Stepless gear roller set and stepless gear roller crusher

A technology of extremely toothed roller set and crusher, which is applied in the field of mining machinery, can solve the problems of low crushing particle size of brittle materials, small footprint, complex structure, etc. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

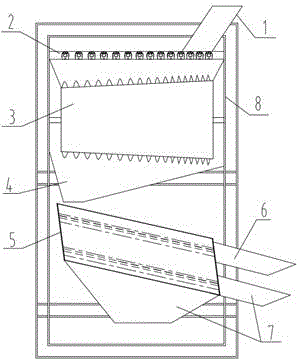

[0032] see Figure 1-3 , which is a schematic structural diagram of a preferred embodiment of the stepless tooth roller crusher of the present invention. As shown in the figure: it includes feeding port 1, sorting feeder 2, stepless toothed roller set 3, screening feeding port 4, screening machine 5, coarse material returning port 6, discharging port 7, main body Rack 8. The feeding port 1 is located above the sorting feeder 2. Below the sorting and feeding machine 2 is a stepless toothed roller group. Below the stepless toothed roller group is a screening feeding port 4, and a screen is set below the screening feeding port 4. Extension 5 and screening machine 5 are connected with a coarse material return port 6 and a discharge port 7; the feeding port 1, the sorting feeder 2, the stepless tooth roller group 3, the screening feeding port 4, and the screening machine 5 , Coarse material return cage material port 6, discharge port 7 are fixed on the main frame 8.

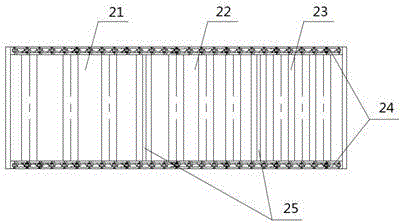

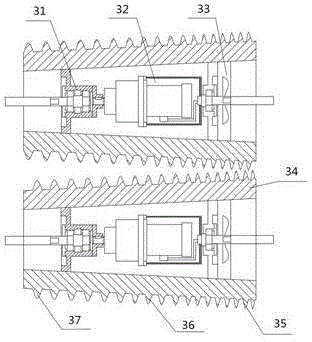

[0033] lik...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com