Composite base material of ABC superfine dry powder extinguishing agent and preparation method thereof

A technology of ultra-fine dry powder and composite substrate, which is applied in fire protection equipment and other directions, can solve the problems of complex preparation process, low moisture absorption rate, easy to form hard blocks, etc., and achieves the effect of simple preparation method, high fire efficiency and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

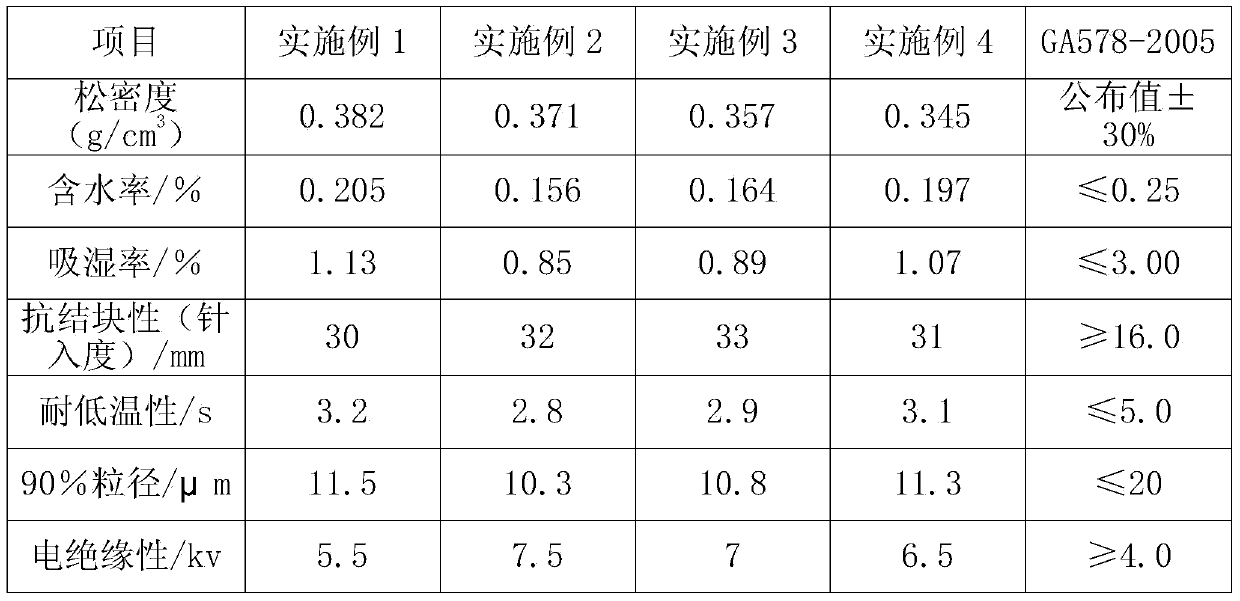

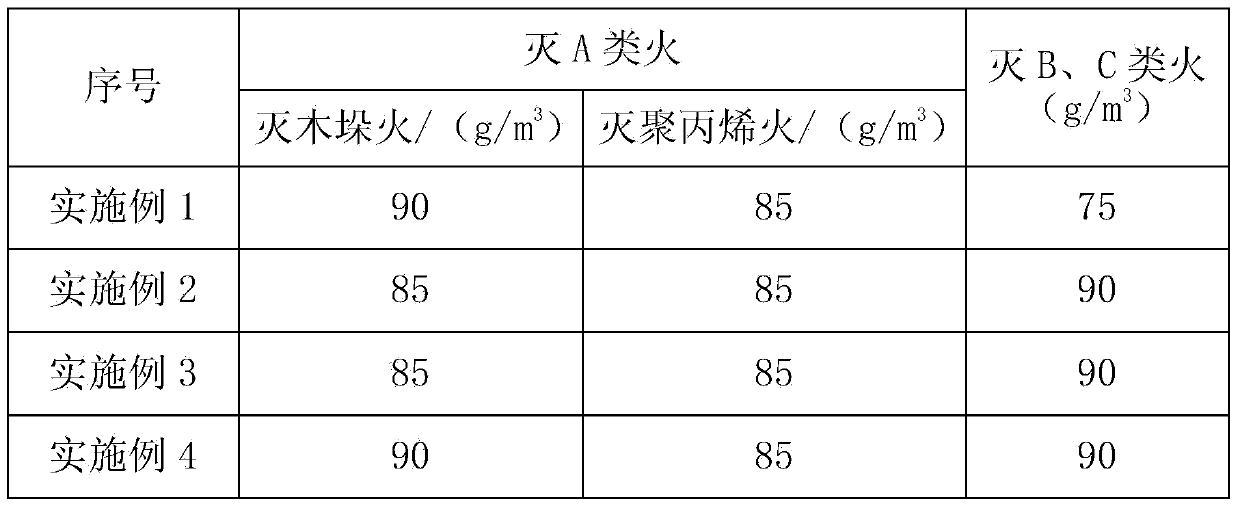

Examples

Embodiment 1

[0021] The preparation of ABC superfine dry powder fire extinguishing agent composite substrate specifically includes the following steps:

[0022] Step 1, each raw material component is taken by weighing 1 ton of total raw material: 150kg of ammonium sulfate (90% particle diameter is less than or equal to 50 μm), and the remainder is type I ammonium polyphosphate (90% particle diameter is less than or equal to 30 μm, degree of polymerization 50 ~200).

[0023] In step 2, the ammonium sulfate and type I ammonium polyphosphate are dried separately to ensure that the moisture content is less than or equal to 0.20%.

[0024] In step 3, add the dried ammonium sulfate and type I ammonium polyphosphate into the high mixer and mix them evenly to obtain the intermediate material A.

[0025] In step 4, the intermediate material A is pulverized and classified by a supersonic airflow mill to obtain a composite base material of ABC superfine dry powder fire extinguishing agent with 90% p...

Embodiment 2

[0027] The preparation of ABC superfine dry powder fire extinguishing agent composite substrate specifically includes the following steps:

