Mechanical mill crusher

A pulverizer and mechanical technology, applied in the field of pulverizers and mechanical mill pulverizers, can solve the problems of unstable pulverized materials, short use time of wearing parts, low graphite pulverization capacity, etc., achieve stable material size and structure, and save energy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

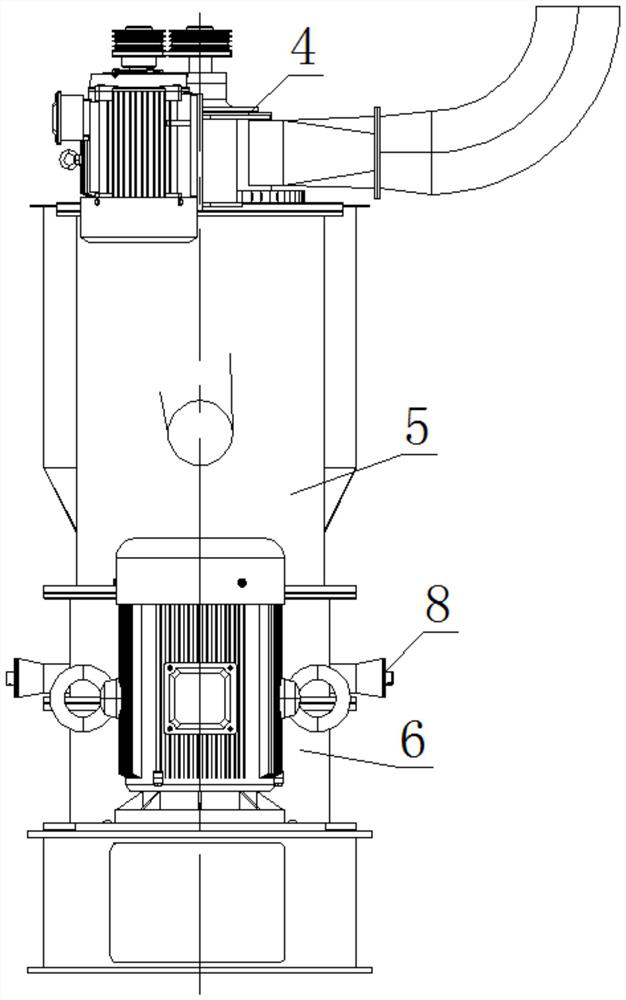

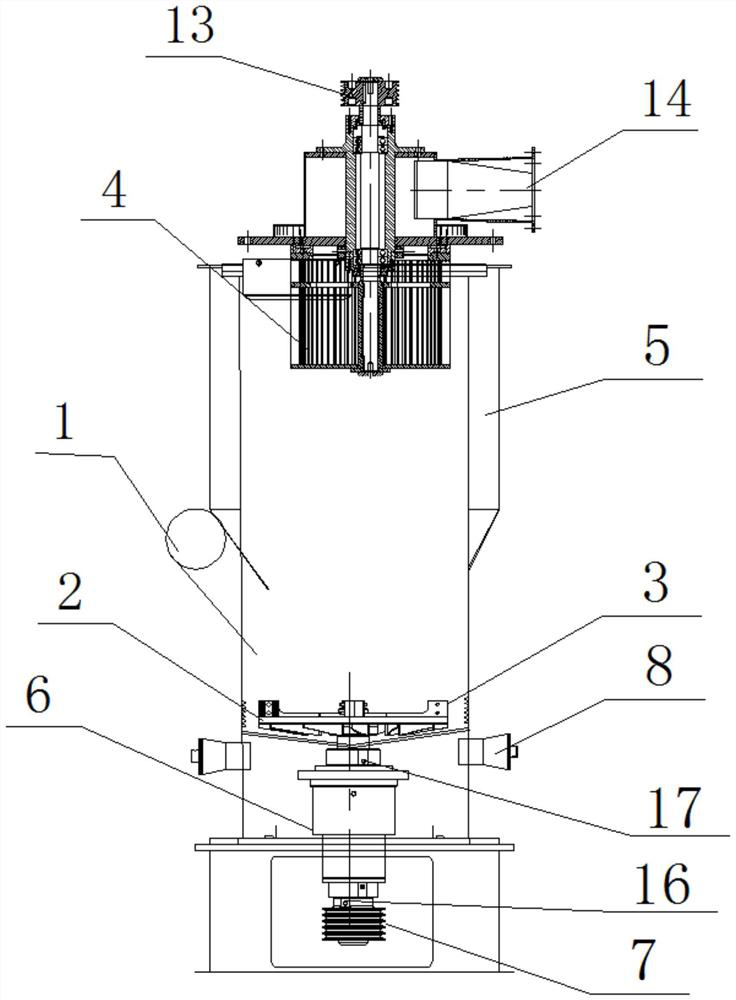

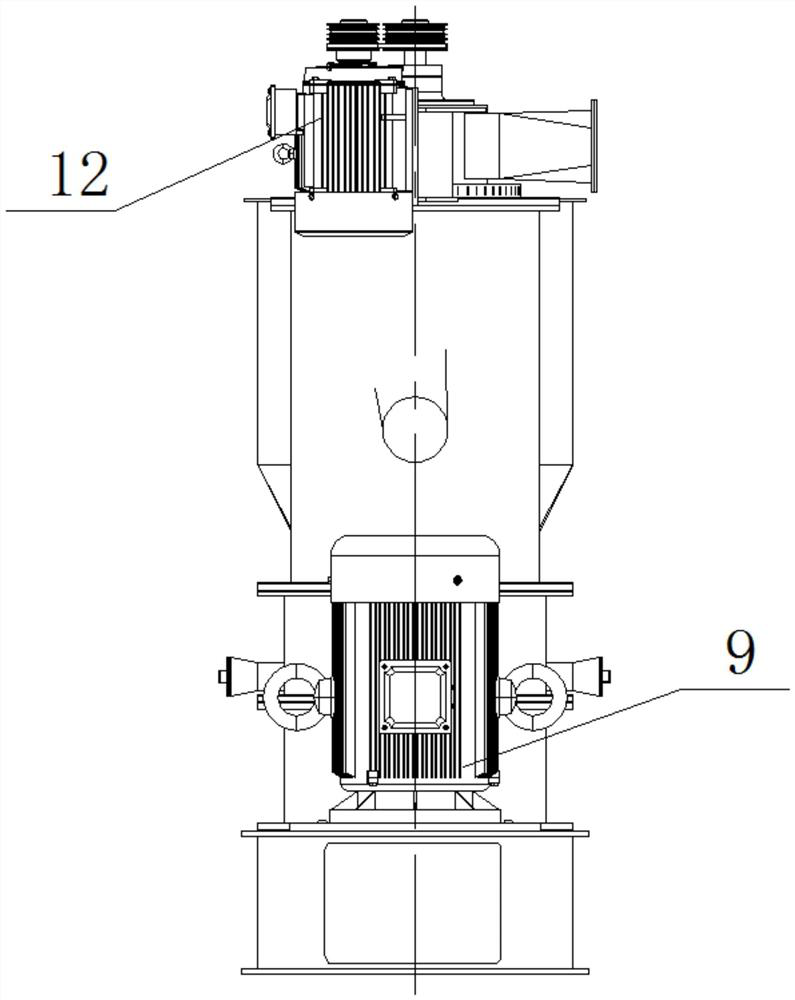

[0019] Specific implementation mode one: combine Figure 1-Figure 8 To illustrate this embodiment, a mechanical mill pulverizer provided in this embodiment includes a classifier 4, a box body 5, a mechanical mill assembly 6, a mechanical mill pulley 7, a classifier pulley 13 and a discharge pipe 14; The mechanical grinding assembly 6 is installed on the bottom of the box body 5, the mechanical grinding pulley 7 is set on the input end of the mechanical grinding assembly 6, the mechanical grinding pulley 7 is connected with the driving parts through a belt, and the classifier 4 is installed on the box body 5 On the top of the top of the classifier, the classifier pulley 13 is set on the input end of the classifier 4, and the discharge pipe 14 is installed on the classifier 4 above the box body 5. The box body 5 is provided with a feed port 1, and the classifier pulley 13 passes through A belt is connected to the drive member.

[0020] In this embodiment, the rotation direction...

specific Embodiment approach 2

