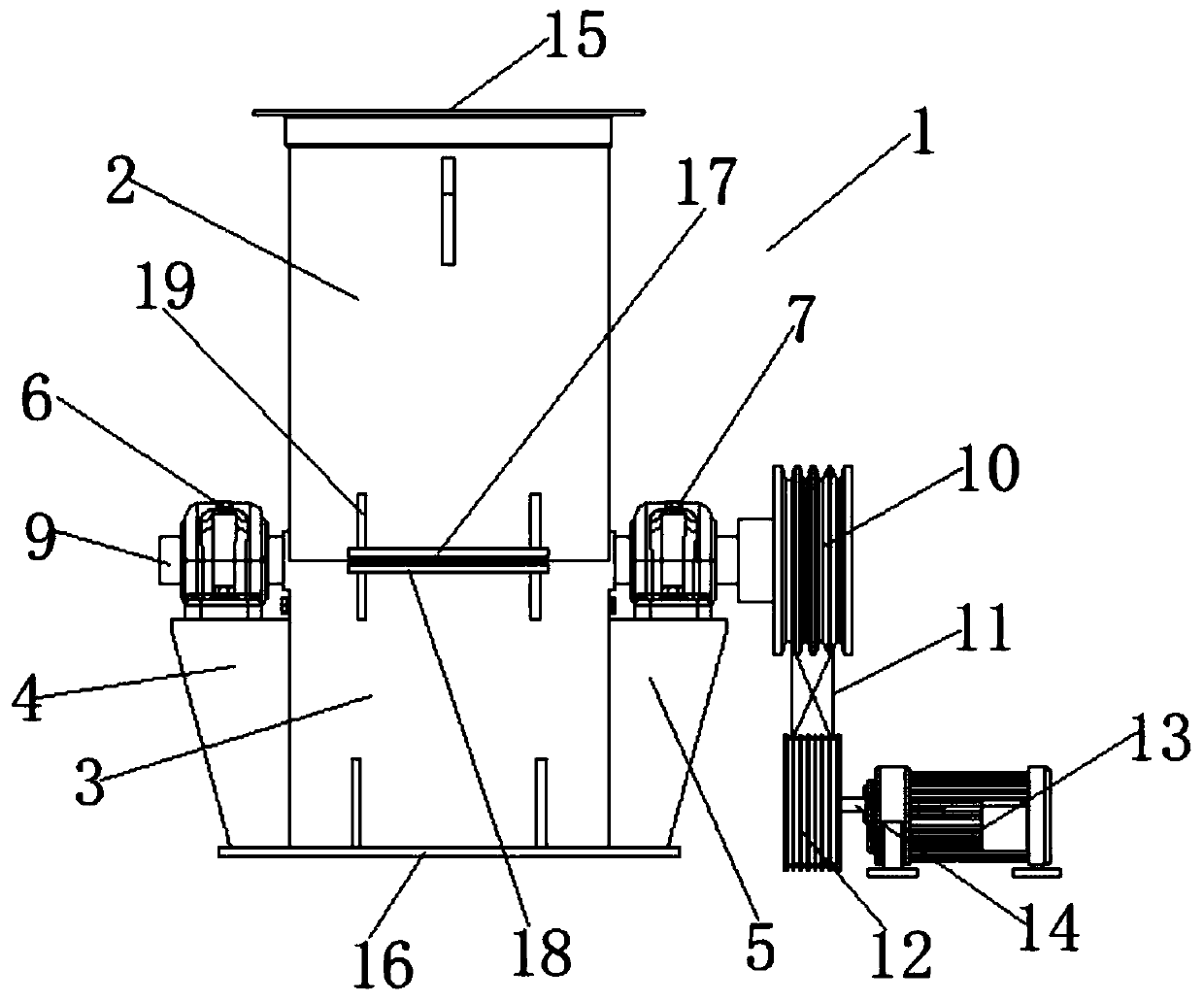

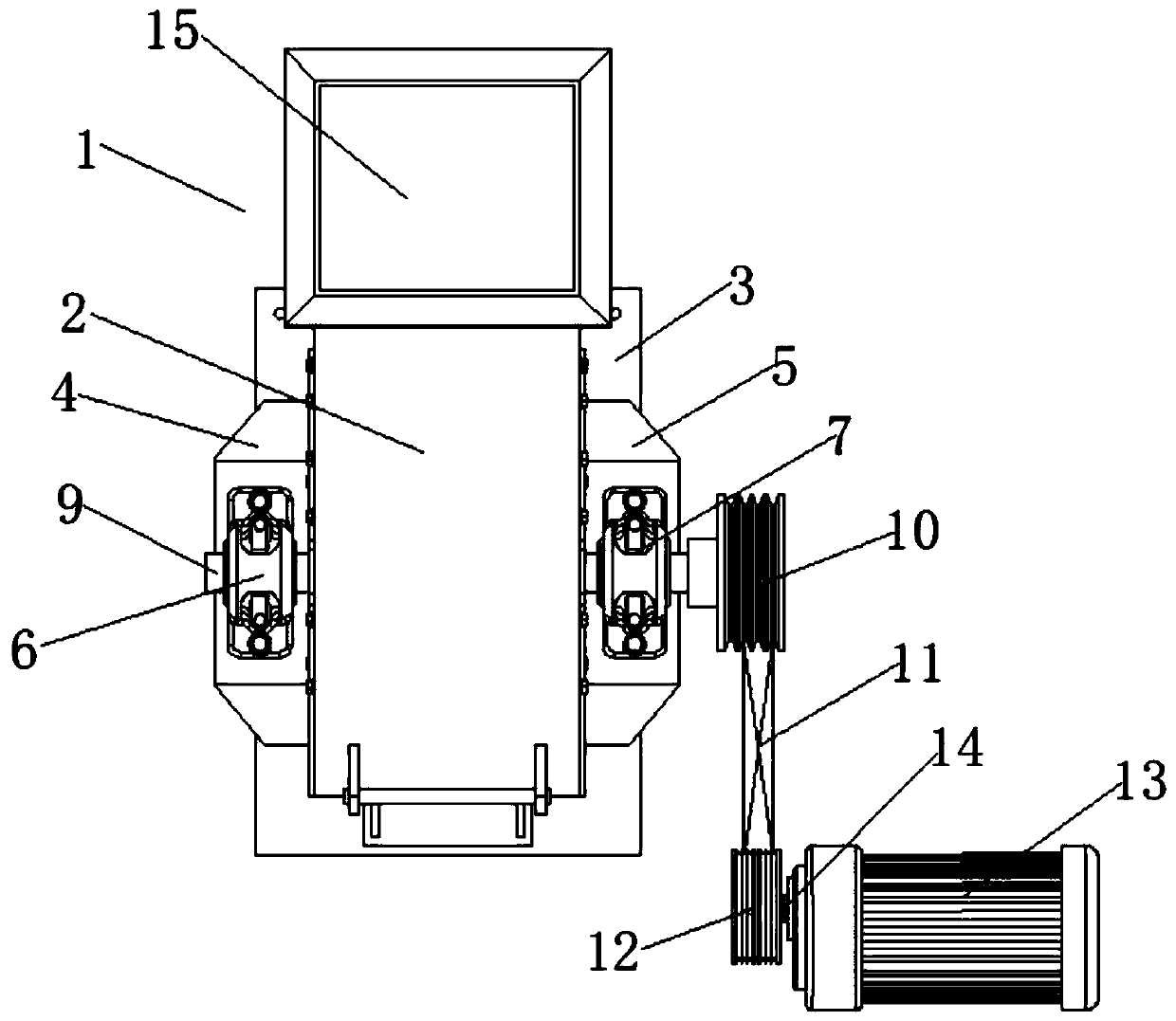

Stepless gear roller set and stepless gear roller crusher

The invention discloses a stepless gear roller set and a stepless gear roller crusher. The stepless gear roller set comprises at least two gear rollers, wherein a gap is formed between the two adjacent gear rollers, and the gap is gradually enlarged from one side to the other side. The stepless gear roller crusher consists of a feed opening, a sorting feeder, the stepless gear roller set, a sieving feed opening, a sieving machine, a coarse material refeeding opening, a discharge opening and a main machine frame. Aiming at overcoming the defects that an existing equipment is complex in structure, is large in size, is high in building cost, and the like, the rate of certified product of particle size after cracking of brittle materials is lower, and the excessive smashing phenomenon is serious, the stepless gear roller crusher is integrated equipment capable of sorting feeding, sorting smashing and sieving. The stepless gear roller crusher has the advantages that the structural design is simple and reasonable, the building cost is low, the floor space is small, the highest particle size certified product rate can achieve about 95%, and the crusher is the most environment-friendly, the most electricity-saving and the most durable.

Owner:上海建冶路桥机器设备有限公司

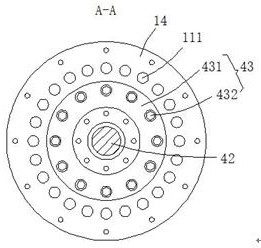

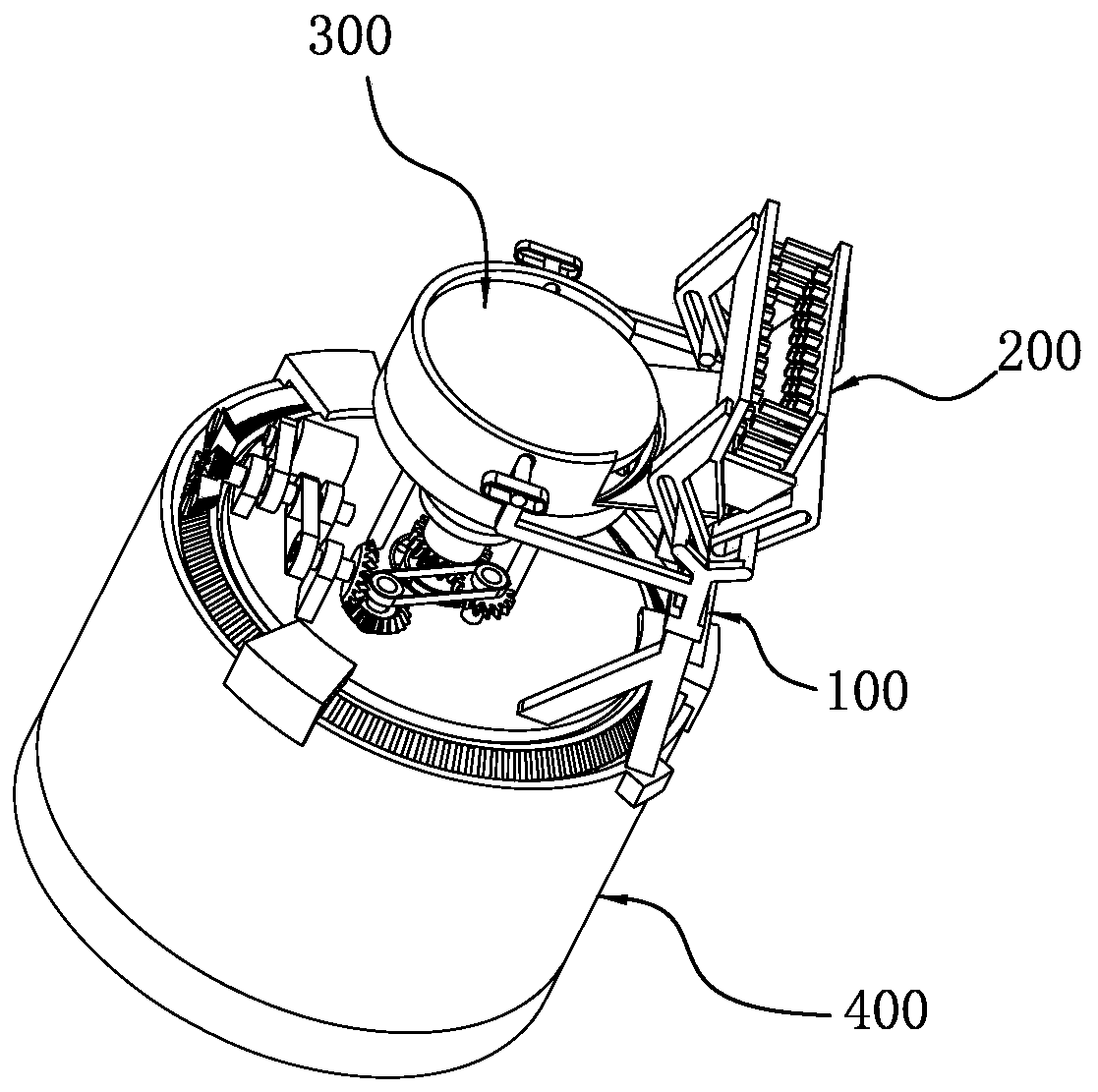

Ball mill used for producing graphite powder

InactiveCN105413813AExcellent crushing speedReduce crushing timeGrain treatmentsSynchronous motorGraphite

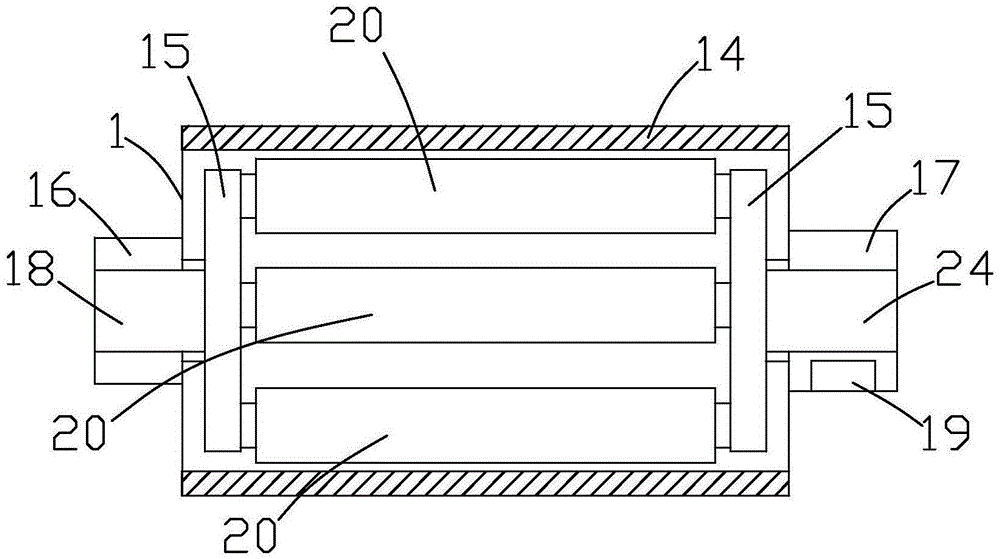

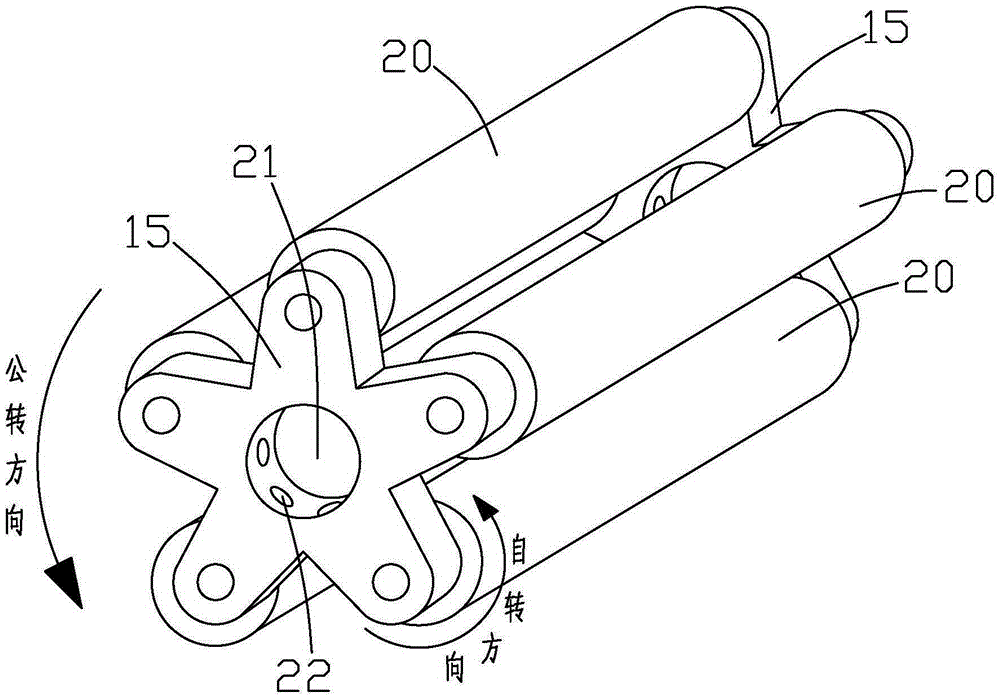

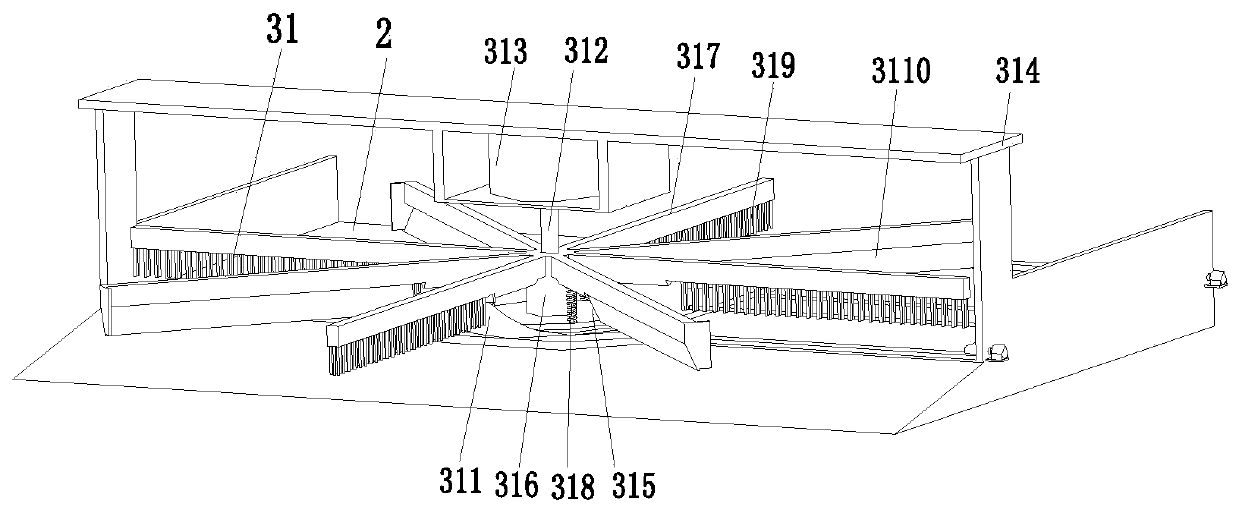

The invention discloses a ball mill used for producing graphite powder. The ball mill comprises a roller, a power drive device, a feeder and a dumping device, wherein two star brackets which are parallel to each other are arranged on the inner part of the roller; material distributing tubes are uniformly arranged on the inner parts of the star brackets; five cylindrical ball-milling tanks which are parallel to each other are uniformly distributed between the two star brackets; the two ends of each cylindrical ball-milling tank are provided with supporting tube racks; a synchronous motor is arranged on the inner parts of the star brackets; the cylindrical ball-milling tanks realize autoroatation around the star brackets; the two ends of the roller are respectively provided with a front positioning bearing and a rear positioning bearing; and the cylindrical ball-milling tanks realize rotation around the front positioning bearing and the rear positioning bearing. The ball mill is simple in structure, high in practicability, not only can realize autoroatation and rotation of the cylindrical ball-milling tanks and improve material crushing efficiency and material crushing quality, but also can pre-heat and crush materials, so that the materials are guaranteed to have certain temperature while being output, and therefore, crushing requirements of different materials are met.

