High voltage power switch

A circuit breaker and power technology, applied in high-voltage air circuit breakers, high-voltage/high-current switches, circuits, etc., can solve problems such as no longer reliable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

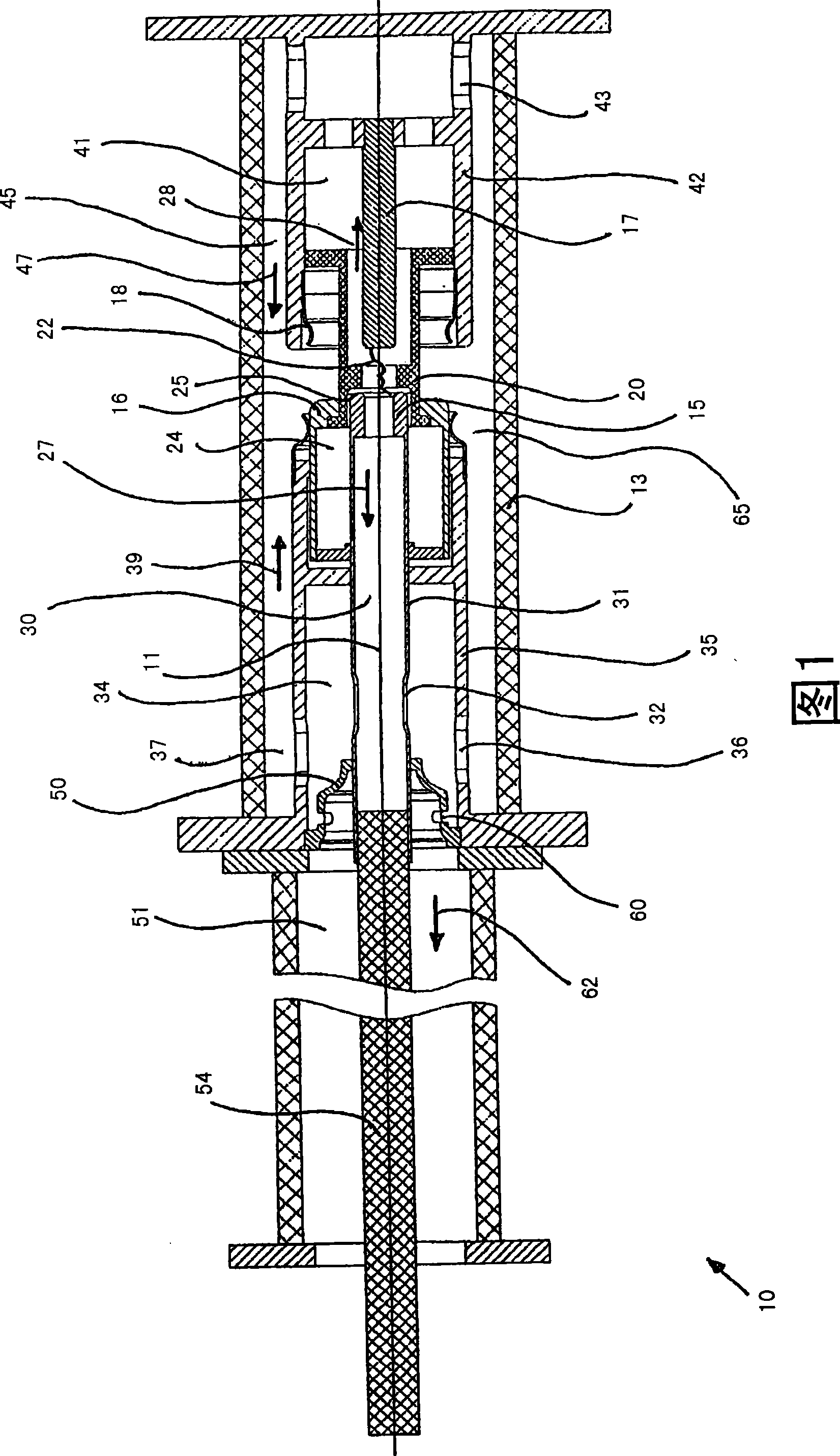

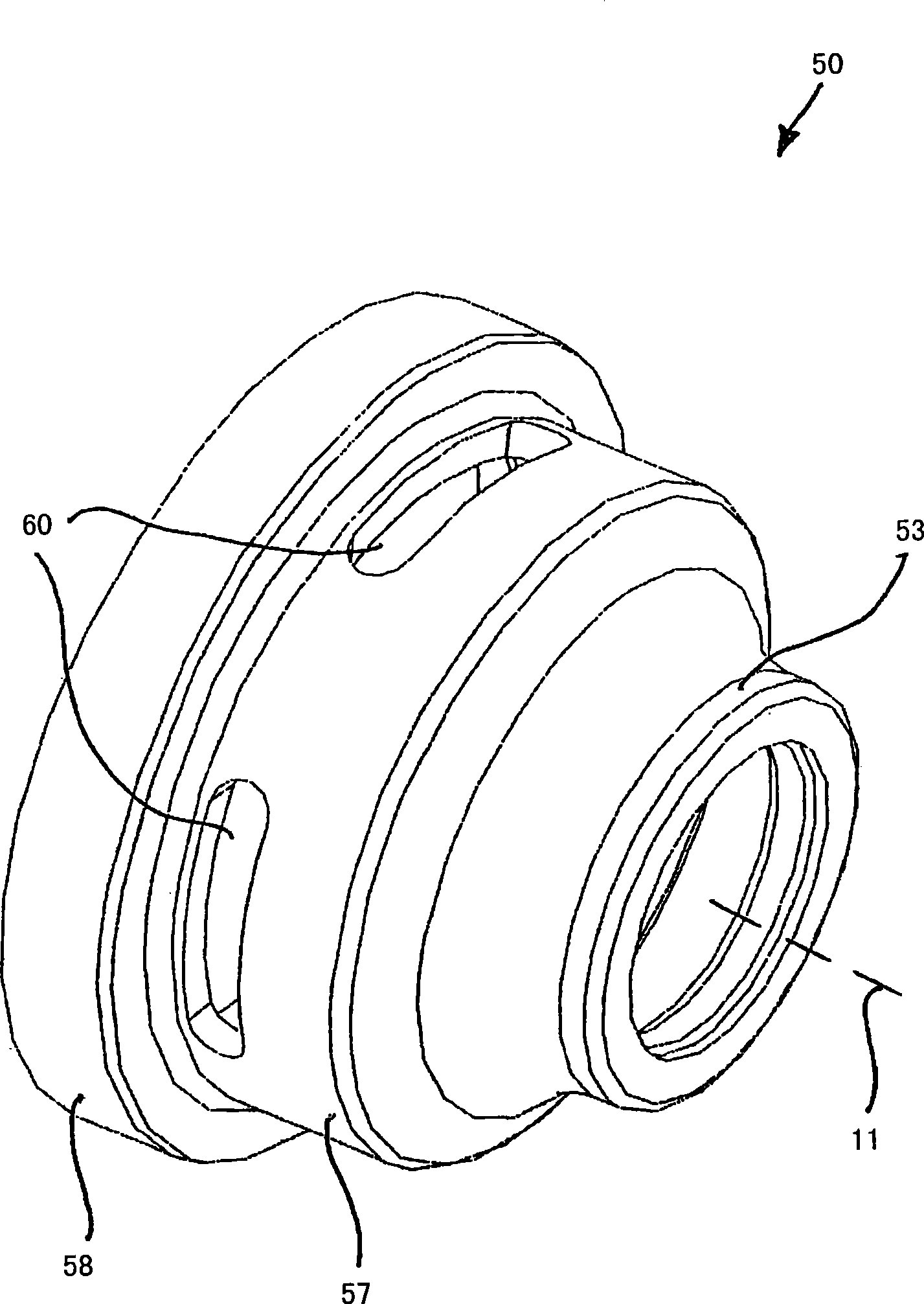

[0022] FIG. 1 shows a high-voltage power circuit breaker 10 , which has a longitudinal axis 11 and is substantially rotationally symmetrical. A quincunx-shaped arcing contact piece 15 with an associated first main current contact piece 16 and a pin with an associated second main current contact piece 18 are accommodated in an interior space of the porcelain housing 13 filled with insulating gas. Shaped arcing contacts 17. Sulfur hexafluoride (SF6) or nitrogen (N2) or tetrafluoromethane (CF4) or mixtures thereof can be used here as insulating gas.

[0023] The main current contacts 16 , 18 are arranged radially outside the arcing contacts 15 , 17 . The contact pieces 15 , 16 as well as the contact pieces 17 , 18 are oriented coaxially relative to one another and can each be moved together in the direction of the longitudinal axis 11 relative to one another, to be precise from a shorted, thus connected, end position to a disconnected position. in the end position thus switched...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com