Tenebrio molitor smashing device

A crushing device and Tenebrio molitor technology, which is applied in swirl devices, lighting and heating equipment, compressors, etc., can solve problems such as uneven crushing, poor applicability, and loss of nutrients in Tenebrio molitor powder, and achieve the goal of ensuring uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

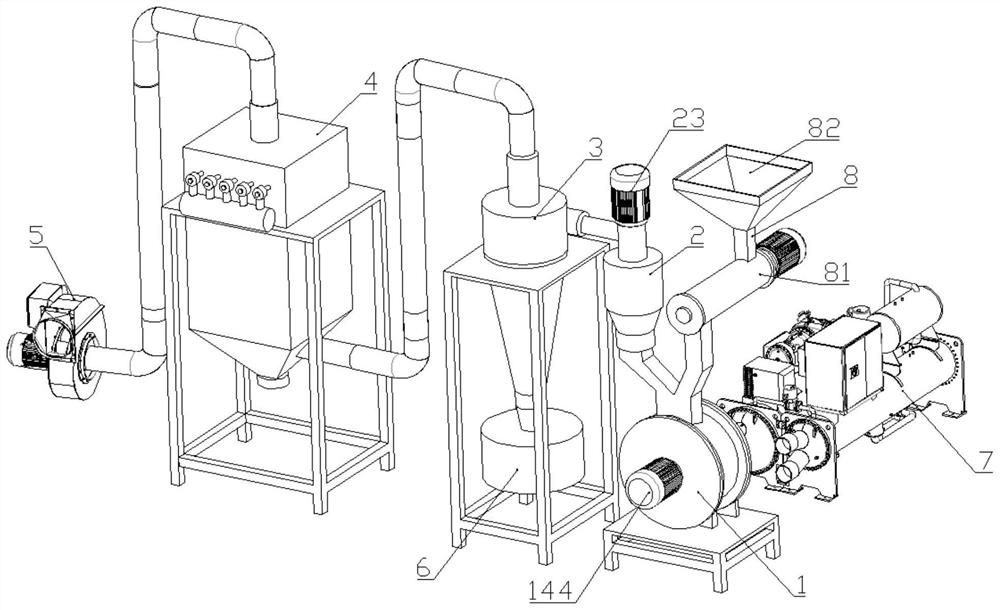

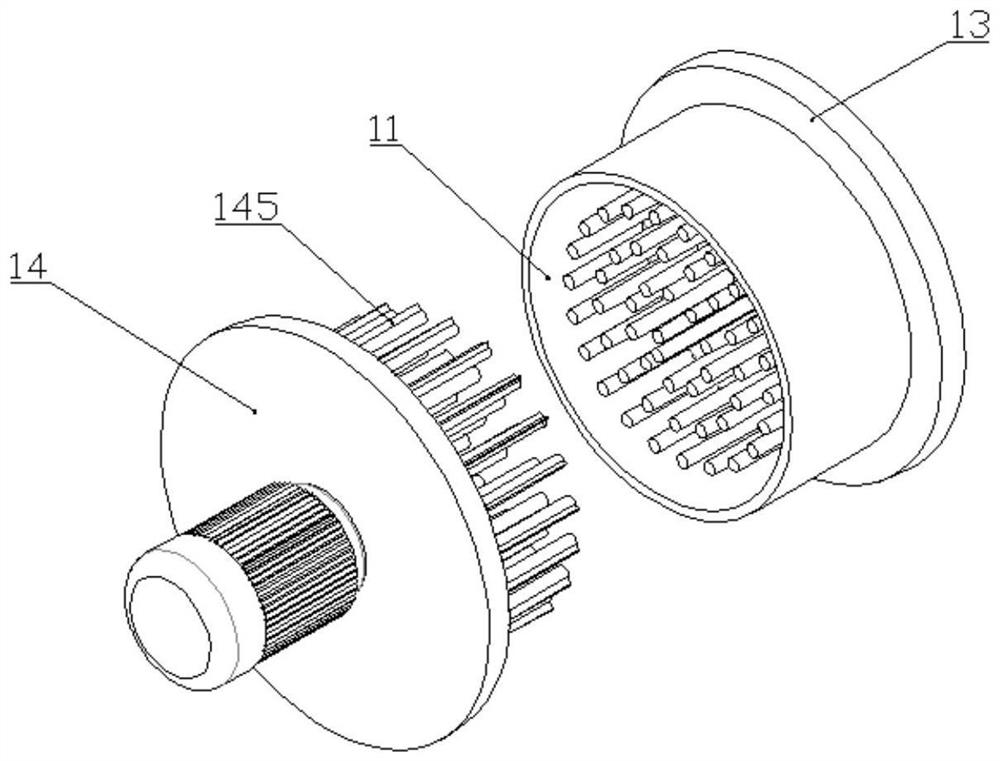

[0037] Such as figure 1 As shown, the invention discloses a Tenebrio molitor crushing device, comprising a crushing mechanism 1, a classifying device 2, a cyclone separator 3, a dust removal tank 4, a blower fan 5, a storage tank 6 and a cooling device 7, and the discharge of the crushing mechanism 1 The mouth is connected with the feed port of the classification mechanism 2, the discharge port of the classification mechanism 2 is connected with the feed port of the cyclone separator 3, the lower end of the cyclone separator 3 is connected with the storage tank 6, and the air outlet of the cyclone separator 3 is connected with the The air inlet of the