Owner:SHENGZHOU SIGMA TECH

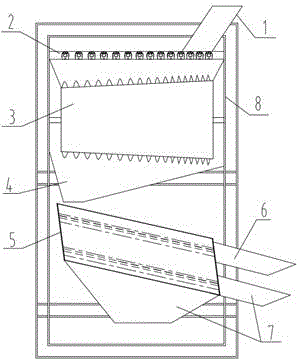

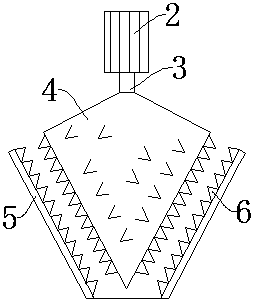

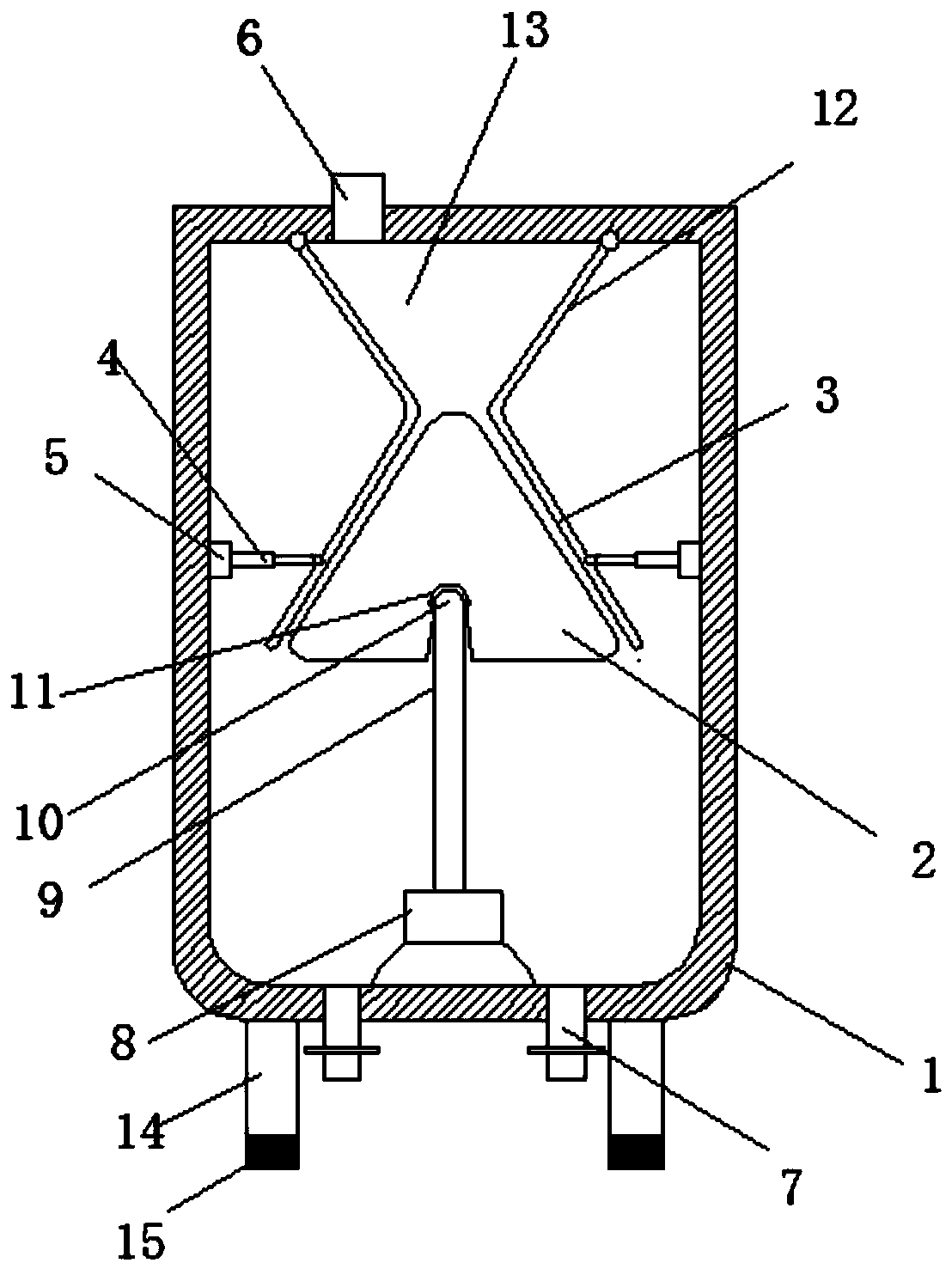

Corrugated paper smashing device good in smashing effect

The invention discloses a corrugated paper smashing device good in smashing effect. A box body is included, and a first motor is installed in the middle of the upper end of the box body; the output end of the first motor is connected with a first rotating shaft, and the tail end of the first rotating shaft is connected with a rhombus smashing rod; a conical barrel is connected between the inner walls of the upper portion of the box body; and the inner wall of the conical barrel is connected with teeth at equal intervals. The corrugated paper smashing device good in smashing effect is reasonable in design; corrugated paper is thrown into the box body through a feeding hopper communicating with the two sides of the upper end of the box body, and the tail end of the feeding hopper communicates with a gap formed by the rhombus smashing rod and the conical barrel; the rhombus smashing rod and the teeth connected to the inner wall of the conical barrel at equal intervals are driven by the first motor to perform friction smashing mutually, so that the corrugated paper can be smashed in advance; and a partition plate is connected between the inner walls of the middle portion of the box body, the middle portion of the upper end of the partition plate communicates with a discharging port located in the bottom end outer side of the conical barrel, and an opening in the bottom end of the conical barrel is smaller than an opening of the discharging port.

Owner:NANJING GAOLING COLOR PRINTING FACTORY

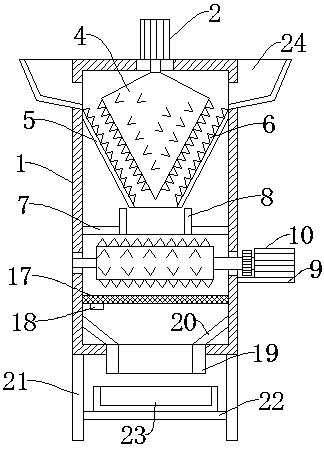

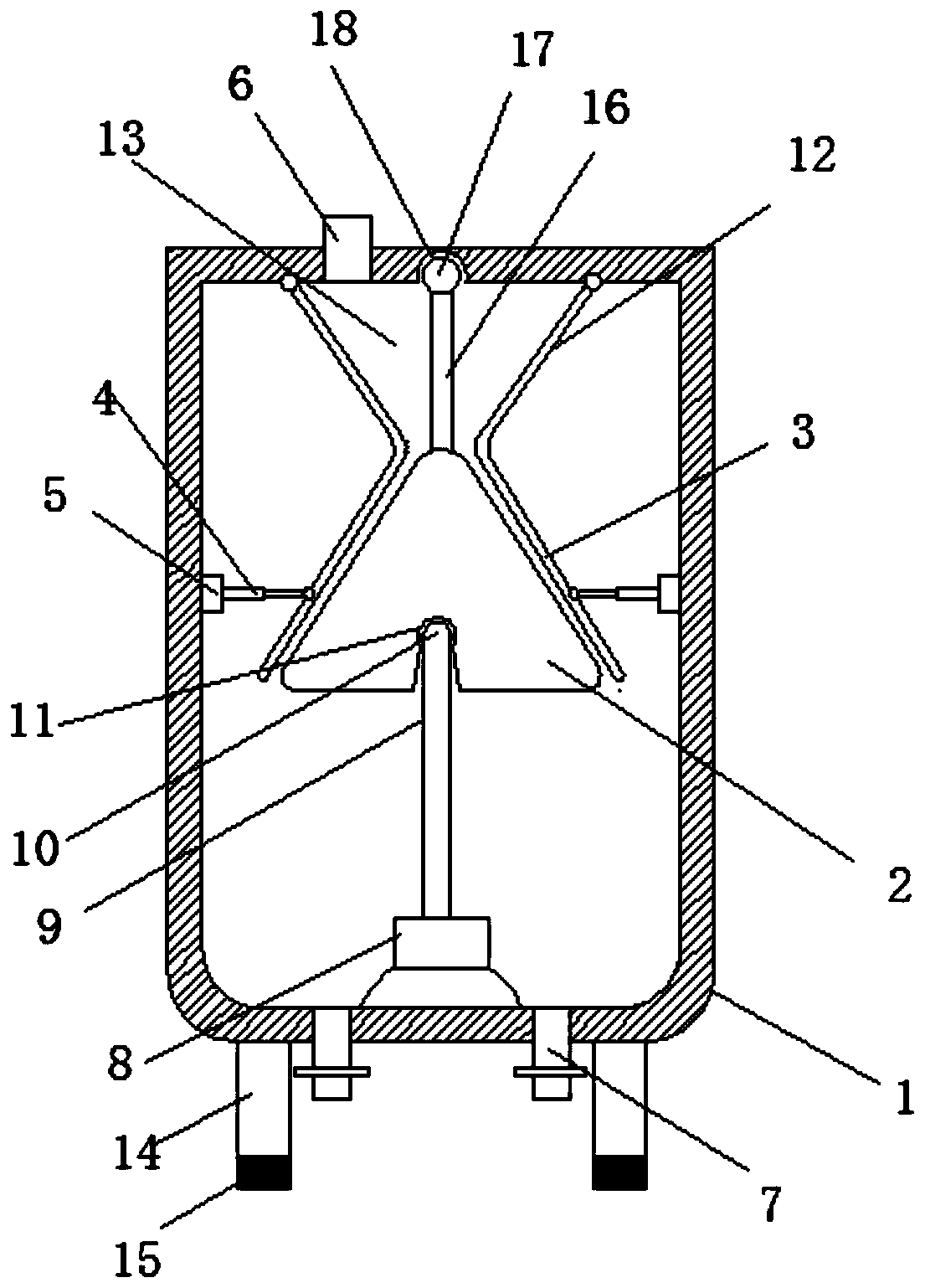

Raw material crushing device for machining

ActiveCN111437978AIncrease contact areaIncrease frictionGrain treatmentsStructural engineeringManufacturing engineering

The invention discloses a raw material crushing device for machining. The raw material crushing device comprises a box body as well as a crushing assembly and a screening assembly which are arranged in the box body, wherein the crushing assembly comprises a crushing hammer, crushing plates and electronic telescopic rods, and the screening assembly is clamped in the position below the crushing assembly through elastic assemblies fixedly mounted on the inner wall of a crushing chamber; and a smashing chamber communicating with the crushing chamber is further formed in the box body and a smashingassembly is arranged in the smashing chamber. With the adoption of the crushing hammer and the crushing plates with multiple groups of crushing teeth, friction force is increased, the crushing effectis improved, and by cooperation with the electronic telescopic rods, the spacing between the crushing hammer and the crushing plates is adjusted and practicability is high; vibrating screens are matched with the smashing assembly, so that the refining effect of raw materials is improved; the vibrating screens are matched with the elastic assemblies, disassembly and assembly are convenient, and flexibility is high; with the adoption of universal wheels provided with brake devices as well as hand rails, the raw material crushing device not only can move, but also can be fixed and has high flexibility; and with the adoption of access doors, replacement of the vibrating screens and overhauling of parts are convenient.

Owner:山东蓬莱电力设备制造有限公司

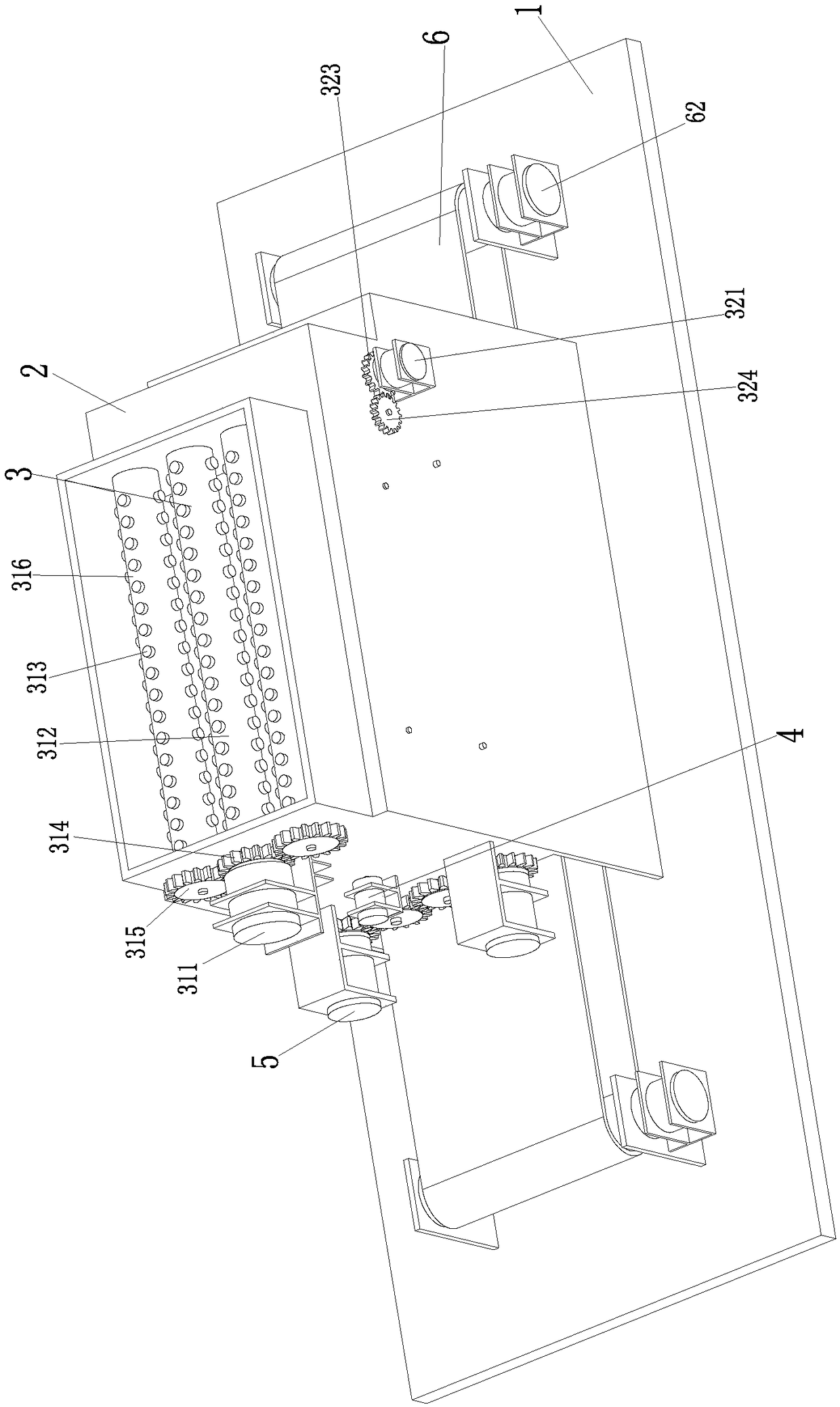

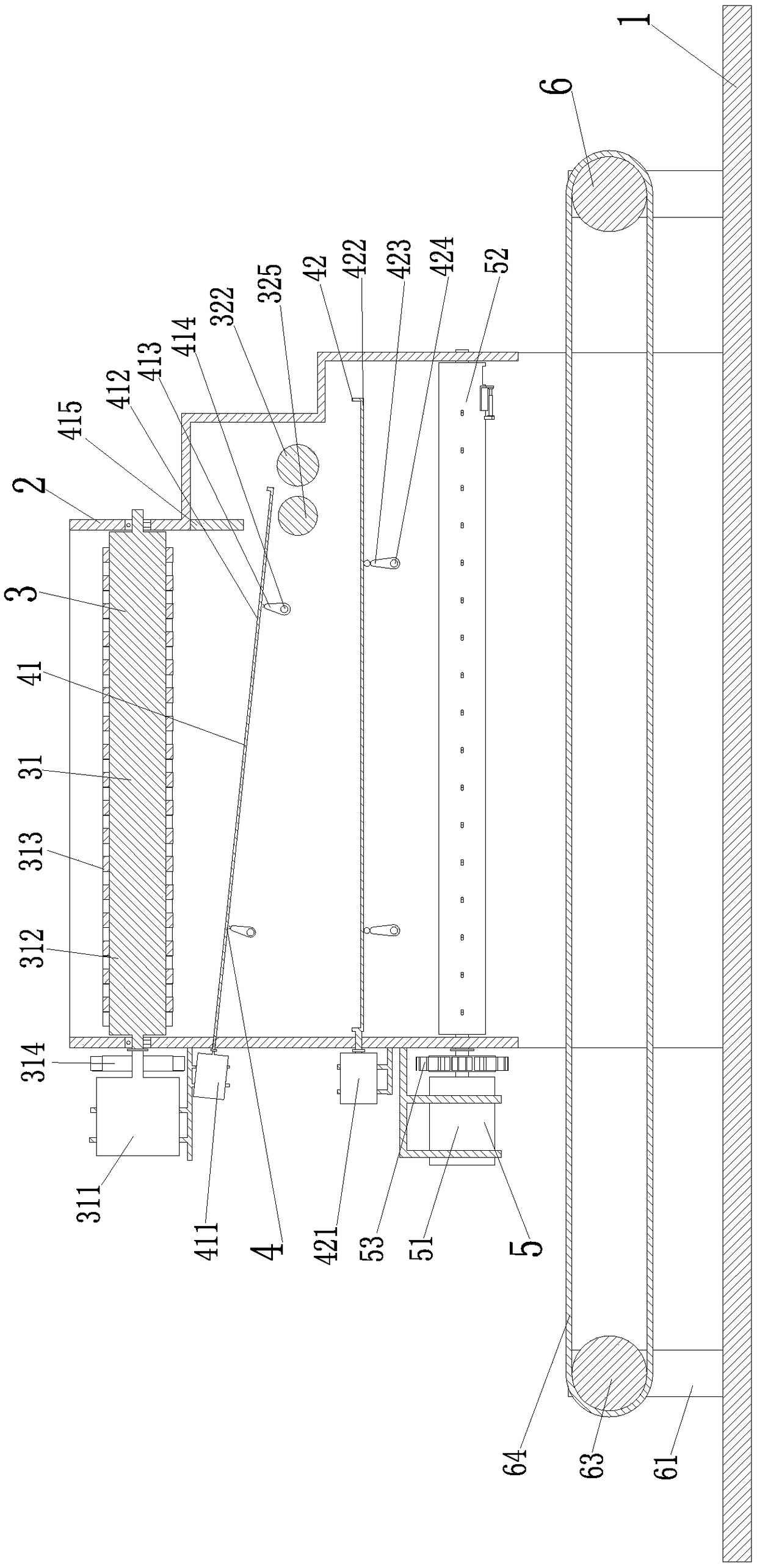

Recovery production device for construction waste added as barren material for brick sintering

The invention discloses a recovery production device for construction waste added as a barren material for brick sintering, and relates to the technical field of waste recovery. To solve the problem that an existing crushing device cannot meet the requirement for complete crushing at a time, and the processes of later screening and re-crushing are added, the following scheme is proposed. The recovery production device comprises a crushing mechanism, a driving mechanism, a screening mechanism and a grinding mechanism, wherein the crushing mechanism, the screening mechanism and the grinding mechanism are all under driving control of the driving mechanism; and the screening mechanism comprises a fixing box, the bottom box wall of the fixing box is fixedly sleeved with a screen, the right boxwall of the fixing box is movably sleeved with a movable frame, and the right outer wall of the fixing box is connected with a push-and-pull mechanism fixedly connected with the movable frame. The recovery production device not only facilitates repeated crushing of raw materials, but also performs screening simultaneously during crushing, which is beneficial to the quality of final crushing; and besides, the whole device adopts the same motor for driving control, the degree of integration is high, and the market competitiveness of the device is improved.

