Patents

Literature

39results about How to "Guaranteed to separate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

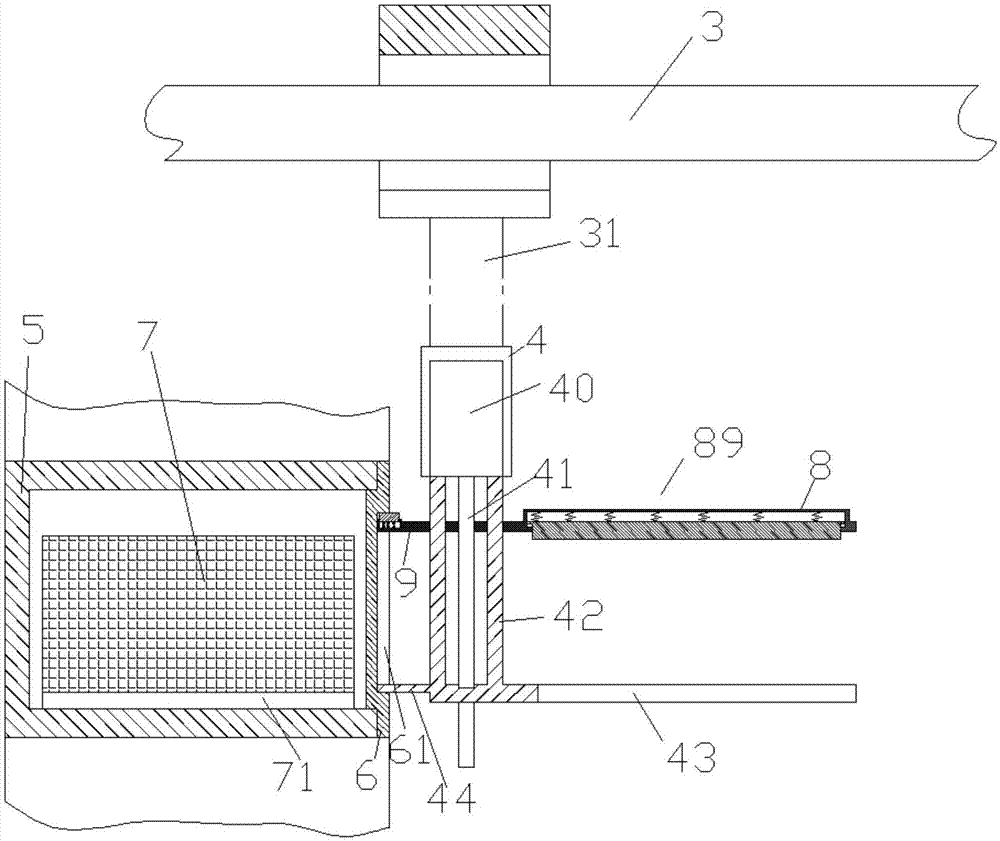

Intelligent storing and fetching system for warehouse logistics

InactiveCN105383848AGuaranteed to separateSimplify structural complexityStorage devicesLogistics managementEngineering

