Efficient crushing device for quartz sand

A high-efficiency pulverization and quartz sand technology, applied in non-rotational vibration suppression, grain processing and other directions, can solve the problems of low pulverization efficiency, poor pulverization effect, affecting the extraction and utilization of quartz sand, and achieve high grinding efficiency, good grinding effect, Good crushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 2

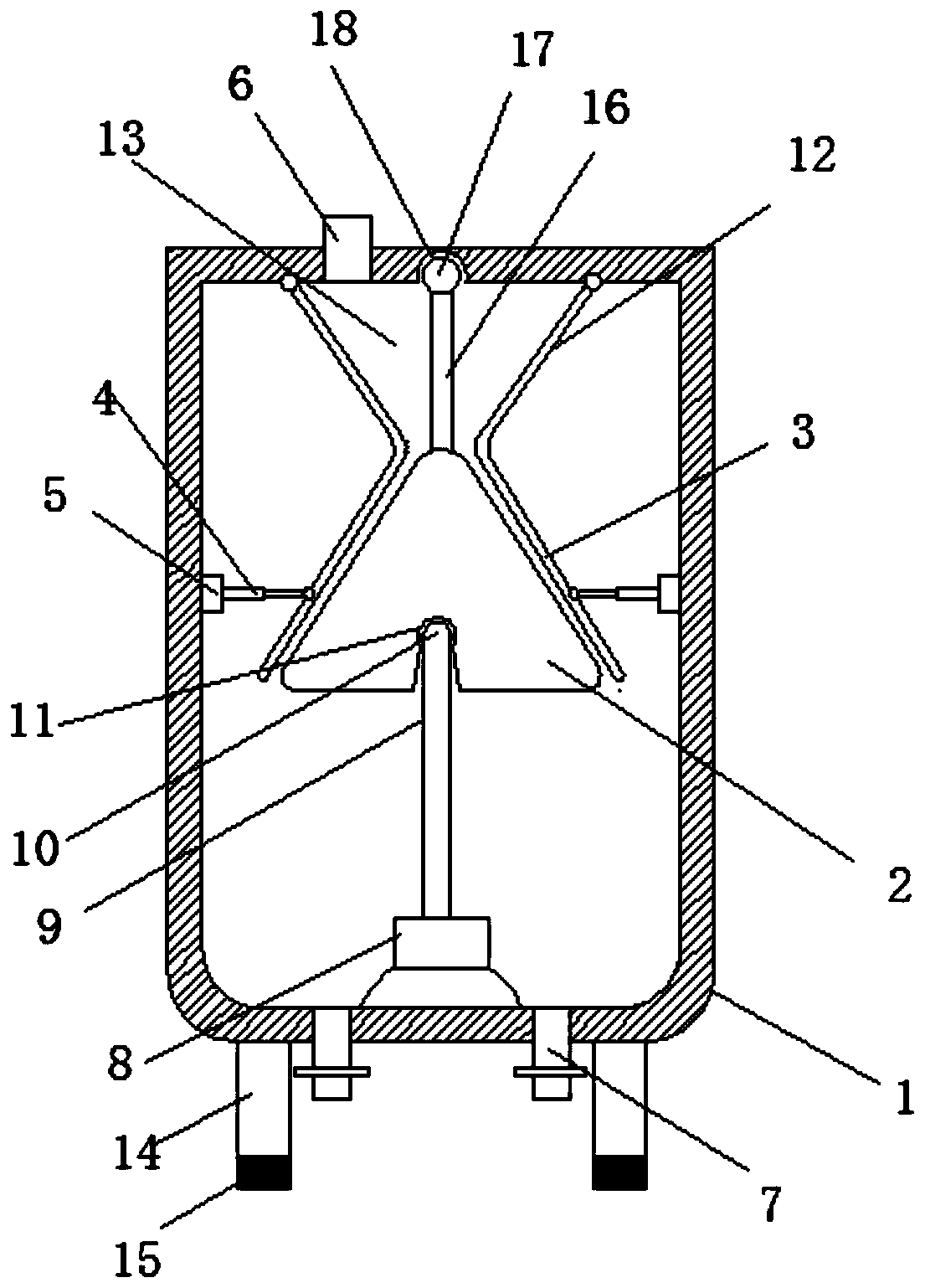

[0028] see figure 2 Shown is the second embodiment of the high-efficiency crushing device for quartz sand of the present invention. The difference between this embodiment and the first embodiment is that the top of the moving cone 2 is fixedly connected with a support rod 16, and the support rod The other end of 16 is connected with sphere 17, and offers the sphere connecting portion 18 that cooperates with this sphere 17 on the inner top wall of box body 1, like this, cooperates between sphere and sphere connecting portion, can make moving cone 2 The swing is more stable.