Owner:六安三创建筑材料有限公司

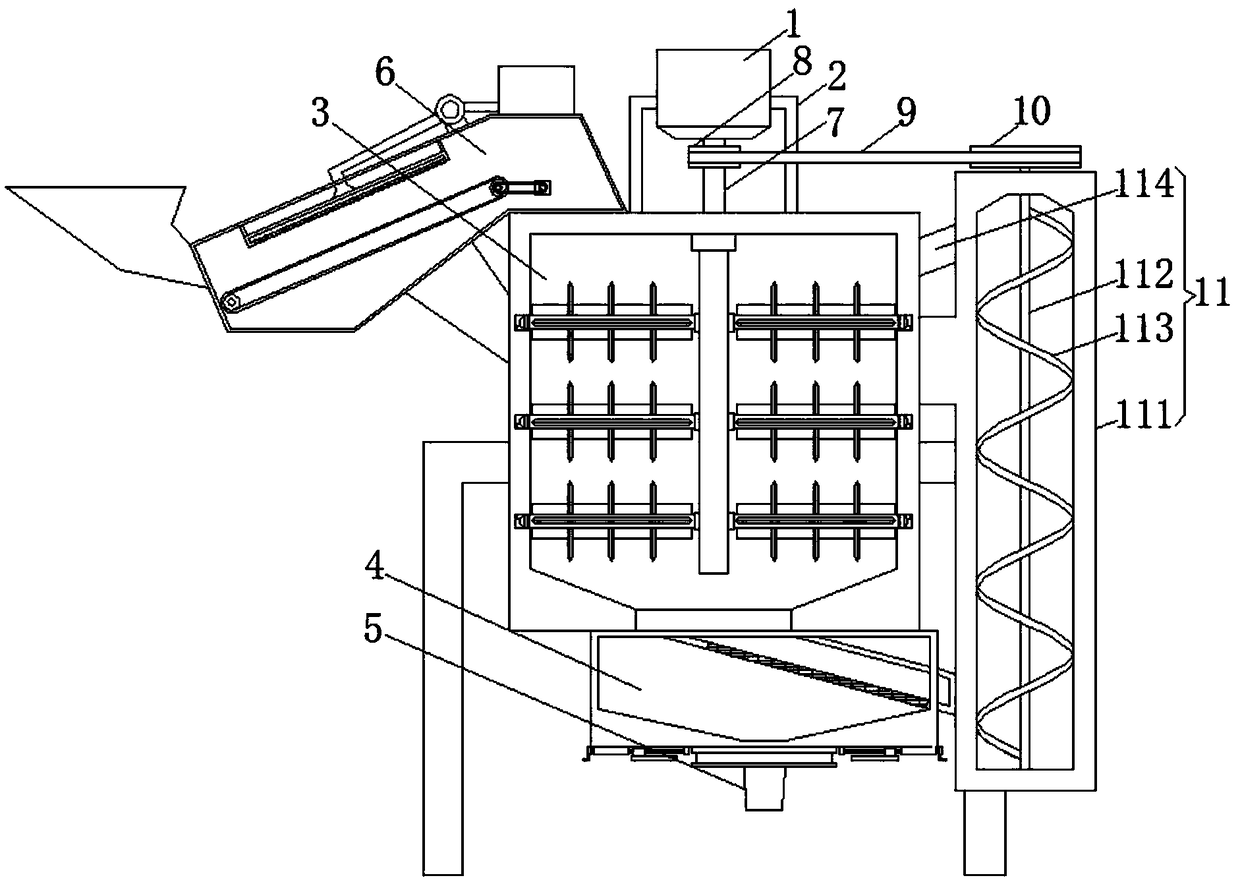

Gravel crushing device for building construction

InactiveCN111013731APrevent fallingAvoid pollutionSievingScreeningSpiral bladeArchitectural engineering

The invention discloses a gravel crushing device for building construction. The device comprises a rack and a crushing assembly arranged on the rack, wherein the bottom of the crushing assembly is provided with a dovetail sliding block and is in sliding connection with a dovetail sliding groove formed in the rack, and a feeding hopper is arranged above the crushing assembly; and a screening deviceand a conveying device communicating with the screening device are arranged in the rack, wherein the screening device is located below the crushing assembly, and the conveying device is arranged on the side wall of the rack. According to the device, the feeding hopper with a feeding door is adopted, so that dust and impurities are prevented from falling in, and the dust, generated during gravel crushing, is prevented forming polluting the environment; the crushing assembly with an adjusting assembly is adopted, so that different gravel crushing requirements can be met, and the flexibility ishigh; a first conveying belt and a second conveying belt which are provided with different sieve holes are adopted, and a first spiral blade and a second spiral blade are matched, so that large-particle gravels are screened out, circulating crushing is achieved, the crushing effect is enhanced, and the uniformity of gravel particles is guaranteed.

Owner:苏肇松

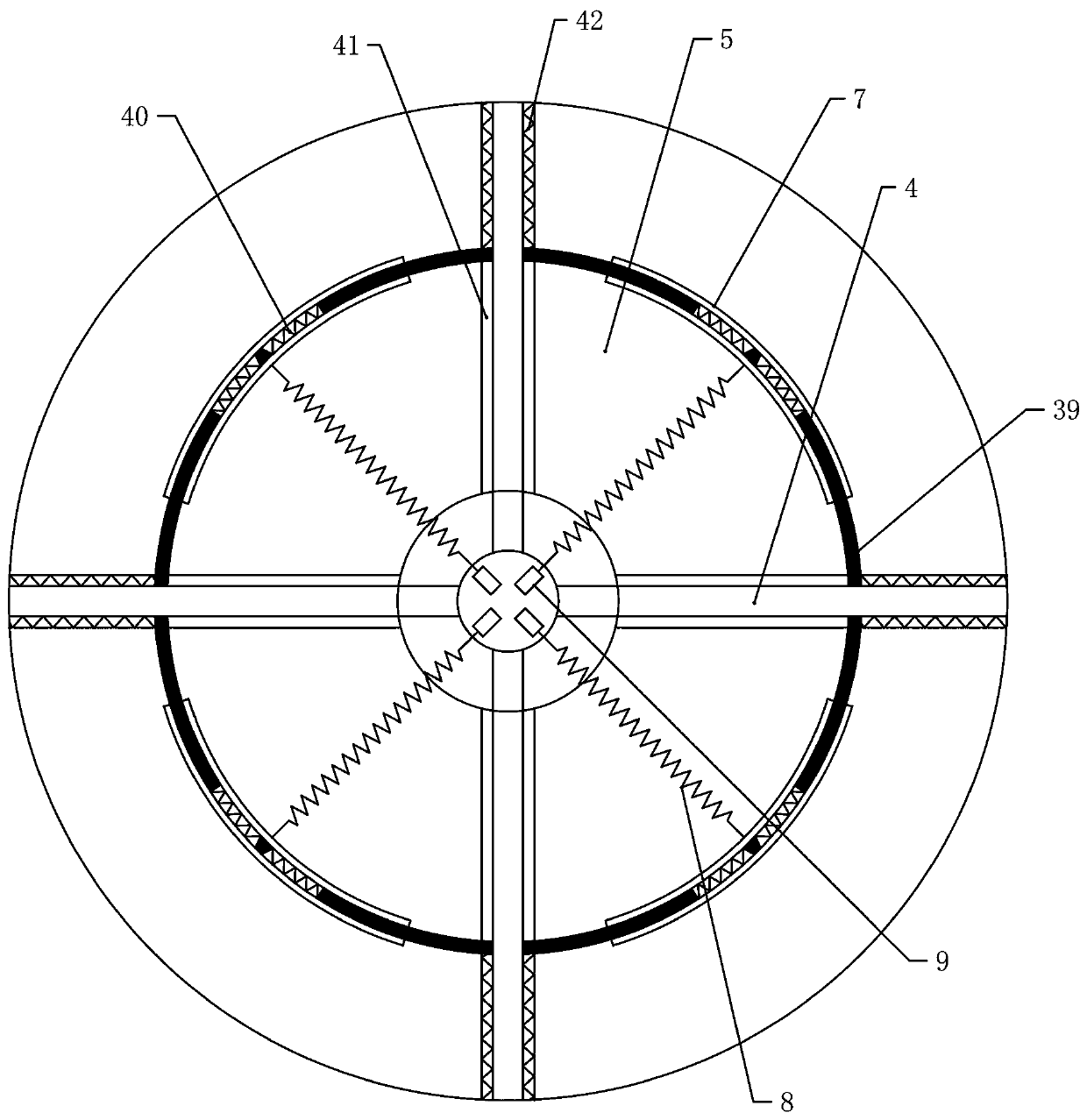

Construction waste treatment device

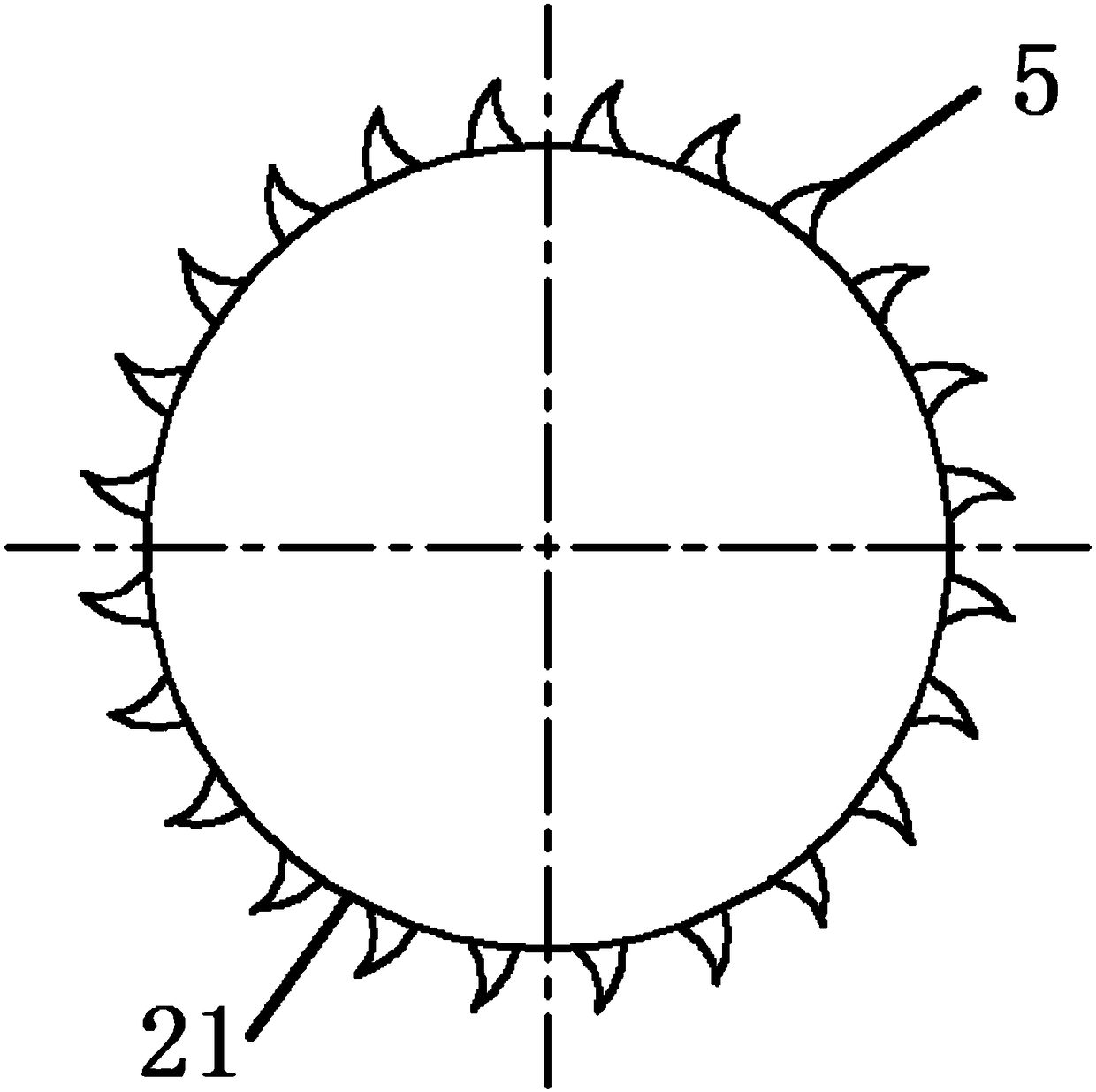

ActiveCN111167585AEffective separationWon't hurtRotary stirring mixersTransportation and packagingCircular discGear wheel

The invention provides a construction waste treatment device. The construction waste treatment device effectively solves the problem that waste metal causes damage to an existing crushing device due to the fact that the crushing device cannot separate concrete and the waste metal. The construction waste treatment device includes an upper tank body, wherein first saw teeth are arranged on the innerside wall of the upper tank body, the center of the upper tank body is rotatably connected with a through pipe, the outer side wall of the through pipe is fixedly connected with a baffle, filter screens are fixed in a crushing bin, the filter screens are slidably connected with push plates, the push plates are connected with first springs, first pulleys are fixed in the through pipe, second pulleys arranged at the upper end of the through pipe are arranged at the upper ends of first pulleys, the second pulleys are coaxially connected with a one-way wheel, helical gears are arranged outside the one-way wheel, the upper parts of the helical gears can be meshed with disc helical teeth, a feeding port placed in the crushing bin is located beside a disc gear, a fixed rod is fixed to the upperend of the disc gear, a cylinder fixedly sleeves the upper end of the fixed rod, and the upper end of the cylinder is connected with the fixed rod in a threaded mode. According to the construction waste treatment device, common crushing requirements can be met, the practicability is high, functions are diversified, and the social market needs can be met.

Owner:ZHENGZHOU UNIV OF IND TECH

Straw crushing apparatus

The invention relates to the technical field of crushing equipment and discloses a straw crushing apparatus, comprising a first motor. A crushing mechanism is fixedly connected to the two sides of thefirst motor through crank plates; a screening mechanism is fixedly connected to the bottom of the crushing mechanism; a receiving mechanism is arranged at the bottom of the screening mechanism; a pretreating mechanism is fixedly connected to the left of the top of the crushing mechanism; a shaft is connected to the bottom of the first motor; the outer upper portion of the shaft is sleeved with afirst driving wheel; a first belt is movably connected outside the first driving wheel; a first driven wheel is movably connected to the right of an inner cavity of the first bet; a return mechanism is connected to the bottom of the first driven wheel; each of the front upper and lower portions and back upper and lower portions of a rotary post is fixedly connected with a transverse blade. The problem that traditional straw crushing equipment has poor functionality is solved such that the straw crushing apparatus has greater functionality.

Owner:王春峰

Novel efficient oil sand crushing machine

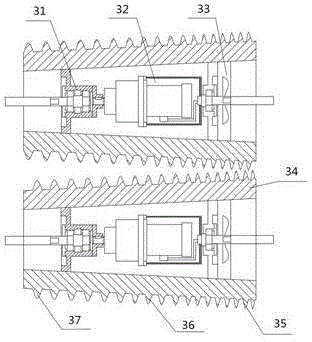

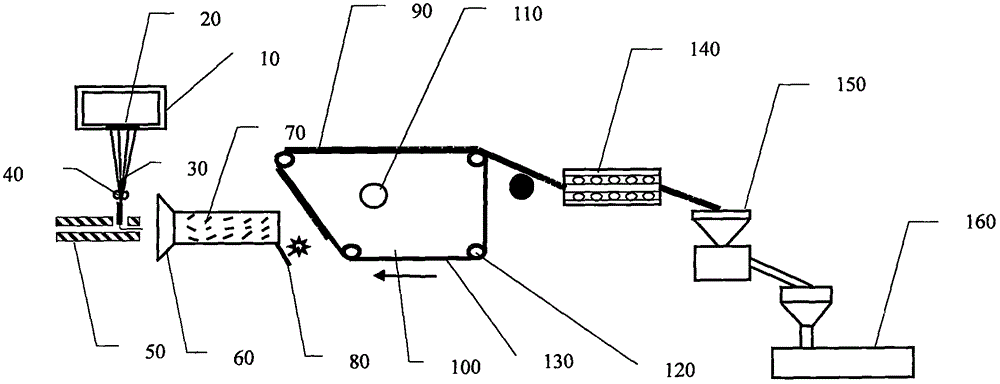

The invention relates to a novel efficient oil sand crushing machine. The novel efficient oil sand crushing machine comprises a separation propelling plant and is characterized in that the separationpropelling plant is used for screening oil sand, a first discharge outlet is arranged below the separation propelling plant, oil sand meeting requirements falls through the gaps and is discharged through the first discharge outlet, and the oil sand which does not meet the requirements enters a primary crushing device; the primary crushing device is close to the outlet end of the separation propelling plant and used for further crushing the oil sand from the separation propelling plant to obtain roughly crushed oil sand, a second discharge outlet is arranged below the separation propelling plant, and the roughly crushed oil sand flows into a secondary crushing device through the second discharge outlet; the secondary crushing device is located below the primary crushing device, a third discharge outlet is arranged below the secondary crushing device, the roughly crushed oil sand is crushed by the secondary crushing device and discharged from the third discharge outlet, each of the primary crushing device and the secondary crushing device comprises two rollers which rotate in opposite directions and crushing teeth arranged on the rollers, and the crushing teeth are arranged around the surfaces of the rollers.

