Impacting, rubbing and reducing mechanism for traditional chinese medicinal materials using ultra-fine air flow

A technology of impact friction and jet pulverization, applied in grain processing and other directions, can solve the problems of poor pulverization applicability, poor low-temperature pulverization performance, mixed pollution pulverization efficiency, etc. The effect of improving the efficiency of fine grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

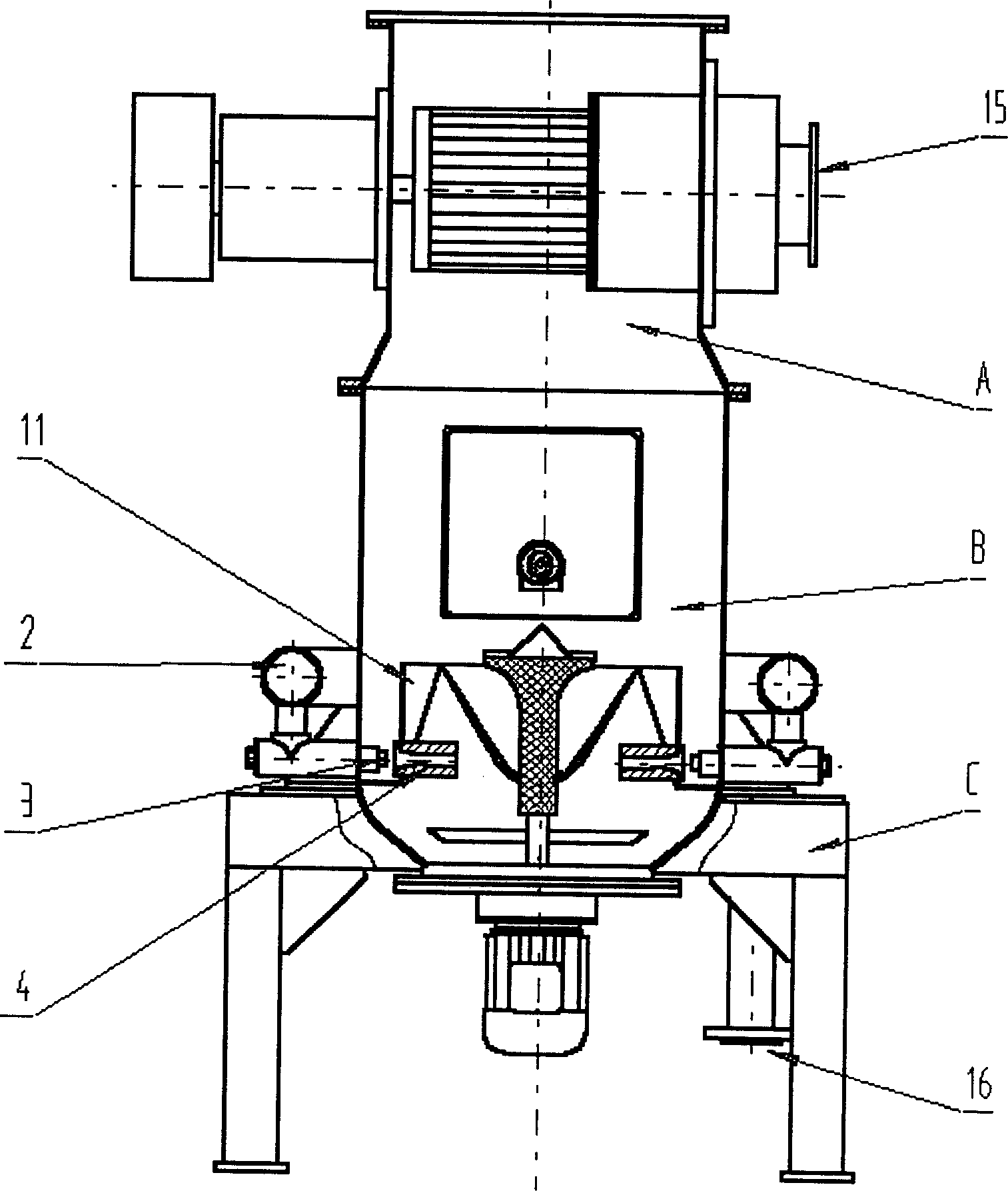

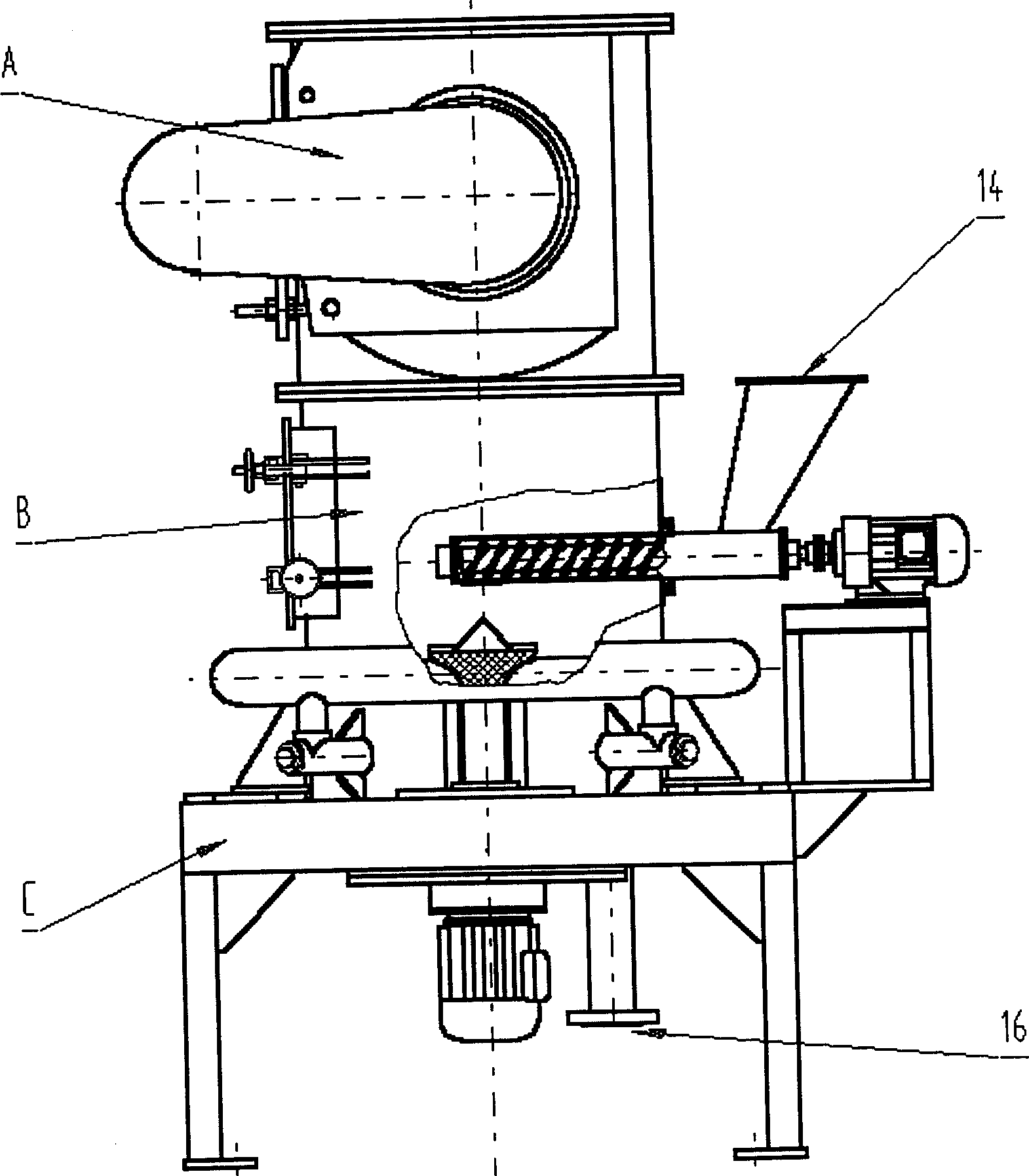