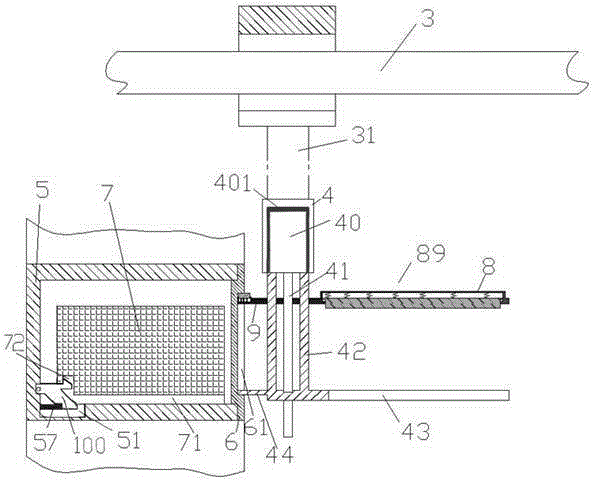

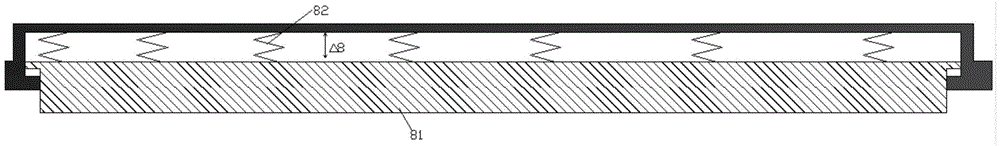

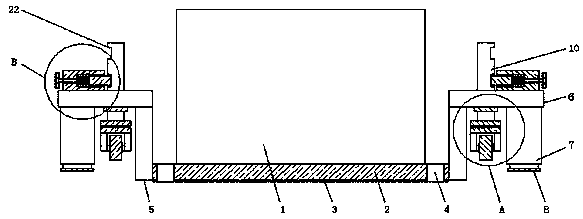

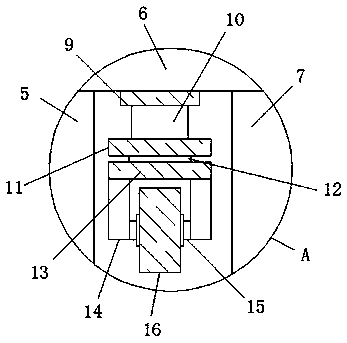

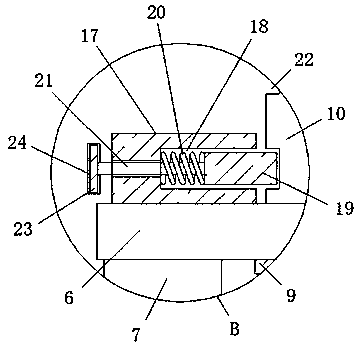

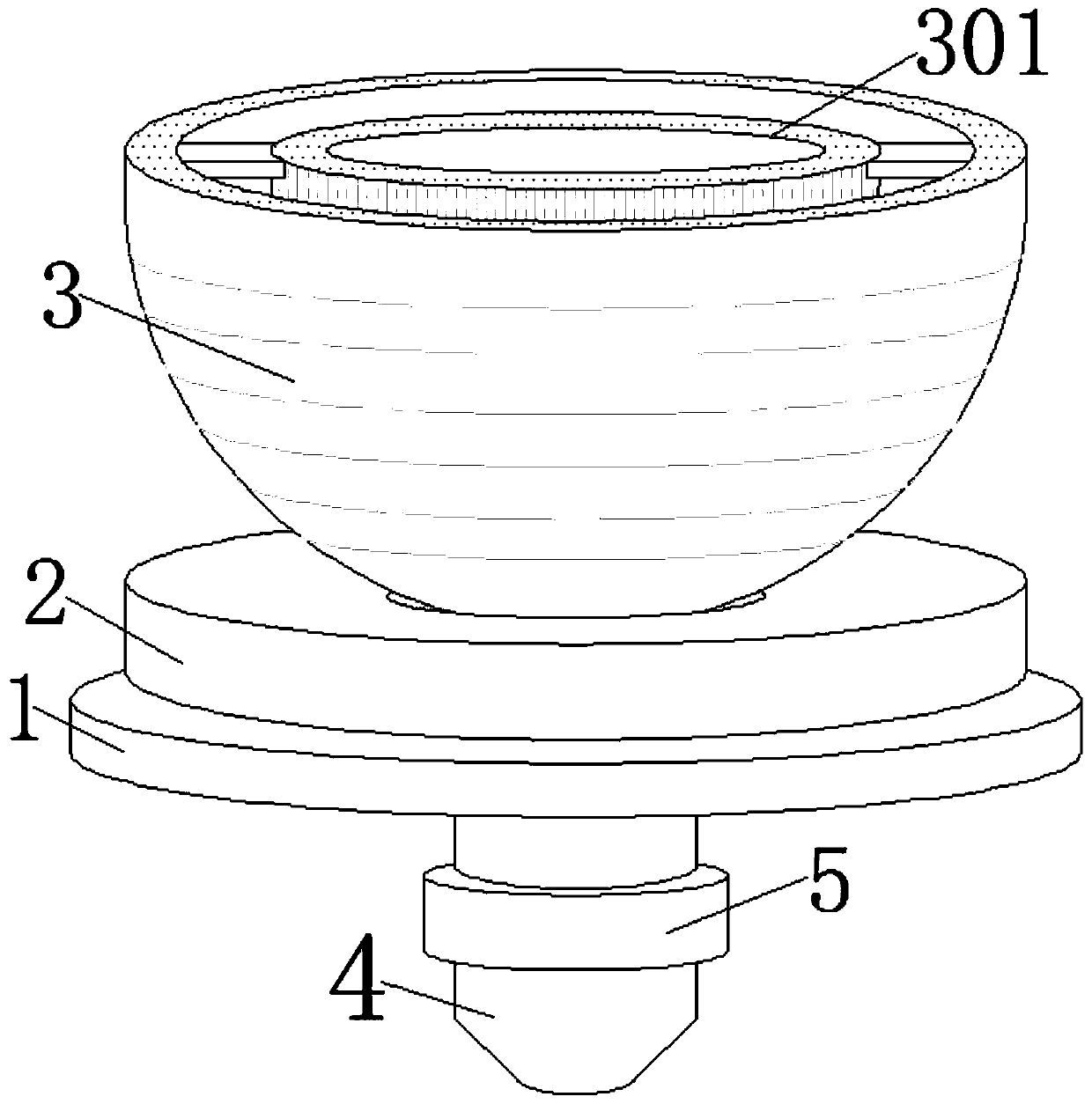

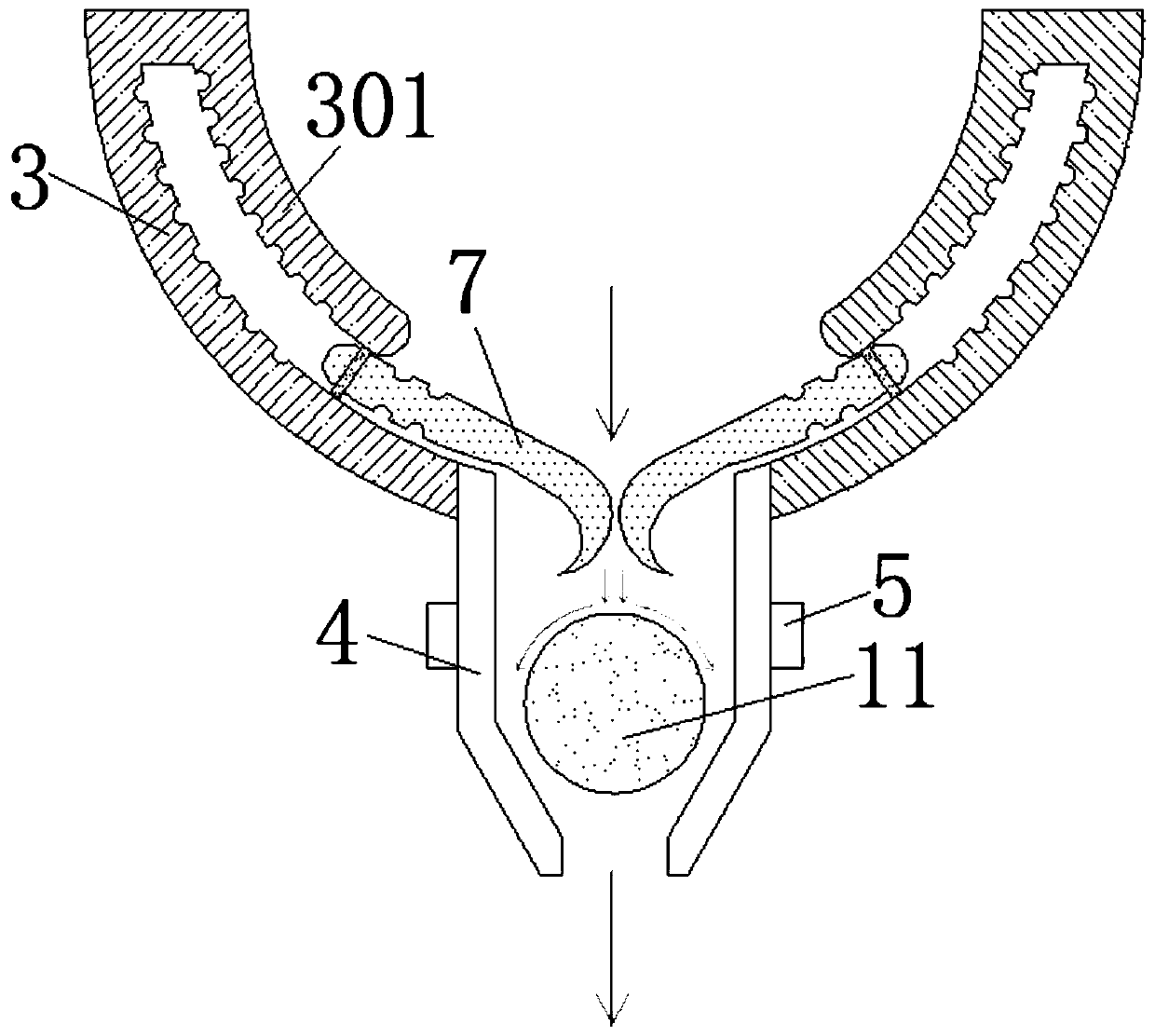

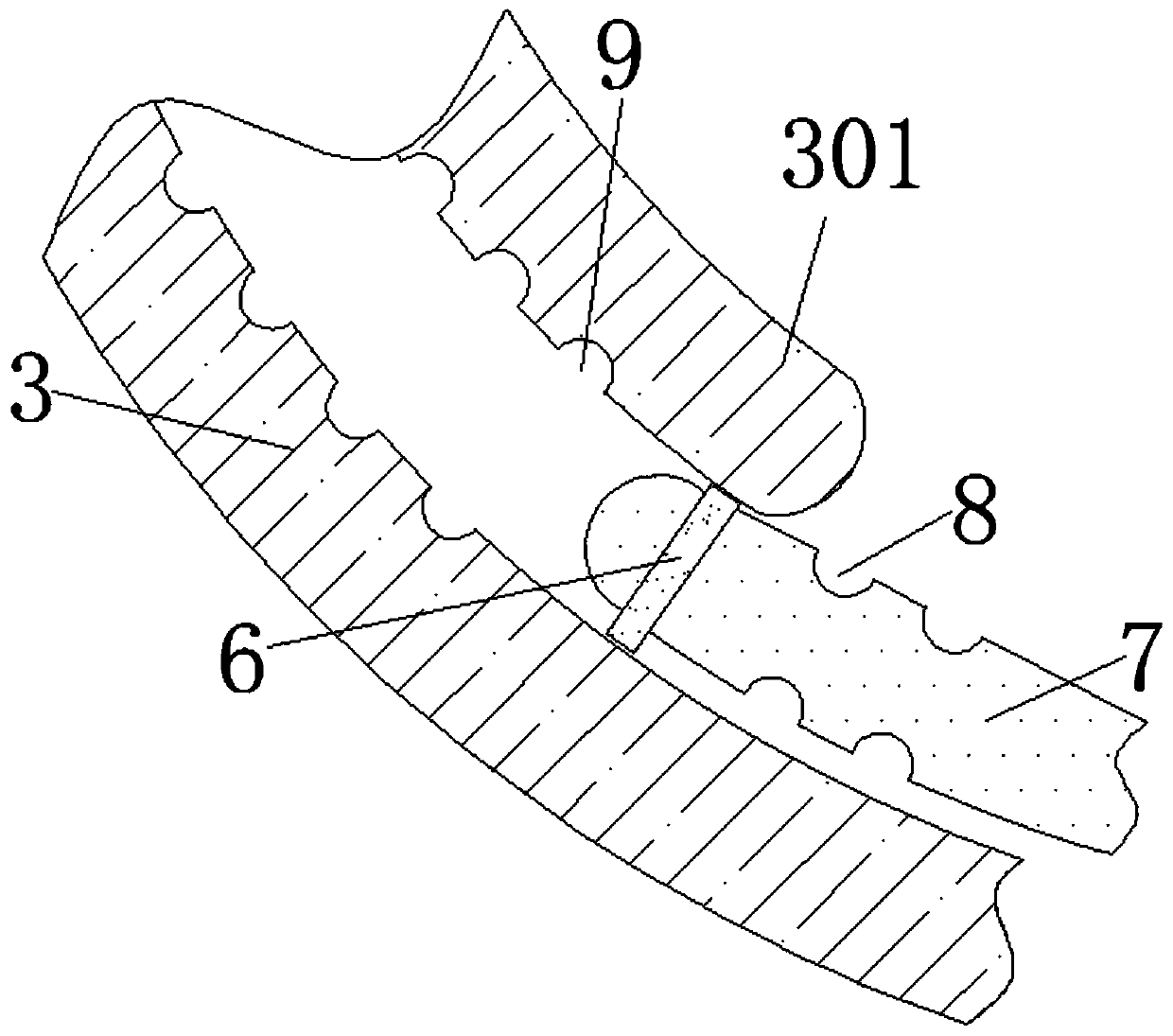

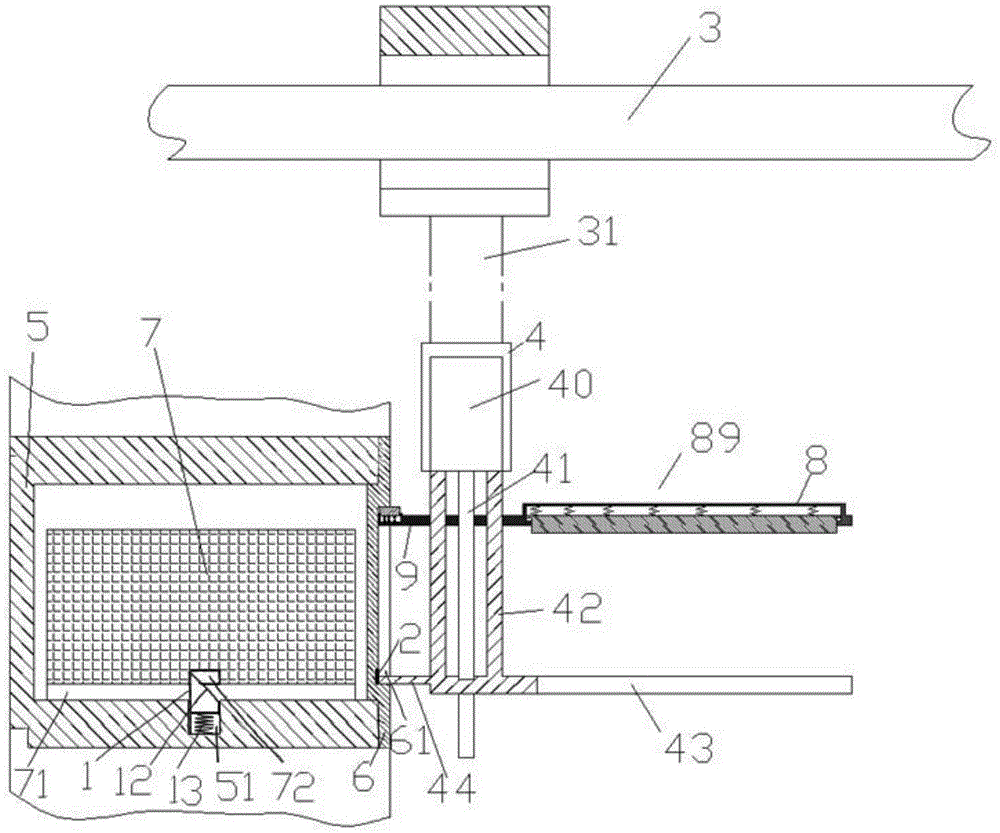

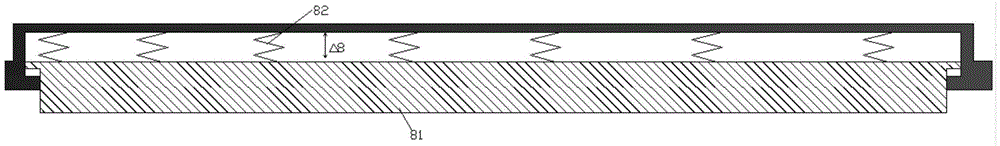

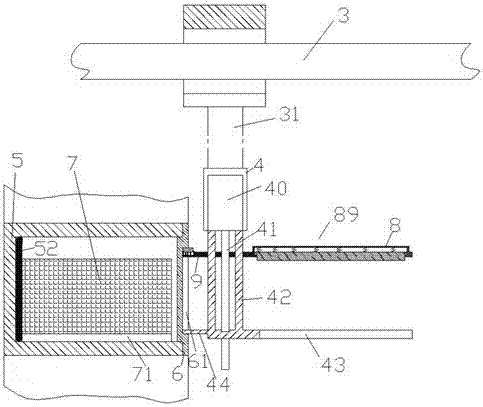

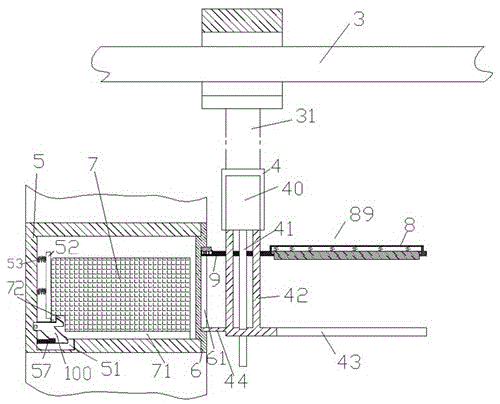

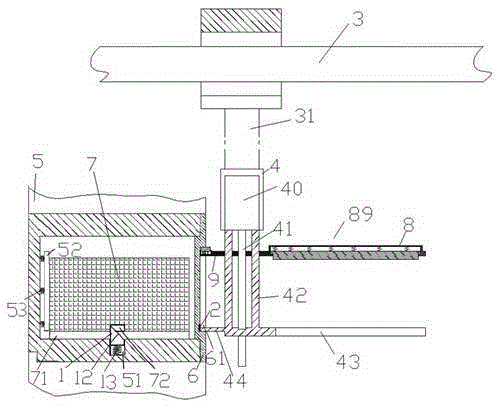

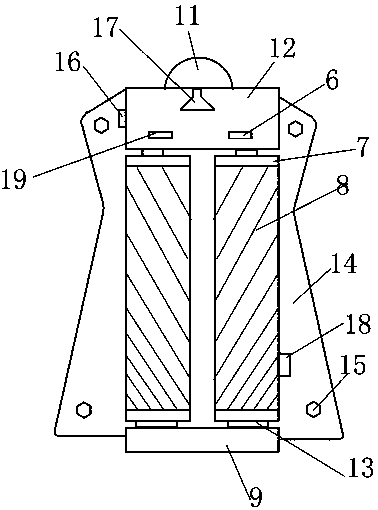

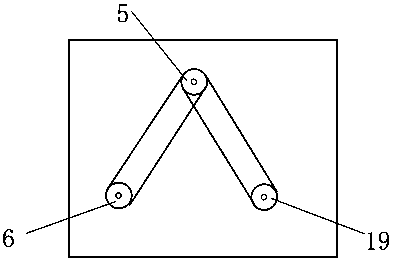

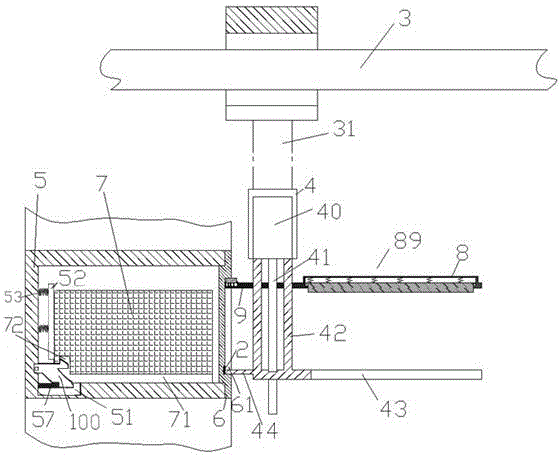

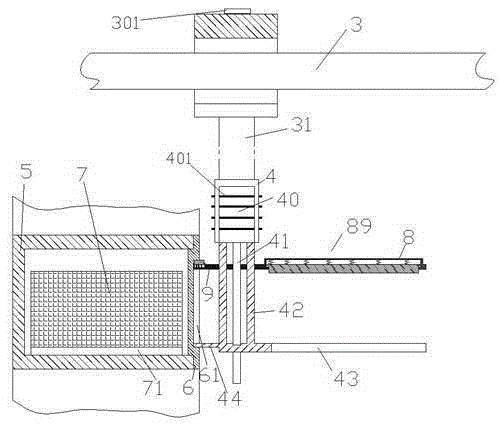

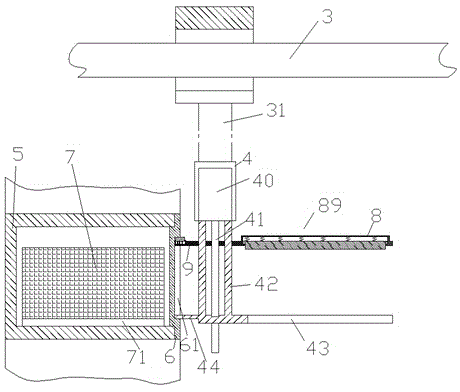

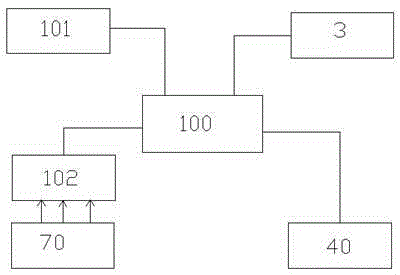

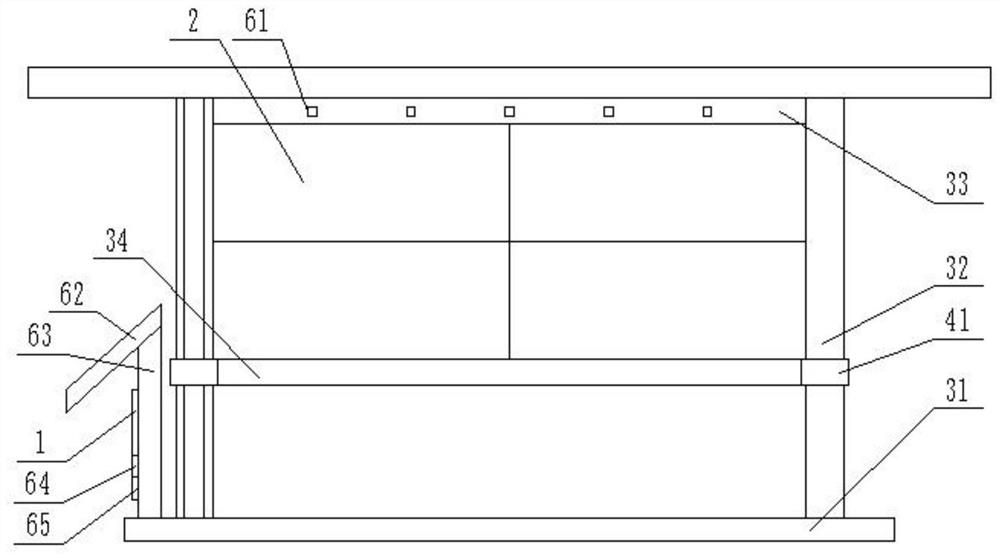

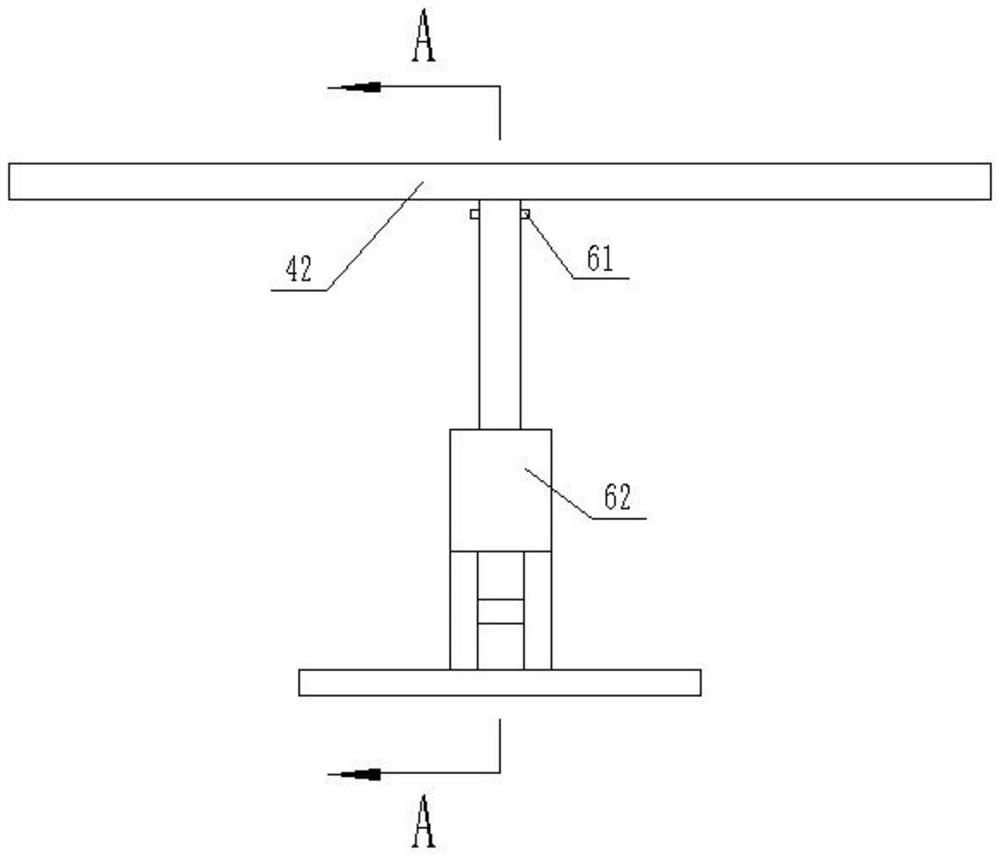

An intelligent storing and fetching system for warehouse logistics comprises a control device (100), a warehouse cabinet body device, a locking device and a material transporting device, wherein the warehouse cabinet body device comprises a plurality of unit cabinets (5) used for containing material boxes (7) with multiple fetching grooves (71) in the bottom faces; an openable covering lid (6) with a holding groove (61) in the outer surface is mounted in a storing and fetching opening of each unit cabinet (5); the material transporting device comprises a driving mechanism (3) and a material box operating device, and the material box operating device is connected with the driving mechanism (3) through a connection rod (31) extending in the vertical direction.

Owner:吴美俊

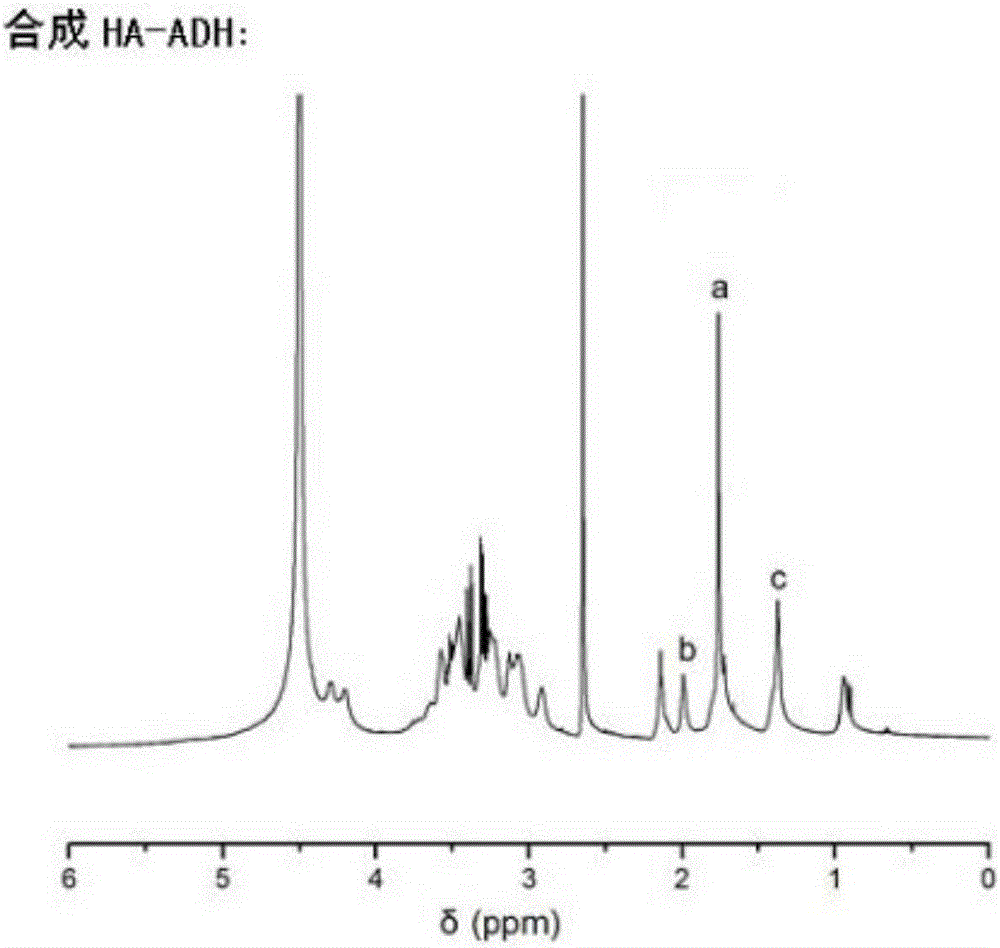

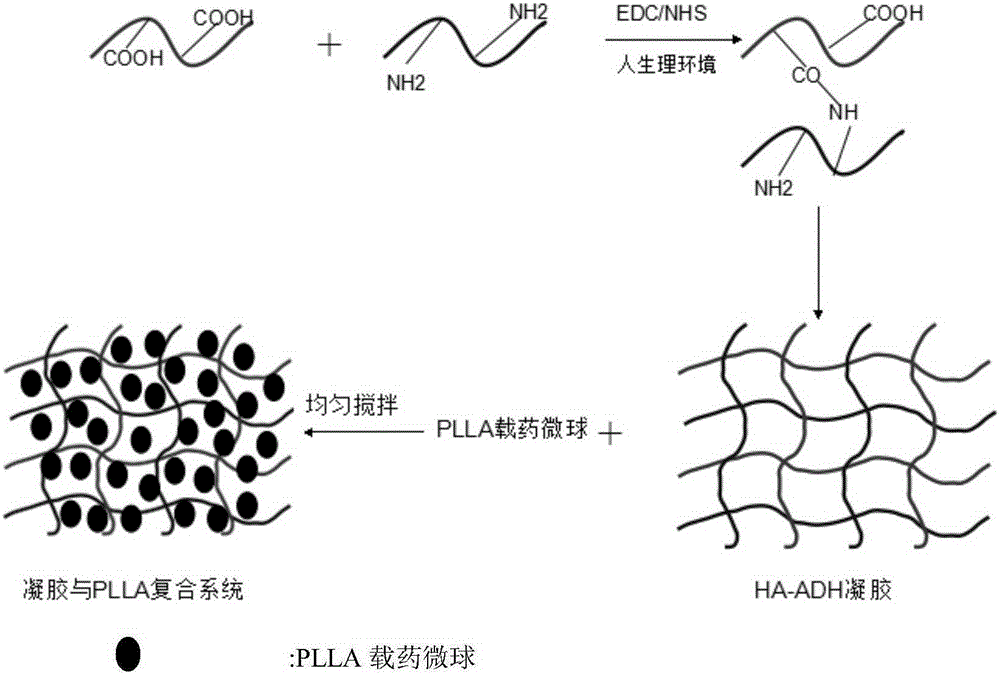

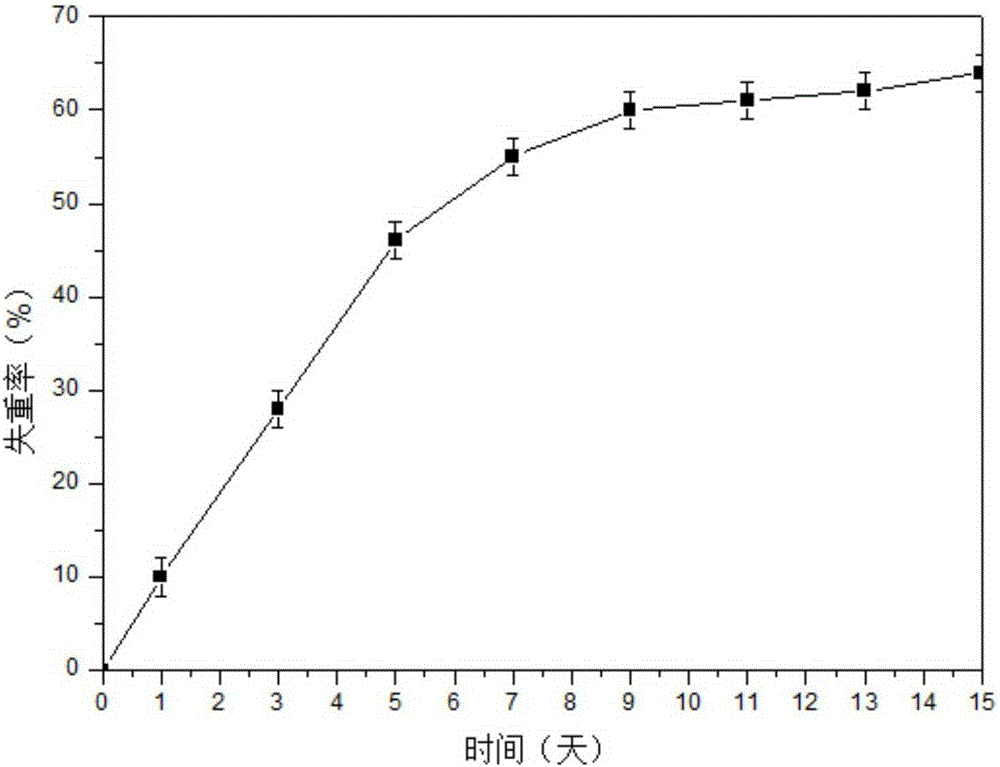

Growth factor porous micro-sphere compound system coated by injectable hydrogel

InactiveCN105288594AHigh drug loadingImprove stabilityNervous disorderPeptide/protein ingredientsCompound systemHyaluronic acid

The invention relates to the preparation of a growth factor porous micro-sphere compound system coated by an injectable hydrogel. The preparation is characterized by comprising a first component, namely HA-ADH sol obtained by cross-linking of hyaluronic acid (HA) and adipic dihydrazide (ADH), and polylactic acid (PLLA) porous micro-spheres which are carried with growth factors and loaded in the first component. The compound system is capable of degrading and slowly releasing the growth factors under physiological conditions, so that the slow releasing of the growth factors in a body is realized, and the problems that the growth factors are released too fast and an action period is too short are solved, thereby reaching the effect of neural restoration.

