Airflow mill of multifunctional fluidized bed

A fluidized bed, multi-functional technology, applied in the field of ultrafine pulverization and surface treatment, fluidized bed jet mill, can solve the problems of inability to meet the requirements of surface modification, lack, classification treatment, etc., to enhance the preparation and treatment functions , the effect of broadening the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

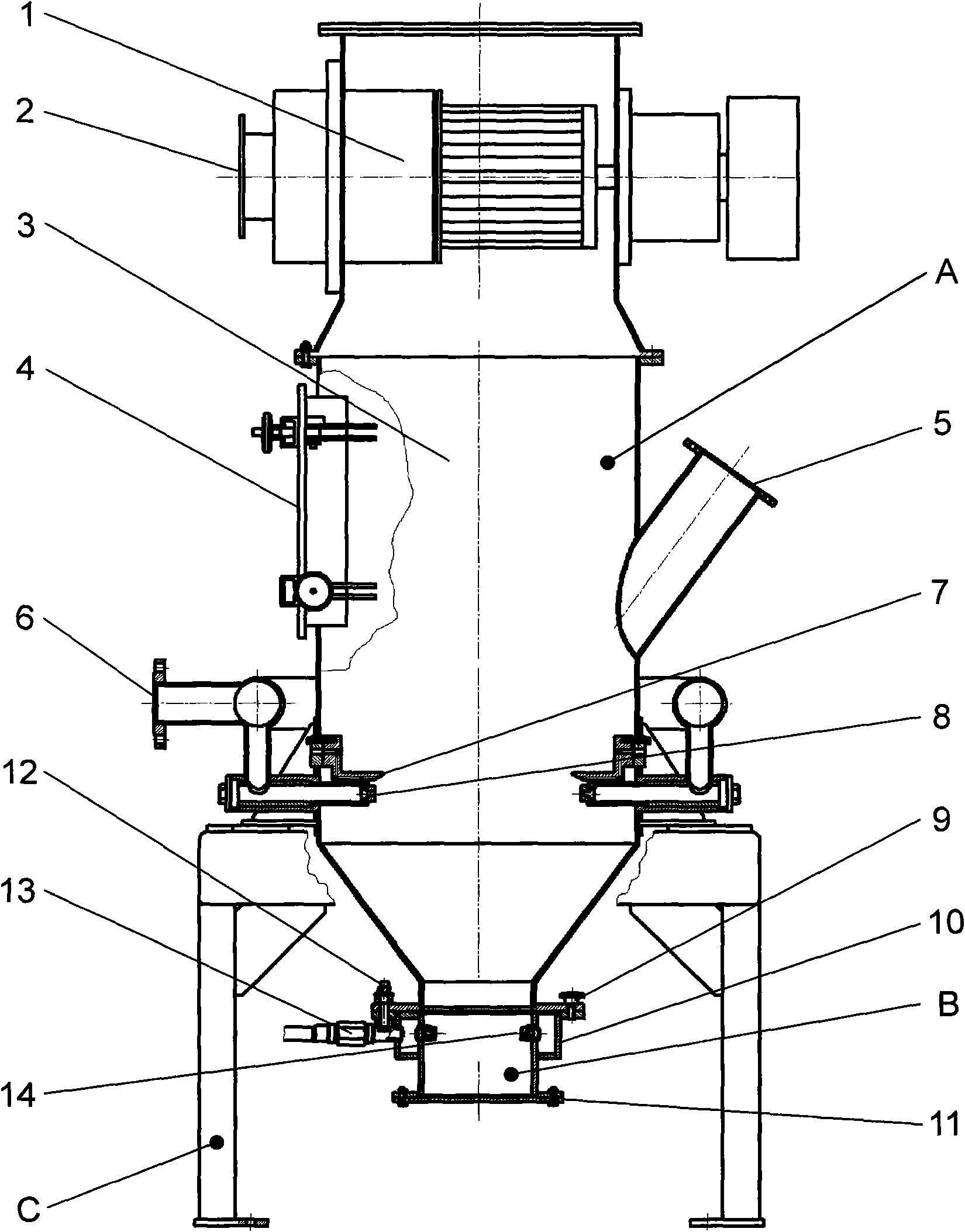

[0019] Such as figure 1 As shown, the multifunctional fluidized bed jet mill is composed of a large amount of material crushing modified part A, a small amount of material crushed auxiliary modified part B, and a machine base C. The upper end of a small amount of material crushed auxiliary modified part B is connected to a large amount of The lower end of material crushing modification part A is connected {flange adopts quick-opening flange 9, hinged by rotating and opening hinge 12, and adopts hinged connection}, small amount of material crushing assists small crushing chamber 16 in modification part B to connect with large amount of material crushing The large crushing chamber 18 in the fluidized bed cylinder body 3 of the reforming part A is connected, and the reforming part A is fixedly connected with the machine base C through bolts for crushing a large amount of materials.