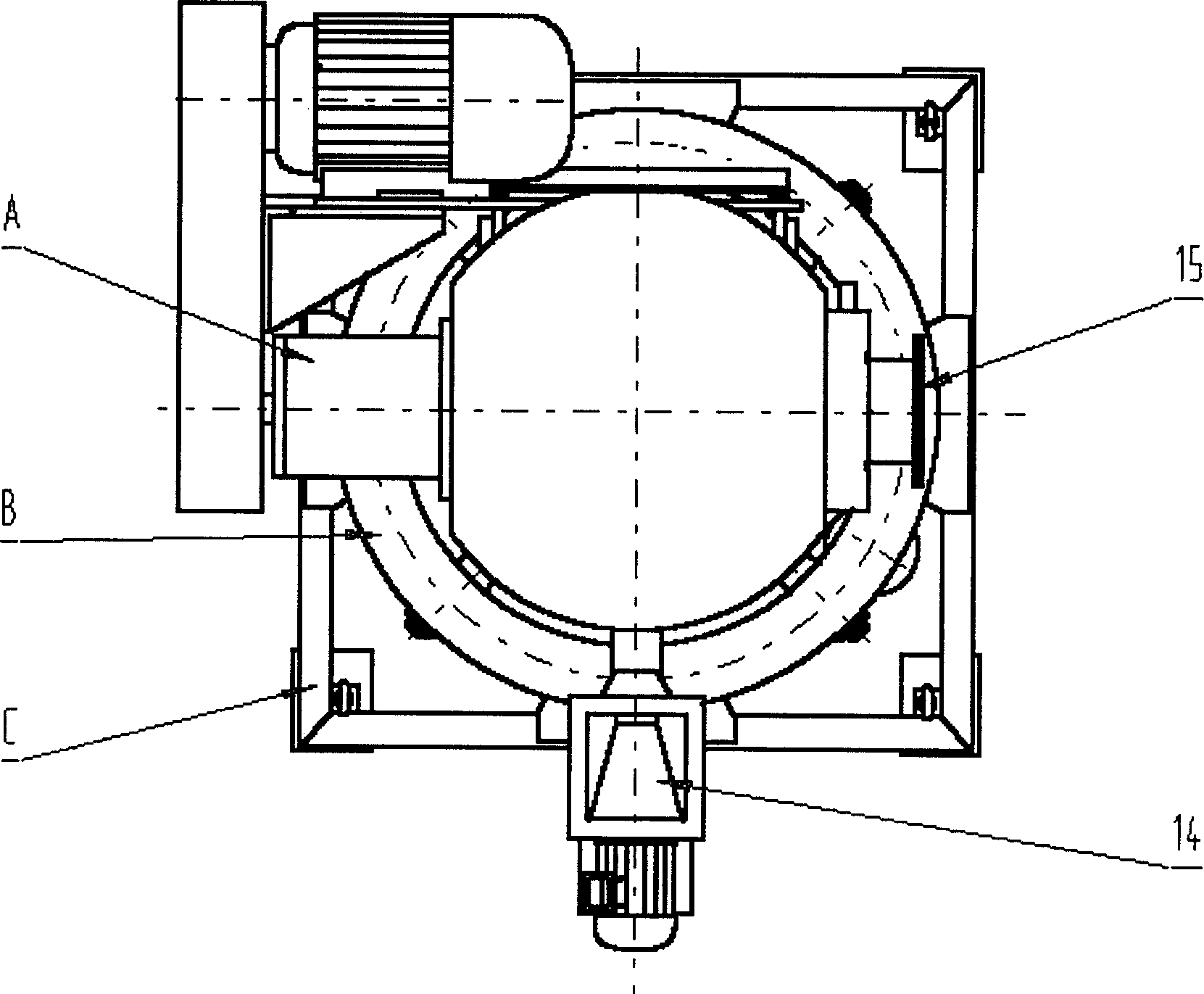

[0031] The impact and friction ultrafine airflow crushing device for Chinese herbal medicines includes a turbine classifying mechanism and a machine base. An impact friction ultrafine airflow milling mechanism B is set between the machine base C and the turbine classifying mechanism A. The upper part of the impact friction ultrafine airflow milling mechanism B is It is connected with the turbine classification mechanism A by a flange, and the support of the impact friction ultra-fine airflow crushing mechanism B is connected with the machine base C by bolts. Such as figure 1 , figure 2 with image 3 shown.

[0032] The impact friction ultra-fine airflow crushing mechanism B is composed of a speed-regulating screw feeder 1, an annular air bag and a nozzle seat connecting pipe 2, a supersonic injection nozzle 3, a mixing acceleration tube 4, a small fan blade 5, a bottom plate 6, Connecting flange 7, grinding door 8, grinding body 9, support 21, centrifugal distributing cone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com