Owner:WUHAN UNIV OF TECH

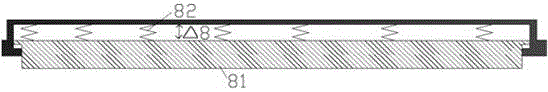

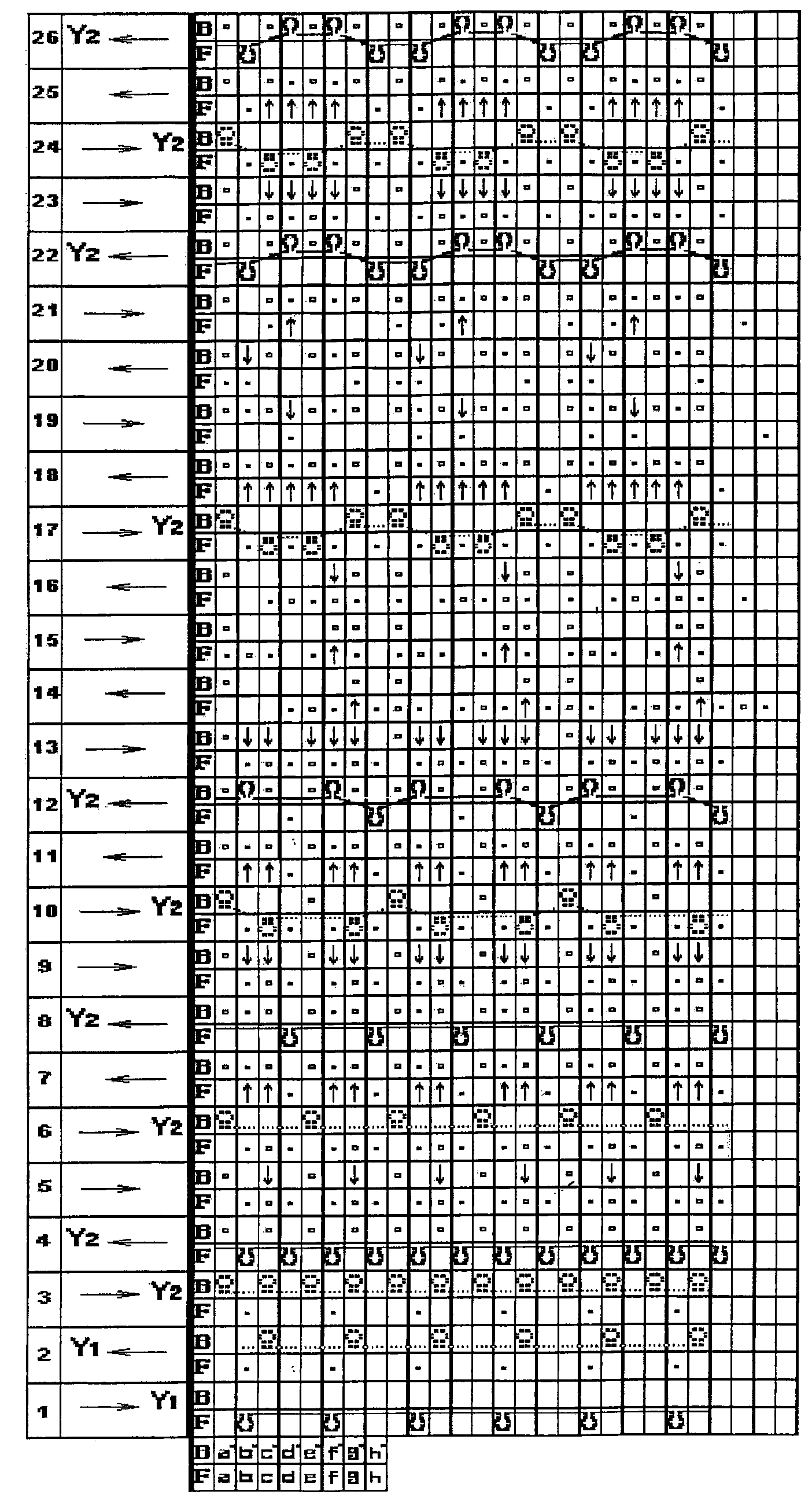

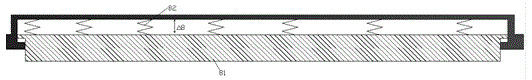

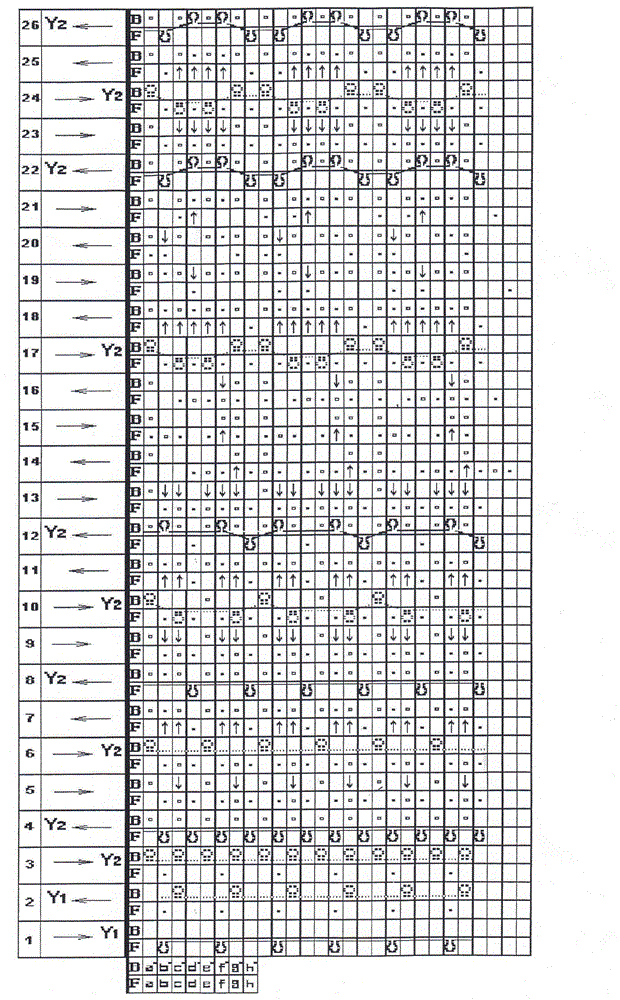

Method for knitting 2*2 rib stitch textile through two-needle bar flat knitting machine

The invention relates to a method for knitting a 2*2 rib stitch textile through a two-needle bar flat knitting machine and belongs to the technical field of a knitting method in a flat knitting machine. According to the method, cylindrical knitting in an alternate needle mode is performed on front and rear needle bars of the two-needle bar knitting machine; when a front piece is knitted, odd needles or even needles of the front needle bar are adopted; when a rear piece is knitted, the odd or even needles of the rear needle bar are adopted; during a knitting process, the knitting in the alternating mode that one line is woven at the front and one line is woven at the back is adopted; the method is characterized in that at least two yarn nozzles are used; the two yarn nozzles are respectively represented by Y1 and Y2; Y1 is used for representing waste yarns or drawn yarns; Y2 is used for representing main yarns; eight needles are taken as one circle of rib stitch; the needles on the front needle bar are successively named as a, b, c, d, e, f, g, h and so on from left to right; the needles on the rear needle bar are successively named as a', b', c' d', e', f', g' h' and so on from left to right. The front and rear cut pieces are kept separated; the rib stitch starting opening is compact and attractive; the quality of the rib stitch textile is increased.

Owner:JIANGSU JINLONG TECHNOLOGY CO LTD

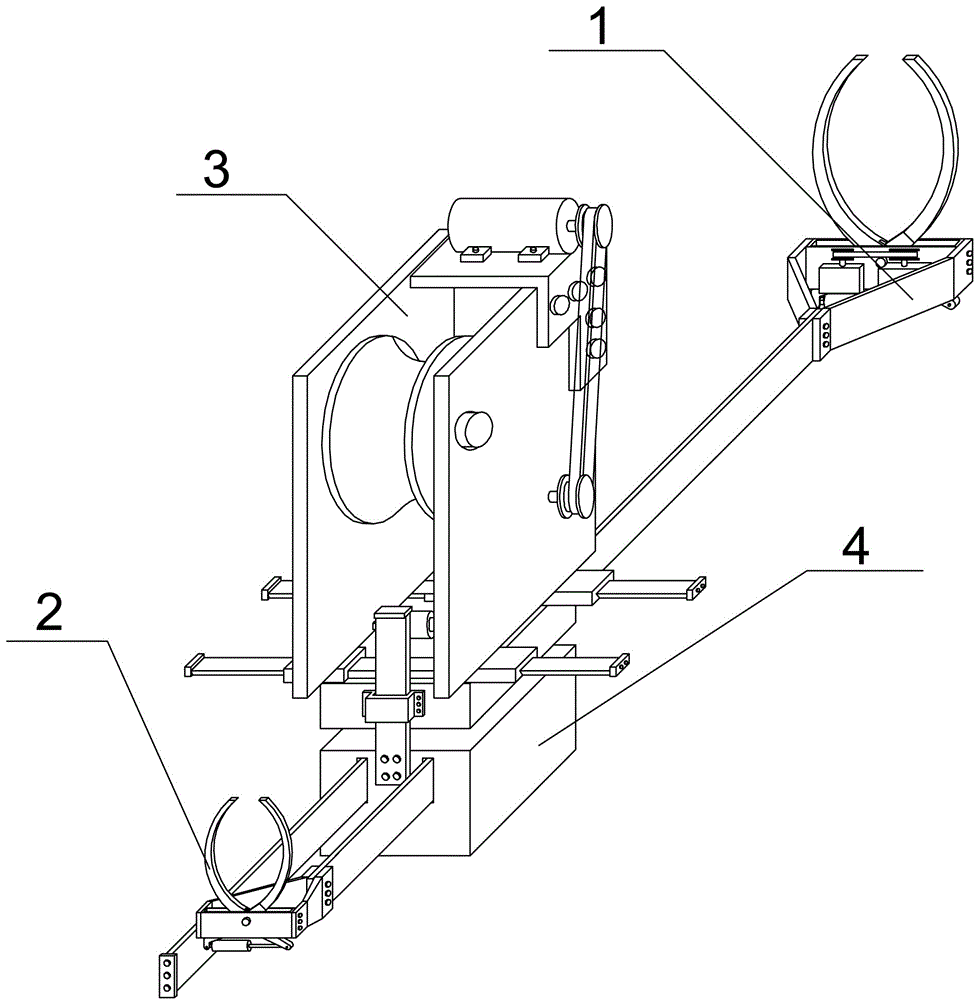

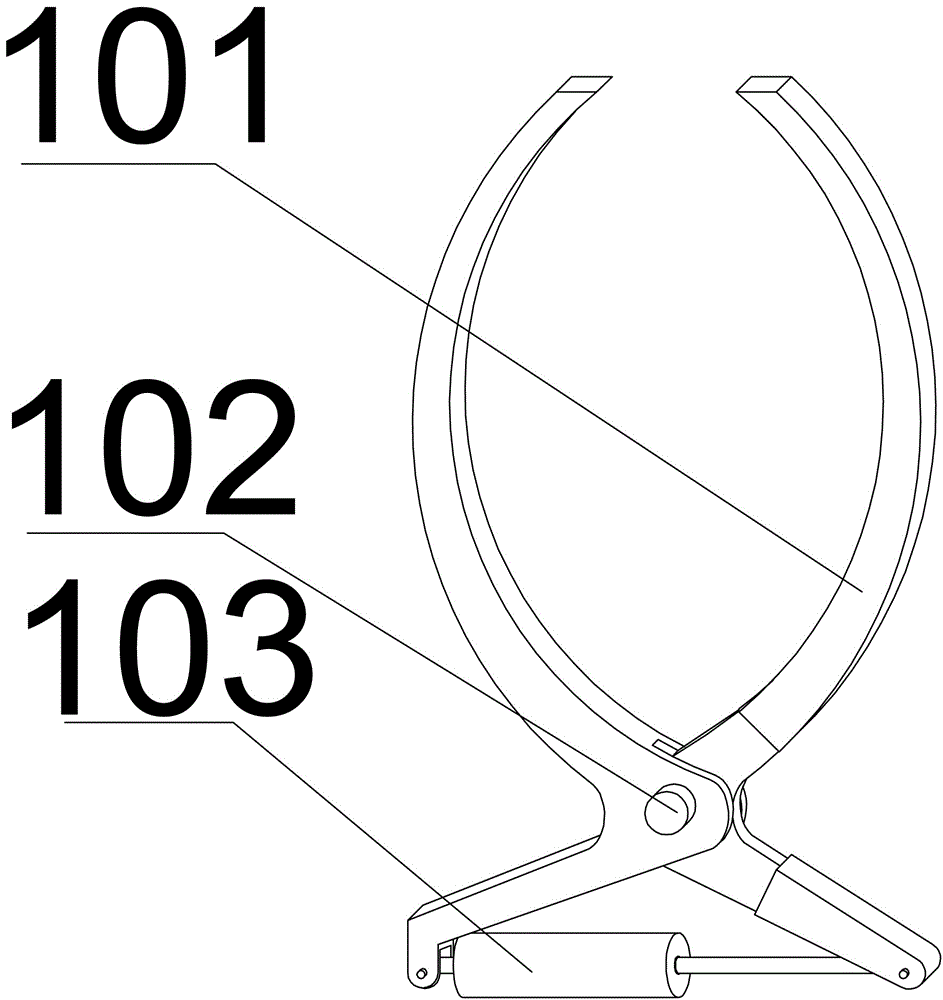

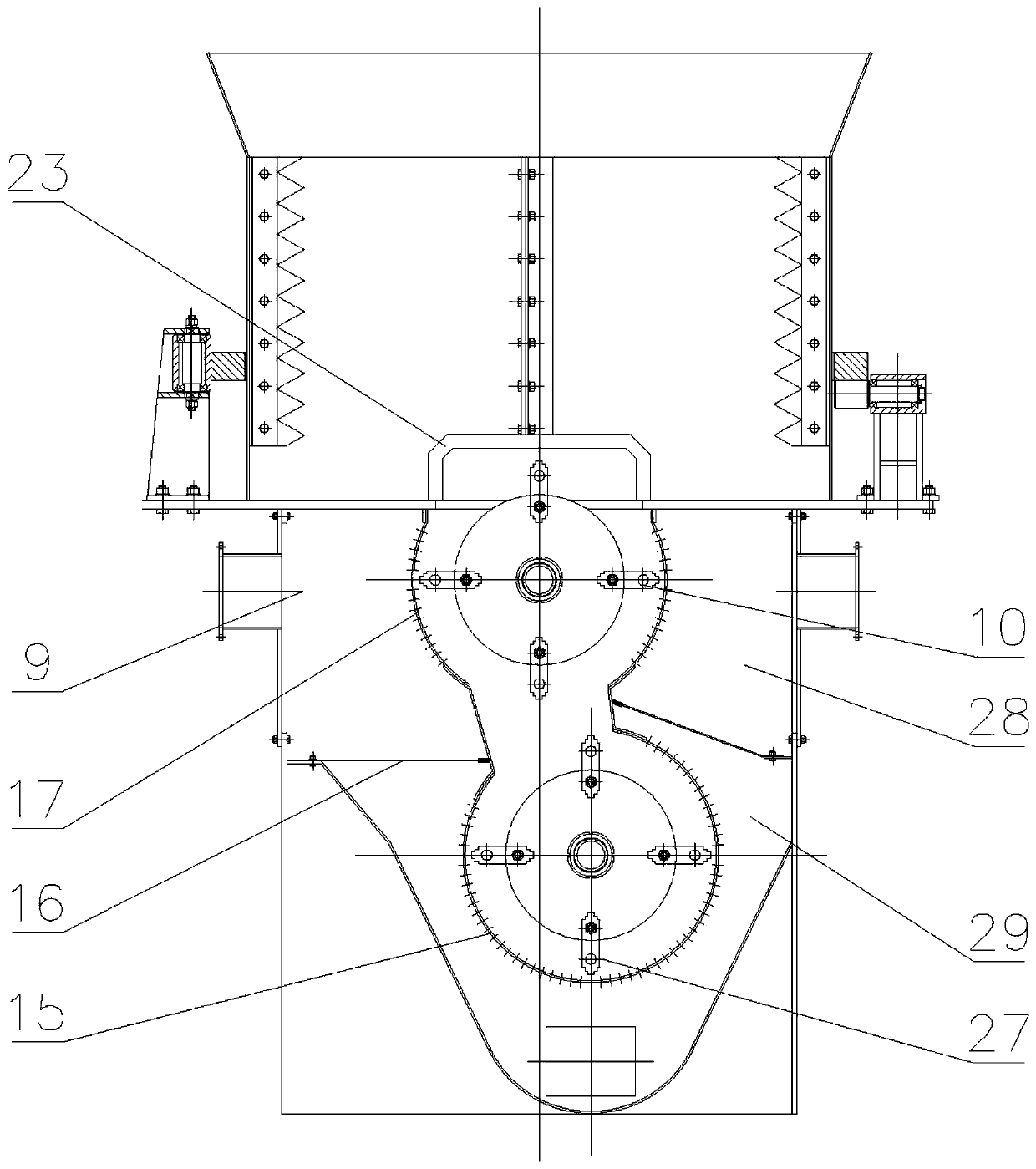

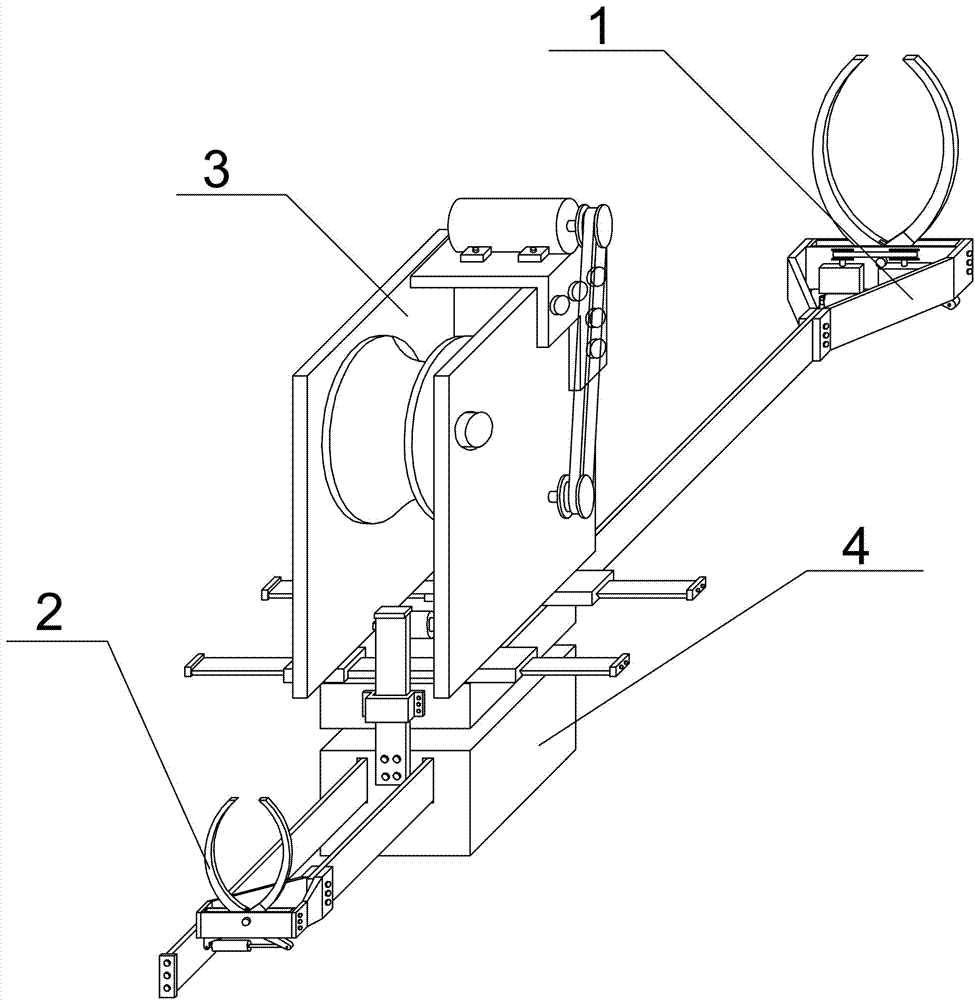

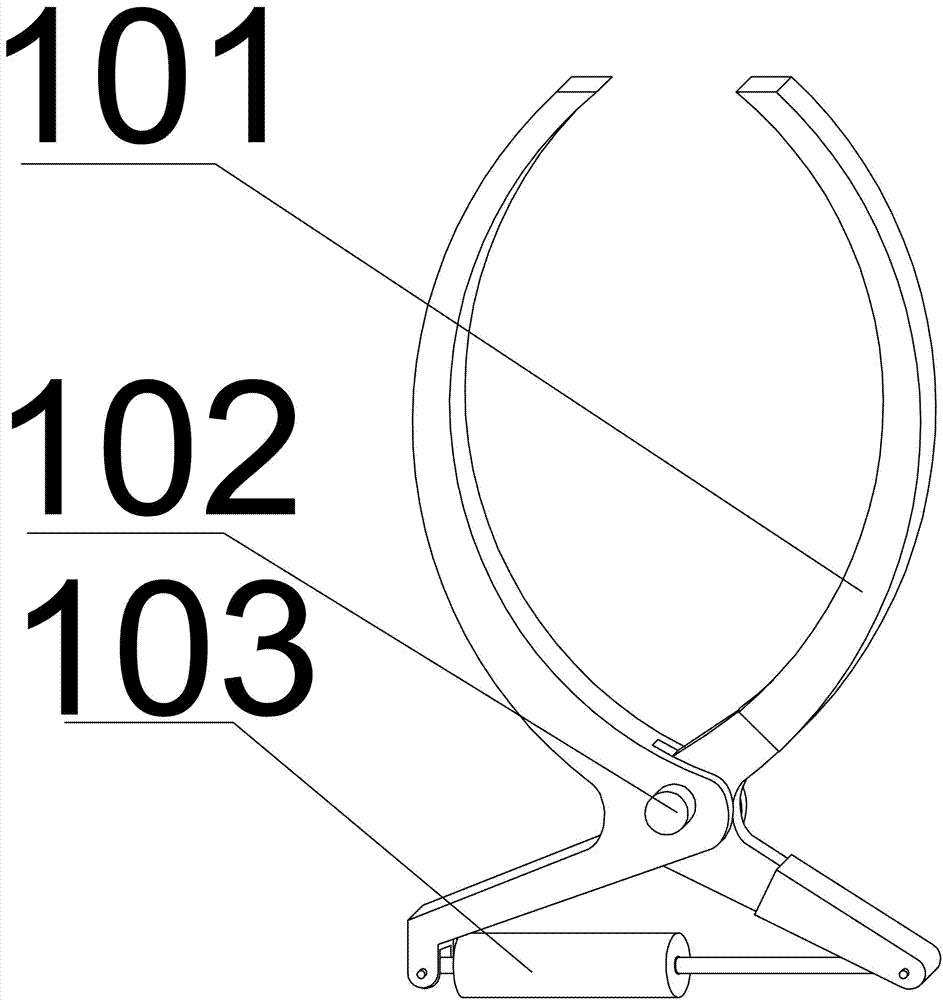

Single-transmission line deicing robot and method

ActiveCN105870866AImprove securityImprove manual workOverhead installationHydraulic cylinderComputer engineering

The invention discloses a single-transmission line deicing robot and method. The single-transmission line deicing robot comprises a first gripper, wherein the first gripper is matched with a motion mechanism; a second gripper is arranged in the motion mechanism; a deicing mechanism is arranged at the top part of the motion mechanism; the first gripper comprises arc-shaped grab bars; the middle parts of two arc-shaped grab bars are connected through a pin shaft; the bottom ends of the two arc-shaped grab bars are fixedly connected through a first hydraulic cylinder; the arc-shaped grab bars, the pin shaft and the first hydraulic cylinder are arranged in a first rectangular box body; first connecting rods are fixed at two side surfaces of the first rectangular box body respectively; the tail ends of the two first connecting rods are connected with long racks respectively; and a first hydraulic drive device is fixed on the side surface of the first rectangular box body. The robot can be automatically elevated when encountering an obstacle and stretch a clamping device to pass cross the obstacle; and meanwhile, ice blocks on the line can be effectively eliminated to achieve the deicing target.

