Growth factor porous micro-sphere compound system coated by injectable hydrogel

A growth factor and porous microsphere technology, applied in the field of biomedical materials for nerve tissue repair, can solve the problems of too fast release of growth factors, short action period, etc., to avoid direct contact, uniform and slow release, good encapsulation and fixation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

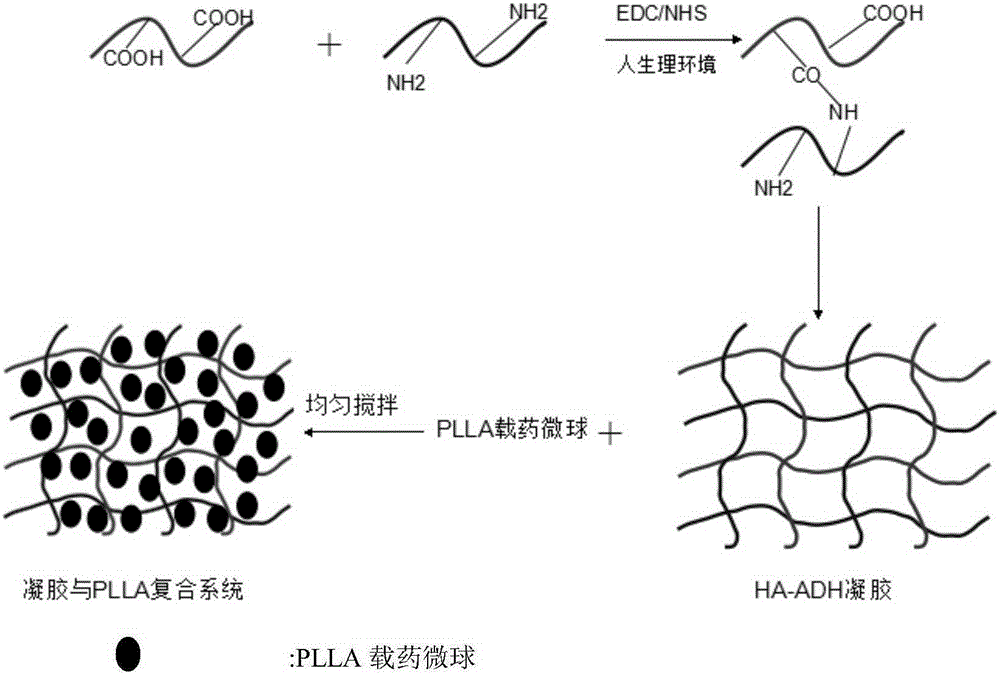

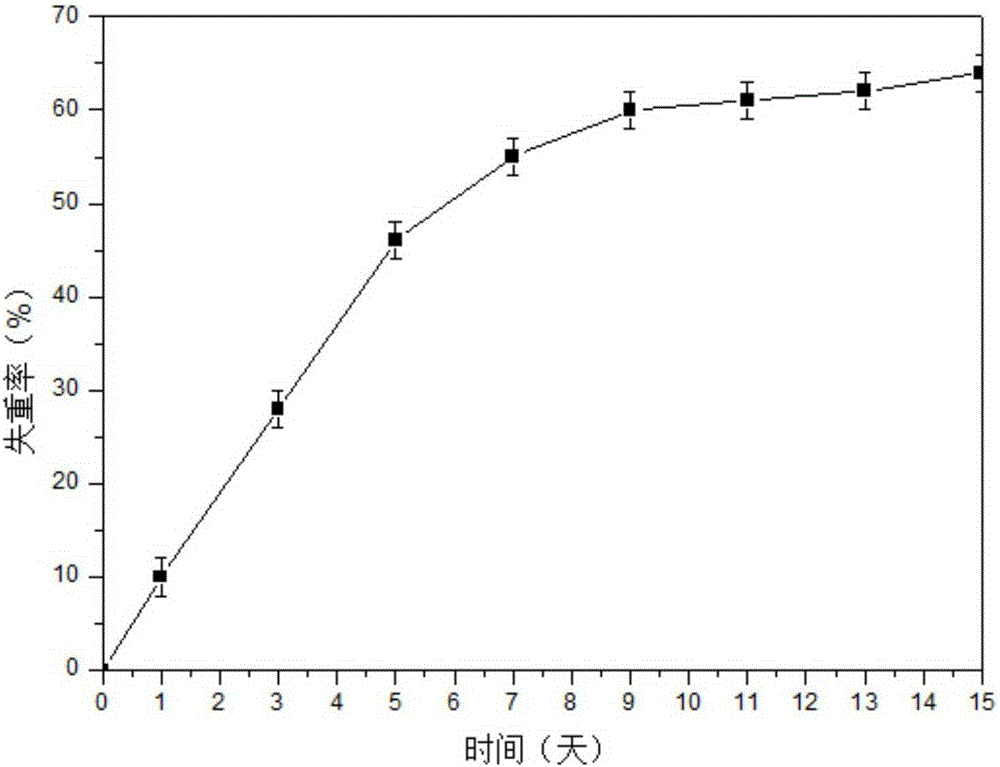

[0044] Preparation of a Growth Factor Porous Microsphere Composite System Encapsulated by Injectable Hydrogel