Owner:PETROCHINA CO LTD

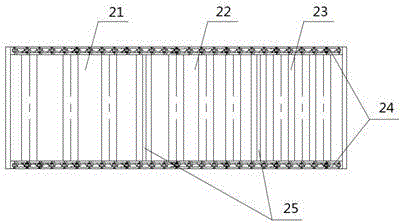

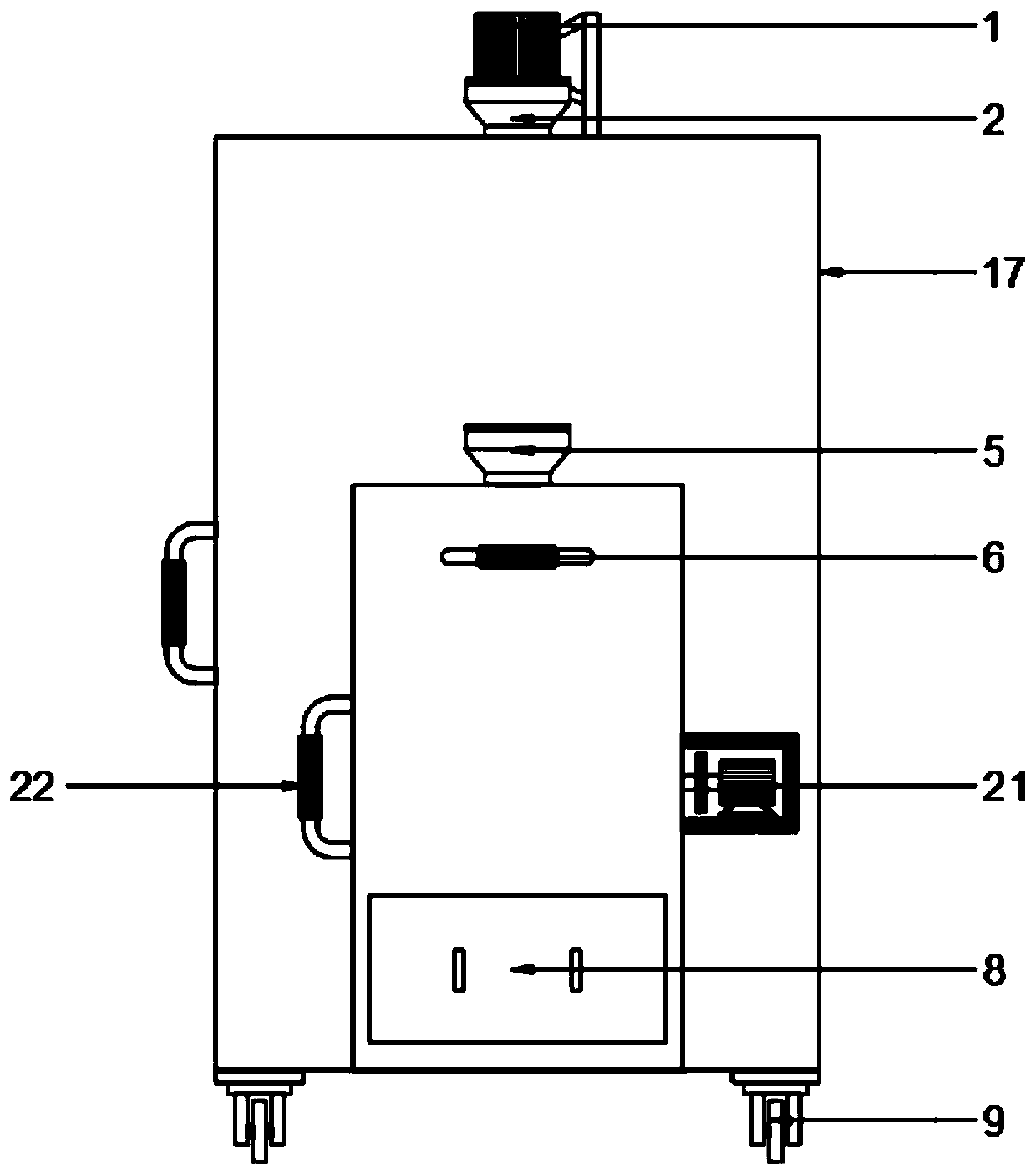

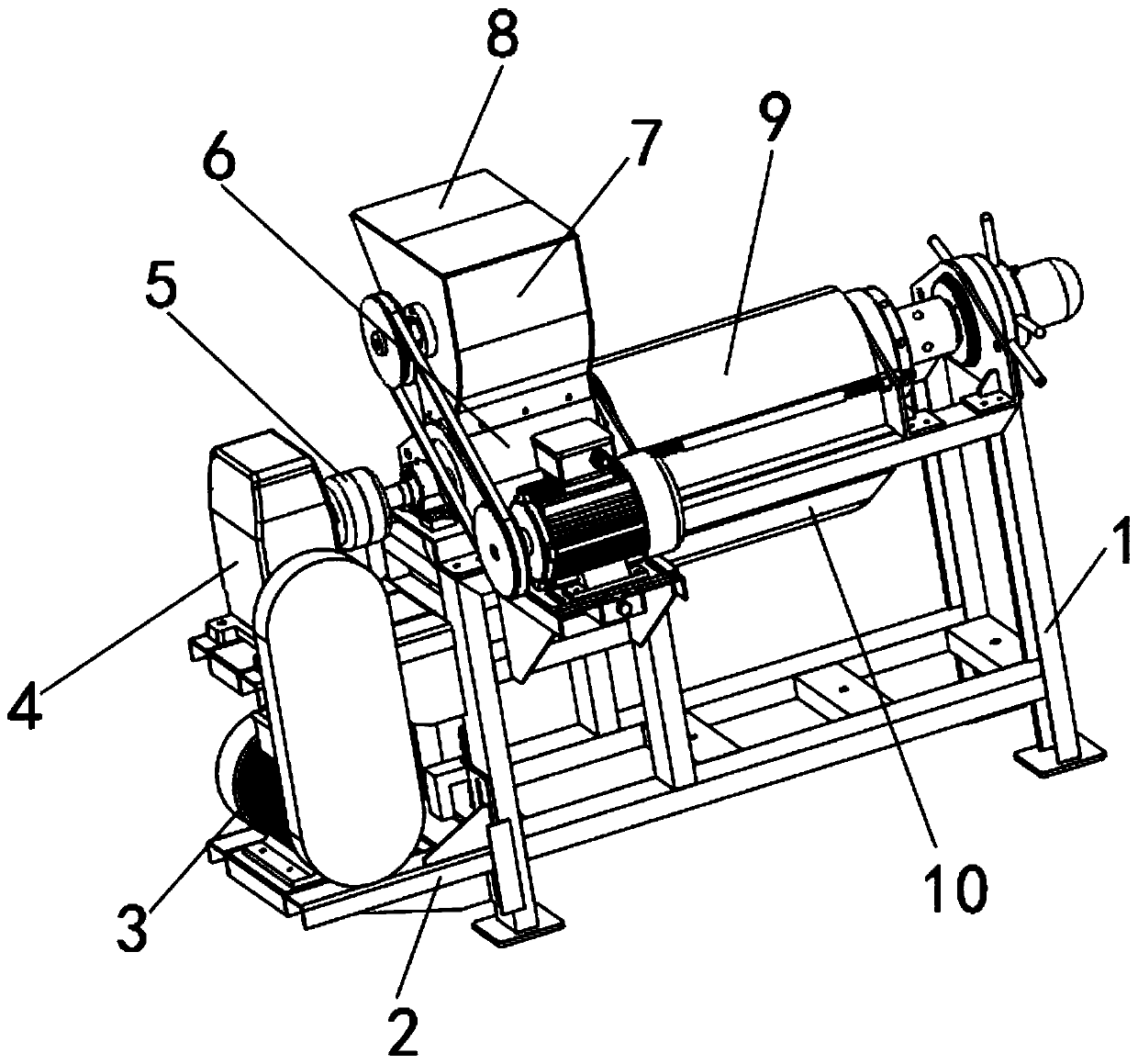

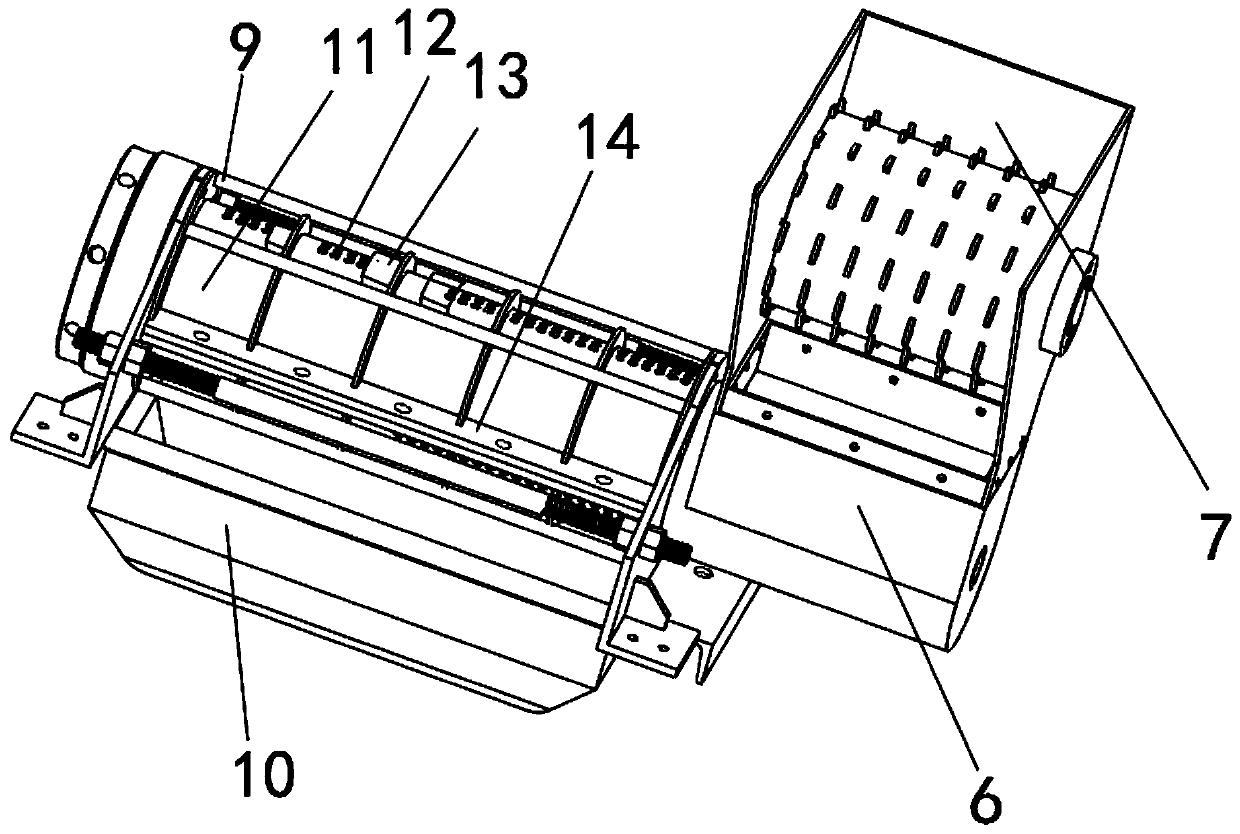

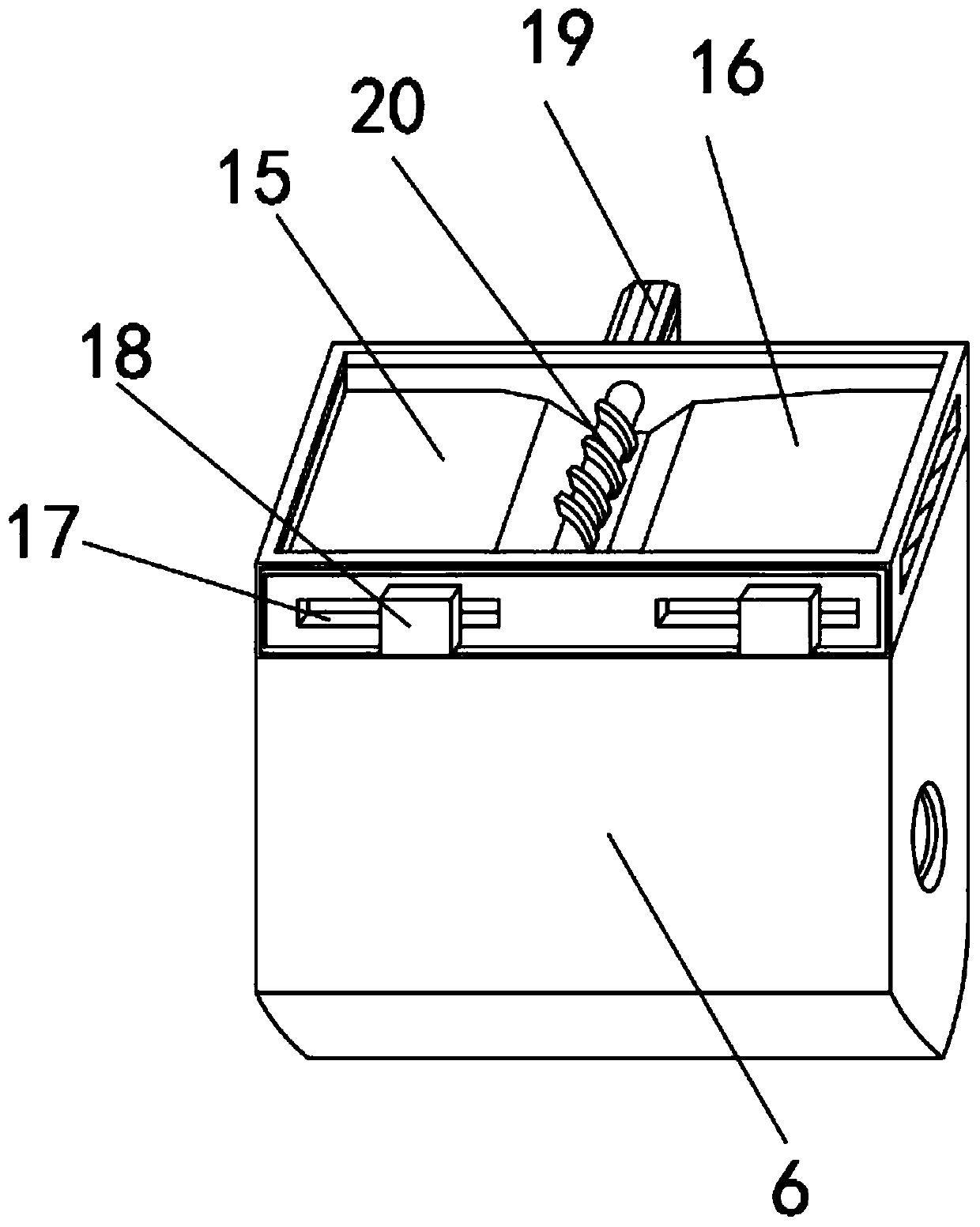

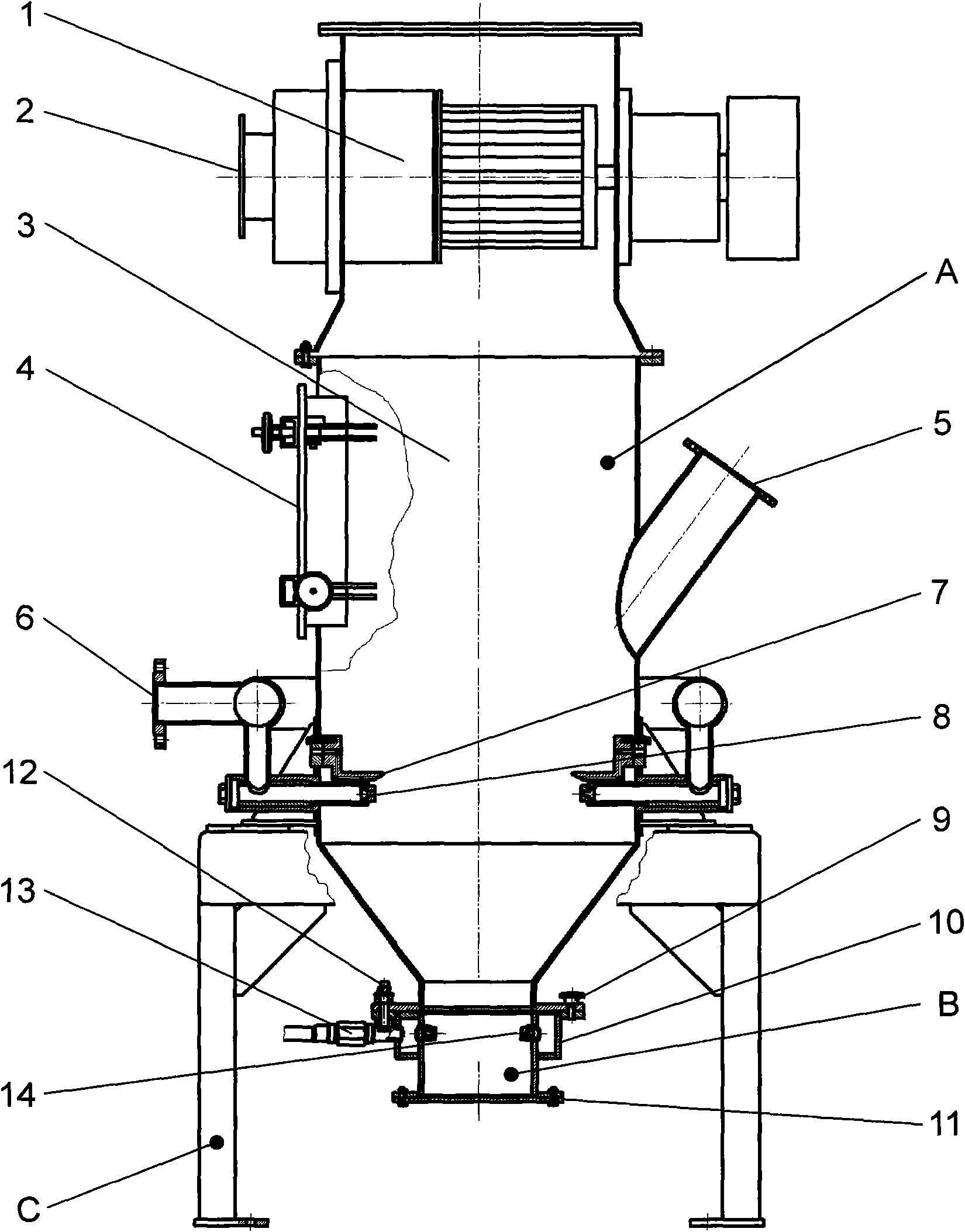

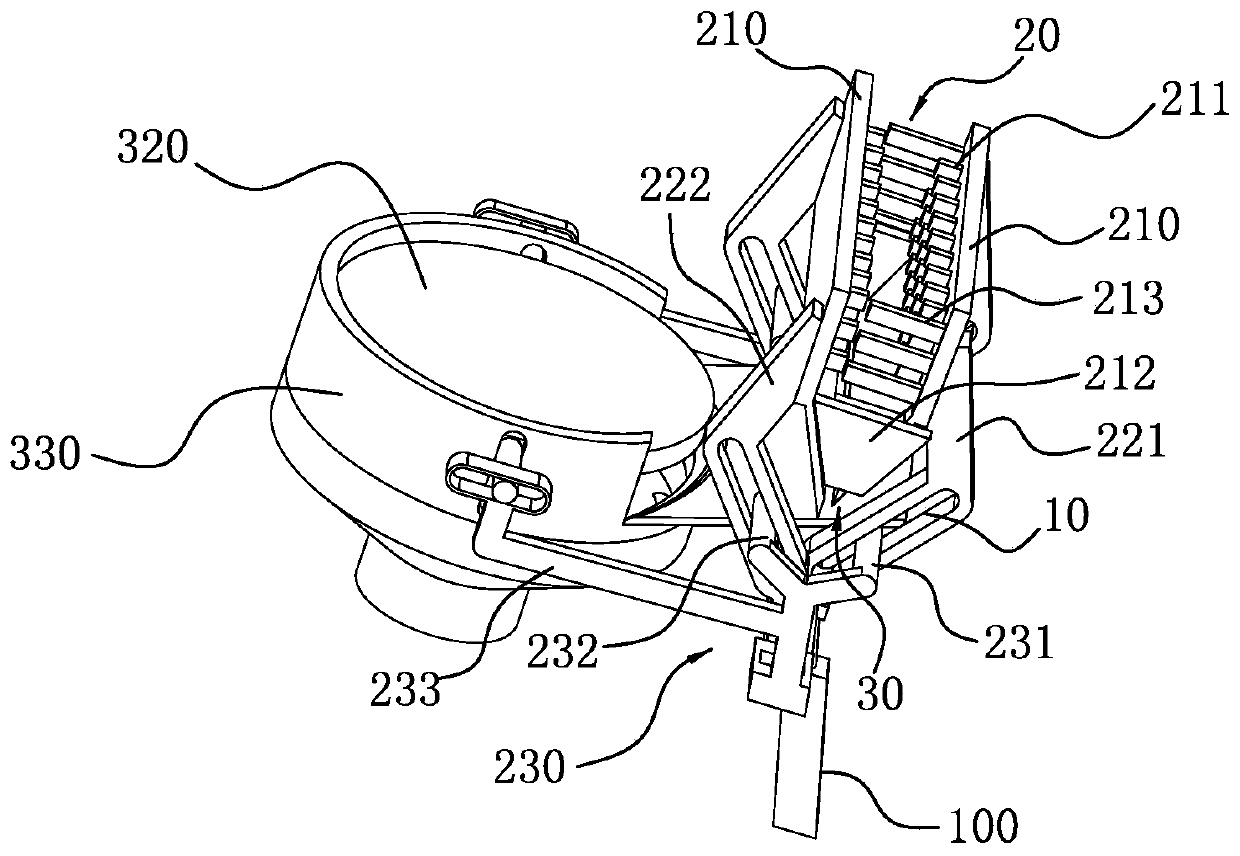

Granulator for producing thermal insulation materials and working method of granulator