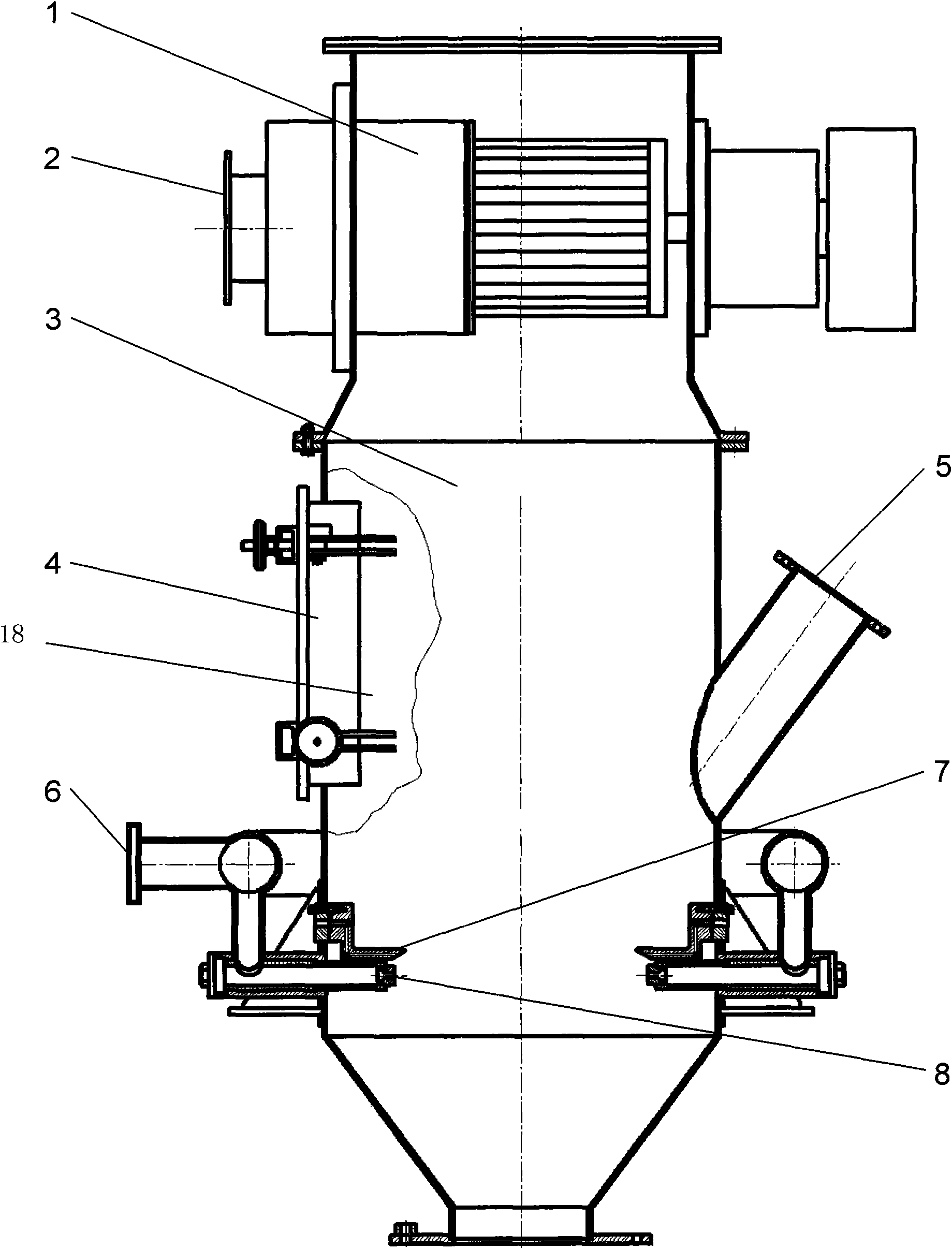

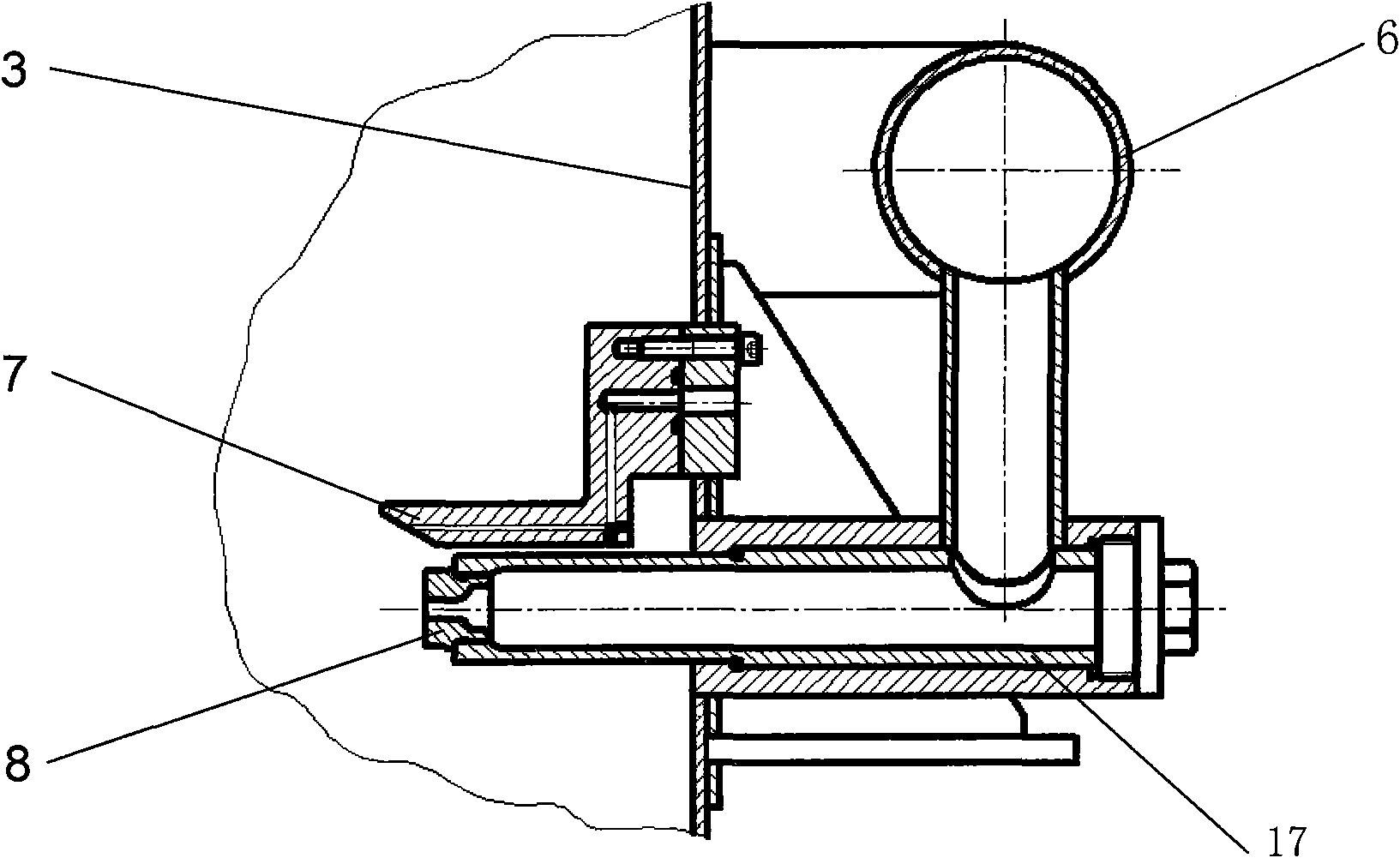

[0020] Such as figure 2 , image 3 As shown, the large amount of material pulverization and mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com