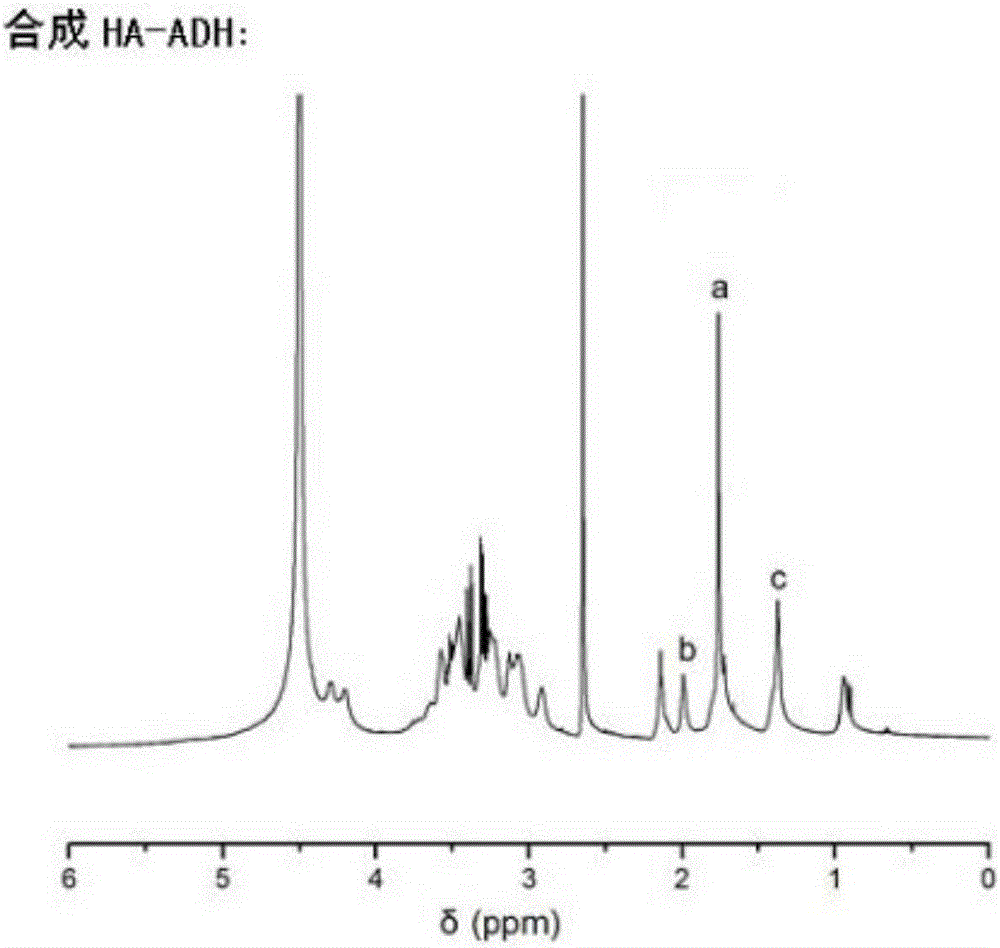

[0045] (1) Dissolve 0.5g HA in 100ml of ultrapure water at 0-4°C, stir magnetically to fully dissolve, then add 2gADH, then add 0.8gEDC and 0.7gNHS, 1mol / lHCl to adjust the pH to 5.0, react for 20h, and dialyze That is to get HA-ADH sol;

[0046] (2) 1.5g of PLLA was dissolved in 20mL of dichloromethane, then added to NGF, bFGF (NGF4.5mg / ml; bFGF was 0.5mg / ml) aqueous phase containing 1g of sodium carbonate and 1.5g of PVA, and stirred Or form an O / W emulsion under ultrasonic conditions, then add 3ml of 26.7% PVA external water phase to it, stir at high speed for a period of time to form a double emulsion, transfer the double emulsion to a beaker, and stir at 300rpm for 80min to solidify. Collect the precipitate by centrifugation and keep the supernatant aqueous phase, wash three times and keep the washing liquid, then freeze-dry the precipitate for 24 hours;

[00...

Embodiment 2

[0067] Preparation of a Growth Factor Porous Microsphere Composite System Encapsulated by Injectable Hydrogel

[0068] (1) Dissolve 1.0g HA in 100ml of ultrapure water at 0-4°C, stir magnetically to fully dissolve, then add 2.0gADH, then add 1.6gEDC and 1.4gNHS, 1mol / lHCl to adjust the pH to 4.5, react for 19h, Dialysis to obtain HA-ADH sol;