InactiveCN110523343AEasy to controlGood blocking effectGranulation in stationary drums/troughsGrain treatmentsThermal insulationEngineering

The invention discloses a granulator for producing thermal insulation materials. The granulator comprises a main frame; a motor support is arranged on the side wall of the main frame; a speed regulating motor is arranged on the top end of the motor support; a speed reducer is arranged at the top end of the main frame and above the speed regulating motor; a bearing seat is connected to one side ofthe speed reducer; one side, close to the bearing seat, of the top end of the main frame is provided with a speed control material box; a feeding box is arranged at the top end of the speed control material box; and a material making cylinder is connected to the side wall of the speed control material box. Through arrangement of a left push plate, a right push plate, a first pull plate and a second pull plate, the feeding speed and the discharging speed of the granulator can be accurately controlled; through arrangement of an adjusting pore plate, the pore size of a discharging hole can be adjusted, so that discharging of particles with different sizes can be facilitated; through arrangement of a crushing roller, primary crushing can be carried out; and through arrangement of fixed crushing blocks and crushing blocks, crushing adjustment can be carried out according to different materials.

Owner:安徽群升建筑工程有限公司

Glass fiber/thermoplastic plastic granules and method for preparing same

The invention relates to glass fiber / thermoplastic plastic granules and a method for preparing the same. The glass fiber / thermoplastic plastic granules comprise glass fibers, thermoplastic plastics and additives and particularly comprise, by weight, 100 parts of the glass fibers, 15-20 parts of the thermoplastic plastics, 20-25 parts of cyclohexanone, 20-25 parts of tetrahydrofuran, 1-5 parts of trithione antimony isooctyl acetate stabilizers, 5-10 parts of epoxy glyceride plasticizers, 1-5 parts of N-hydroxymethyl acrylamide cross-linking agents, 0.1-0.5 part of macrogol ester lubricants and 3-8 parts of tricresyl phosphate flame retardants. The method includes particular steps of melting glass balls; drawing wires; feeding the wires into cotton collecting chambers; uniformly mixing the wires and slurry with one another at outlets to obtain mixtures; feeding the mixtures into curing furnaces along with movement of cotton collecting nets and curing the mixtures at the low temperatures; smashing the mixtures in smashing machines; plasticizing and cutting the mixtures in double-screw extrusion granulators to obtain the glass fiber / thermoplastic plastic granules. The glass fiber / thermoplastic plastic granules and the method have the advantages that the glass fiber / thermoplastic plastic granules prepared by the aid of the method are high in strength, toughness and plasticity, low in cost and easy to process, and technologies for the glass fiber / thermoplastic plastic granules are simple.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

All-in-one machine with straw collecting, crushing and outputting functions

The invention discloses an all-in-one machine with straw collecting, crushing and outputting functions. The machine is characterized by comprising a power input shaft, a pick-up device, a crushing device, a connection device, a transmission device, gear sets, a supporting shaft and a scattering device, wherein the pick-up device is arranged in a rack shell; the supporting shaft in the middle of the pick-up device is connected to the rack shell through a bearing; a spiral conveyor is used as the transmission device, and is mounted behind the pick-up device and connected to the rack shell through a bearing; picked straw is conveyed to a feed port of the crushing device by the spiral conveyor; the crushing device is fixed on the rack shell through a crusher supporting frame; a power output end of a tractor is connected with an input end of the all-in-one machine, and power is transmitted to the pick-up device, the transmission device and the crushing device through the gear sets respectively.

Owner:NANJING AGRICULTURAL UNIVERSITY

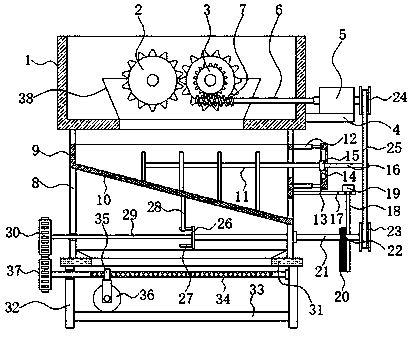

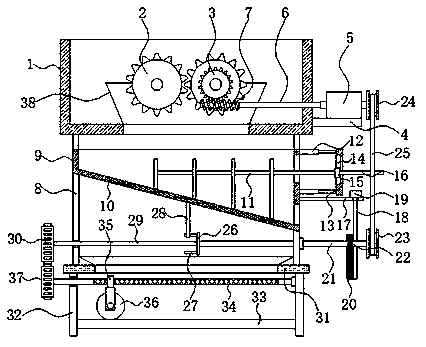

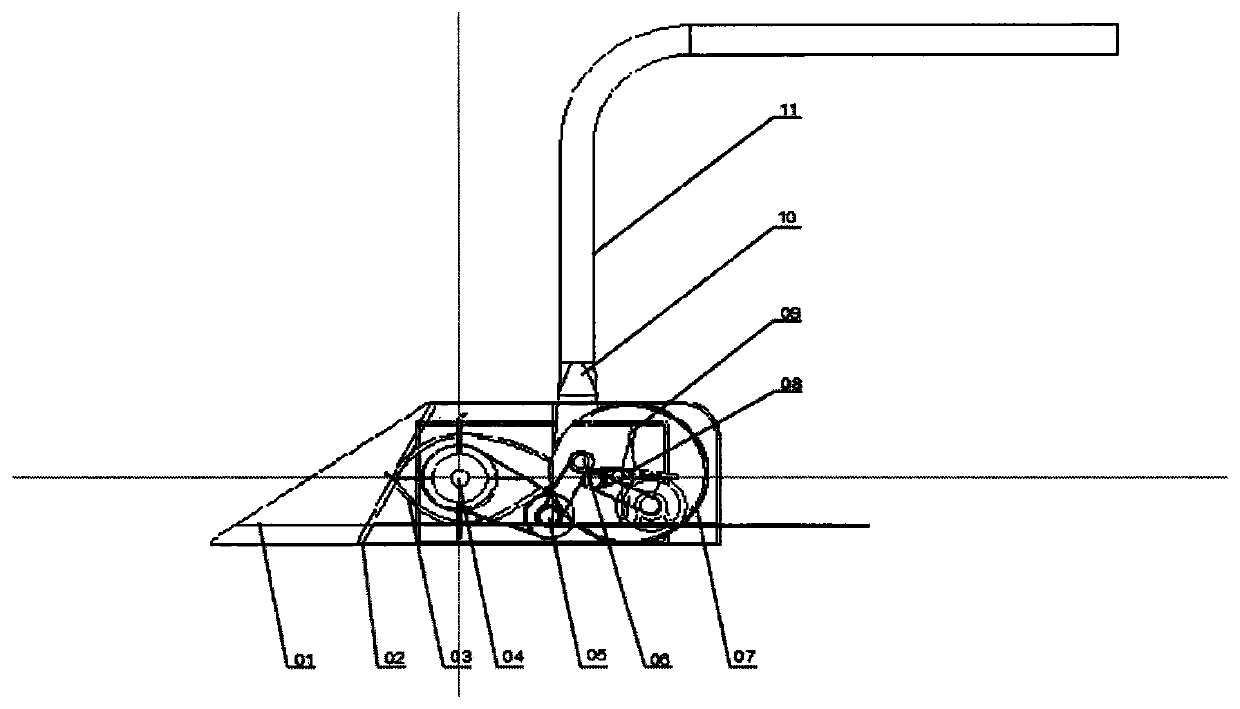

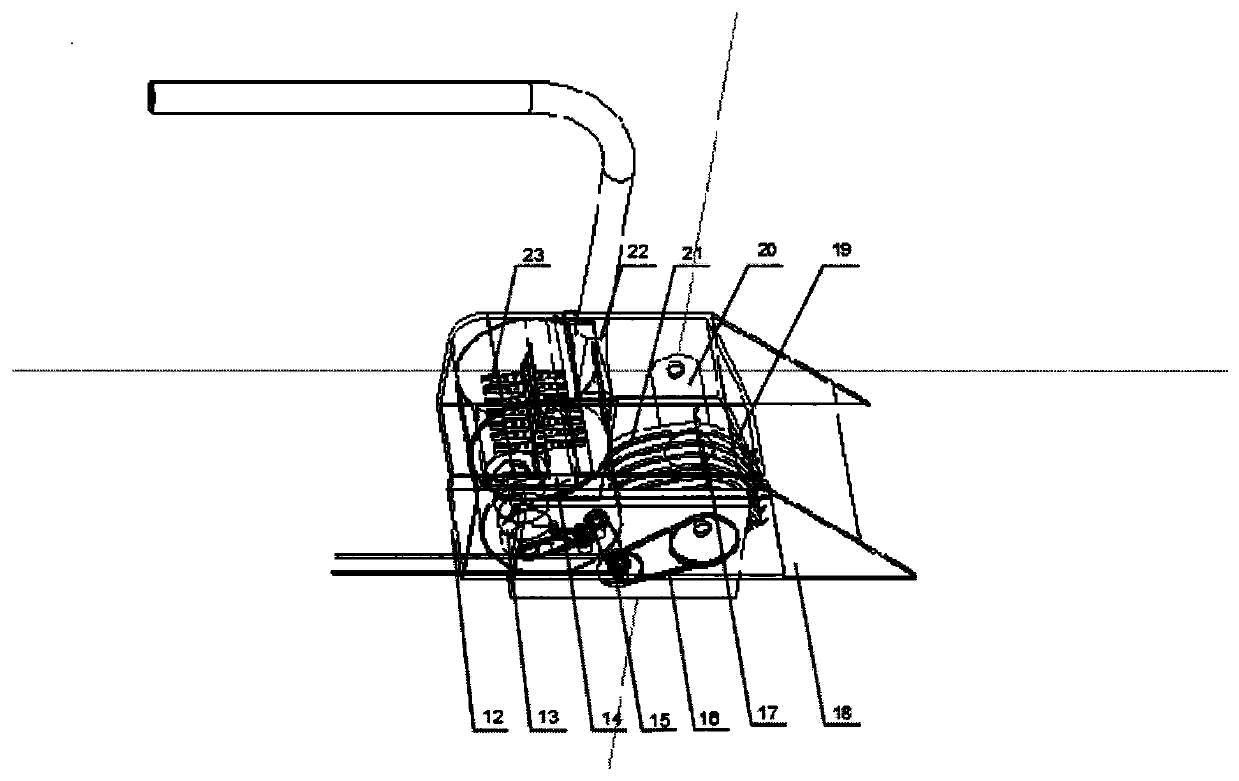

A recovery device for wall plastering materials used in building construction

ActiveCN109057252BExtended service lifeAchieve recyclingBuilding constructionsArchitectural engineeringSlurry

The invention relates to a wall painting material recovery device for building construction. The device comprises a collecting box, a bottom plate, a collecting device and a smashing device, wherein the bottom plate is arranged at the lower end of the front end face of the collecting box, the collecting device is arranged at the upper end face of the bottom plate, the smashing device is arranged in the collecting box, the collecting device comprises a collecting mechanism arranged at the front end of the upper end face of the bottom plate, a transporting mechanism is arranged at the right sideface of the bottom plate, the collecting mechanism comprises a fixing cylinder, and the fixing cylinder is arranged in the middle of the front end of the upper end face of the bottom plate. The wallpainting material recovery device for the building construction has the advantages that the problems are solved that manual recovery wastes time and labor and is low in working efficiency, mechanicalrecovery cannot clean away semi-solid slurry, is not thorough in cleaning, cannot meet smashing requirements, and reduces the service life of a machine due to the fact that remaining slurry rusts themachine; the recovery of wall painting waste slurry can be achieved, the operation is simple, the recovery is thorough, smashing is thorough, the service life of the machine is long, the time and thelabor are saved, and the labor efficiency is high.