Owner:CHINA THREE GORGES UNIV

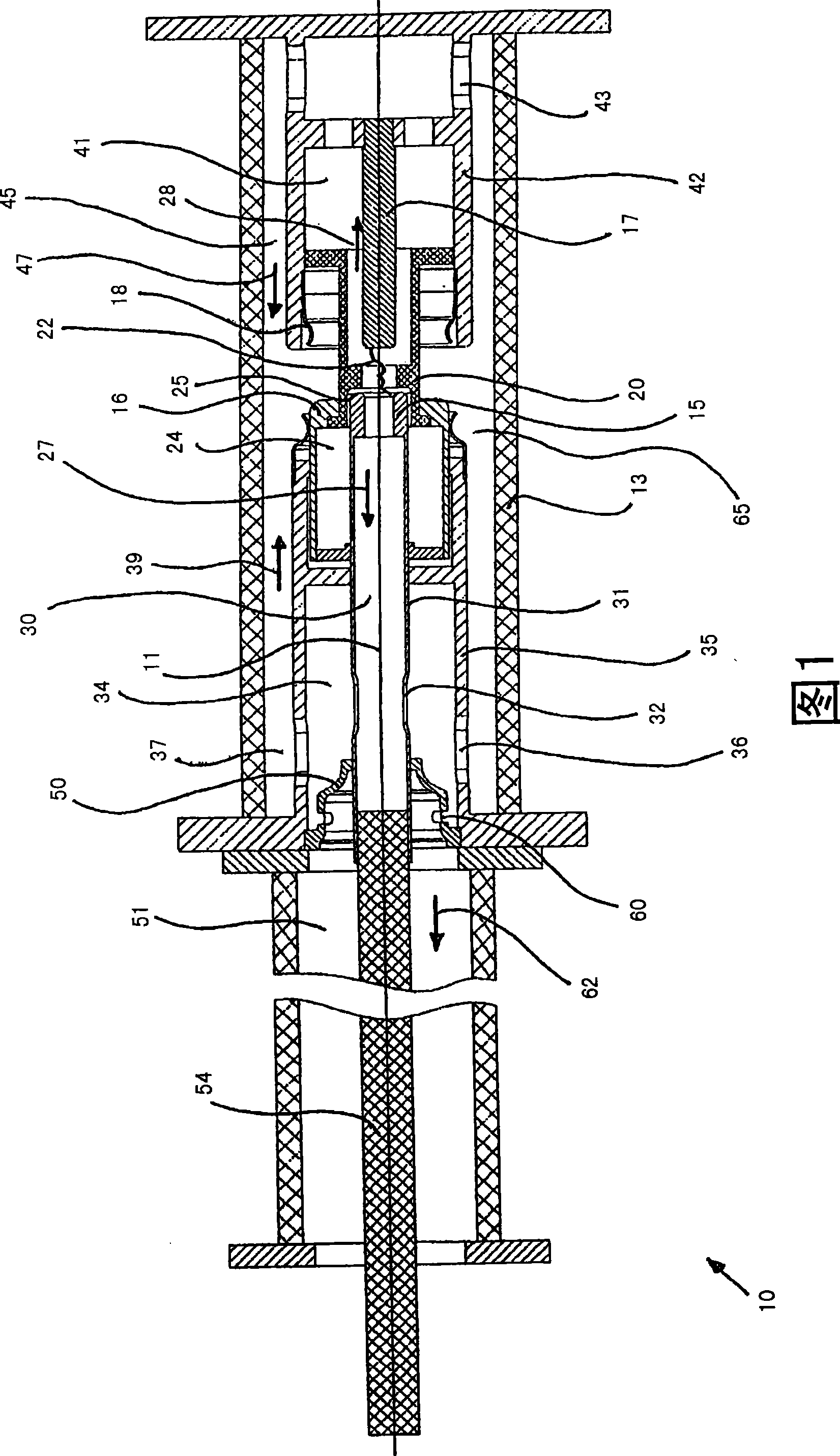

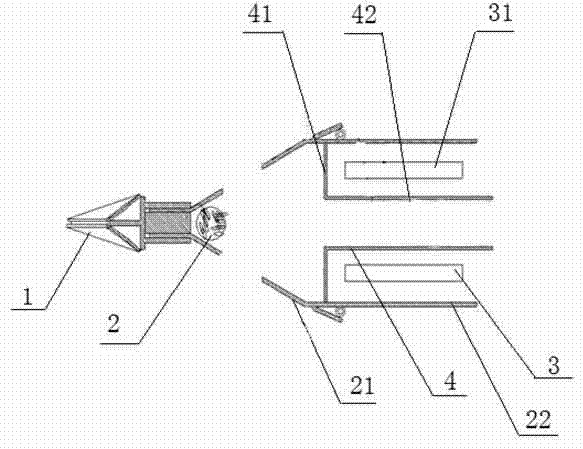

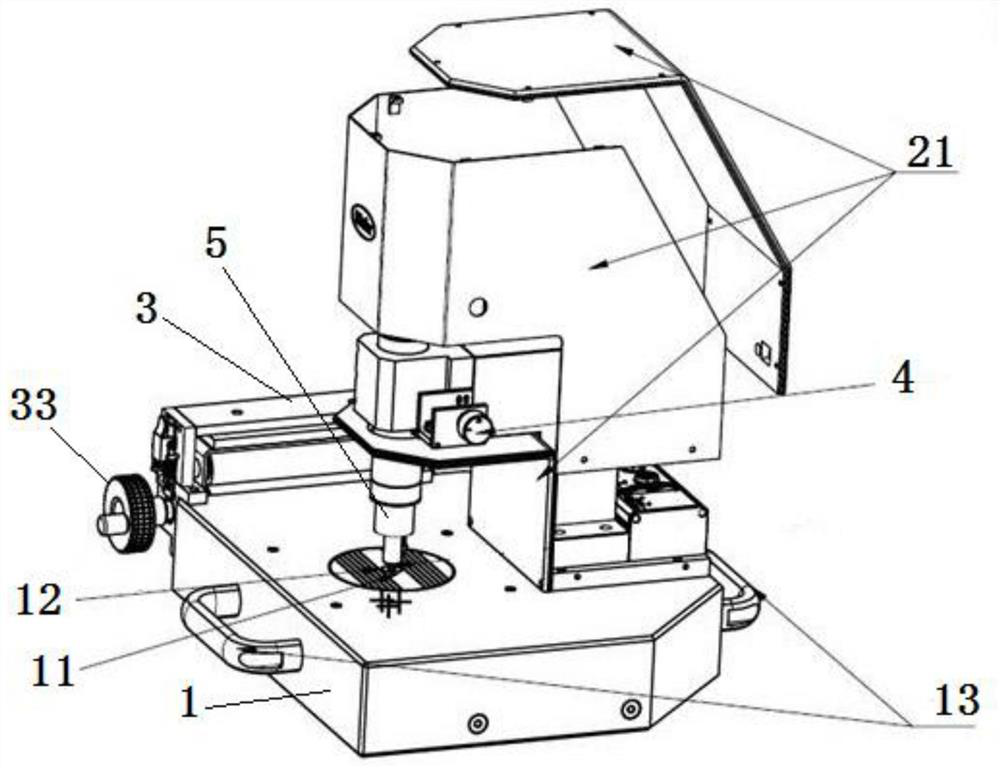

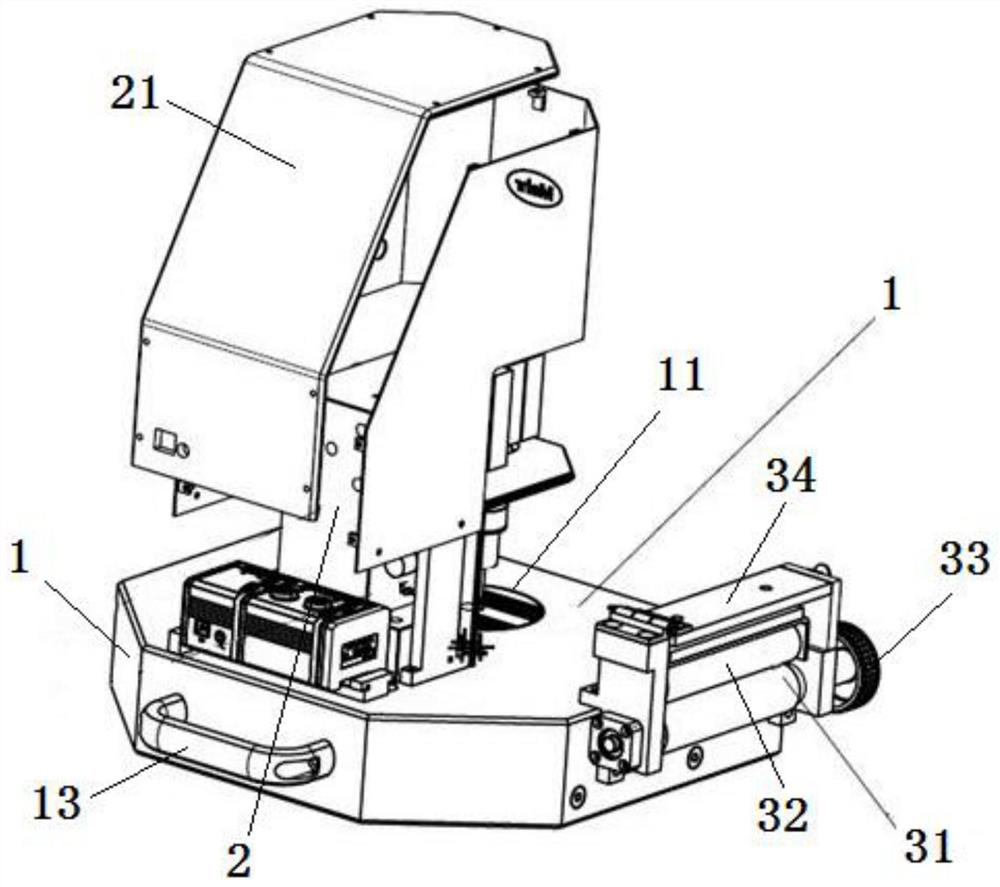

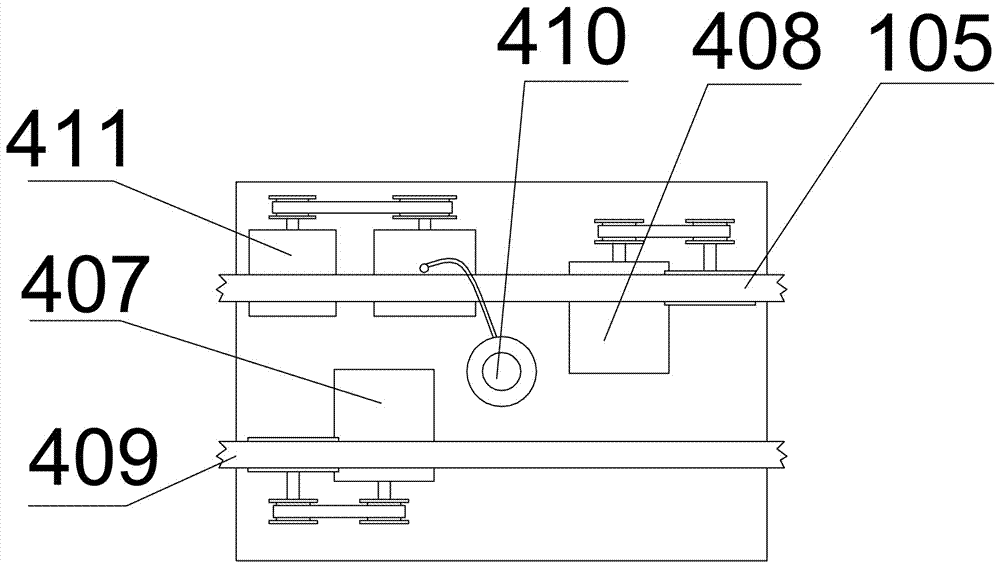

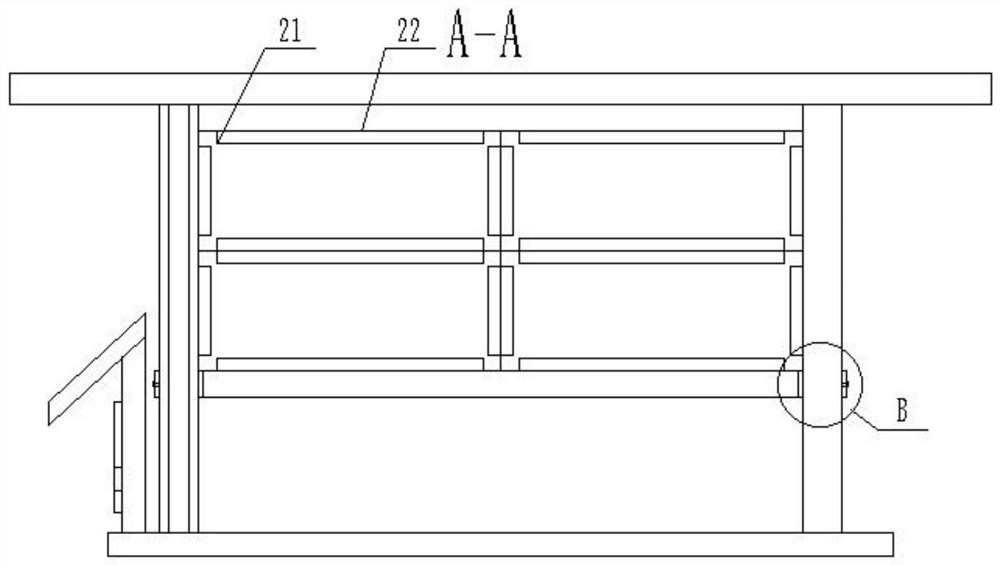

Intelligent warehouse logistics system provided with locking pins

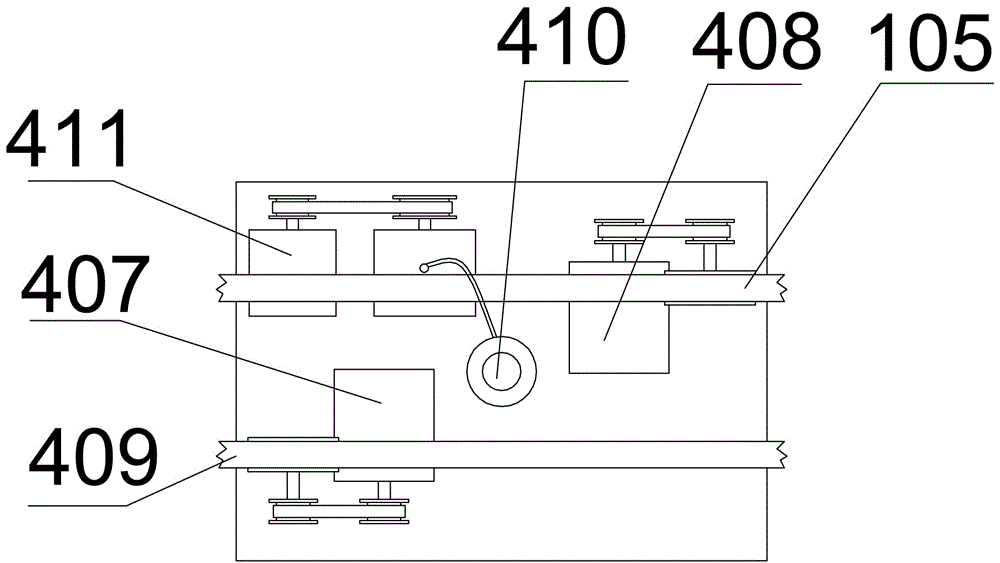

InactiveCN105416951AGuaranteed to separateSimplify structural complexityStorage devicesLogistics managementMaterial transport

An intelligent warehouse logistics system provided with locking pins comprises a control device (100), a storage cabinet device, a locking device and a material transport device, wherein the storage cabinet device comprises a plurality of unit cabinets (5) used for containing material boxes (7), a plurality of grabbing grooves (71) are formed in the bottom surface of each material box (7), and openable covers (6) with holding grooves (61) formed in the outer surfaces are installed at storing-fetching ports of the unit cabinets (5); the material transport device comprises a driving mechanism (3) and a material box operating device which is connected with the driving mechanism (3) through a connecting rod (31) which extends in the vertical direction.

Owner:叶绍靖

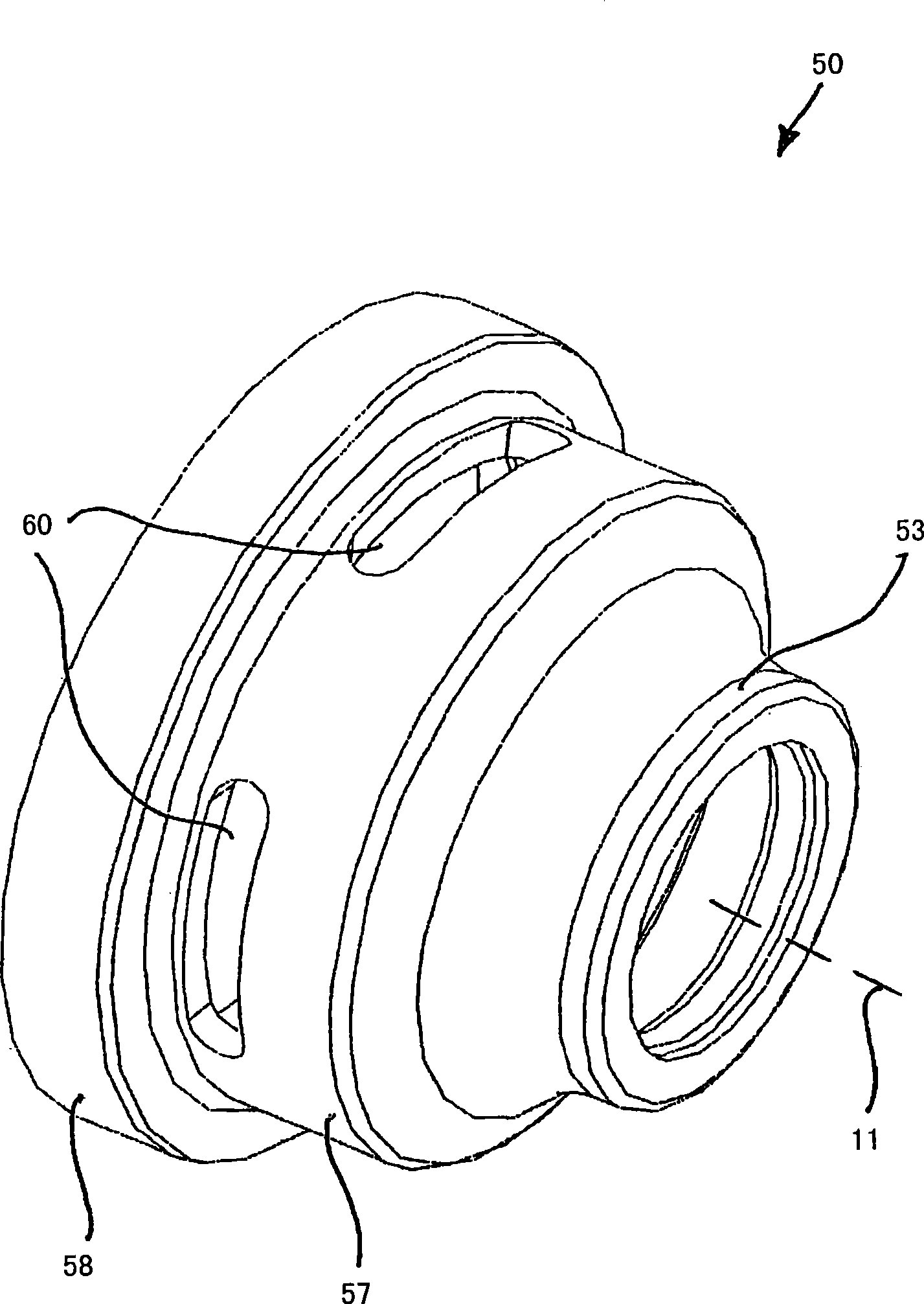

High voltage power switch

InactiveCN101425426AGuaranteed to separateCross-sectional area can varyHigh-tension/heavy-dress switchesAir-break switchesEngineeringHigh pressure

Described is a high-voltage circuit breaker provided with two opposite-arranged arcing contacts, which are surrounded by an insulating nozzle. Furthermore provided are two main contacts, arranged opposite each other outside of the insulating nozzle, with respectively one of these contacts being assigned to one of the two arcing contacts. The high-voltage circuit breaker is provided, in at least one embodiment, with at least one device for diverting an insulating gas flow from the region between the two arcing contacts, wherein a respective insulating gas flow is conducted outside of the insulating nozzle and in the direction toward the main contacts. A diverting device is provided, which is equipped with a mechanism for diverting insulating gas from the insulating gas flow that is diverted from the region between the two arcing contacts, such that the two insulating gas flows moving from both directions toward the main contacts have approximately the same effect on the insulating gas that is present in the region of the two main contacts, thereby ensuring that the insulating gas is not displaced significantly in this region.