[0021] Specific implementation mode two: combination Figure 1-Figure 4 The present embodiment is described. In the mechanical mill pulverizer provided in this embodiment, the impeller of the classifier 4 is arranged in the box body 5, and the annular sealing plate at the top of the impeller and the sealing plate at the bottom of the cyclone collector are arranged through a labyrinth seal. The input end of the classifier 4 rotating shaft is fixedly inserted on the classifier pulley 13, and the output end of the classifier 4 rotating shaft passes through the cyclone collector and is fixedly connected with the impeller. Other structural connections are the same as in the first embodiment.

[0022] During the work of this application, the processed graphite below is sorted by the impeller of the classifier 4. After processing, the graphite that meets the specifications enters the cyclone collector, and the graphite that does not meet the specifications falls into the mechanical g...

specific Embodiment approach 3

[0023] Specific implementation mode three: combination Figure 1-Figure 4 The present embodiment is described. In the mechanical mill pulverizer given in the present embodiment, the drive components include a mechanical mill motor 9 and a classifier motor 12. The output end of the classifier motor 12 is equipped with a drive pulley, and the classifier motor 12 housing Close to the classifier 4 and installed on the box body 5, the driving pulley on the classifier motor 12 and the classifier pulley 13 are connected by multiple belt transmissions, and the output end of the mechanical grinding motor 9 is equipped with a driving pulley. The housing of the mechanical grinding motor 9 is installed on the On the casing 5, the driving pulley of the mechanical grinding motor 9 and the mechanical grinding pulley 7 are connected through a plurality of belt transmissions. Other structural connections are the same as in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com