Owner:中铁十八局集团北京工程有限公司

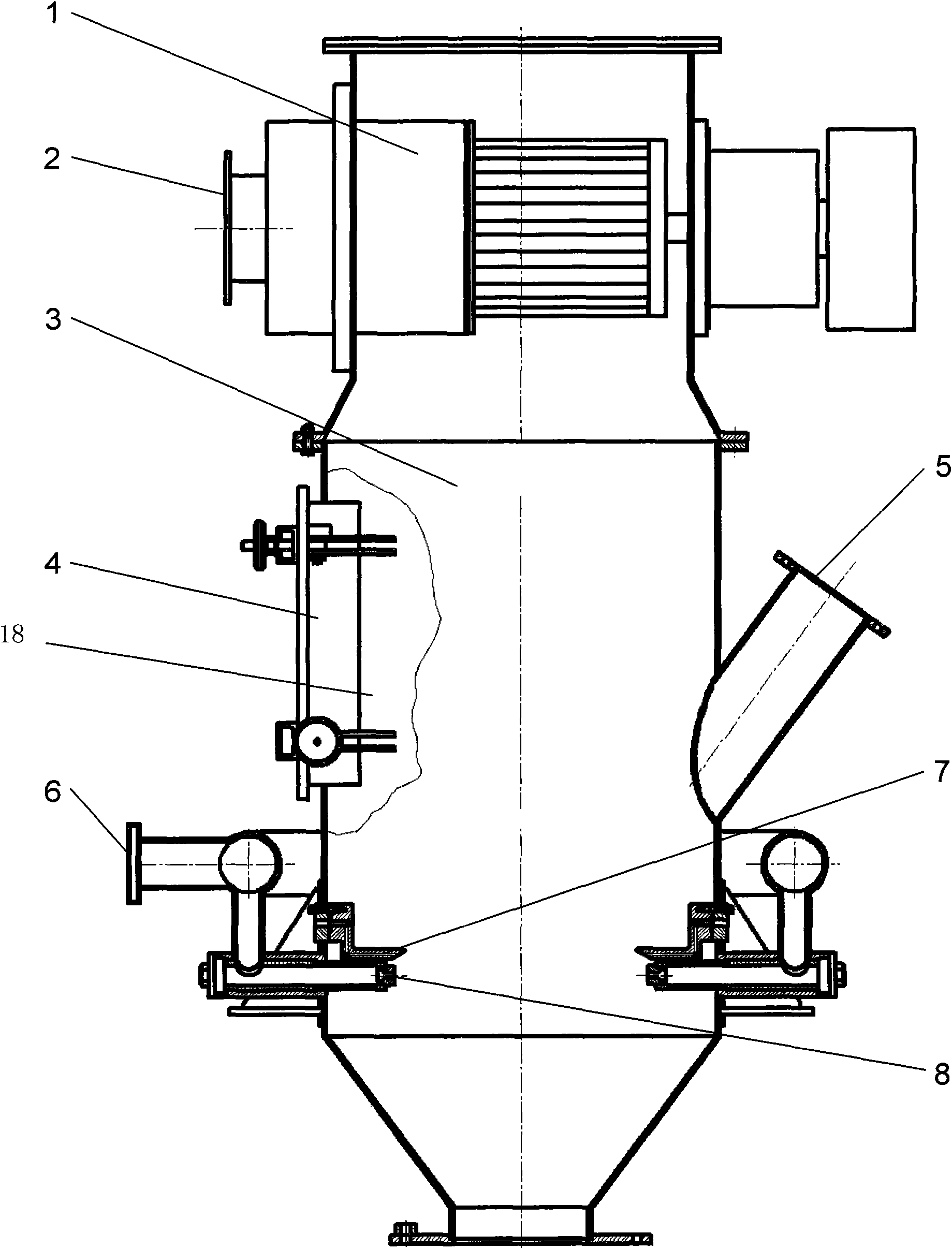

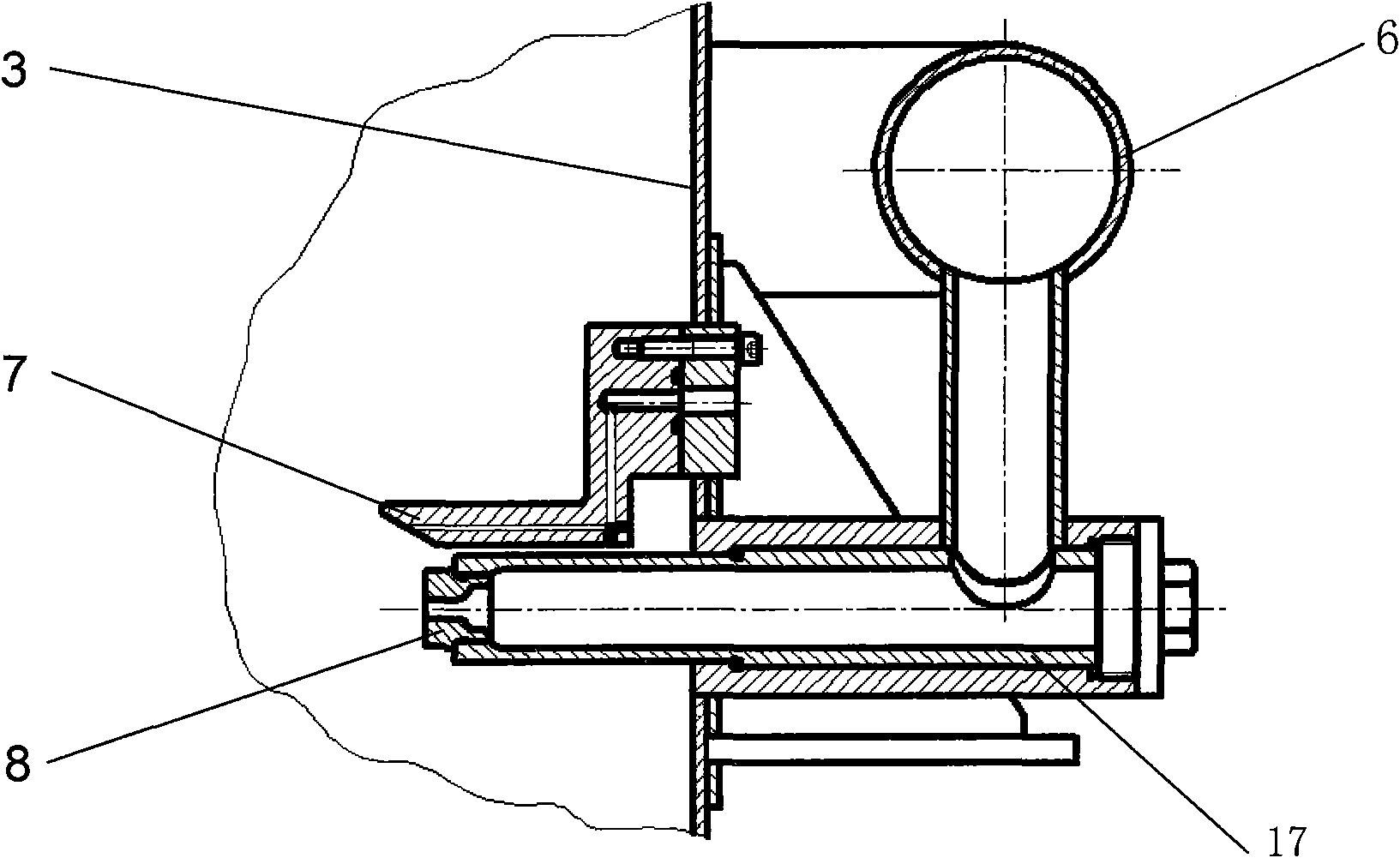

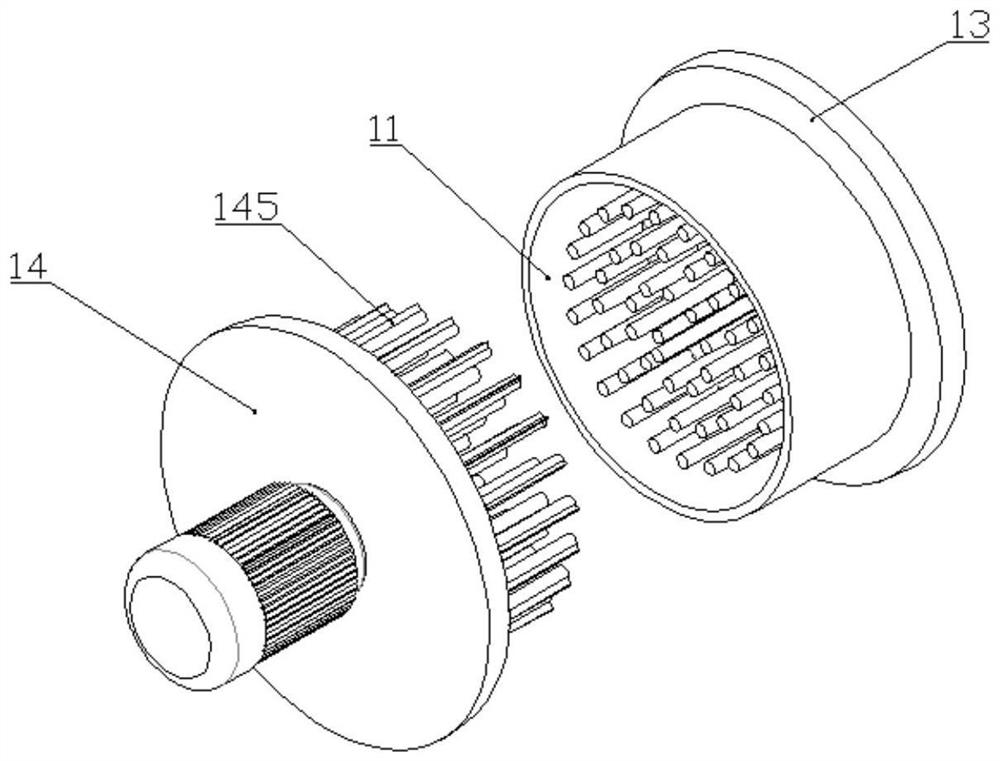

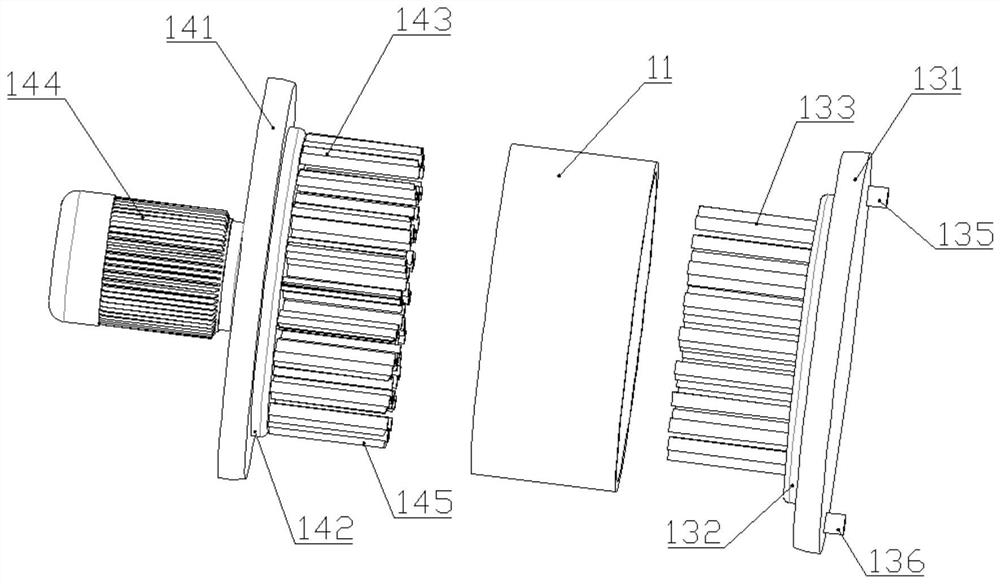

Broad spectrum biomass crushing device

InactiveCN103721803AAdaptableReduce energy consumptionGrain treatmentsEngineeringMechanical engineering

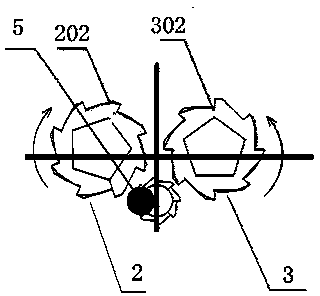

The invention provides a broad spectrum biomass crushing device which is concise and quick, great in handling capacity, strong in material adaptability, low in energy consumption and homogeneous. The broad spectrum biomass crushing device is characterized by comprising a motor, a differential mechanism, a stator part, a first rotor part and a second rotor part, wherein the first rotor part comprises a first rotor shaft and a plurality of first rotor blades; the second rotor part comprises a second rotor shaft and a plurality of second rotor blades; the first and second rotor shafts are arranged parallely up and down; the stator part comprises a plurality of stator blades, and the center of the stator part is located right below the centers of the first and second rotor parts and between the first and second rotor parts; a motor output shaft is connected with the input end of the first rotor shaft, and the output ends of the first and second rotor shafts are connected with the differential mechanism.

Owner:山东百川同创能源有限公司

Fixed-gap tooth-free roller-couple grinder

The invention discloses a fixed-gap tooth-free roller-couple grinder. The fixed-gap tooth-free roller-couple grinder comprises a rack. A crushing mechanism is fixed to the rack. The top of the crushing mechanism communicates with a feeding hopper, and the bottom of the crushing mechanism communicates with a discharging hopper. The crushing mechanism comprises a roller couple including a first grinding roller and a second grinding roller which are arranged in parallel, and the part between the first grinding roller and the second grinding roller crushes materials. The end of the first grinding roller and the end of the second grinding roller are placed between a bearing upper groove guide rail and a bearing lower groove guide rail through bearing blocks. An elastic element is arranged between the bearing block at the end of the first grinding roller and the bearing block at the end of the second grinding roller. A distance adjusting and positioning device is arranged on the outer side of the bearing block of the first grinding roller or the outer side of the bearing block of the second grinding roller and adjusts and fixes a gap between the first grinding roller and the second grinding roller. In the crushing process, the gap between the first grinding roller and the second grinding roller is kept unchangeable. According to the grinder, the fixed-gap crushing work of the materials can be achieved, tooth-free transmission can be achieved, and the grinder is suitable for the crushing work of dry type materials.

Owner:SHANDONG ACADEMY OF AGRI MACHINERY SCI

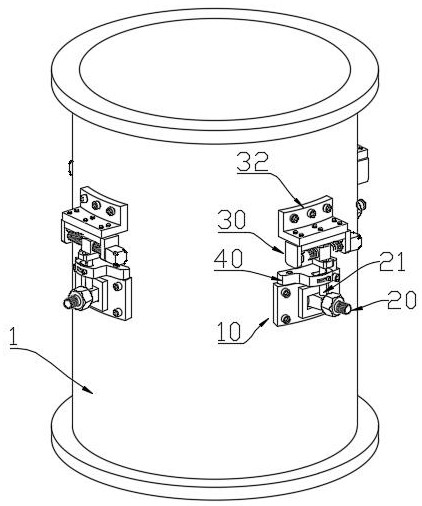

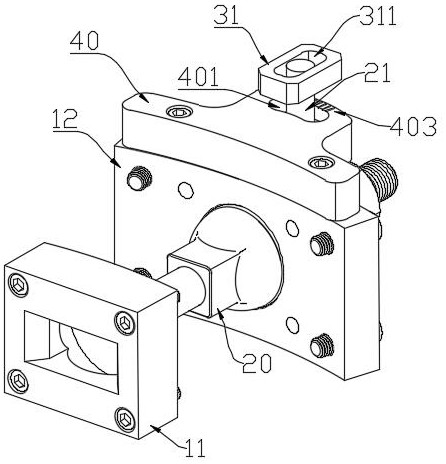

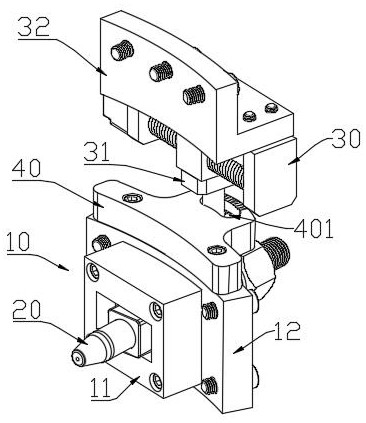

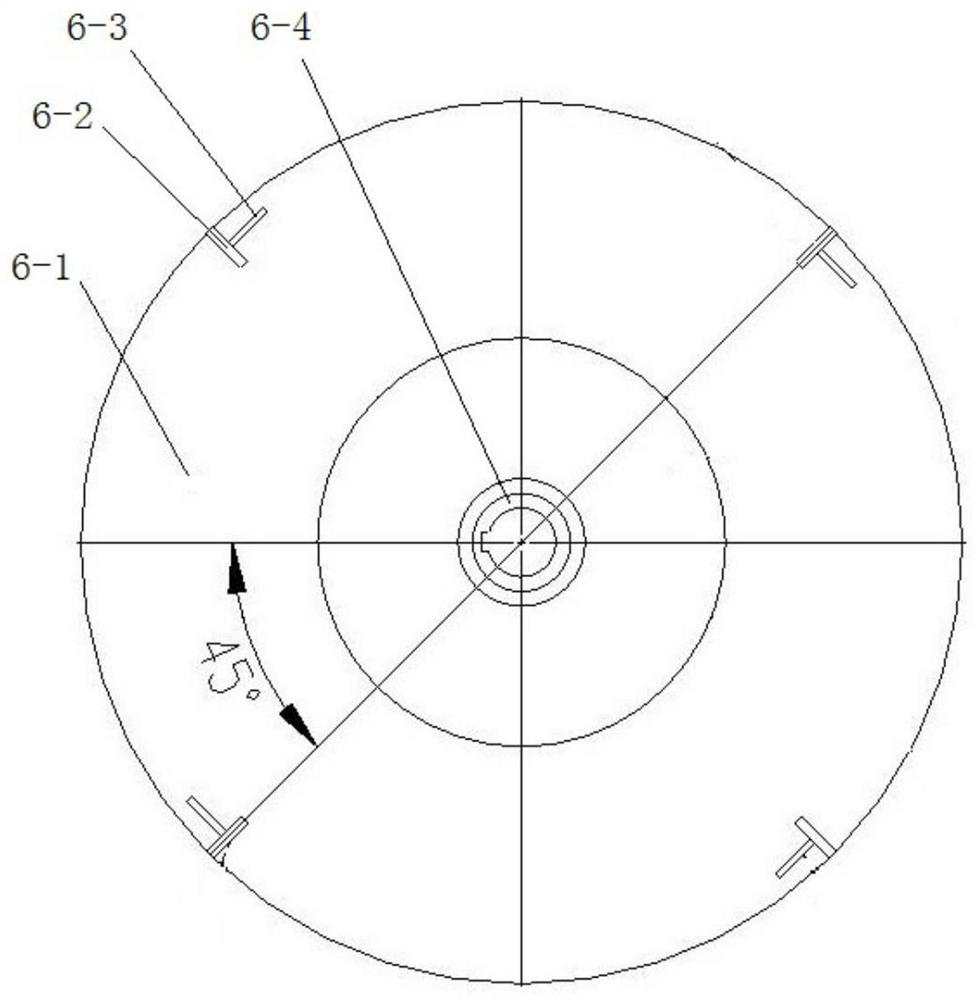

Automatic nozzle adjusting mechanism applied to fluidized bed type pulverizer

PendingCN114308324AImprove efficiencyMeet crushing requirementsGrain treatmentsFluidized bedStructural engineering

The invention discloses an automatic nozzle adjusting mechanism applied to a fluidized bed type pulverizer, comprising: a plurality of mounting seats for rotatably fixing nozzles, the mounting seats being mounted on the side wall of a fluidized bed; the driving mechanism is used for controlling the nozzle to rotate, and the driving mechanism is fixed on the side wall of the fluidized bed. According to the invention, the angle of the nozzle of the fluidized bed can be adjusted, so that the crushing requirements of particles with different sizes can be met without replacing different fluidized beds, the use efficiency of the fluidized bed and the adaptability to different materials are greatly improved, and the requirements of customers are greatly met.

Owner:熊斌

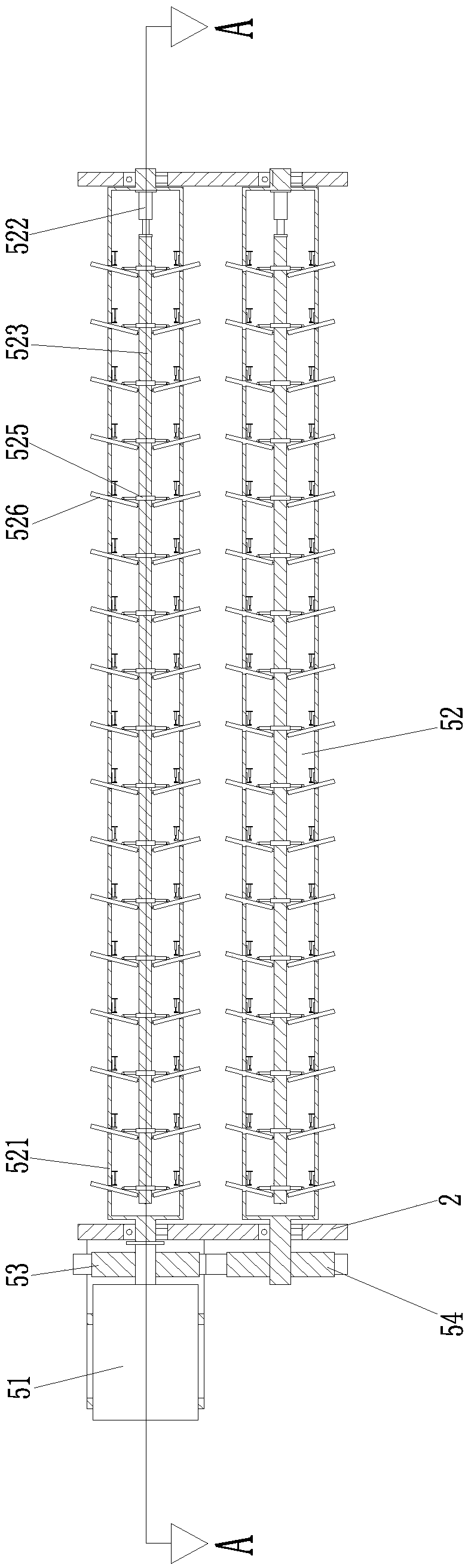

Wet material smashing device

PendingCN113426547AEvenly crushedSolve the technical problems of long crushing operation time and low crushing efficiencyCocoaGrain treatmentsProcess engineeringIndustrial engineering

The invention provides a wet material smashing device and belongs to the technical field of wet material smashing. The wet material smashing device comprises smashing mechanisms, a feeding assembly, a step tooth structure, a discharging assembly and a driving mechanism, the driving mechanism rotates in the multiple sets of smashing mechanisms and is matched with the multiple smashing assemblies to conduct extrusion, and wet materials can be smashed through extrusion of the smashing mechanisms and the driving mechanism; and the multiple sets of smashing mechanisms are stacked up and down, the smashing granularity of the wet materials by the multiple smashing assemblies is gradually reduced from top to bottom, the materials are fed into the smashing mechanisms through the feeding assembly, the materials are discharged from the smashing mechanism at the bottom end through the discharging assembly, the wet materials are sequentially and gradually smashed from top to bottom in the multiple sets of smashing mechanisms, and finally the smashing effect is achieved. The wet material smashing device has the advantages that the wet material smashing operation time is short, the wet materials are uniformly smashed in the smashing mechanisms, the smashing requirement can be met, the smashing efficiency is high, and the operation progress of the smashing procedure is met.