Owner:GENERAL ELECTRIC TECH GMBH

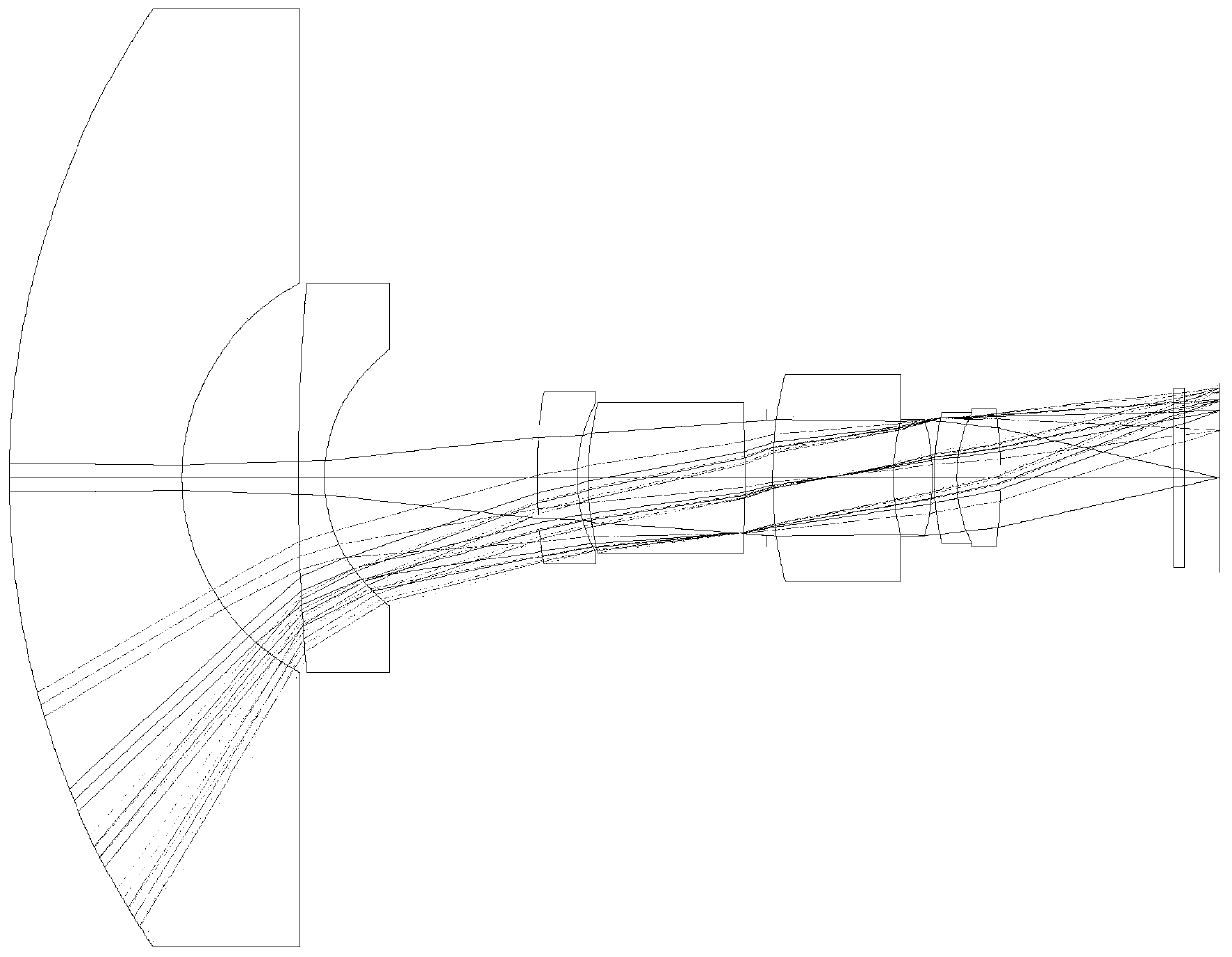

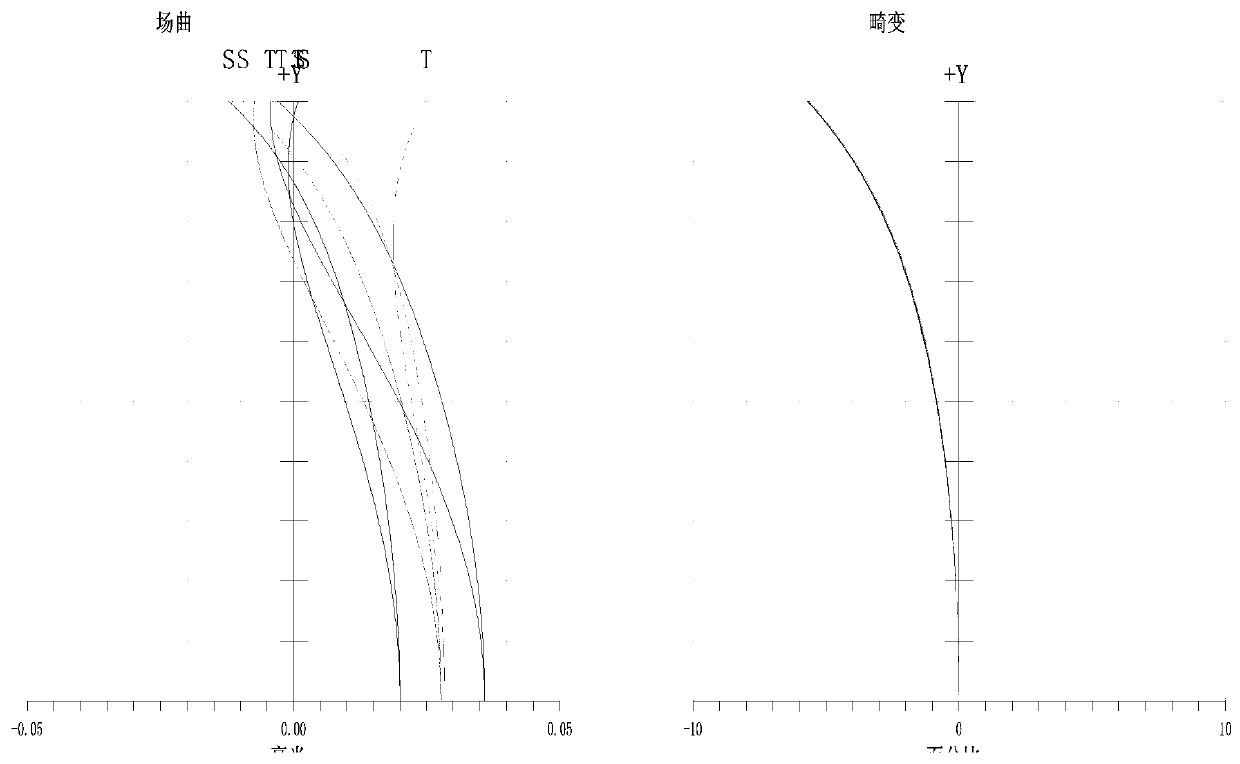

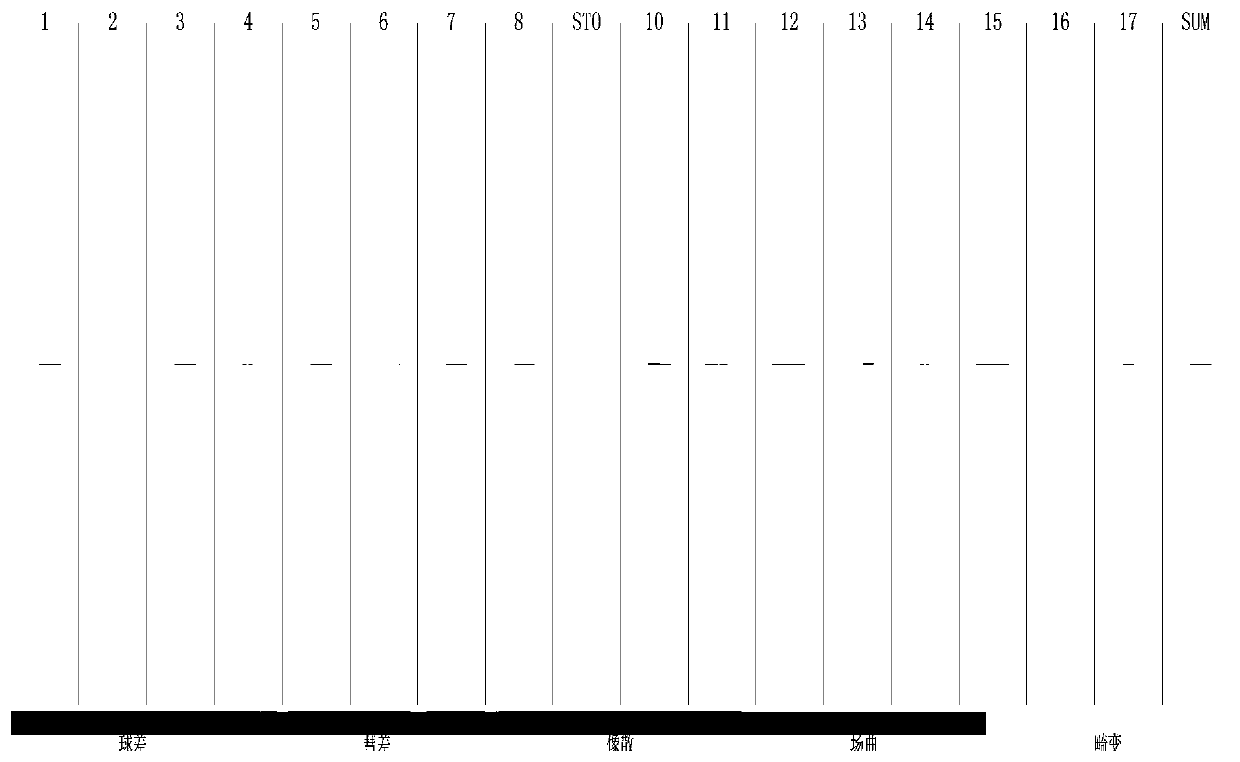

Fisheye lens

PendingCN111474690AEnhance edge illuminationGood uniformity of illuminationOptical elementsOphthalmologyThermal distortion

The invention relates to the field of lenses and particularly relates to a fisheye lens. The fisheye lens comprises a front lens group, a diaphragm and a rear lens group which are sequentially arranged in the incident direction of light, wherein the ratio of the focal length f of the fisheye lens to the focal length f1 of the front lens group is -4.2 <f / f1<-3.6, and the ratio of the focal length fof the fisheye lens to the focal length f2 of the rear lens group is 3.4< f / f2< 5.5. The fisheye lens is advantaged in that the F-thermal distortion of the fisheye lens can reach +10%, the field angle is larger than 190 degrees, the application spectrum range is 400-950 nm, the center is 10 pixels / degrees, an edge is larger than 19.5 pixels / degrees, the pixel size of a sensor is larger than 1.5 microns, and the method can be applied to the environment with high edge image requirements.

Owner:FOCTEK PHOTONICS LNC

Intelligent storage logistics system with locking block

InactiveCN105480631AGuaranteed to separateSimplify structural complexityStorage devicesEngineeringLogistics management

An intelligent storage logistics system with a locking block comprises a control device (100), a storage cabinet device, a locking device and a material conveying device. The storage cabinet device comprises a plurality of unit cabinets (5) used for containing material boxes (7) with a plurality of grabbing grooves (71) in the bottom faces. Shrouds (6) capable of being opened and closed are arranged at taking and storing openings of the unit cabinets (5), wherein control grooves (61) are formed in the outer surfaces of the shrouds (6). The material conveying device comprises a drive mechanism (3) and a material box operation device connected with the drive mechanism (3) through a connecting rod (31) extending in the vertical direction.

Owner:莫钦超

Pipe welding machine convenient to move

InactiveCN109746595AEasy to moveMove quicklyWelding/cutting auxillary devicesAuxillary welding devicesSoftware engineeringPipe welding

The invention relates to the technical field of welding equipment, and discloses a pipe welding machine convenient to move. The pipe welding machine convenient to move comprises a base, fixing columnsare fixedly connected to the two sides of the base, a fixing plate is fixedly connected to the top of each fixing column, and a hydraulic telescopic rod is fixedly connected to the side, far away from the corresponding fixing column, of the bottom of each fixing plate; a circular-ring-shaped column is fixedly connected to an inner cavity of each fixing plate, and a movable column is movably sleeved with each circular-ring-shaped column; and a fixing block is fixedly connected to the top of each fixing plate, a limiting groove is formed in the side, close to the corresponding movable column, of each fixing block, a clamping block is movably sleeved with each limiting groove, and a clamping groove is formed in the side, close to the corresponding fixing block, of each movable column. According to the pipe welding machine convenient to move, through cooperation of the hydraulic telescopic rods, the movable columns, the fixing blocks, the limiting grooves, the clamping blocks and the clamping grooves, each pipe welding machine can be moved only through one person, manpower and time which are consumed when the pipe welding machine is moved are reduced, and the pipe welding machine moving efficiency of workers is improved.

Owner:扬州未来塑胶制品有限公司

Novel feeding device capable of preventing fish feed from being mixed

InactiveCN111406691AGuaranteed to separateAvoid mixingClimate change adaptationPisciculture and aquariaNutritionLiquid storage tank

The invention relates to the technical field of feeds and discloses a novel feeding device capable of preventing a fish feed from being mixed. The novel feeding device comprises a floating plate, wherein a water inlet bin is fixedly arranged on the upper surface of the floating plate; the upper surface of the water inlet bin is in threaded connection with a feeding frame; a material separating frame is fixedly arranged in the feeding frame; a discharge pipe is fixedly arranged at the lower end of the feeding frame; the lower part of the discharge pipe sequentially penetrates through the waterinlet bin and the floating plate and extends below the floating plate to be sleeved with a counterweight. Through cooperative use of the discharge pipe, the counterweight, rubber blocks, movable blocks, water outlet channels, liquid storage tanks and flow guide grooves, loach sucks a nutrient solution while sucking the feed, the nutrient solution is separated from the feed; the feed is prevented from being mixed with the nutrient solution to cause faster evaporation; and meanwhile, the situation that a paste feed will absorb water while in contact with the water and the nutrient solution willbe diluted and cannot reach the original standard of nutrition supplemented for the loach to cause nutrition imbalance of the prepared fish feed is also avoided.

Owner:陈芬芬

Intelligent warehouse logistics access system

InactiveCN105416955AGuaranteed to separateSimplify structural complexityStorage devicesLogistics managementEngineering

The invention relates to an intelligent warehouse logistics access system, comprising a control device (100), a warehousing cabinet device, a locking device and a material transportation device, wherein the warehousing cabinet device comprises a plurality of unit cabinets (5) used for holding materials boxes (7), a plurality of grabbing grooves (71) are formed in the bottom surfaces of the material boxes, openable cover caps (6) are arranged at the access ports of the unit cabinets (5), and holding grooves (61) are formed in the outer surfaces of the openable cover caps (6); and the material transportation device comprises a driving mechanism (3) and a material box operating device connected with the driving mechanism (3) by a connecting rod (31) extending in the vertical direction.

Owner:梁群清

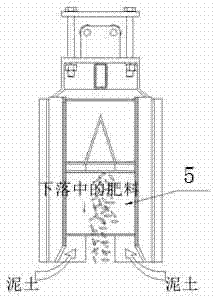

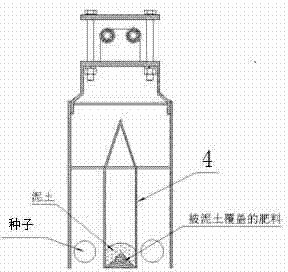

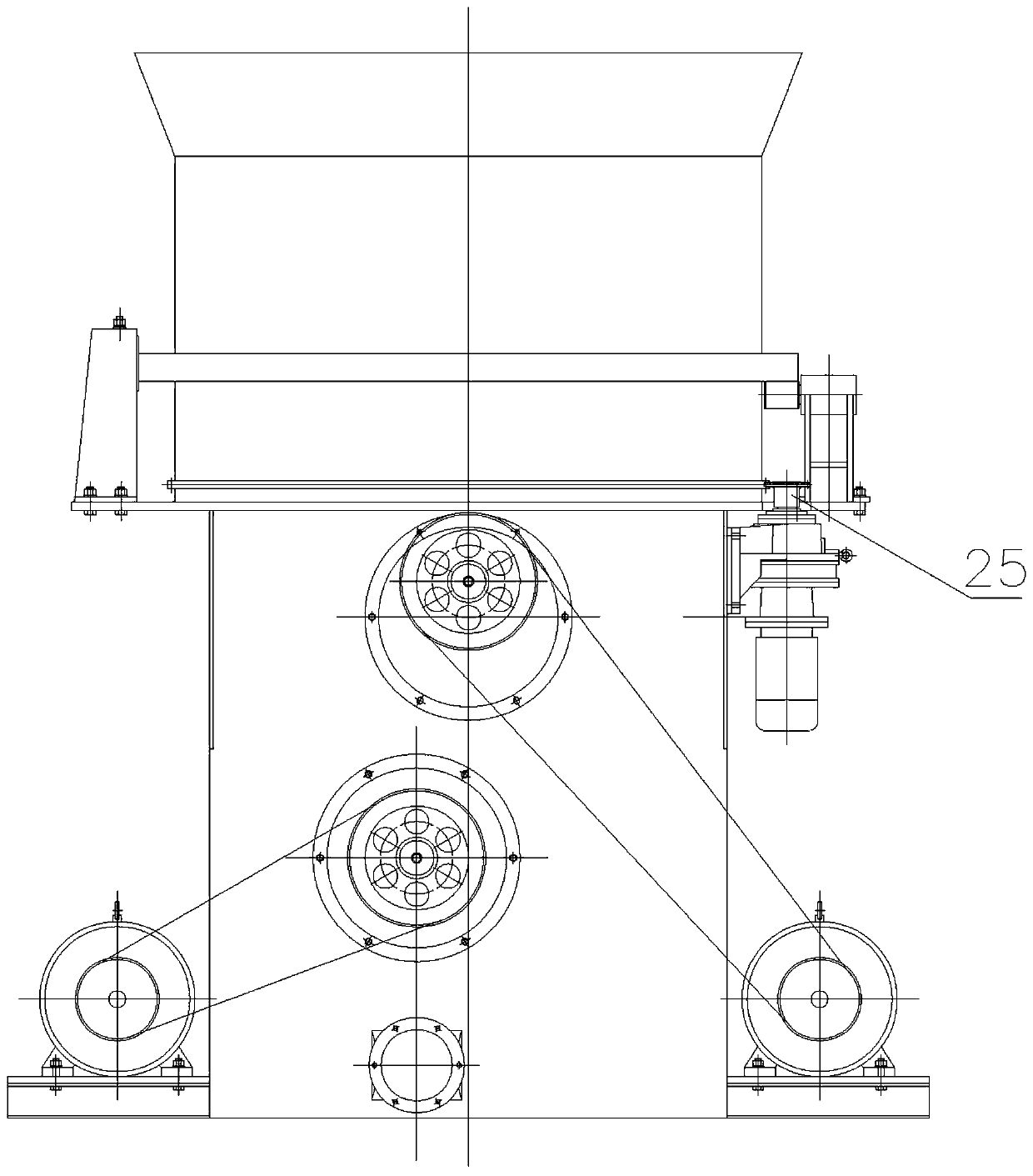

Ditcher of sugarcane planting machine for isolation type trench fertilization

ActiveCN104255122AGuaranteed to separateAppropriate distancePlantingFurrow making/coveringUltimate tensile strengthBiology

The invention relates to the technical field of agricultural equipment, and in particular relates to a ditcher of a sugarcane planting machine for isolation type trench fertilization. An isolation module is arranged between a fertilization module and a seeding module, so that seeds and fertilizer are isolated, and the distance between the seeds and the fertilizer is proper, uniform and fixed; therefore, the risk of seedling burning is avoided, and the nutrients of the fertilizer can be fully absorbed; the utilization rate of the fertilizer is increased; meanwhile, artificial planting is not needed, and the labor intensity of workers is alleviated. Since a distance value between the tip part of a ditching plough and a base plate of the ditcher is 50-80mm, so that the tip part of the ditching plough can go deep into soil; therefore, a second trench can be conveniently formed below a first trench formed by extrusion, and thus the fertilizer is buried conveniently.