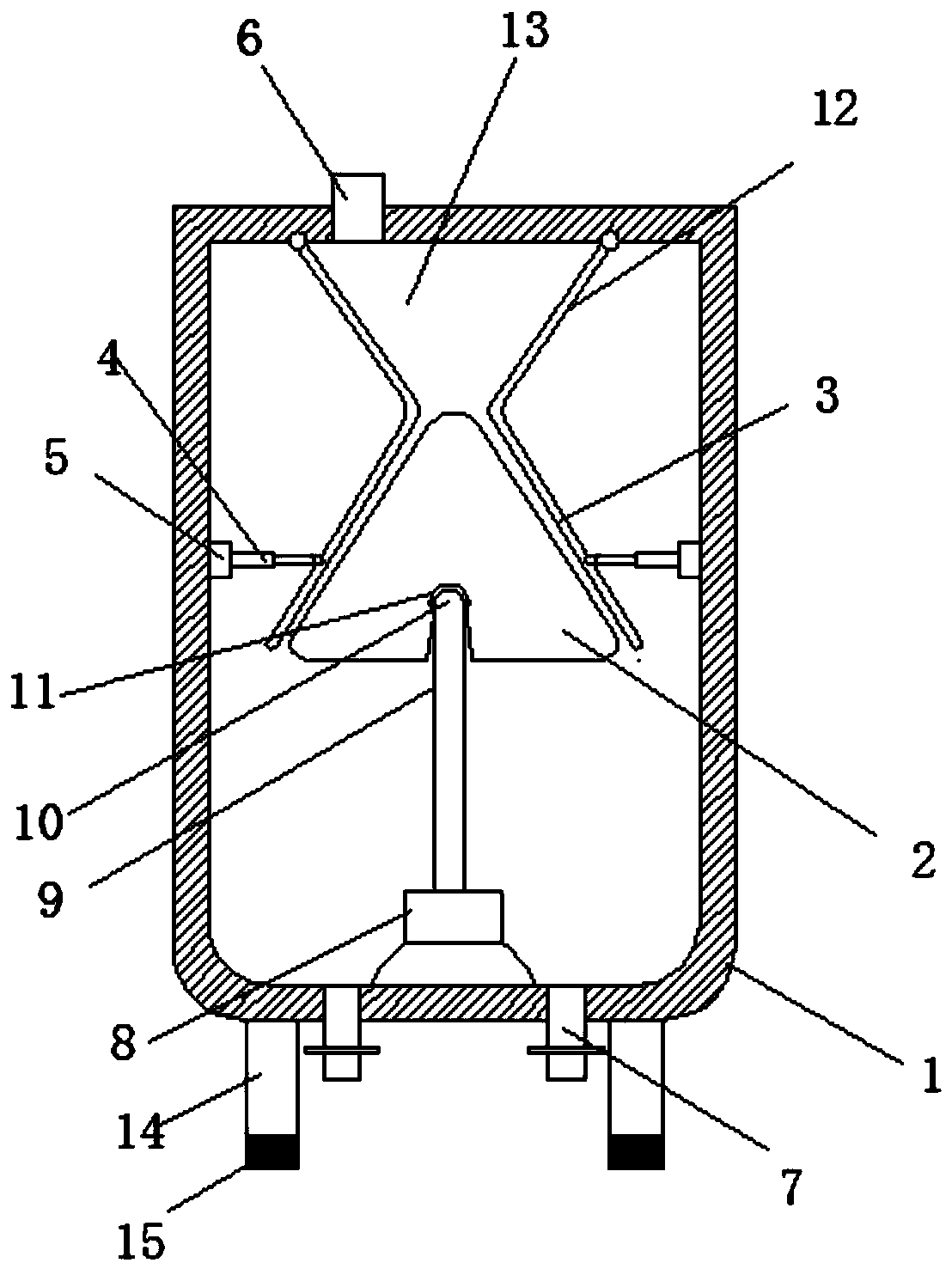

[0029] The specific working process of the pulverizing device of the present invention: the quartz sand raw material to be pulverized is dropped into the collecting chamber 13 through the feed port 6, the driving motor 8 is started, and the driving motor 8 drives the moving cone 2 to rotate, and then enters the fixed cone 3. It forms extrusion with the quartz sand to be crushed in the gap of the moving c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com