Owner:河北赞弘机械设备有限公司

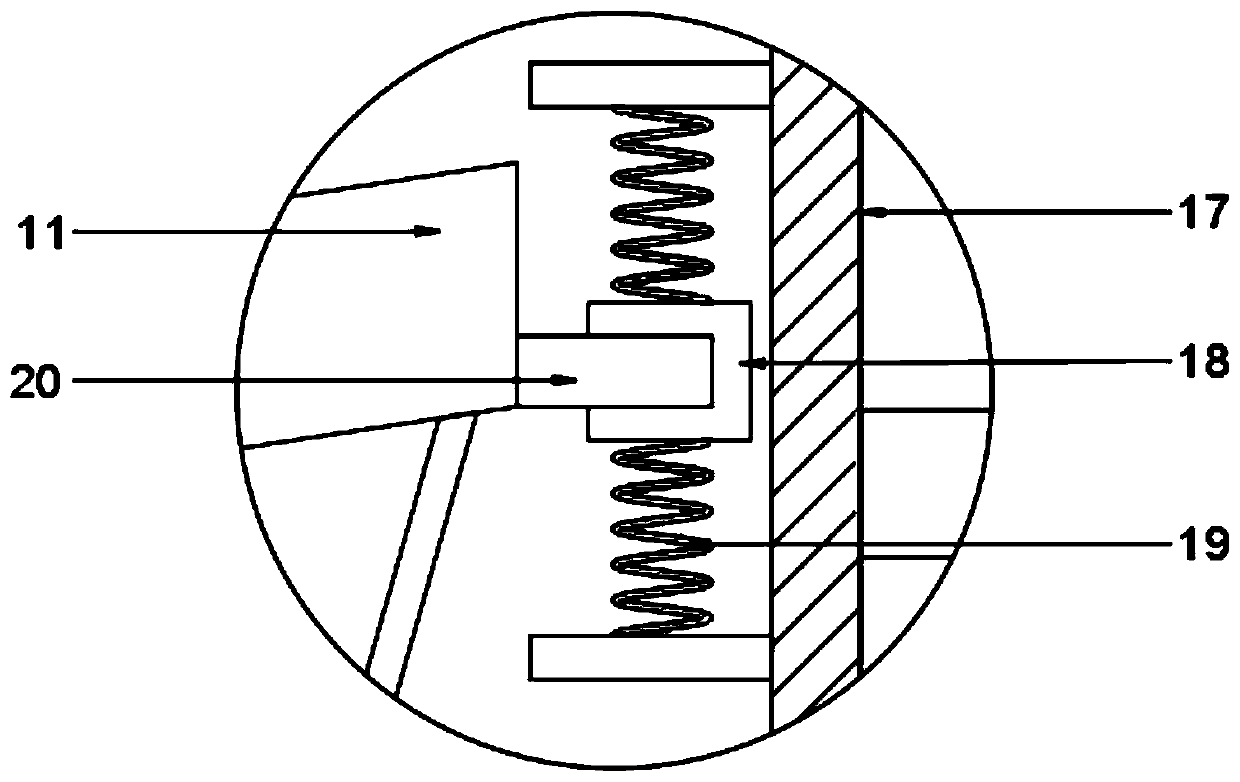

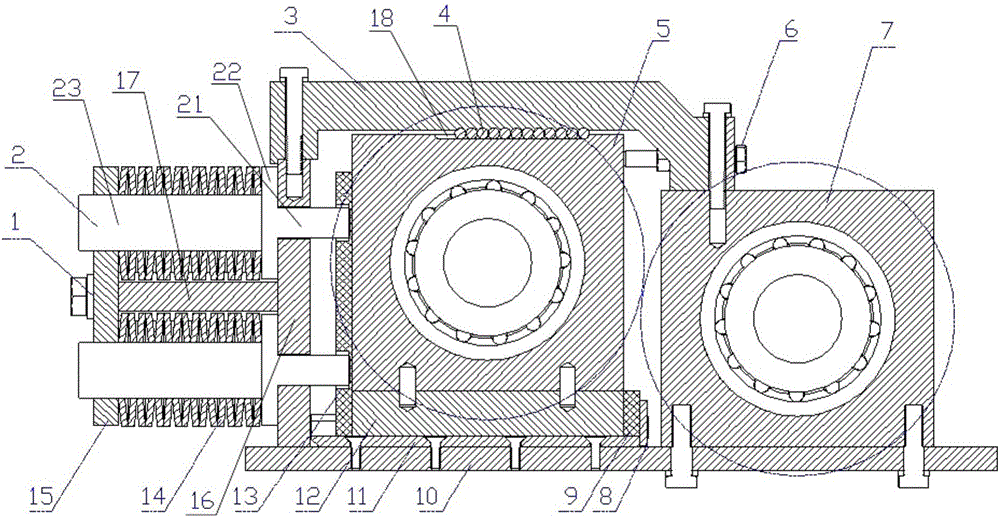

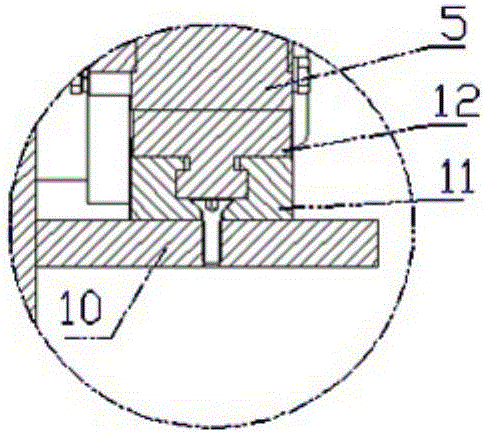

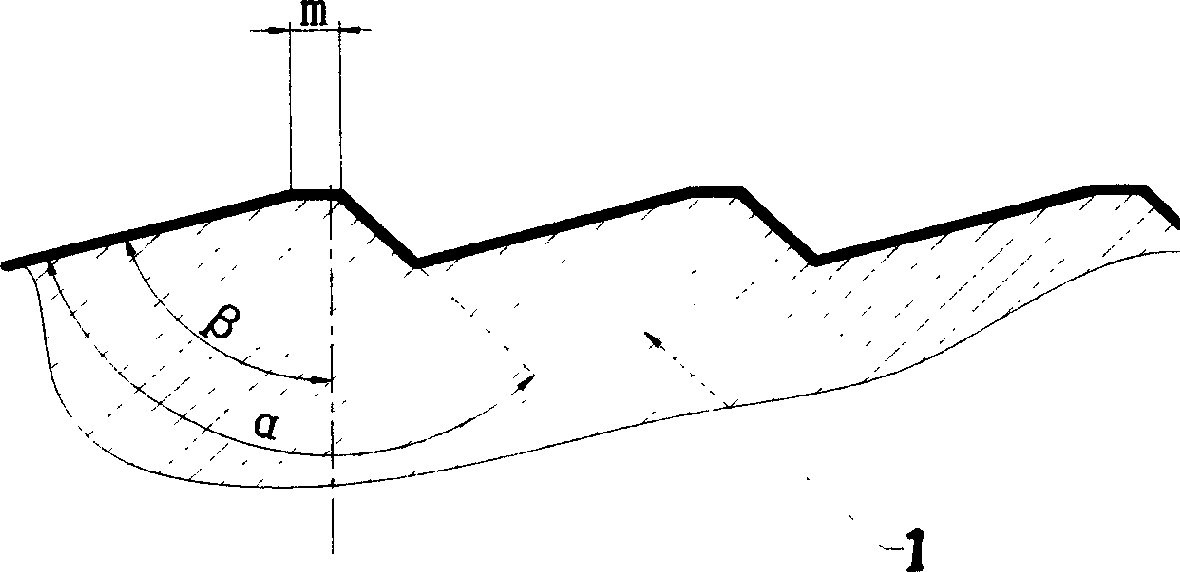

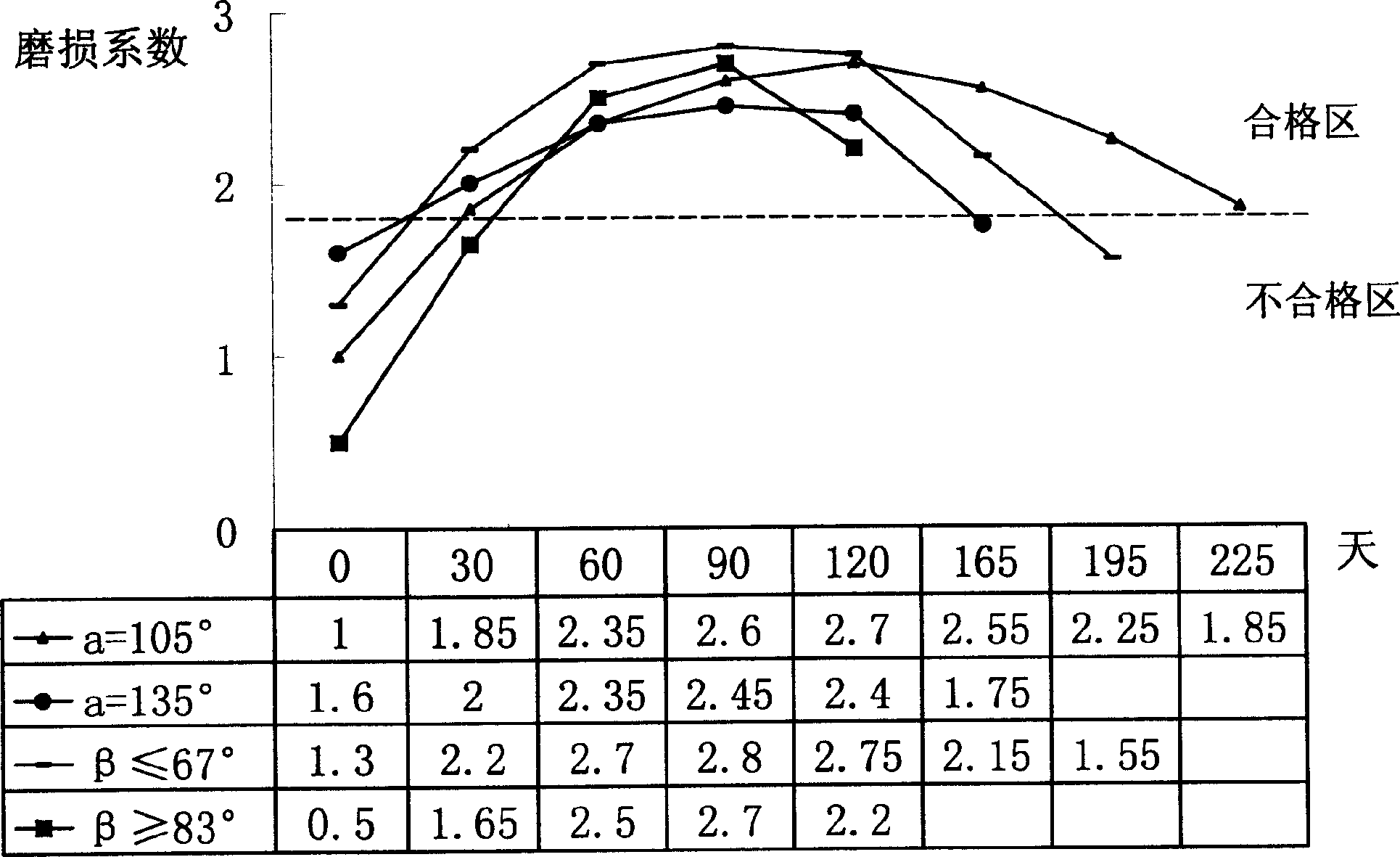

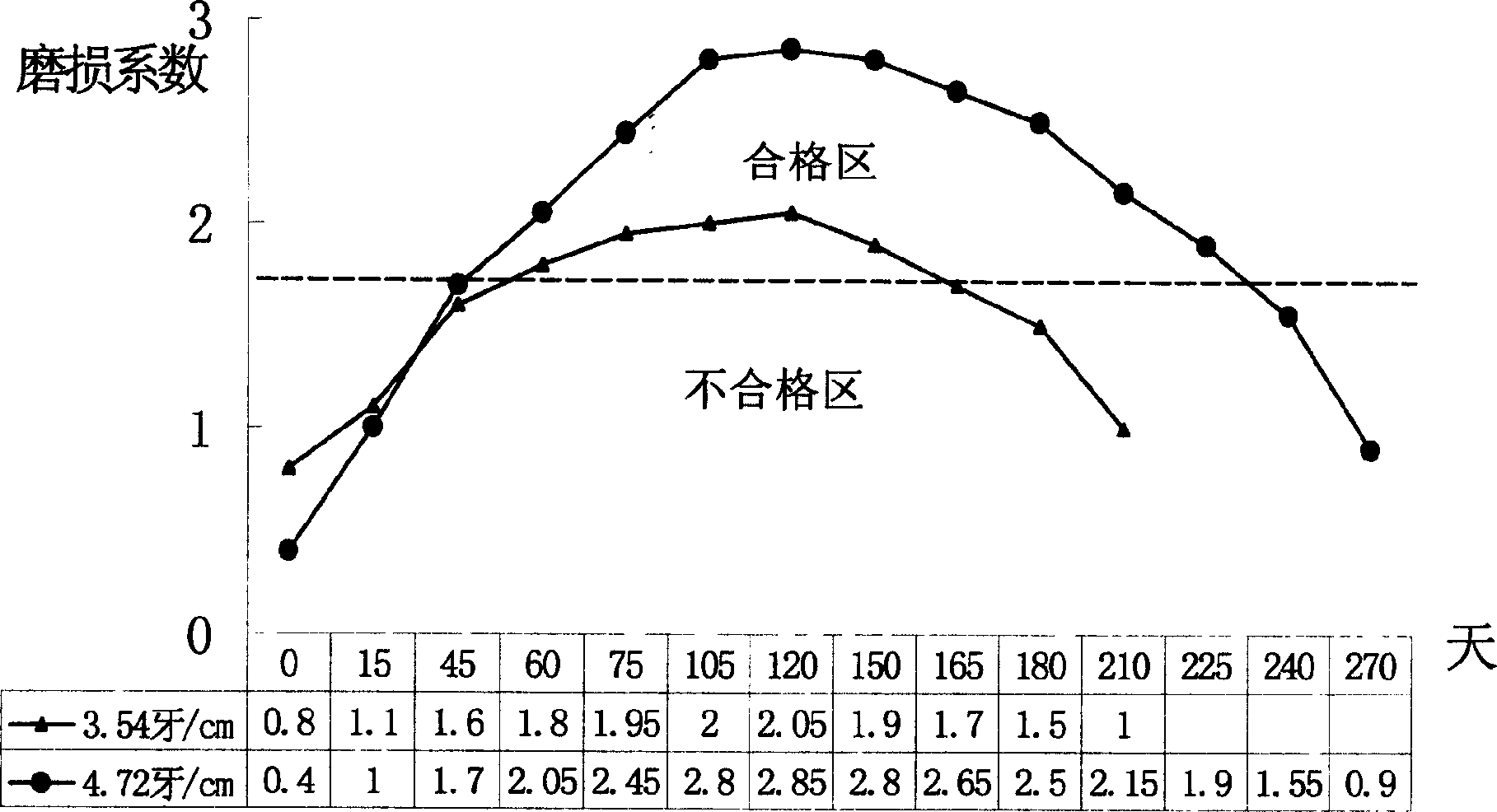

Rapidly returning device for roll crusher

ActiveCN106423386AImprove speed and stabilityMeet crushing requirementsGrain treatmentsEngineeringCrusher

The invention relates to a rapidly returning device for a roll crusher. The rapidly returning device comprises a base, a fixed bearing block and a slidable bearing block are parallelly arranged on the base, a frame type sliding seat is arranged on the outer side of the slidable bearing block and comprises a connecting arm, a vertical support plate and a T-shaped sliding way, one end of the connecting arm is fixedly connected with the top end of the vertical support plate, the other end of the connecting arm is fixedly connected with the top end of the fixed bearing block, the T-shaped sliding way is fixed on the base, the bottom of the slidable bearing block is connected with the T-shaped sliding way through a T-shaped sliding rail, the top of the slidable bearing block is connected with the connecting arm through a roll ball, and an elastic restoring mechanism is arranged on the vertical support plate. The rapidly returning device is simple in structure and convenient to assemble and can automatically and rapidly return and rapidly reset when meeting hard substances, gaps between tooth rollers can be rapidly and reliably adjusted, and continuous and stable operation of the roll crusher is ensured.

Owner:ZOOMLION HEAVY MASCH CO LTD

Airflow mill of multifunctional fluidized bed

InactiveCN101648154AAchieve ultra-fine crushingMeet crushing requirementsChemical/physical/physico-chemical nozzle-type rreactorsGrain treatmentsFluidized bedSpray nozzle

The invention relates to an airflow mill of a fluidized bed, in particular to an airflow mill of a multifunctional fluidized bed, which comprises a pulverizing modification part of a large amount of materials and a machine base, wherein the pulverizing modification part of a large amount of materials is fixedly connected with the machine base by a bolt; the airflow mill of the fluidized bed is characterized in that the lower end of the pulverizing modification part of a large amount of materials is connected with the upper end of a pulverizing auxiliary modification part of a little materialsby a flange, and a small pulverizing cavity in the pulverizing auxiliary modification part of a small amount of materials is communicated with a big pulverizing cavity in a cylinder body of a fluidized bed of the pulverizing modification part of a large amount of materials; and a plurality of groups of modifier injection atomizing nozzles are fixedly connected to the inner wall of the lower part of the cylinder body of the fluidized bed, the number of the modifier injection atomizing nozzles corresponds to that of a plurality of groups of opposite flushing type pulverizing spray nozzles, the modifier injection atomizing nozzles are positioned at an adjacent position at the upper part corresponding to the opposite flushing type pulverizing spray nozzles, and an input joint of the modifier injection atomizing nozzles is positioned outside the cylinder body of the fluidized bed. The airflow mill of the fluidized bed both has a function of superfine pulverizing to a small amount of materials and a function of modified pulverizing to the surface of a powder body.