Owner:SOUTH SUBTROPICAL CROPS RES INST CHINESE ACAD OF TROPICAL AGRI SCI +1

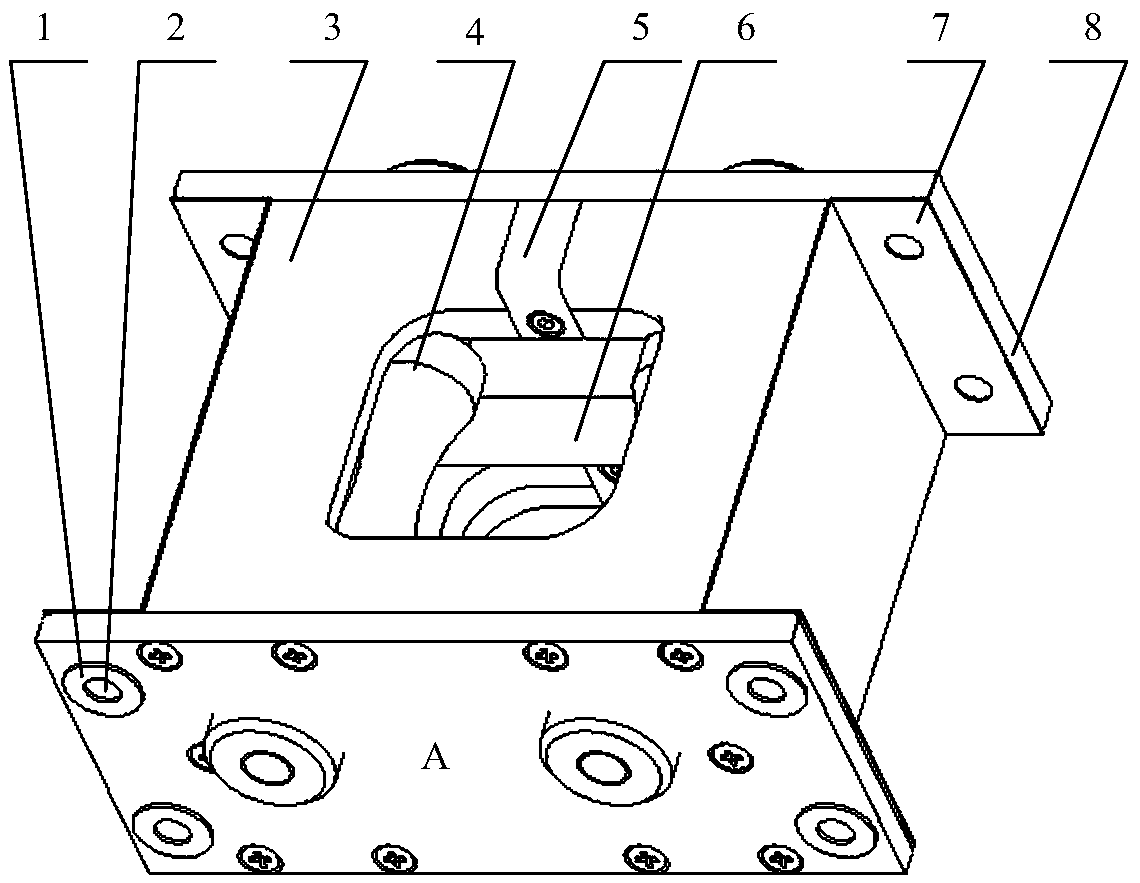

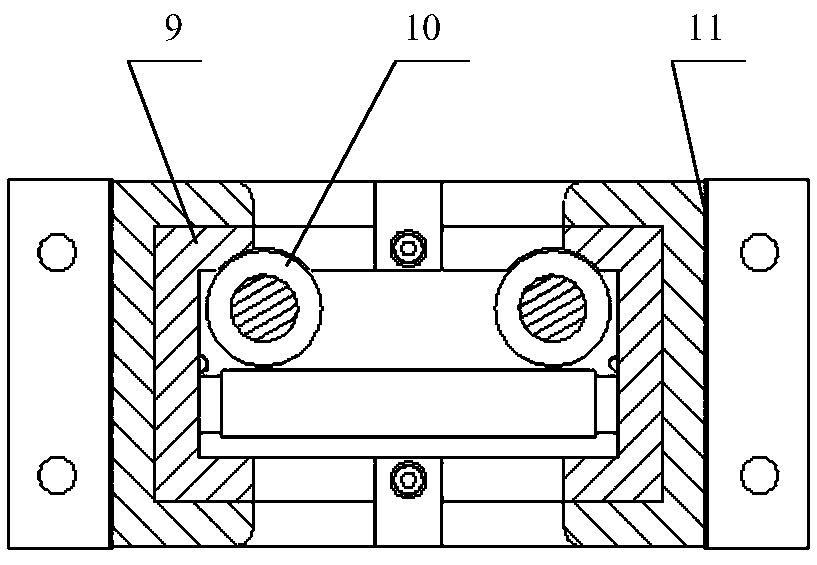

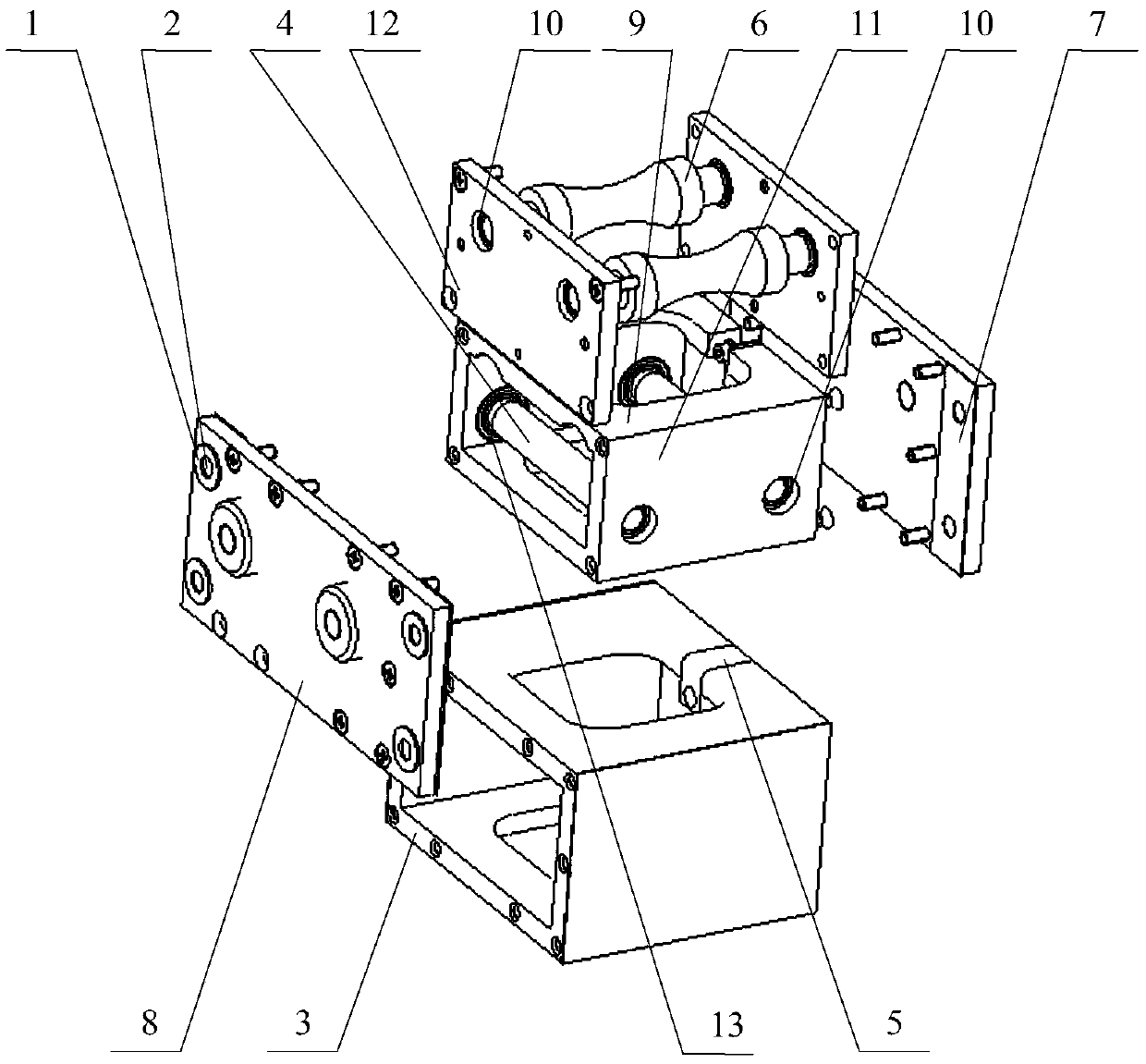

Cable guiding device

InactiveCN105501397AAct as a fixed supportReduce frictionWaterborne vesselsFilament handlingEngineeringFriction force

The invention discloses a cable guiding device. The device comprises a fairlead, a long shaft bracket, two long roll shafts, two short roll shafts, two short shaft brackets and two cover plates, wherein the fairlead and the long shaft bracket are hollow cuboids with openings at two ends and nested with each other, and guiding holes are formed in centers of two opposite end surfaces; the two short shaft brackets are mounted at openings in two ends of the long shaft bracket; the two cover plates are mounted outside the fairlead and attached to the two short shaft rackets; the long shaft bracket and the two short shaft brackets form a mounting chamber; in the mounting chamber, the two long roll shafts are mounted in parallel, the two short roll shafts are mounted in parallel, axial directions of the long roll shafts are perpendicular to the axial directions of the short roll shafts, and planes of the two shafts are parallel; through holes are formed in centers of the long roll shafts and the short roll shafts, a cable penetrates from the guiding hole in one end and then penetrates out of the guiding hole in the other end via the through holes. The cable guiding device can be mounted on an underwater buoyancy-driven lifting platform and is small in friction force, simple in structure, reliable in sliding, resistant to seawater corrosion and capable of being applied modularly.

Owner:710TH RES INST OF CHINA SHIPBUILDING IND CORP

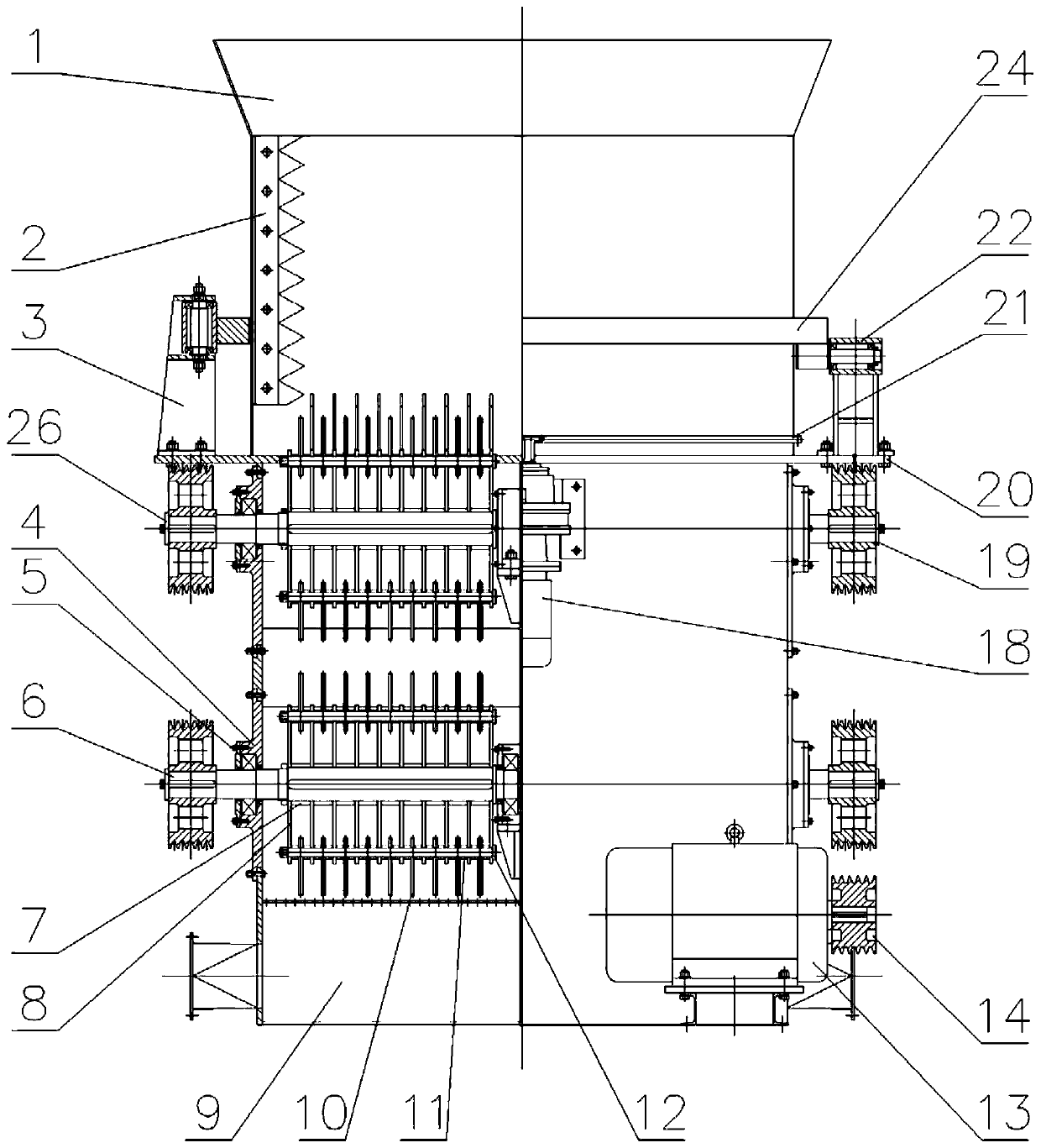

Vertical Straw Crusher

The invention discloses a vertical straw pulverizer. The pulverizer comprises a box and a drum; a working board is arranged above the box, and the box is internally provided with a first group of hammer pieces and a second group of hammer pieces which are in series connection in an up-down mode; a feeding port is formed in the working board, and grids are installed above the feeding port; the working board is fixedly provided with multiple transverse rolling wheels and multiple longitudinal rolling wheels; the drum is externally provided with a drum flange and internally provided with sawtoothed bundle breaking knives; the lower end surface of the drum flange is matched with the longitudinal rolling wheels in a contact mode, and therefore the longitudinal rolling wheels can support the drum flange; the transverse rolling wheels are matched with the drum flange in an edge contact mode. The vertical straw pulverizer has the advantages that the structure is reliable, and light impuritiesand materials after crushing can be directly separated; a bale breaking function is achieved, bundles of straw or large bales of straw can be directly crushed, the processing amount is large, and theefficiency is high.

Owner:黑龙江鹏业农业发展股份有限公司

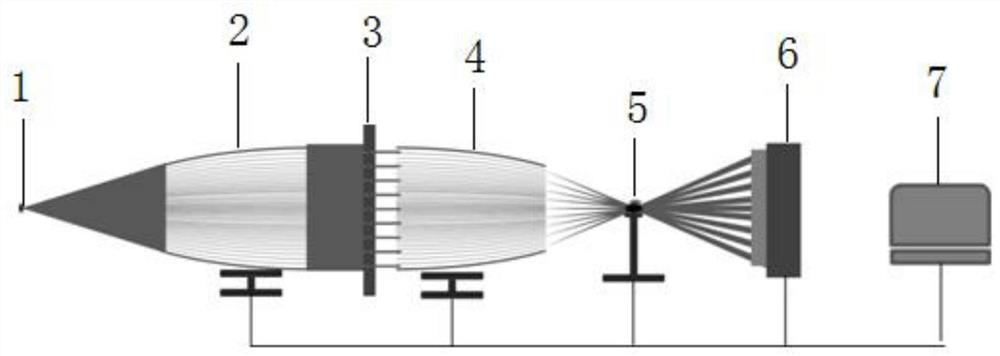

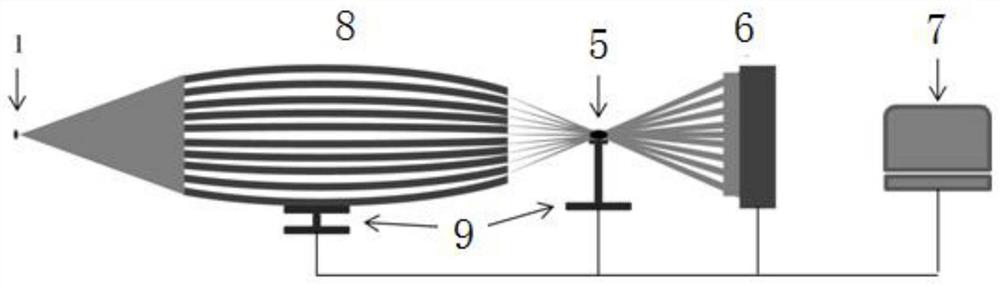

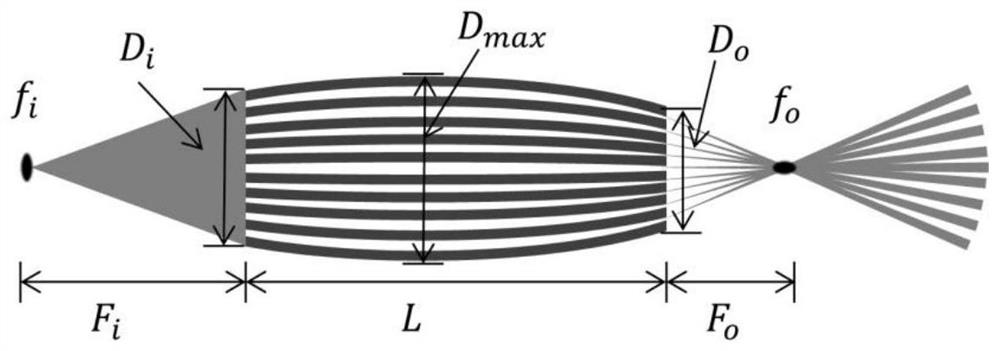

All-optical X-ray microscopic imaging system

PendingCN113203757ANo ghostingGuaranteed to separateUsing wave/particle radiation meansMaterial analysis by transmitting radiationMicro imagingBeam splitter

The invention provides an all-optical X-ray microscopic imaging system which comprises an X-ray generator and further comprises a beam splitter, wherein the beam splitter is used for splitting an X-ray beam emitted by the X-ray generator into independent conical X-ray light beams and converging the X-ray light beams at the focal point behind the X-ray light beams, and the converging position is the position where a focal spot is located; a sample is placed at the focal spot; the beam splitter is manufactured in a manufacturing mode of manufacturing a multi-capillary X-ray lens; adjacent sub-tubes of the beam splitter are formed by drawing thick-wall glass tubes; and the diameter D of the sub-tube is greater than the size of the focal spot. The beam splitter adopted by the system provided by the invention has enough thickness, so that light beams emitted from the beam splitter can be separated, a finally formed projection image has no ghosting, and the imaging efficiency of the system is high; and the system is simple in structure, low in cost and convenient to popularize and use.

