Glass cup body processing technology for food processor

A food processing machine and technology of processing technology, applied in the direction of glass pressing, glass forming, glass furnace equipment, etc., can solve the problems of bulky glass body, difficulty and inconvenience in glass body manufacturing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

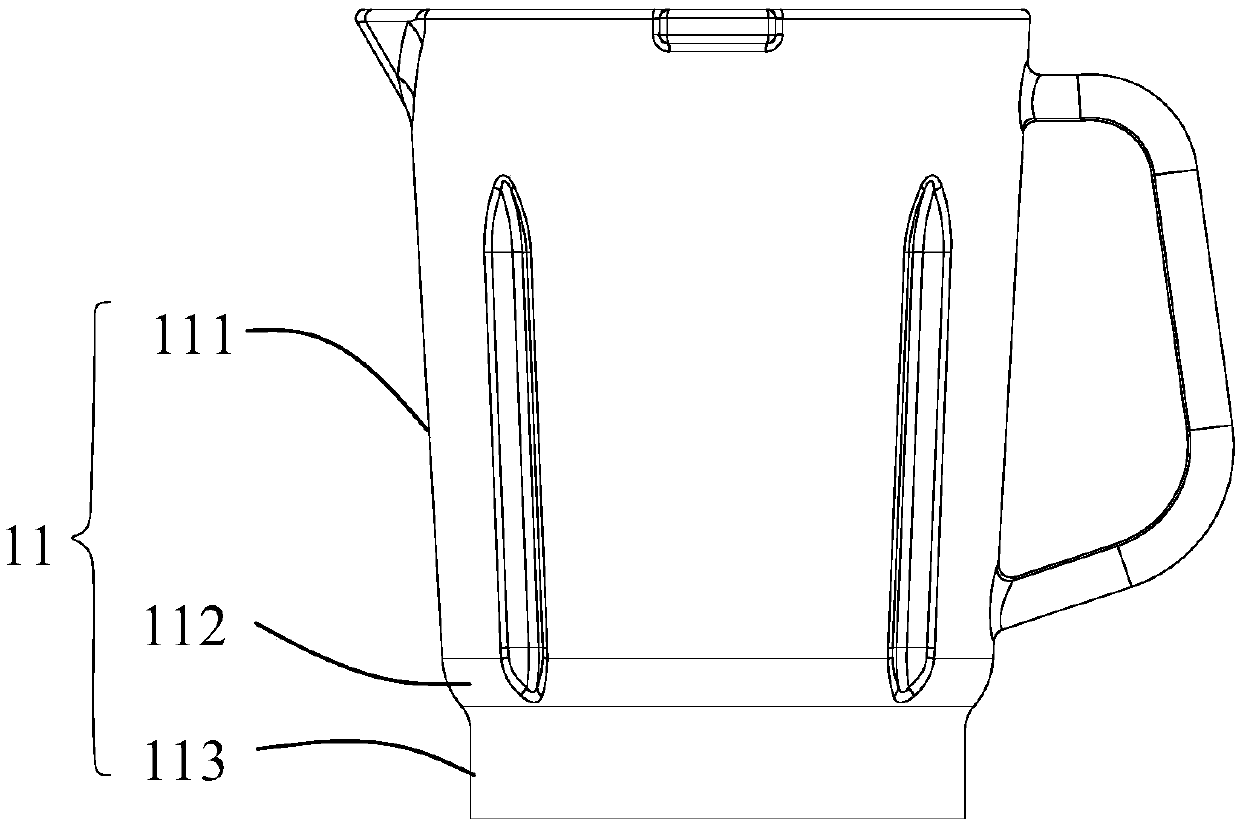

[0033] see figure 1 The schematic diagram of the first preferred embodiment of the glass body manufactured by the glass body processing technology for the food processor, the glass body processing technology for the food processor at least includes the following stages:

[0034] (1) Melting stage: melting glass raw materials containing borax and silica sand in a kiln above 1500°C;

[0035] (2) Press forming stage: the above-mentioned glass raw materials are cooled to 1100°C to 1400°C and sent to the forming mold for pressing and forming. The temperature of the forming mold is 500°C to 900°C. The glass raw material is pressed into an irregular round glass body 11 with unequal wall thickness;

[0036] (3) Annealing stage: send the glass body 11 into a tunnel furnace with a temperature lower than 600°C for annealing and cooling;

[0037] (4) Bottom cutting stage: cut off the bottom of the annealed glass body 11 and grind the cutting position.

[0038] In the melting stage, in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com