Vibration-proof intelligent warehouse logistics system

A technology of intelligent warehousing and logistics system, applied in the field of warehousing and logistics, to achieve the effect of simplifying the complexity of the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

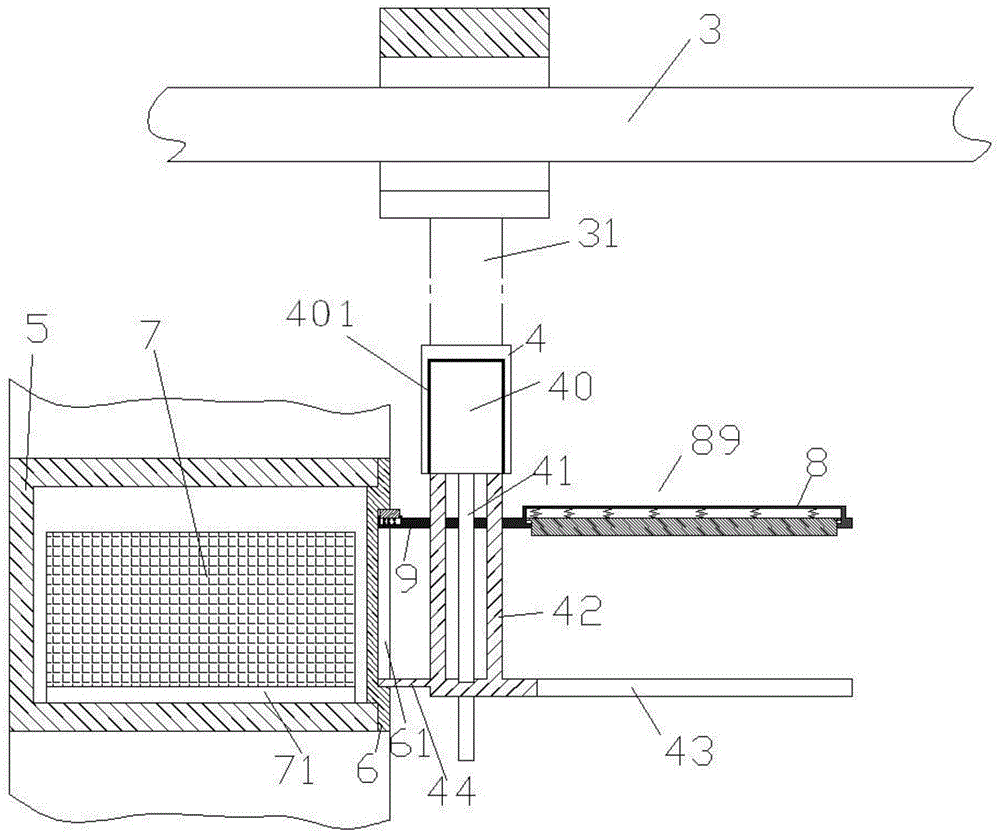

[0011] combined with figure 1 -4, the present invention is explained in detail.

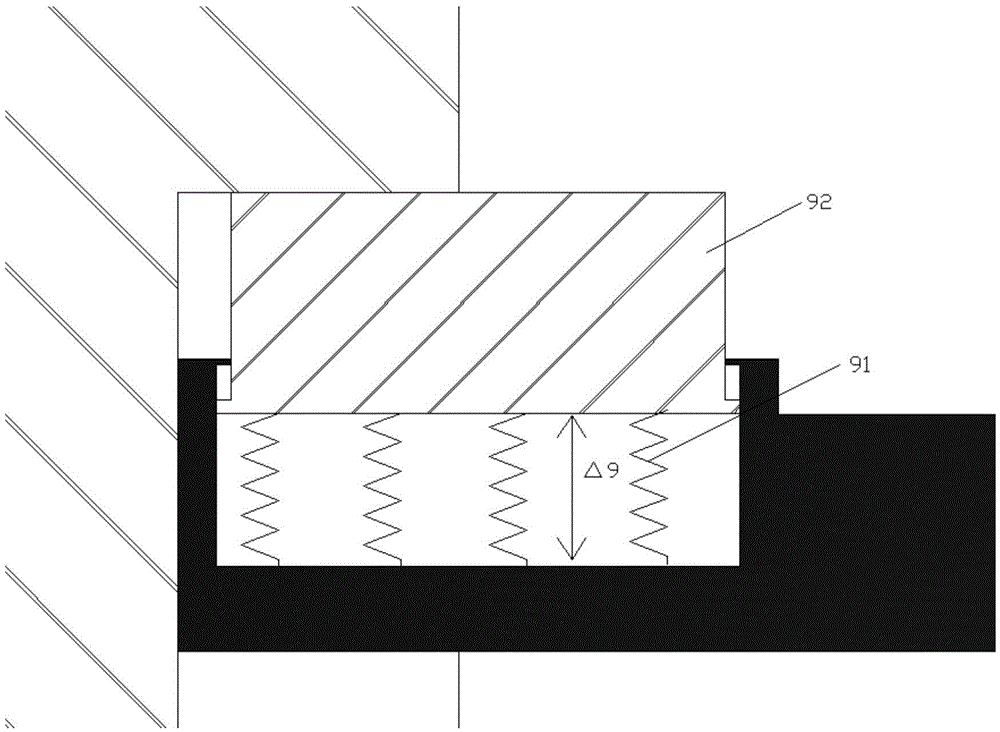

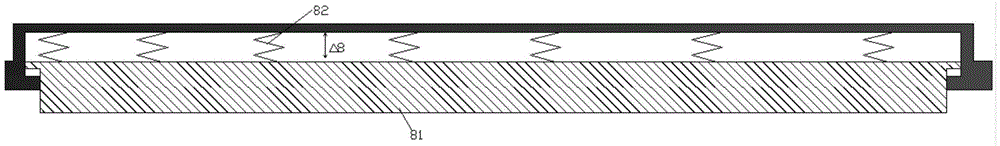

[0012] An anti-vibration intelligent storage and logistics system according to an embodiment includes a control device 100, a storage cabinet device, and a material transportation device, wherein the storage cabinet device includes a plurality of grasping slots for accommodating the bottom surface The unit cabinet 5 of the material box 7 of 71, the access port of the unit cabinet 5 is equipped with an openable cover 6 with a grip groove 61 on the outer surface; the material transport device includes a drive mechanism 3 and a vertical The connecting rod 31 extending in the vertical direction is connected to the material box operating device with the drive mechanism 3, and the driving mechanism 3 can drive the material box operating device to translate in the vertical direction, around the connecting rod 31 The axis rotates and can move in translation in the left and right directions and front and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com