Method for knitting 2*2 rib stitch textile through two-needle bar flat knitting machine

A rib weave, double needle bed technology, applied in knitting, weft knitting, textiles and papermaking, etc., can solve the problems of loose opening, affect the appearance, affect the improvement of grades, etc., and achieve the effect of quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

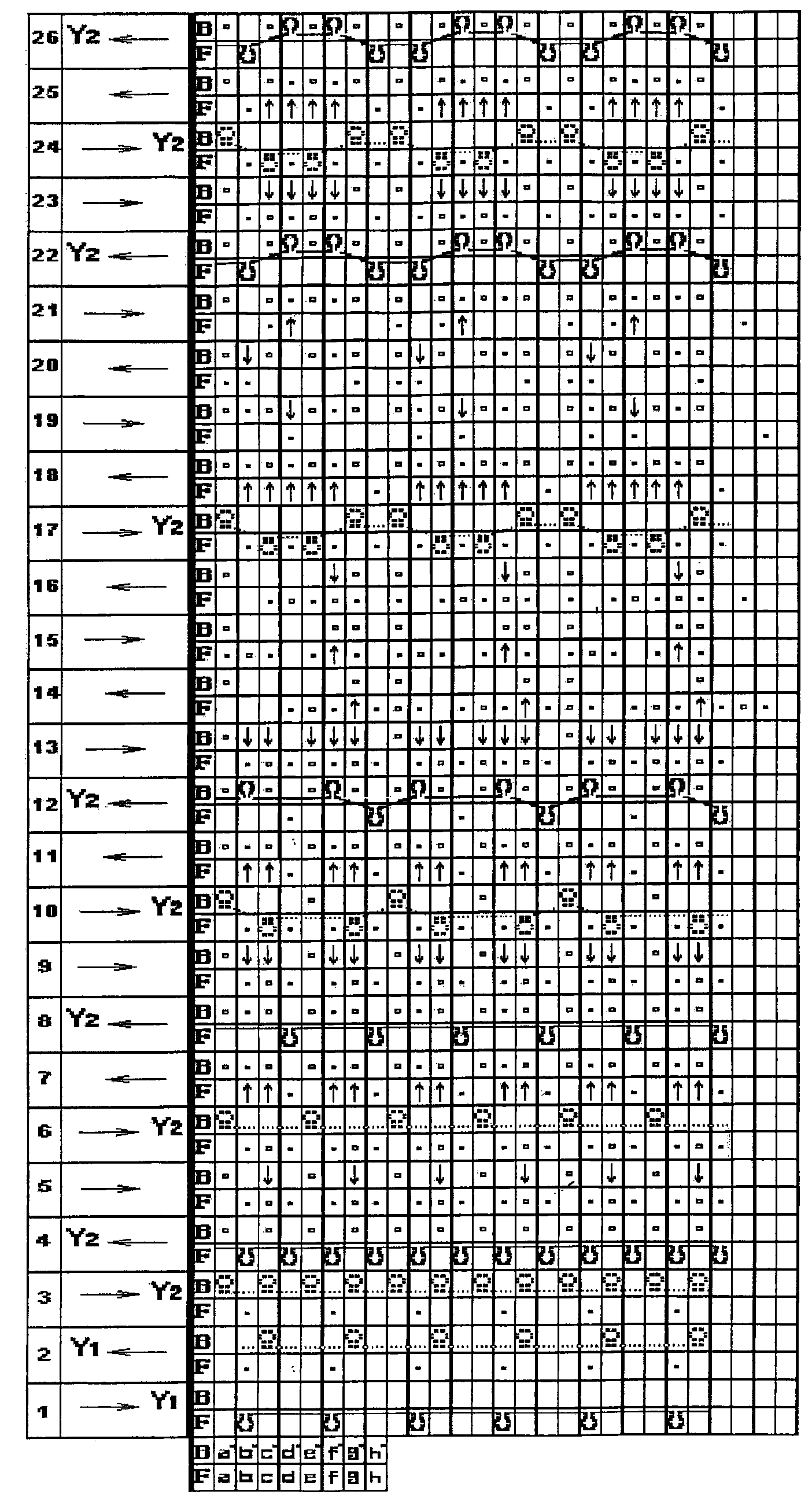

[0039] see figure 1 . Among them, the dotted line indicates the coil of the back garment, the solid line indicates the coil of the front garment, "F" indicates the front bed, "B" indicates the back bed, Indicates the front needle bed stitch, Indicates the stitches on the rear needle bed, "·" indicates the needles on which the front garment stitches are hung, "·" indicates the needles on which the rear garment stitches are hung, "↑" indicates the transfer from the front bed to the rear bed, "↓" indicates the rear bed Transfer to the front bed, "Y1" means waste yarn or drawn yarn, "Y2" means main yarn. also, figure 1 "←" in means that the nose moves to the left, and "→" means that the nose moves to the right.

[0040] In this embodiment, knitting is carried out on a flatbed knitting machine having a pair of front and back needle beds. It is realized by circular knitting in the way of 1 needle every 1 stitch, and the odd or even needles on the front bed are used for knitti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com