Owner:北京市辐射中心

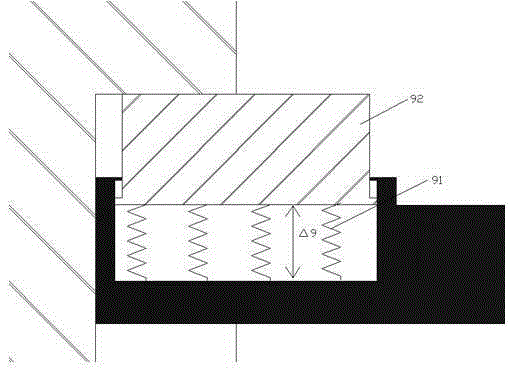

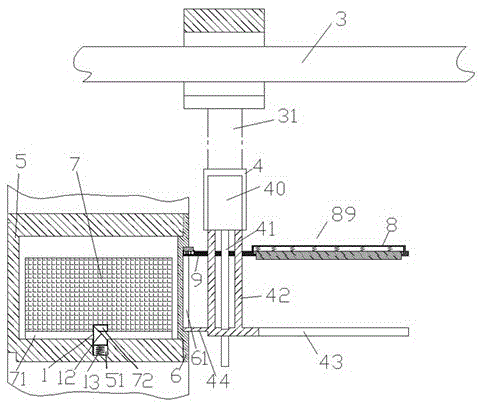

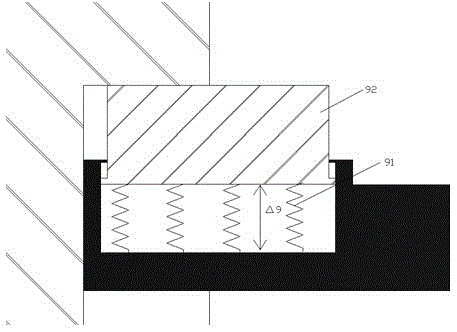

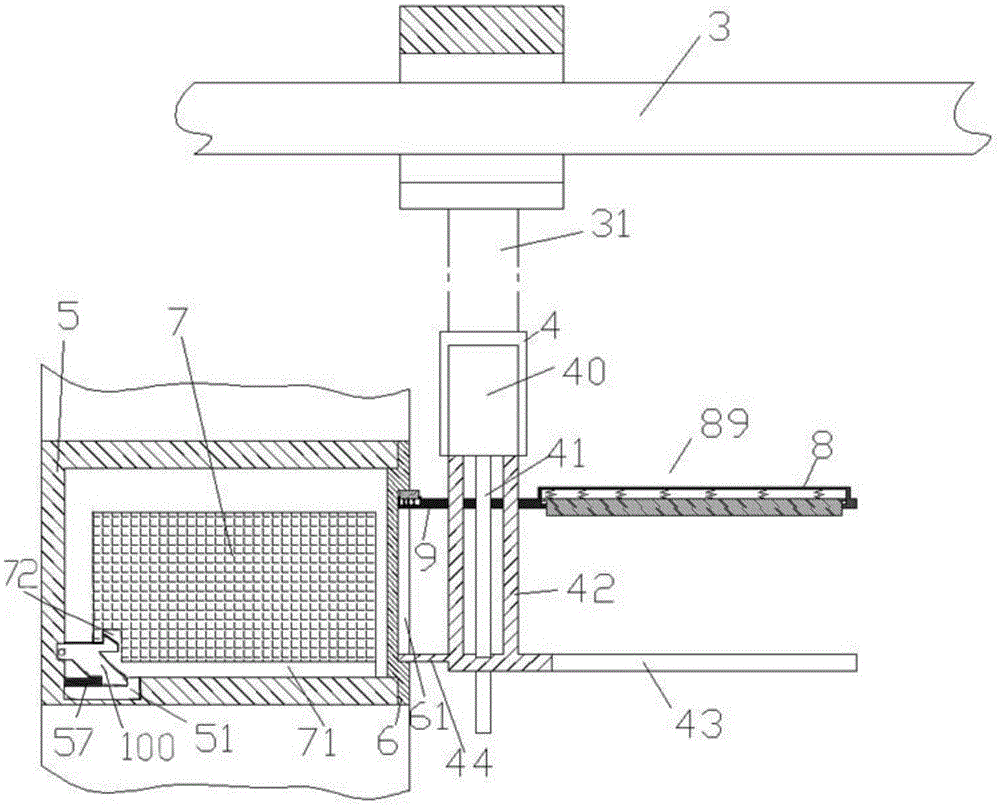

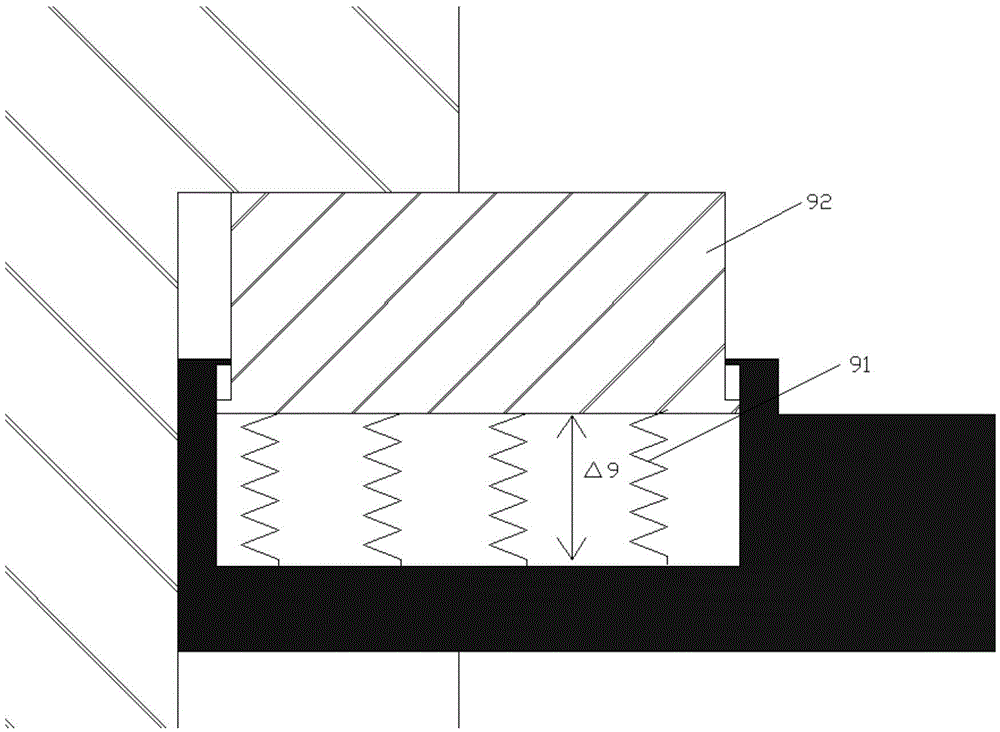

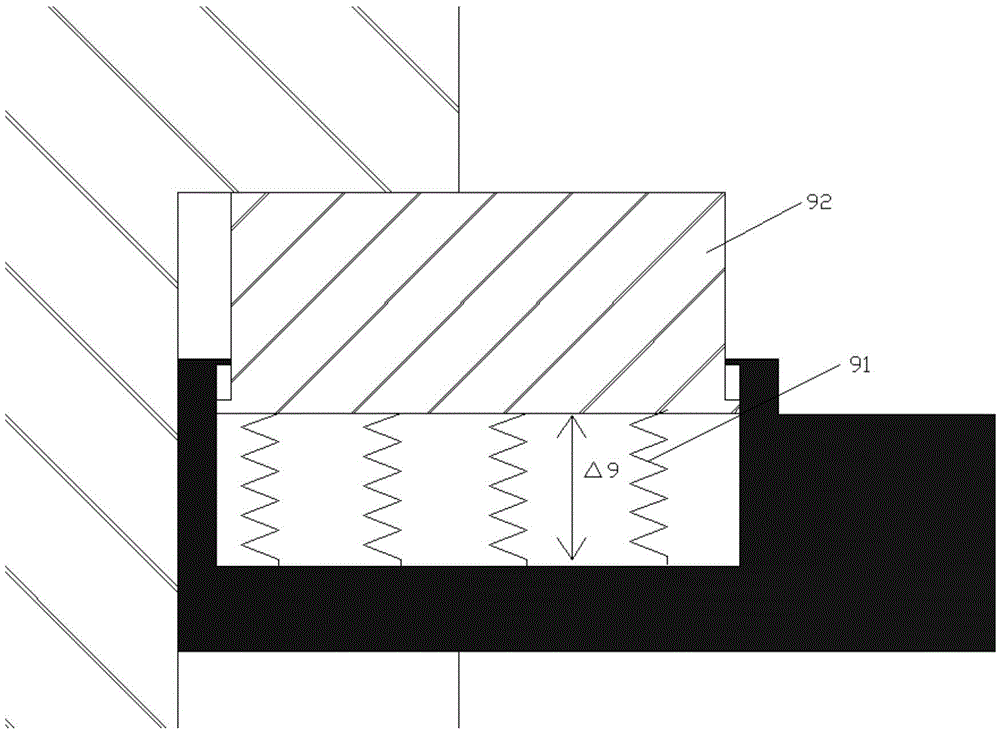

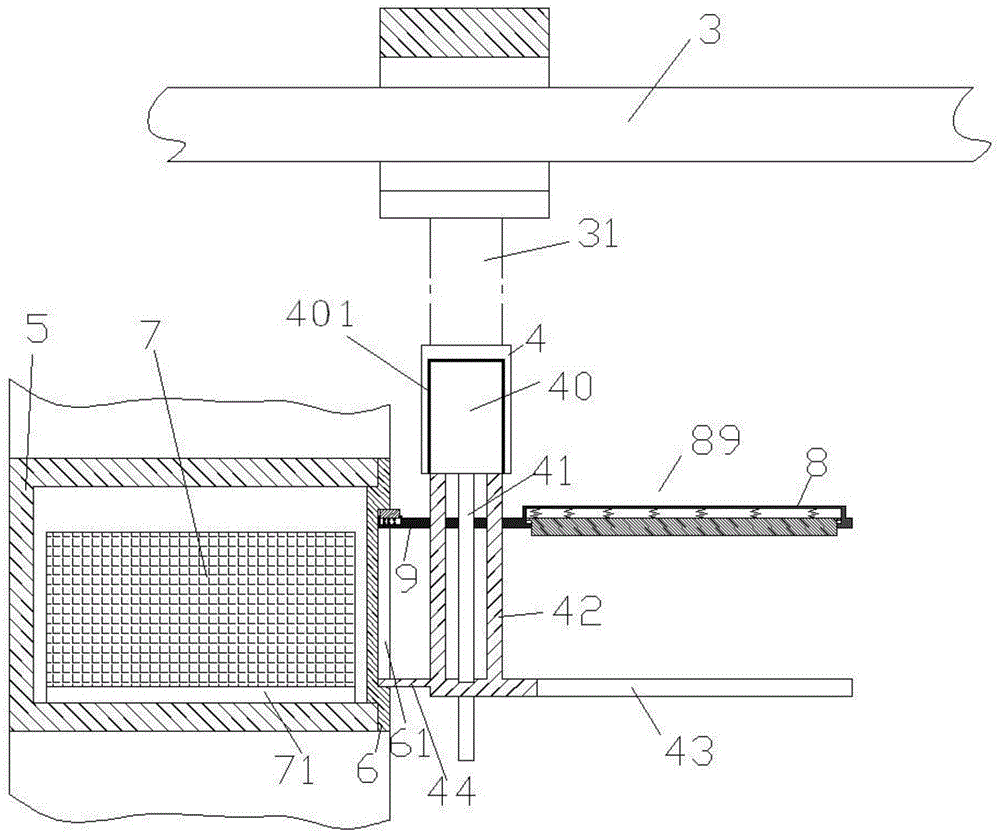

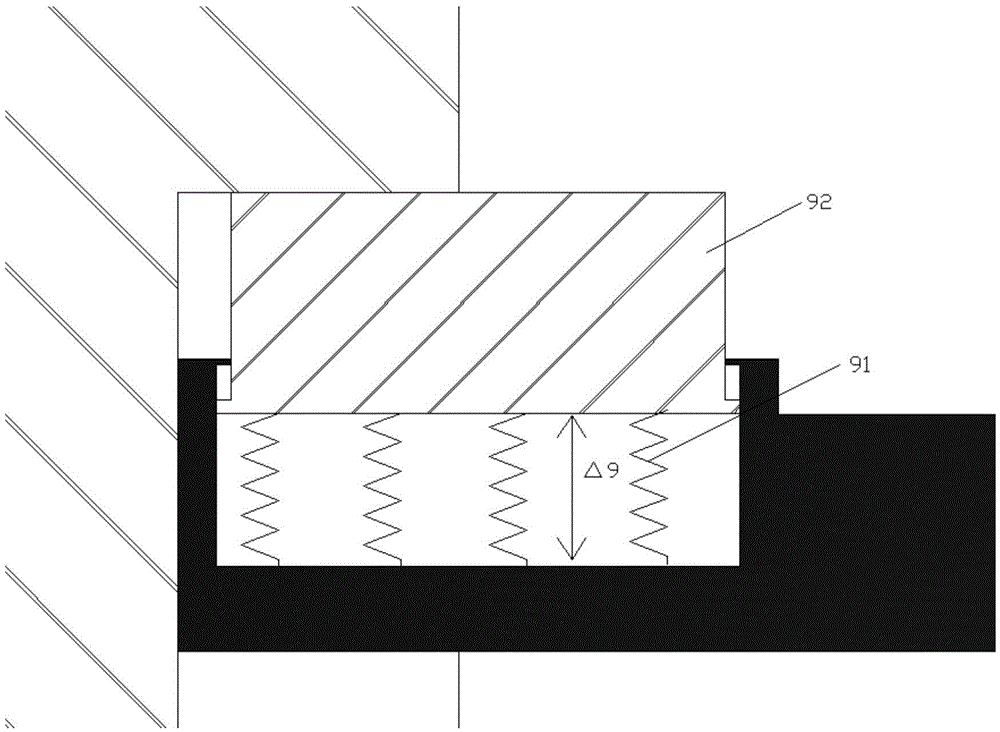

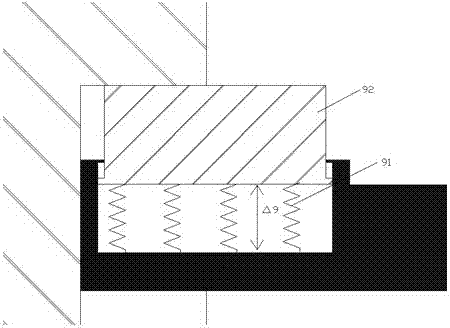

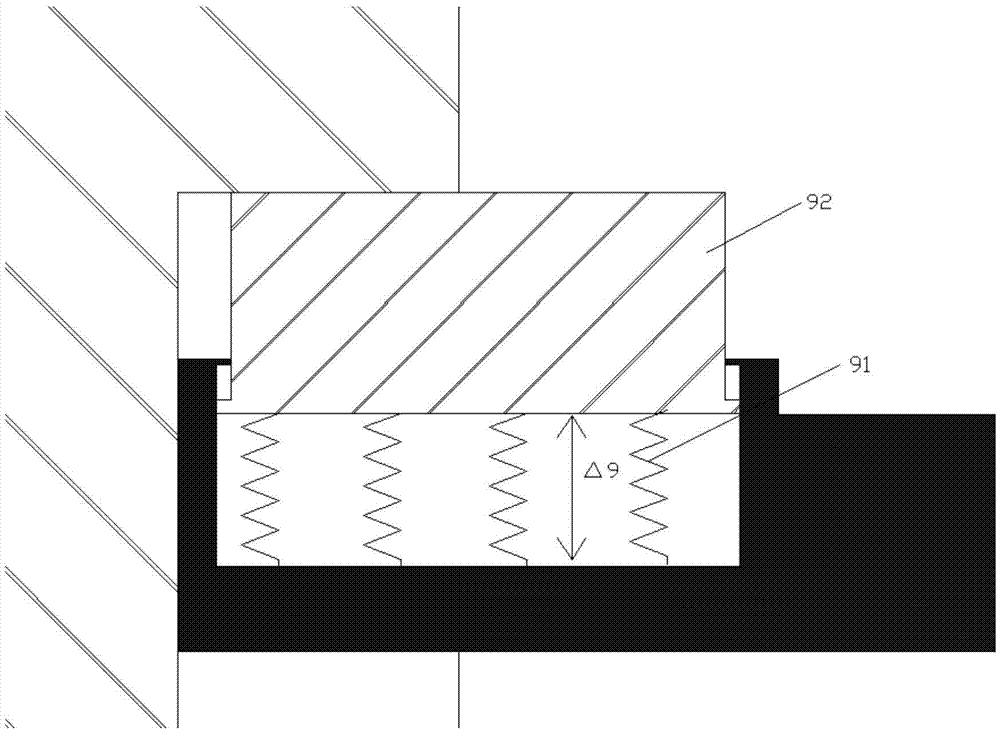

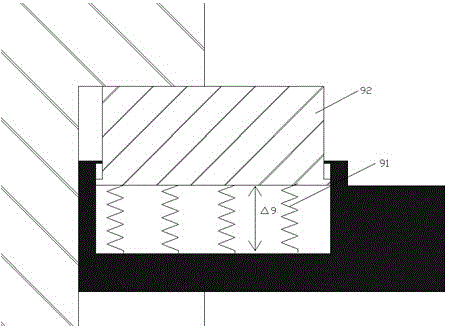

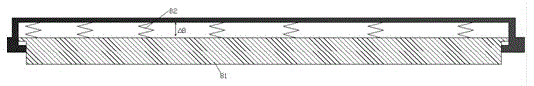

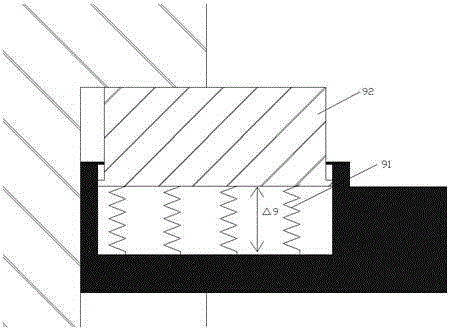

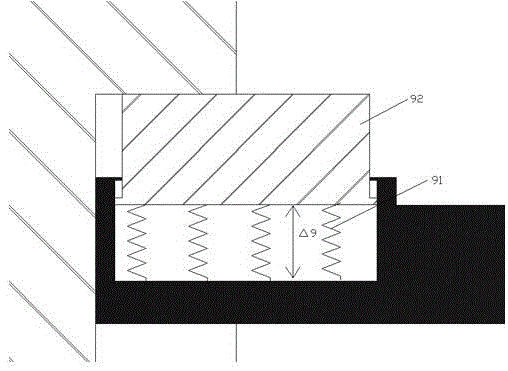

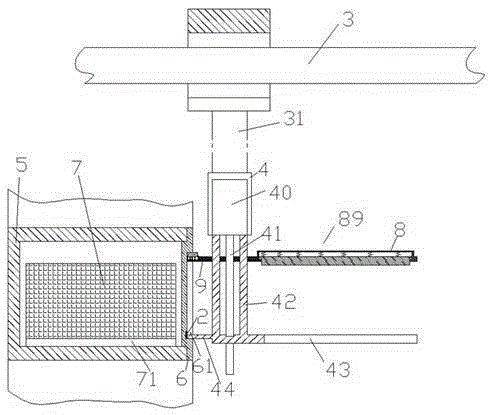

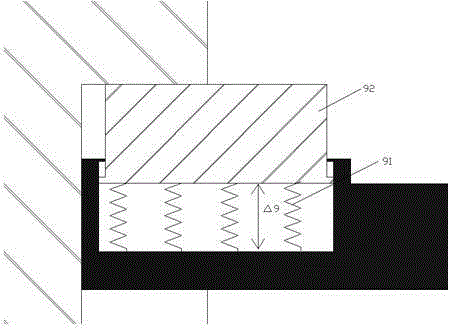

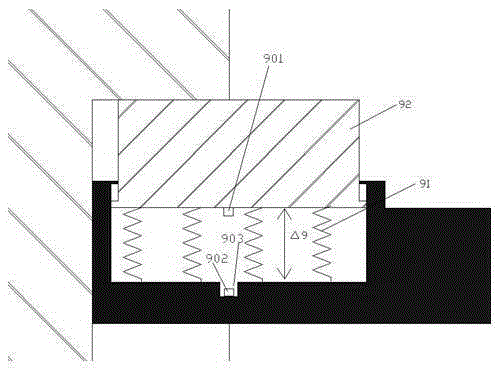

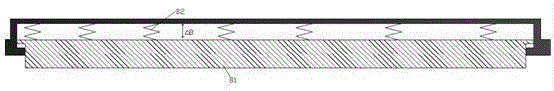

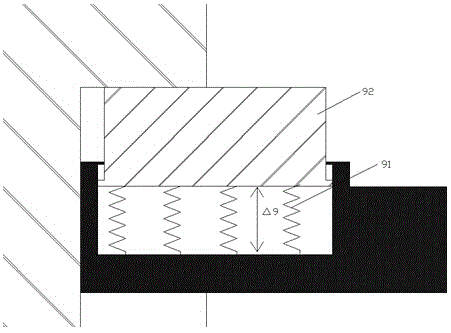

Vibration-proof intelligent warehouse logistics system

InactiveCN105416961ASimplify structural complexityGuaranteed to separateStorage devicesEngineeringAccess port

The invention relates to a vibration-proof intelligent warehouse logistics system, comprising a control device (100), a warehousing cabinet device and material transportation device, wherein the warehousing cabinet device comprises a plurality of unit cabinets (5) used for holding material boxes (7), a plurality of grabbing grooves (71) are formed in the bottom surfaces of the material boxes (7), openable cover caps (6) are arranged at the access ports of the unit cabinets (5), and holding grooves (61) are formed in the outer surfaces of the openable cover caps (6); and the material transportation device comprises a driving mechanism (3) and a material box operating device connected with the driving mechanism (3) by a connecting rod (31) extending in the vertical direction.

Owner:梁群清

An Intelligent System for Warehousing and Logistics

ActiveCN105416953BGuaranteed to separateSimplify structural complexityStorage devicesLogistics managementEngineering

An intelligent system for warehouse logistics comprises a control device (100), a storage cabinet device and a material transport device, wherein the storage cabinet device comprises a plurality of unit cabinets (5) used for containing material boxes (7), a plurality of grabbing grooves (71) are formed in the bottom surface of each material box (7), and openable covers (6) with holding grooves (61) formed in the outer surfaces are installed at storing-fetching ports of the unit cabinets (5); the material transport device comprises a driving mechanism (3) and a material box operating device which is connected with the driving mechanism (3) through a connecting rod (31) which extends in the vertical direction.