dust removal tank 4 is connected, the air outlet of the dust removal tank 4 is connected with a fan 5, the crushing mechanism 1 is connected with a cooling device 7 for cooling the crushing chamber 11, and Tenebrio molitor enters from the feed port of the crushing mechanism 1 after drying. In the pulverizing mechanism 1, the cool...

Embodiment 2

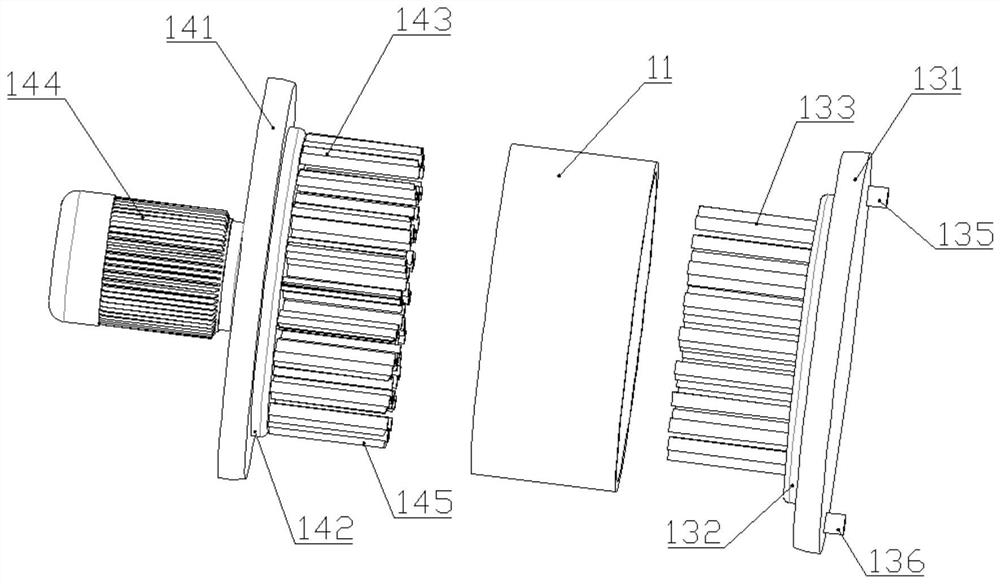

[0044] Such as Figure 6 As shown, the difference between this embodiment and Embodiment 1 is that the first connecting plate 131, the first disk 132, the first crushing rod 133 and the crushing chamber 11 are of an integrated structure, and the first connecting plate 131, the first The chamber wall of disc 132, the first crushing rod 133 and crushing chamber 11 is a hollow structure, and the cavity wall of the first connecting plate 131, the first disc 132, the first crushing rod 133 and the crushing chamber 11 is hollow. The structure is connected to the integral second hollow chamber 135 , and the second hollow chamber 135 is connected to the cooling device 7 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com