All-in-one machine with straw collecting, crushing and outputting functions

An all-in-one machine and straw technology, applied in the field of agricultural machinery, can solve problems such as perishable and rotten, complicated process, and increased utilization cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

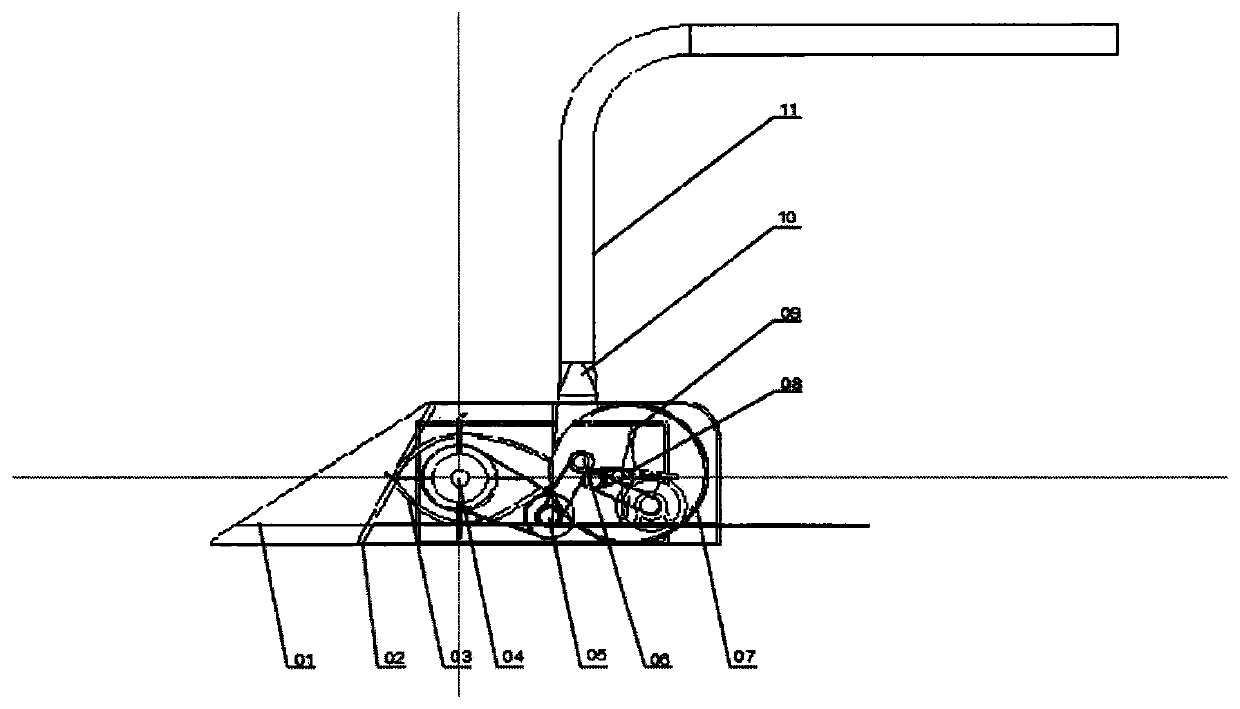

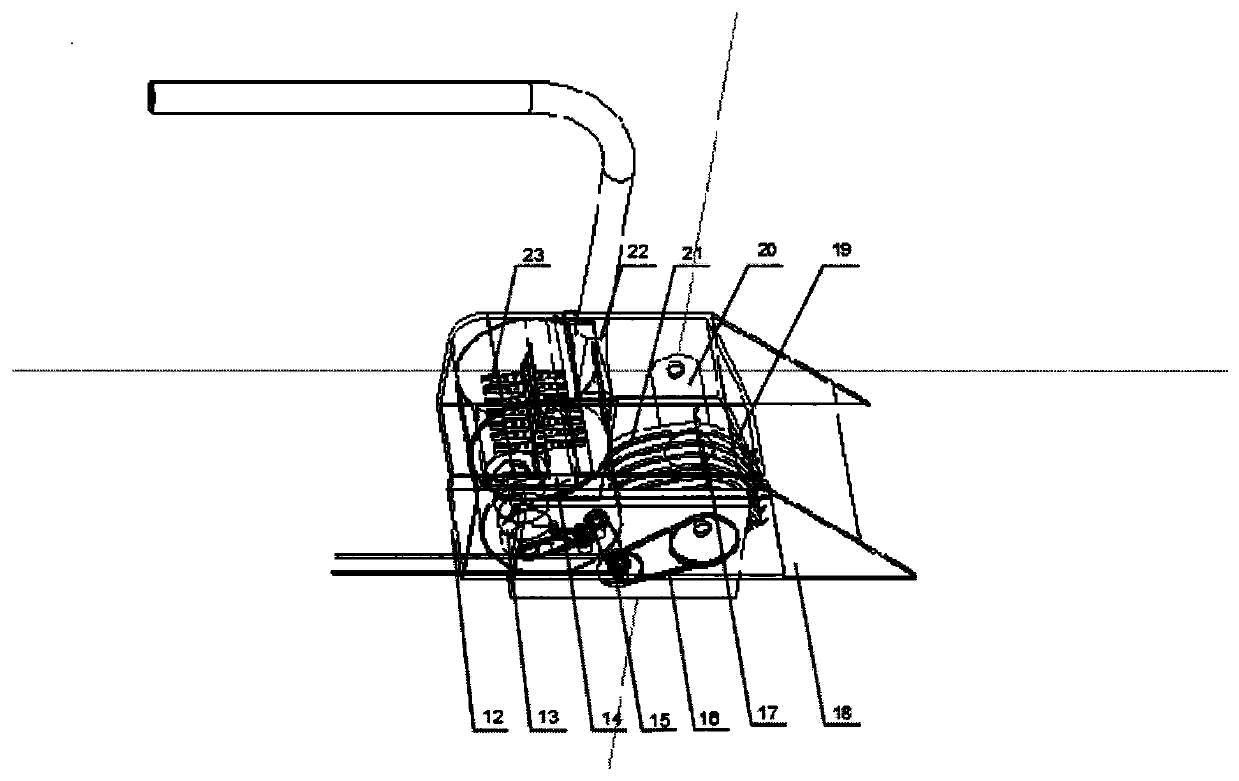

[0014] Such as figure 1 , figure 2 As shown, a straw collecting, crushing and outputting integrated machine, its main mechanism includes a picking device 21, a crushing device 23, a transmission device 14, a support frame (02, 18), a vehicle frame (01, 12), a gear set (05 , 16), pulley group (06, 15), support shaft (picking device) 04, main shaft (08, 20), etc. The all-in-one machine pick-up device is arranged in the vehicle frame (01, 12), the pick-up device is connected with the vehicle frame 02 through the support shaft 04, the main shaft 20 of the crushing device is installed on the vehicle frame through a bearing; the transmission device 14 is installed on the pick-up device 22 At the rear, the throwing device is installed above the sieve plate 10 of the crushing device; the power from the traction tractor is delivered to the pick-up device, the transmission device, and the crushing device through the gear set and the pulley set of the all-in-one machine.

[0015] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com