Fixed-gap tooth-free roller-couple grinder

A pulverizer and crushing mechanism technology, applied in the direction of grain processing, etc., can solve the problems of uneven material particle size, gear wear, loud noise, etc., and achieve the effect of increasing service life, improving production efficiency, and avoiding efficiency loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

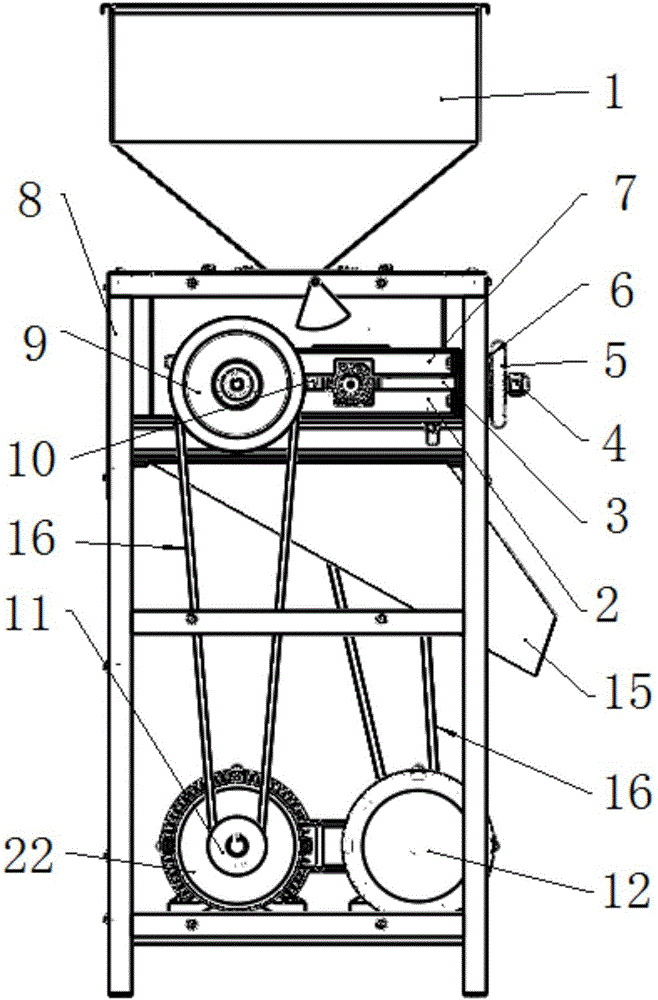

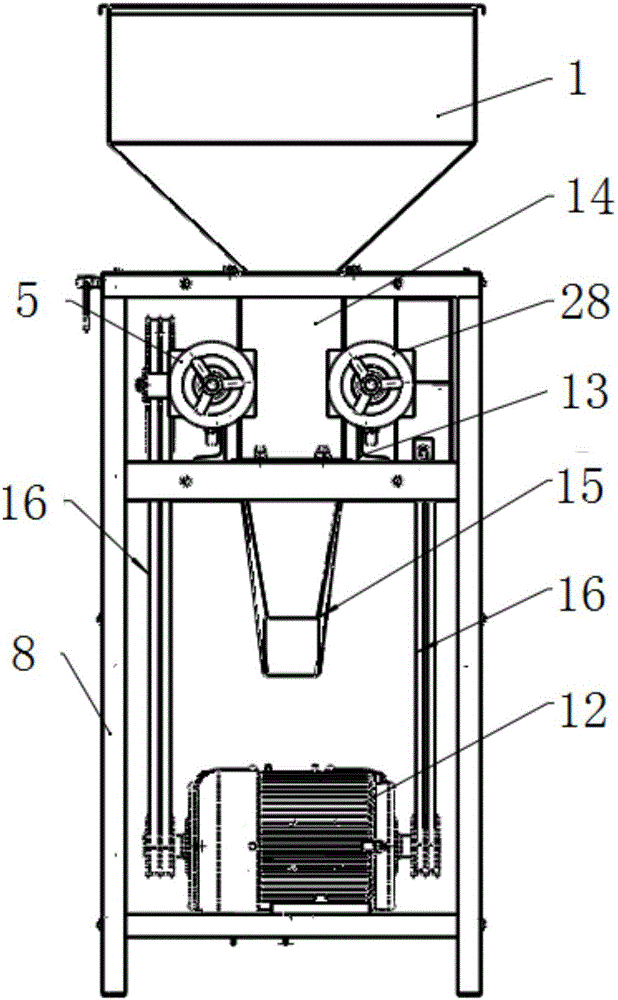

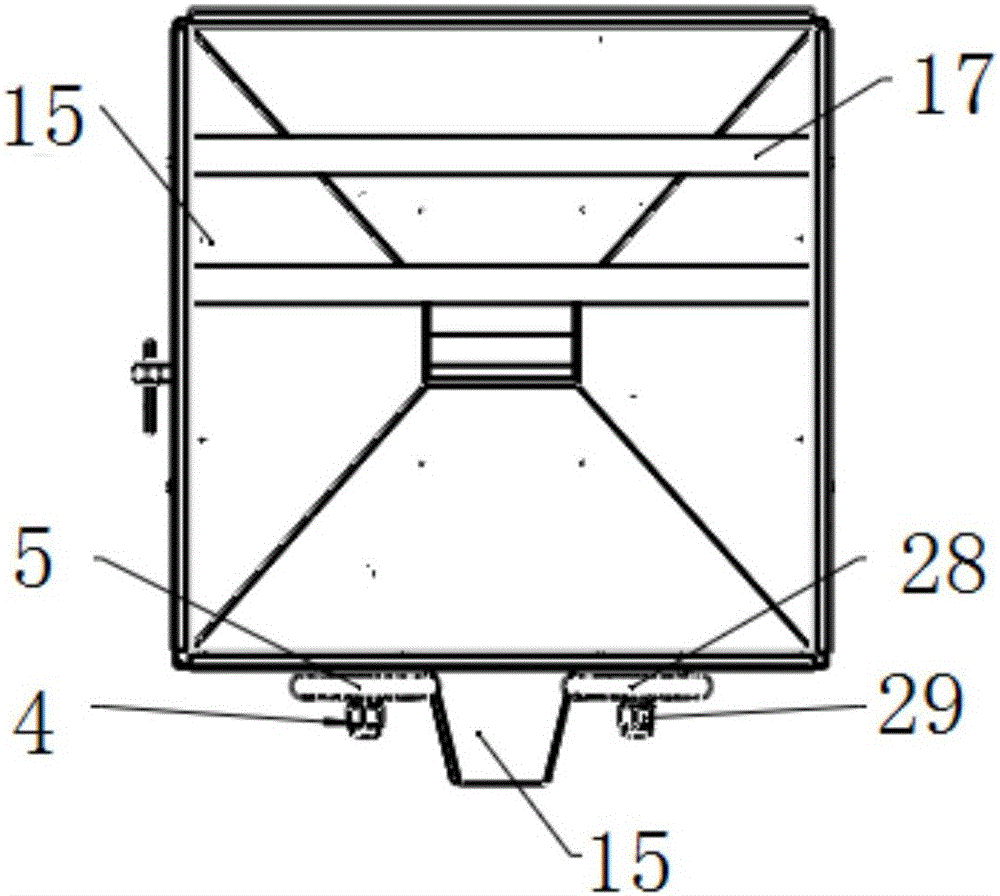

[0022] like Figure 1-Figure 2 As shown in the figure, the fixed-gap free tooth-to-roll pulverizer consists of a feeding hopper 1 and a discharging hopper 15, a grinding roller I18 and a grinding roller II20, etc. The feeding hopper 1 is installed above the frame 8. The transmission mode is that the motor I22 drives the grinding roller I18 to rotate through the pulley I9, and the motor II12 drives the grinding roller II20 to rotate through the pulley II21. The system where the grinding roller I18 is located and the system where the grinding roller II20 is located are two. The independent transmission mechanism does not interfere with each other.

[0023] The gap between the grinding roller I18 and the grinding roller II20 before pulverization is adjustable, and the gap between the grinding roller I18 and the grinding roller II20 is jointly adjusted by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com