Owner:佛山市快图仕互联科技有限公司

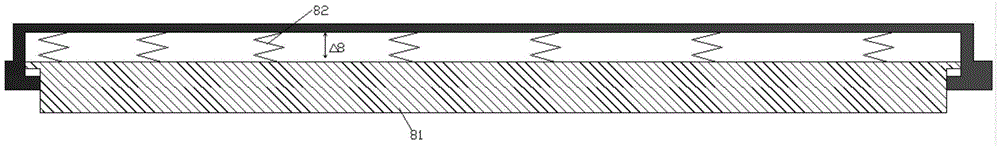

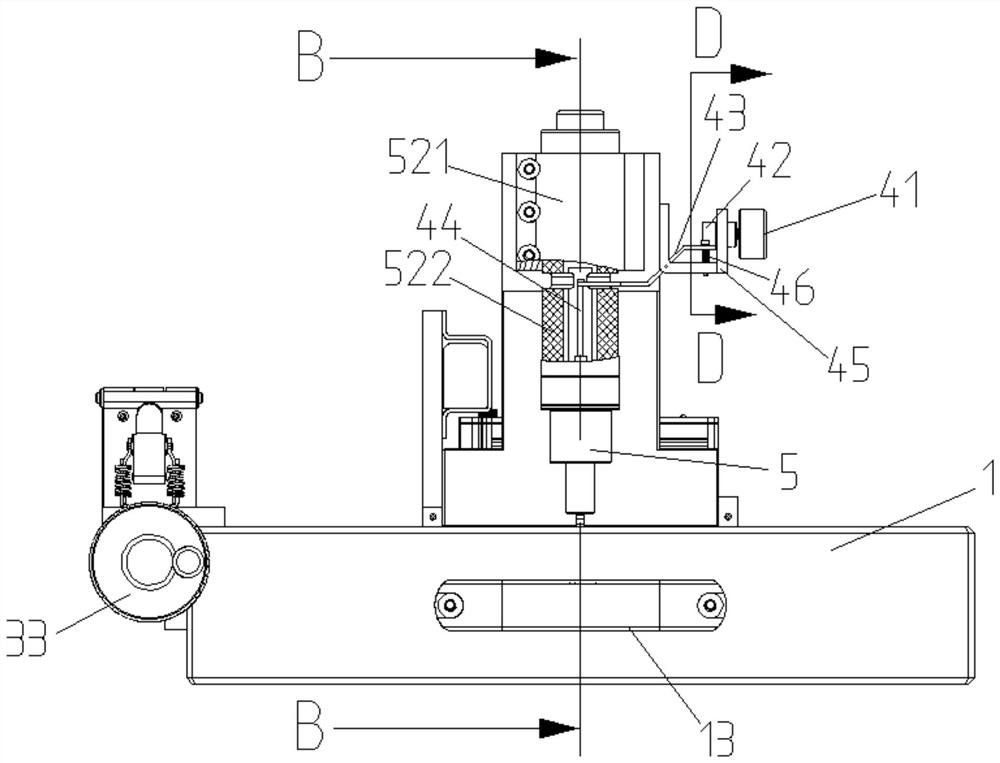

Lithium battery film thickness gauge

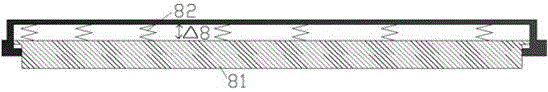

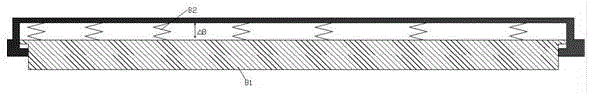

ActiveCN113188499ASmall compression deformationGuaranteed high precision measurementMeasurement devicesEngineeringMechanical engineering

The invention discloses a lithium battery film thickness gauge which comprises a measuring base, a measuring arm, a film moving mechanism, a lifting mechanism and a measuring mechanism, wherein the measuring arm is arranged on the measuring base; the lifting mechanism is arranged on a measuring wall; the measuring mechanism is arranged on the lifting mechanism; the film moving mechanism is arranged on one side of the measuring base; a measurement position on the measurement base is connected with an adsorption device; and the measuring mechanism comprises a measuring probe, a micro sensor and a high-precision analog-to-digital conversion module. According to the lithium battery film thickness gauge, the contact surface is increased and the compression deformation of the film is reduced by the measuring mechanism, and high-precision measurement is ensured; the lifting structure is used for avoiding compression deformation of the film caused by rapid movement impact; an over-range gap is connected between the lifting rod and the sensor, so that the influence of the lifting mechanism on the sensor is avoided; the film moving mechanism avoids deformation caused by manual dragging, so that the movement is smooth and uniform; and the measurement position is connected with the adsorption device, so that the film is in complete contact with the measurement platform, and accurate measurement is ensured.

Owner:马尔精密量仪(苏州)有限公司

Single transmission line deicing robot and method

ActiveCN105870866BImprove securityImprove manual workOverhead installationHydraulic cylinderControl engineering

The invention discloses a single-transmission line deicing robot and method. The single-transmission line deicing robot comprises a first gripper, wherein the first gripper is matched with a motion mechanism; a second gripper is arranged in the motion mechanism; a deicing mechanism is arranged at the top part of the motion mechanism; the first gripper comprises arc-shaped grab bars; the middle parts of two arc-shaped grab bars are connected through a pin shaft; the bottom ends of the two arc-shaped grab bars are fixedly connected through a first hydraulic cylinder; the arc-shaped grab bars, the pin shaft and the first hydraulic cylinder are arranged in a first rectangular box body; first connecting rods are fixed at two side surfaces of the first rectangular box body respectively; the tail ends of the two first connecting rods are connected with long racks respectively; and a first hydraulic drive device is fixed on the side surface of the first rectangular box body. The robot can be automatically elevated when encountering an obstacle and stretch a clamping device to pass cross the obstacle; and meanwhile, ice blocks on the line can be effectively eliminated to achieve the deicing target.

Owner:CHINA THREE GORGES UNIV

Operating speed-adjustable intelligent warehouse logistics system

InactiveCN105438706ASimplify structural complexityGuaranteed to separatePackagingStorage devicesOperating speedEngineering

The invention discloses an operating speed-adjustable intelligent warehouse logistics system which comprises a control device (100), a warehouse cabinet device and a material transportation device, wherein the warehouse cabinet device comprises a plurality of unit cabinets (5) used for accommodating material boxes (7) of which the bottom surfaces are provided with a plurality of grabbing grooves (71); openable and closable cover caps (6) of which the outer surfaces are provided with holding grooves (61) are mounted at the access openings of the unit cabinets (5); and the material transportation device comprises a driving mechanism (3), and a material box operating device connected with the driving mechanism (3) through a connecting rod (31) extending in the vertical direction.

Owner:莫钦超

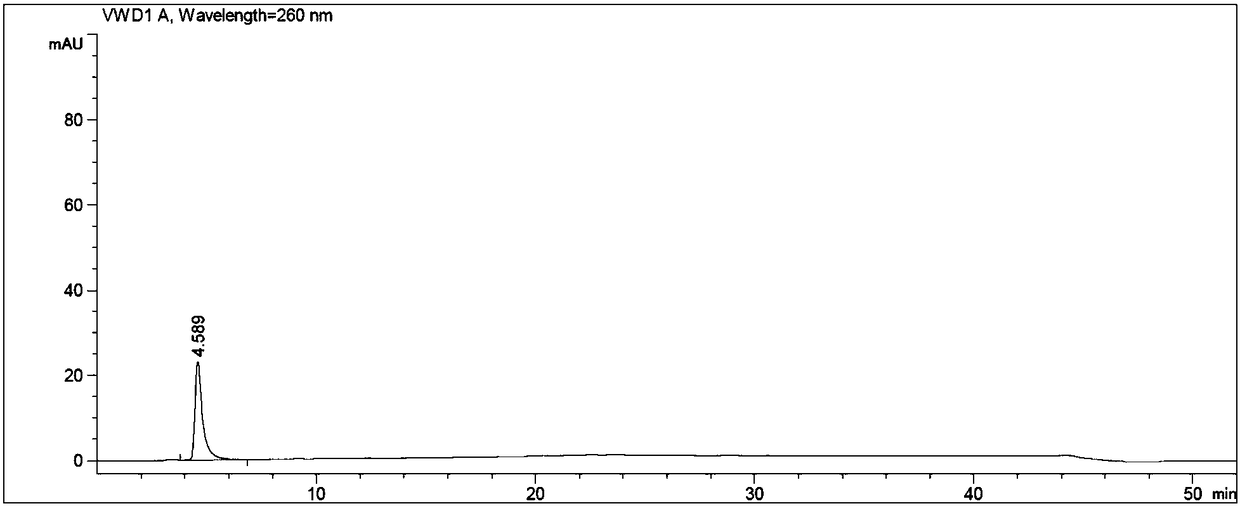

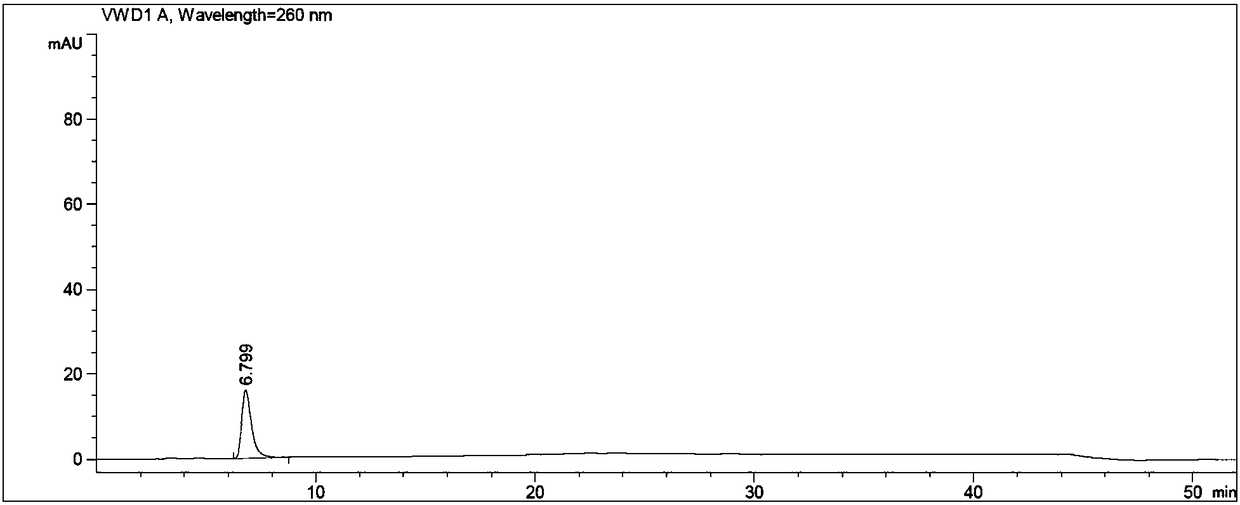

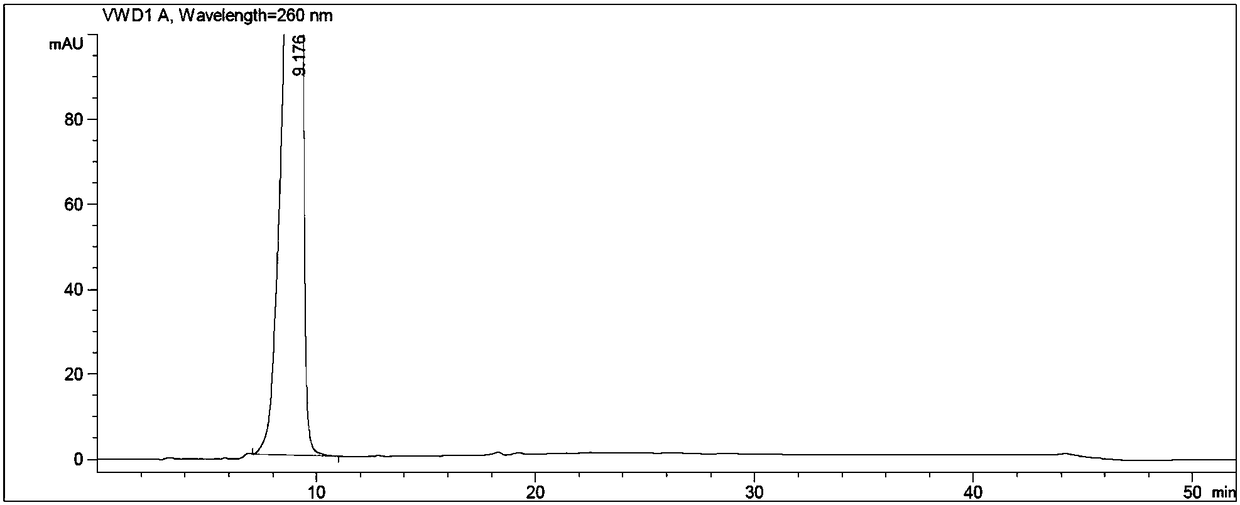

A kind of preparation method of adefovir dipivoxil hydroxymethyl impurity

ActiveCN106167503BLow costReduce environmental costsComponent separationGroup 5/15 element organic compoundsImpurityHydroxymethyl

A preparing method of a hydroxymethyl impurity of adefovir dipivoxil is provided. The method includes S1) a step of preparing crude hydroxymethyl impurity of the adefovir dipivoxil, with the crude hydroxymethyl impurity being prepared from 2.5-4.0 parts by weight of N-methyl-2-pyrrolidone, 1.0 part by weight of adefovir A-4, 1.0-1.5 parts by weight of triethylamine and 2.0-3.6 parts by weight of chloromethyl pivalate, S2) a step of filtering a crude adefovir dipivoxil compound solution for purification, and S3) a step of subjecting the crude adefovir dipivoxil compound dry product prepared in the step S2) to secondary crystallization for purification.

Owner:FUJIAN COSUNTER PHARMA CO LTD

Intelligent warehouse logistics system capable of being unlocked rapidly

InactiveCN105416952AGuaranteed to separateSimplify structural complexityStorage devicesLogistics managementEngineering

An intelligent warehouse logistics system capable of being unlocked rapidly comprises a control device (100), a storage cabinet device, a locking device and a material transport device, wherein the storage cabinet device comprises a plurality of unit cabinets (5) used for containing material boxes (7), a plurality of grabbing grooves (71) are formed in the bottom surface of each material box (7), and openable covers (6) with holding grooves (61) formed in the outer surfaces are installed at storing-fetching ports of the unit cabinets (5); the material transport device comprises a driving mechanism (3) and a material box operating device which is connected with the driving mechanism (3) through a connecting rod (31) which extends in the vertical direction.

Owner:叶建格

Warehouse logistics storage system

InactiveCN105346915AGuaranteed to separateSimplify structural complexityStorage devicesLogistics managementHolding tank

The invention discloses a warehouse logistics storage system. The warehouse logistics storage system comprises a control device (100), a warehouse cabinet device, a locking device and a material transportation device, wherein the warehouse cabinet device comprises multiple unit cabinets (5) for accommodating material boxes (7) provided with multiple grabbing tanks (71) in the bottom surfaces; access ports of the unit cabinets (5) are provided with openable covers (6) having holding tanks (61) in the outer surfaces; and the material transportation device comprises a driving mechanism (3), and a material box operation device connected with the driving mechanism (3) through a connecting rod (31) extending in the vertical direction.

Owner:叶建格

A method of knitting and wearing 2×2 rib weave fabric by a double-needle bed flat knitting machine

The invention relates to a method for knitting a 2*2 rib stitch textile through a two-needle bar flat knitting machine and belongs to the technical field of a knitting method in a flat knitting machine. According to the method, cylindrical knitting in an alternate needle mode is performed on front and rear needle bars of the two-needle bar knitting machine; when a front piece is knitted, odd needles or even needles of the front needle bar are adopted; when a rear piece is knitted, the odd or even needles of the rear needle bar are adopted; during a knitting process, the knitting in the alternating mode that one line is woven at the front and one line is woven at the back is adopted; the method is characterized in that at least two yarn nozzles are used; the two yarn nozzles are respectively represented by Y1 and Y2; Y1 is used for representing waste yarns or drawn yarns; Y2 is used for representing main yarns; eight needles are taken as one circle of rib stitch; the needles on the front needle bar are successively named as a, b, c, d, e, f, g, h and so on from left to right; the needles on the rear needle bar are successively named as a', b', c' d', e', f', g' h' and so on from left to right. The front and rear cut pieces are kept separated; the rib stitch starting opening is compact and attractive; the quality of the rib stitch textile is increased.

Owner:JIANGSU JINLONG TECHNOLOGY CO LTD

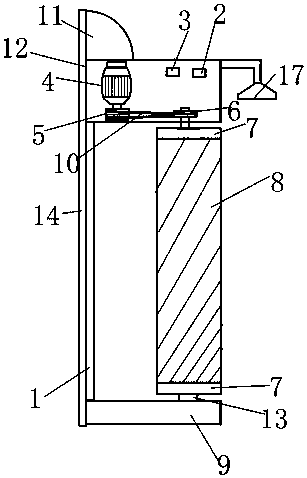

A spiral bath rubbing back massage system device

The invention discloses a spiral back rubbing and massaging system device for bathing, which comprises a bracket, a rotary speed controller, a direct current motor, a spiral rotating shaft, a spiral back rubbing towel, a support, a plastic leather belt, a top cap, a spiral rotating shaft core, a support plate, a shower head and a water inlet, wherein the support is arranged at the bottom end of the bracket; the top cap is arranged at the top end of the bracket; the support plate is arranged on the back side of the bracket; a screw hole is formed in the support plate; the spiral rotating shaft is arranged in the bracket; the spiral rotating shaft core is arranged at the center of circle of the spiral rotating shaft; the spiral rotating shaft is coated with the spiral back rubbing towel; the direct current motor is mounted in the top cap; a first belt pulley is mounted on an output shaft of the direct current motor; a direct current power supply and the rotary speed controller are arranged in the top cap; the shower head is arranged on the top cap; a hood is arranged at the top end of the top cap; and a spiral rotating shaft switch is arranged on the side wall of the top cap. The spiral back rubbing and massaging system device is convenient to clean, has the advantages of improved safety, wide application range and simple structure, and has a health-care effect.

Owner:WUHAN YUSHEN SCI & TECH DEV CO LTD

Storing-fetching system for warehouse logistics

InactiveCN105416949AGuaranteed to separateSimplify structural complexityStorage devicesLogistics managementEngineering

A storing-fetching system for warehouse logistics comprises a control device (100), a storage cabinet device, a locking device and a material transport device, wherein the storage cabinet device comprises a plurality of unit cabinets (5) used for containing material boxes (7), a plurality of grabbing grooves (71) are formed in the bottom surface of each material box (7), and openable covers (6) with holding grooves (61) formed in the outer surfaces are installed at storing-fetching ports of the unit cabinets (5); the material transport device comprises a driving mechanism (3) and a material box operating device which is connected with the driving mechanism (3) through a connecting rod (31) which extends in the vertical direction.

Owner:吴美俊

Intelligent warehousing system for logistics

InactiveCN105366258AGuaranteed to separateSimplify structural complexityStorage devicesLogistics managementEngineering

The invention discloses an intelligent warehousing system for logistics. The intelligent warehousing system for logistics comprises a control device (100), a warehousing cabinet body device and a material transport device, wherein the warehousing cabinet body device comprises a plurality of unit cabinets (5) used for accommodating material boxes (7), each material box (7) is provided with a plurality of grabbing grooves (71) on the bottom surface, and a cover cap (6) capable of being opened and closed, and provided with a holding groove (61) on the outer surface is installed at an access port of each unit cabinet (5); and the material transport device comprises a drive mechanism (3) and a material box operation device connected with the drive mechanism (3) through a connection rod (31) which extends in a vertical direction.

Owner:叶建格

Convenient intelligent warehouse logistics system

InactiveCN105366257AControl operationThe control device can control the operationStorage devicesLogistics managementEngineering

The invention discloses a convenient intelligent warehouse logistics system. The convenient intelligent warehouse logistics system comprises a control device (100), a warehousing cabinet body device and a material transport device, wherein the warehousing cabinet body device comprises a plurality of unit cabinets (5) used for accommodating material boxes (7); each material box (7) is provided with a plurality of grabbing grooves (71) on the bottom surface; and a cover cap (6) capable of being opened and closed and provided with a holding groove (61) in the outer surface is installed at an access port of each unit cabinet (5); and the material transport device comprises a drive mechanism (3) and a material box operation device connected with the drive mechanism (3) through a connection rod (31) which extends in the vertical direction.

Owner:吴美俊

Intelligent warehouse logistics system

InactiveCN105346909AGuaranteed to separateSimplify structural complexityLidsStorage devicesLogistics managementHolding tank

The invention discloses an intelligent warehouse logistics system. The intelligent warehouse logistics system comprises a control device (100), a warehouse cabinet device and a material transportation device, wherein the warehouse cabinet device comprises multiple unit cabinets (5) for accommodating material boxes (7) provided with multiple grabbing tanks (71) in the bottom surfaces; access ports of the unit cabinets (5) are provided with openable covers (6) having holding tanks (61) in the outer surfaces; and the material transportation device comprises a driving mechanism (3), and a material box operation device connected with the driving mechanism (3) through a connecting rod (31) extending in the vertical direction.

Owner:何先进

Multifunctional bulletin board convenient to replace

PendingCN113257155AImprove efficiencyAvoid running aroundWriting boardsIlluminated signsSoftware engineeringMechanical engineering

The invention relates to a multifunctional bulletin board convenient to replace, and belongs to the technical field of propaganda equipment. The multifunctional bulletin board comprises: a bracket; a display assembly arranged on the bracket and used for displaying propaganda content; a scoring assembly arranged on the bracket and used for scoring the propaganda content by the reader; and a controller arranged on the bracket and electrically connected with the scoring assembly. According to the invention, the publicity board composed of a plurality of rectangular boards can make writing preparation in advance, and the publicity board with a proper size is assembled according to publicity content, so that the environment is prevented from influencing replacement efficiency, drawing personnel are prevented from running and being tired, and the comfort of the drawing personnel is improved; through the supporting plate, it can be guaranteed that drawing content is separated from the outside in the transportation process, the drawing content is prevented from being damaged, and use convenience is further improved; and the multifunctional bulletin board is easy to operate, high in practicability and worthy of popularization.

Owner:SHENYANG NORMAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com