Owner:WUHAN UNIV OF TECH

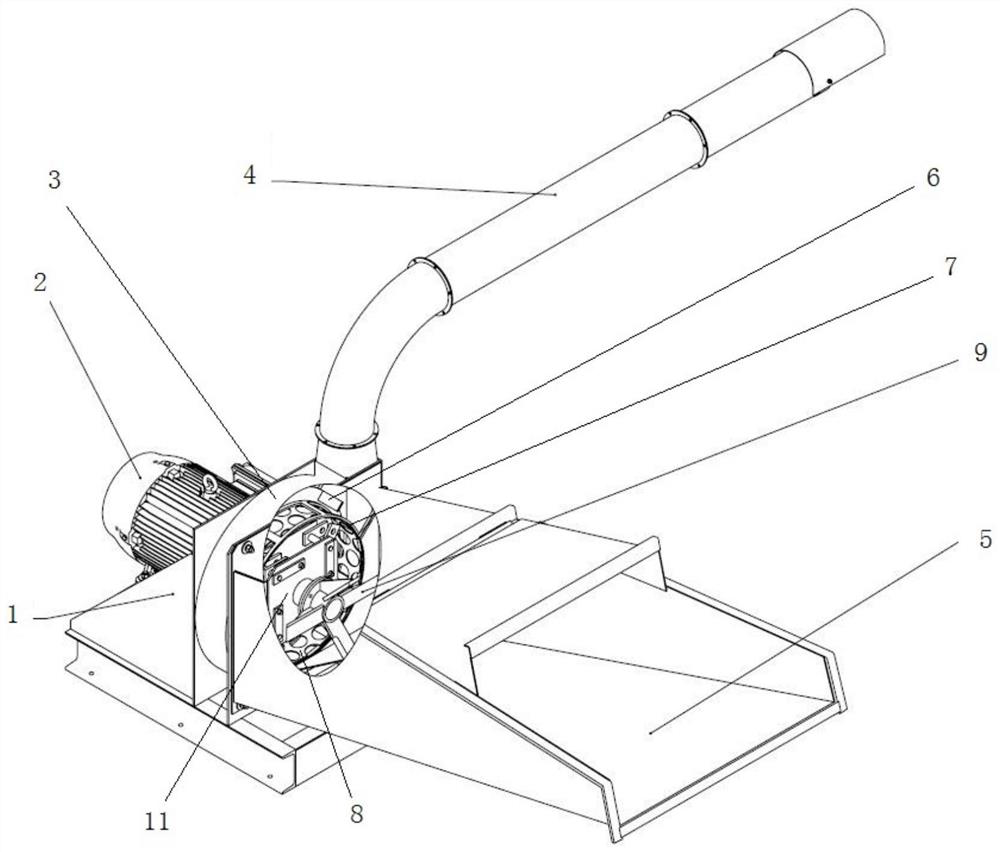

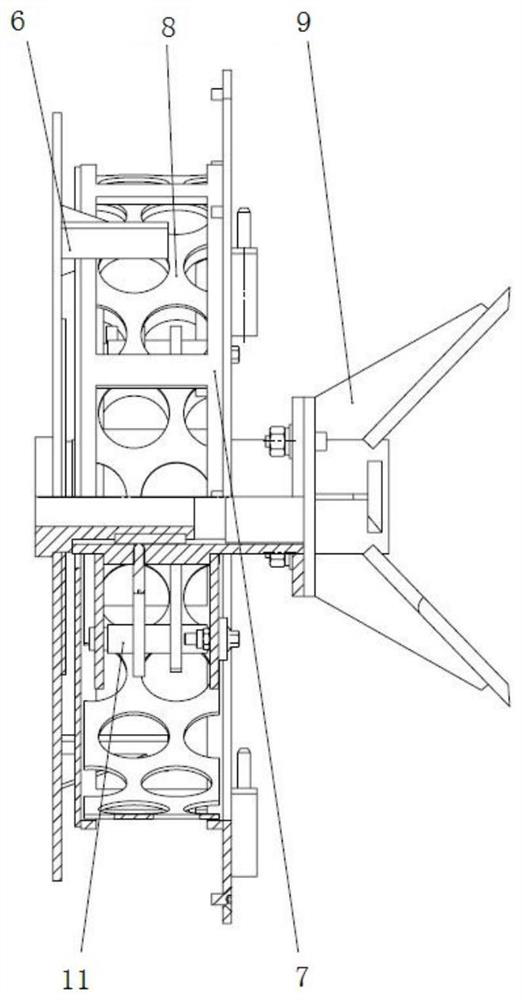

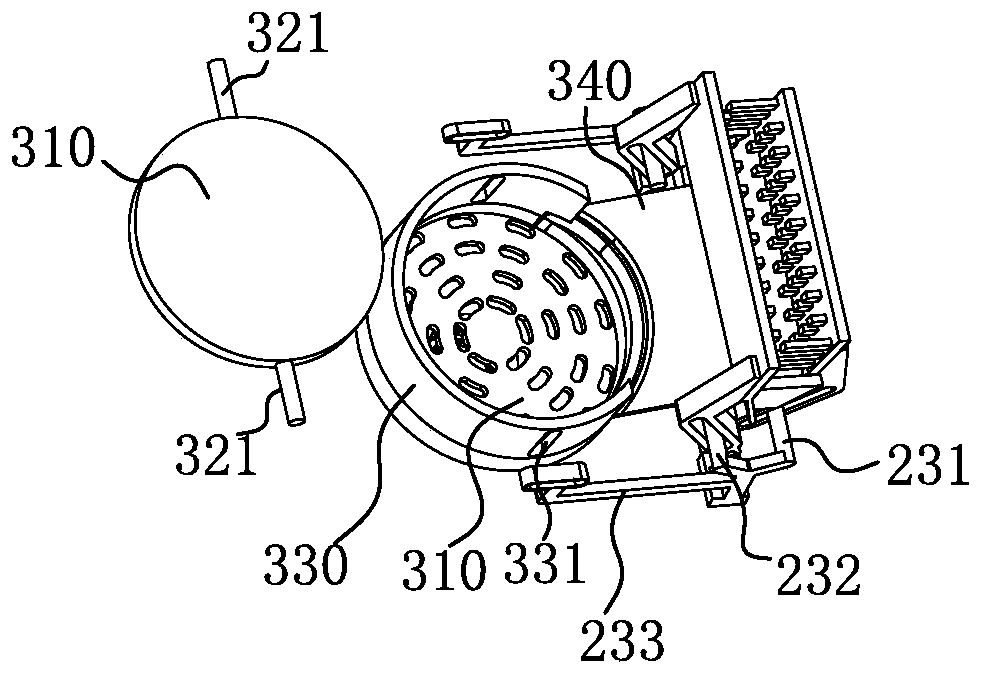

Square bundle straw crusher capable of achieving blending cutting and beating secondary crushing

PendingCN112335423AImprove crushing efficiencyImprove processing qualityCuttersGrain treatmentsAgricultural engineeringElectric machinery

The invention discloses a square bundle straw crusher capable of achieving blending cutting and beating secondary crushing. The crusher comprises a base, a motor and a shell are mounted on the base, the shell is connected with a discharge pipe and a feed port, a crushing mechanism is mounted in the shell, and the square bundle straw crusher is characterized in that the crushing mechanism is directly connected and driven by the motor, and an impeller, a hammering cutting mechanism and a blending cutting mechanism are mounted on an extension shaft of the motor. A crushing chamber is further installed outside the hammering cutting mechanism in the machine shell, and a screen is additionally installed in the crushing chamber. The straw crusher belongs to the type of processing coarse and hardstraw, is suitable for coarse and hard dry straw, and can meet the requirement of crushing coarse and hard dry and wet square baled straw. The crusher has important practical significance and good development prospect for improving the mechanization level of straw resource utilization in China and promoting the development of the cattle and sheep industry.

Owner:INST OF AGRI MECHANIZATION XINJIANG AGRI INST

Efficient crushing device for quartz sand

PendingCN110124781AImprove grinding effectImprove grinding efficiencyNon-rotating vibration suppressionGrain treatmentsArchitectural engineeringDrive motor

The invention discloses an efficient crushing device for quartz sand. The efficient crushing device comprises a box. A feeding opening and discharging openings are formed in the top and the bottom ofthe box correspondingly. A movable cone and a fixed cone cooperating with the movable cone are further arranged in the box. The top of the fixed cone is hinged to the inner top wall of the box. The bottom of the fixed cone is connected with telescopic rods, and the other end of each telescopic rod is connected with an output shaft of a telescopic air cylinder fixed to the inner wall of the box. Adrive motor is fixed to the bottom wall of the box. A main shaft is connected to an output shaft of the drive motor. A spherical tile is arranged at the top of the main shaft. A spherical supporting portion is upwards arranged in the middle of the bottom of the movable cone. The movable cone is mounted on the spherical tile at the top of the main shaft through the supporting portion. The crushingdevice has the advantages of being good in crushing effect and high in crushing efficiency, the crushing clearance can be adjusted, and therefore the crushing requirements of different quartz sand rawmaterials are met.

Owner:新沂市引河石英材料有限公司

Vertical Straw Crusher

The invention discloses a vertical straw pulverizer. The pulverizer comprises a box and a drum; a working board is arranged above the box, and the box is internally provided with a first group of hammer pieces and a second group of hammer pieces which are in series connection in an up-down mode; a feeding port is formed in the working board, and grids are installed above the feeding port; the working board is fixedly provided with multiple transverse rolling wheels and multiple longitudinal rolling wheels; the drum is externally provided with a drum flange and internally provided with sawtoothed bundle breaking knives; the lower end surface of the drum flange is matched with the longitudinal rolling wheels in a contact mode, and therefore the longitudinal rolling wheels can support the drum flange; the transverse rolling wheels are matched with the drum flange in an edge contact mode. The vertical straw pulverizer has the advantages that the structure is reliable, and light impuritiesand materials after crushing can be directly separated; a bale breaking function is achieved, bundles of straw or large bales of straw can be directly crushed, the processing amount is large, and theefficiency is high.

Owner:黑龙江鹏业农业发展股份有限公司

Plastic pulverizer

InactiveCN111055402AEasy to separateEasy maintenancePlastic recyclingGrain treatmentsEngineeringMachine

The invention relates to the technical field of crushing machinery, and particularly relates to a plastic pulverizer which comprises a crusher. The crusher is provided with an upper machine body and alower machine body. The top end of a first bearing table is fixedly connected with a first bearing fixing piece. The top end of a second bearing table is fixedly connected with a second bearing fixing piece. Bearings are fixedly arranged on the first bearing fixing piece and the second bearing fixing piece. A feeding opening is formed in the upper left side of the upper machine body. A discharging opening is formed in the bottom end of the lower machine body. A crushing cutter is fixedly arranged on a crushing cutter mounting plate. A screen is fixedly arranged on the lower machine body and located on the lower side of the crushing cutter. An impact baffle is arranged on the inner wall of the upper side of the upper machine body. Plastic can be effectively prevented from jumping out of the feeding opening in a smashing process. The plastic which is not smashed thoroughly can be left in a smashing cavity through the filter screen and continues to be smashed by the crushing cutter. Thesmashing efficiency of the crusher can be improved, and the smashed plastic can meet the smashing requirement.

Owner:浙江华威设备制造有限公司

A kind of glass fiber/thermoplastic particle and preparation method thereof

ActiveCN105778212BImprove mechanical propertiesGood physical and mechanical propertiesThermoplasticCross-link

The invention relates to glass fiber / thermoplastic plastic granules and a method for preparing the same. The glass fiber / thermoplastic plastic granules comprise glass fibers, thermoplastic plastics and additives and particularly comprise, by weight, 100 parts of the glass fibers, 15-20 parts of the thermoplastic plastics, 20-25 parts of cyclohexanone, 20-25 parts of tetrahydrofuran, 1-5 parts of trithione antimony isooctyl acetate stabilizers, 5-10 parts of epoxy glyceride plasticizers, 1-5 parts of N-hydroxymethyl acrylamide cross-linking agents, 0.1-0.5 part of macrogol ester lubricants and 3-8 parts of tricresyl phosphate flame retardants. The method includes particular steps of melting glass balls; drawing wires; feeding the wires into cotton collecting chambers; uniformly mixing the wires and slurry with one another at outlets to obtain mixtures; feeding the mixtures into curing furnaces along with movement of cotton collecting nets and curing the mixtures at the low temperatures; smashing the mixtures in smashing machines; plasticizing and cutting the mixtures in double-screw extrusion granulators to obtain the glass fiber / thermoplastic plastic granules. The glass fiber / thermoplastic plastic granules and the method have the advantages that the glass fiber / thermoplastic plastic granules prepared by the aid of the method are high in strength, toughness and plasticity, low in cost and easy to process, and technologies for the glass fiber / thermoplastic plastic granules are simple.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Multi-mode crushing ball mill

ActiveCN111229433AImprove crushing efficiencyMeet crushing requirementsGrain treatmentsArchitectural engineeringStructural engineering

The invention discloses a multi-mode crushing ball mill. The multi-mode crushing ball mill comprises a driving piece, a first crushing mechanism, a grinding mechanism and a second crushing mechanism;the driving piece drives the first crushing mechanism to crush building stones; after the building stones are crushed, the driving piece drives a grinding mechanism to grind the building stones; and then the second crushing mechanism further crushes the building stones after the building stones reach the predetermined sizes. The building stones are doubly crushed through the first crushing mechanism and the second crushing mechanism, the first crushing mechanism and the grinding mechanism are powered by the same driving piece so as to be synchronously carried out; the whole crushing ball millis simple in structure and high in crushing efficiency; and the building stones sieved by a sieve plate can be crushed through the second crushing mechanism so that the building stones discharged froma discharge port completely meet the crushing requirement.

Owner:博兴兴博投资有限公司

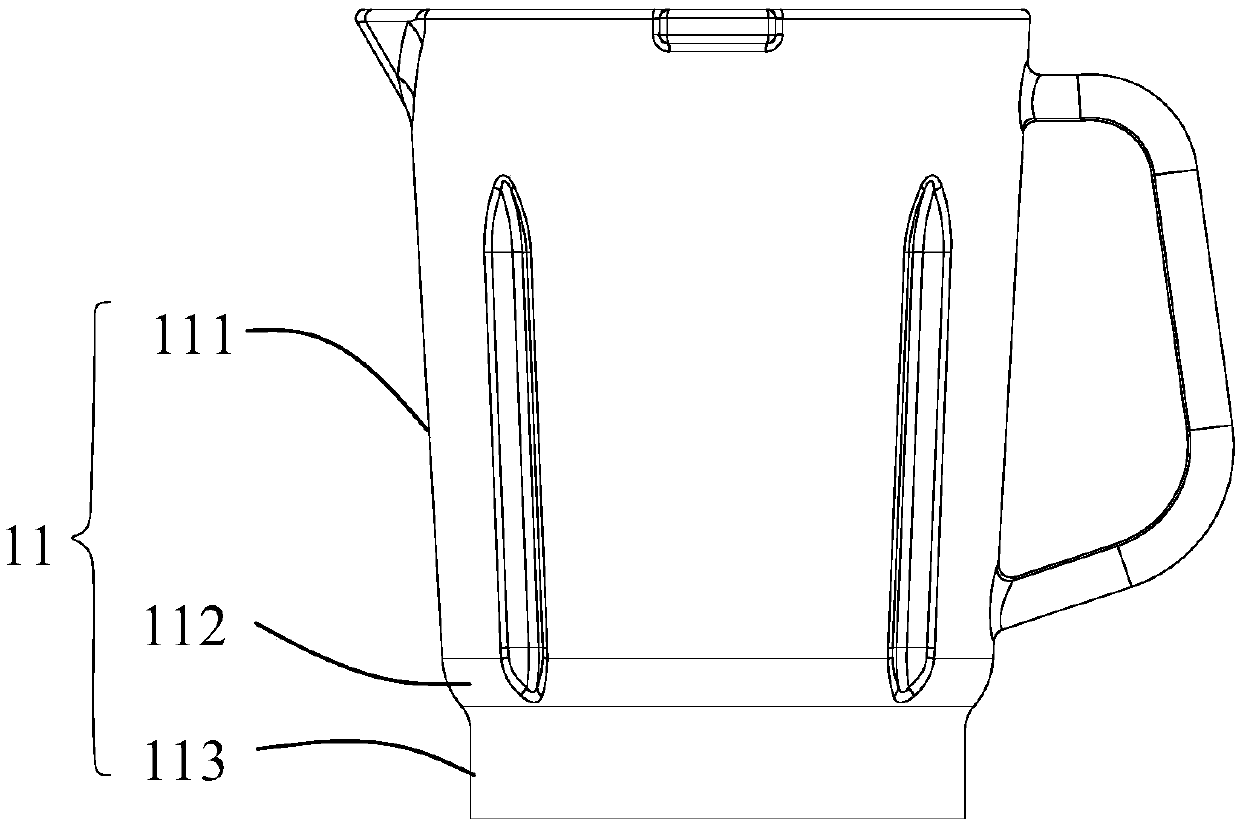

Glass cup body processing technology for food processor

ActiveCN111358315AReduce weightEasy to useGlass furnace apparatusGlass pressing apparatusComposite materialMachining process

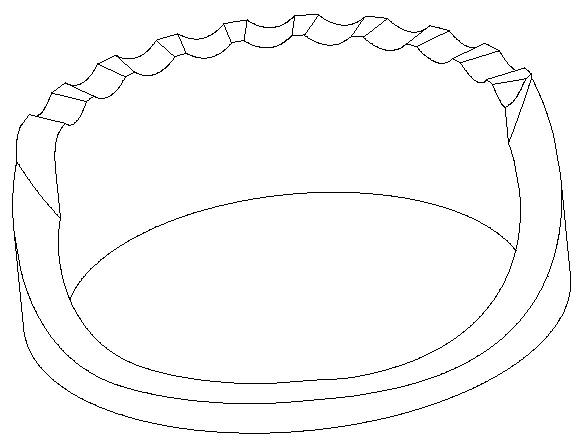

The invention relates to a glass cup body processing technology for a food processor. The glass cup body processing technology at least comprises the following stages: (1) a melting stage: melting a glass raw material containing borax and silica sand in a kiln with the temperature of 1500 DEG C or above; (2) a compression molding stage: cooling the glass raw material to 1100-1400 DEG C, feeding the glass raw material into a molding die, carrying out compression molding, controlling the temperature of the molding die to 500-900 DEG C, and pressing the glass raw material into a glass cup body with different wall thicknesses and an irregular circular cross section within 5 seconds by using a stamping pressure of more than 4 tons; (3) an annealing stage: feeding the glass cup body into a tunnel furnace of which the temperature is lower than 600 DEG C, annealing and cooling; and (4) a bottom cutting stage: cutting off the bottom of the annealed glass cup body and grinding the cutting position. The prepared glass cup body is light and handy and is convenient for a user to take, place and operate.

Owner:JOYOUNG CO LTD

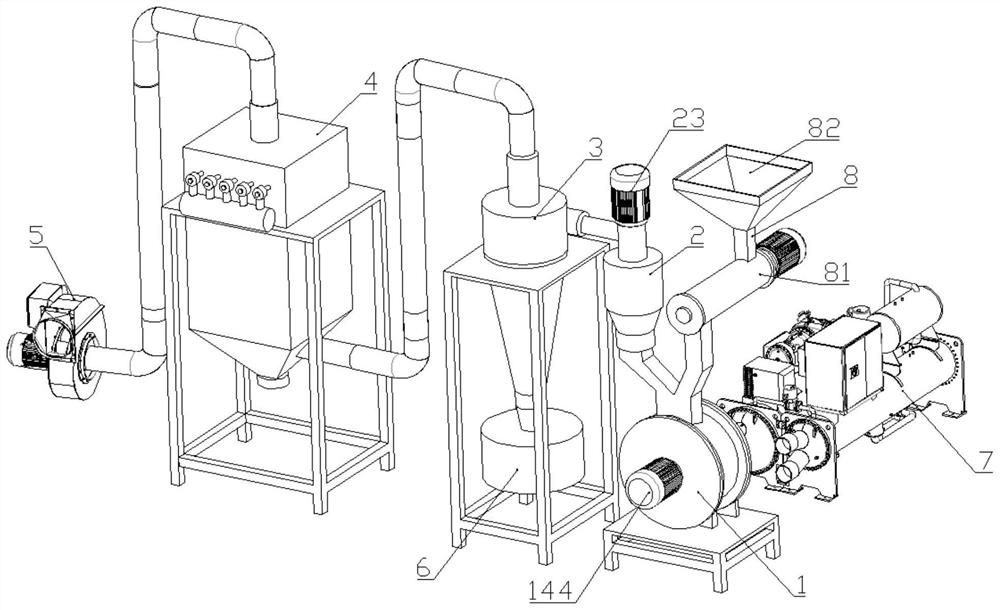

Tenebrio molitor smashing device

PendingCN113649126AGuaranteed uniformityAvoid uneven crushingVortex flow apparatusCompression machines with non-reversible cyclePhencycloneMechanical engineering

The invention discloses a tenebrio molitor smashing device. The tenebrio molitor smashing device comprises a smashing mechanism, a discharging port of the smashing mechanism is connected with a feeding port of a grading mechanism, a discharging port of the grading mechanism is connected with a feeding port of a cyclone separator, the lower end of the cyclone separator is connected with a storage tank, an air outlet of the cyclone separator is connected with an air inlet of a dust removal tank, an air outlet of the dust removal tank is connected with a fan, and the smashing mechanism is connected with a cooling device. According to the tenebrio molitor smashing device, uneven smashing caused by adhesion of tenebrio molitor powder due to oil seepage of tenebrio molitor due to temperature rise in the tenebrio molitor smashing process is prevented, meanwhile, the cooling device cools the tenebrio molitor powder in the smashing process, nutritional ingredients of the tenebrio molitor powder are reserved, the grading mechanism can meet the smashing requirements of tenebrio molitor powder with different granularities, and scraping plate is arranged on a second smashing rod on the outermost side, so that the tenebrio molitor powder on the inner wall of a smashing chamber can be scraped into the smashing chamber, and the smashing uniformity of the tenebrio molitor powder is ensured.

Owner:青岛新农康源生物工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com