[0069] (2) 2.25g of PLA was dissolved in 20mL of dichloromethane, then added to NGF, bFGF (NGF7.875mg / ml; bFGF is 0.75mg / ml) aqueous phase containing 2.0g sodium carbonate and 3.0gPVA, in Form an O / W emulsion under stirring or ultrasonic conditions, then add 6ml of 26.7% PVA external water phase to it, stir at high speed for a period of time to form a double emulsion, transfer the double emulsion to a beaker, stir at 300rpm for 100min to solidify. Collect the precipitate by centrifugation and keep the supernatant aqueous phase, wash three times and keep the washing liquid, then freeze-dry the precipitate for 36 hours;

[0070] (3) At 0...

Embodiment 3

[0089] Preparation of a Growth Factor Porous Microsphere Composite System Encapsulated by Injectable Hydrogel

[0090] (1) Dissolve 1.0g HA in 100ml ultrapure water under the condition of 0-4℃, magnetically stir until fully dissolved, then add 3.0gADH, then add 1.6gEDC and 1.4gNHS, 1mol / lHCl to adjust the pH to 5.5, react for 21h, Dialysis to obtain HA-ADH sol;

[0091] (2) 1.5g of PLA was dissolved in 20mL of dichloromethane, then added to NGF, bFGF (NGF9.5mg / ml; bFGF was 1mg / ml) aqueous phase containing 1g of sodium carbonate and 1.5g of PVA, stirring or Form an O / W emulsion under ultrasonic conditions, then add 3ml of 26.7% PVA external water phase to it, stir at high speed for a period of time to form a double emulsion, transfer the double emulsion to a beaker, and stir at 300rpm for 110min to solidify. Collect the precipitate by centrifugation and keep the supernatant aqueous phase, wash three times and keep the washing liquid, and then freeze-dry the precipitate for 30 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com