Machine for directly driving spiral motion motor and use of machine

A technology of helical motion and machinery, which is applied to rotary drilling rigs, grinding machine parts, electromechanical devices, etc., can solve the problems of inconvenient installation, dismantling, handling, and large size of construction machinery, and achieves low cost, simple structure, The effect of small mechanical size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

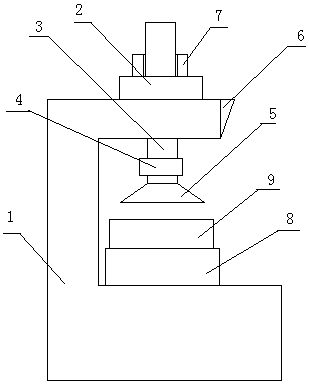

[0033] Example 1: figure 1 It is a schematic diagram of the basic structure of a surface grinder directly driven by a spiral motion motor of the present invention. The surface grinder includes: the frame 1 is equipped with a spiral motion motor 2, the mover 3 of the spiral motion motor 2 is directly used as the main shaft of the grinder, the main shaft 3 is equipped with a fixture 4 and a grinding head 5, and the spiral motion generated by the spiral motion motor 2 replaces the existing one. The rotary motion of the main motor of the grinder and the linear motion of the hydraulic feed mechanism, the electric control unit 6 is connected to the screw motion motor 2, and the electromagnetic clamping device 7 is installed between the mover 3 of the screw motion motor 2 and the frame 1 , the frame 1 is equipped with a liftable workbench 8, and the liftable workbench 8 can be adjusted in height according to the size of the workpiece 9. When the grinding machine is in operation, fir...

Embodiment 2

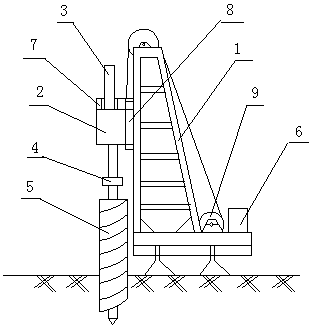

[0034] Example 2: figure 2 It is a schematic diagram of the basic structure of an auger drill directly driven by a helical motion motor of the present invention. The auger drilling machine includes: a helical motion motor 2 is installed on the frame 1, and the mover 3 of the helical motion motor 2 is directly used as the main shaft of the auger drilling machine, and the clamp 4 and the auger bit 5 are installed on the main shaft 3, and the helical motion generated by the helical motion motor 2 replaces the The rotary motion of the main motor of the existing engineering drilling rig and the linear motion of the hydraulic feed mechanism, the electric control unit 6 is connected to the screw motion motor 2, and the electromagnetic clamping device is installed between the mover 3 of the screw motion motor 2 and the frame 1 Device 7, a guide rail 8 is installed between the frame 1 and the screw motor 2, the screw motor 2 can move up and down along the guide rail 8 under the action...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com