[0028] Step 1, each raw material component is taken by weighing 1 ton of total raw material: 200kg of ammonium sulfate (90% particle diameter is less than or equal to 50 μm), and the remainder is type I ammonium polyphosphate (90% particle diameter is less than or equal to 30 μm, degree of polymerization 50 ~200).

[0029] In step 2, the ammonium sulfate and type I ammonium polyphosphate are dried separately to ensure that the moisture content is less than or equal to 0.20%.

[0030] In step 3, add the dried ammonium sulfate and type I ammonium polyphosphate into the high mixer and mix them evenly to obtain the intermediate material A.

[0031] In step 4, the intermediate material A is pulverized and classified by a supersonic airflow mill to obtain a composite base material of ABC superfine dry powder fire extinguishing agent with 90% p...

Embodiment 3

[0033] The preparation of ABC superfine dry powder fire extinguishing agent composite substrate specifically includes the following steps:

[0034] Step 1, each raw material component is taken by weighing 1 ton of total raw material: 220kg of ammonium sulfate (90% particle diameter is less than or equal to 50 μm), and the remainder is type I ammonium polyphosphate (90% particle diameter is less than or equal to 30 μm, degree of polymerization 50 ~200).

[0035] In step 2, the ammonium sulfate and type I ammonium polyphosphate are dried separately to make the moisture content less than or equal to 0.20%.

[0036] In step 3, add the dried ammonium sulfate and type I ammonium polyphosphate into the high mixer and mix them evenly to obtain the intermediate material A.

[0037] In step 4, the intermediate material A is pulverized and classified by a supersonic airflow mill to obtain a composite base material of ABC superfine dry powder fire extinguishing agent with 90% particle si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com