All-optical X-ray microscopic imaging system

A microscopic imaging and X-ray technology, applied in the direction of using wave/particle radiation, material analysis using radiation, instruments, etc., can solve the problems of sample projection image overlap, complex optical path adjustment system, and difficult optical path adjustment, etc., so as to facilitate popularization Easy to use, simple system structure, simple image reconstruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

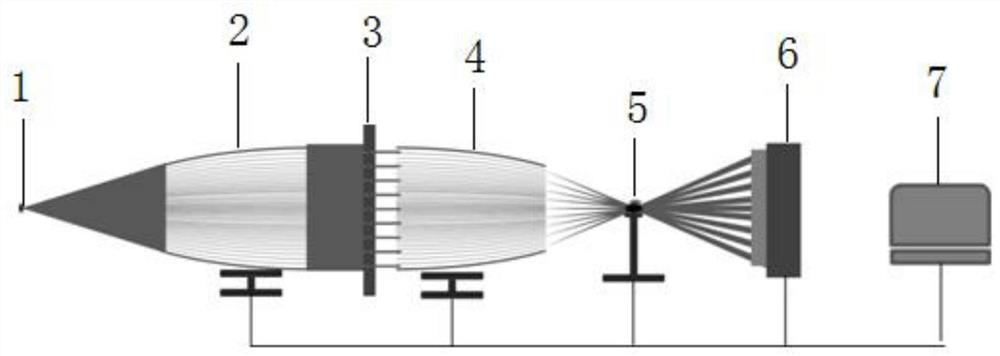

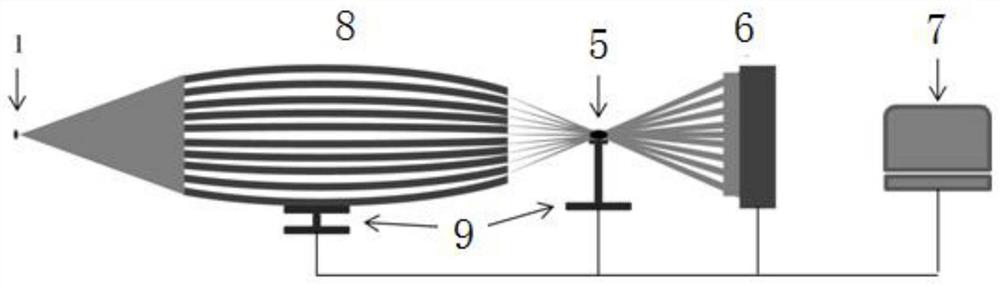

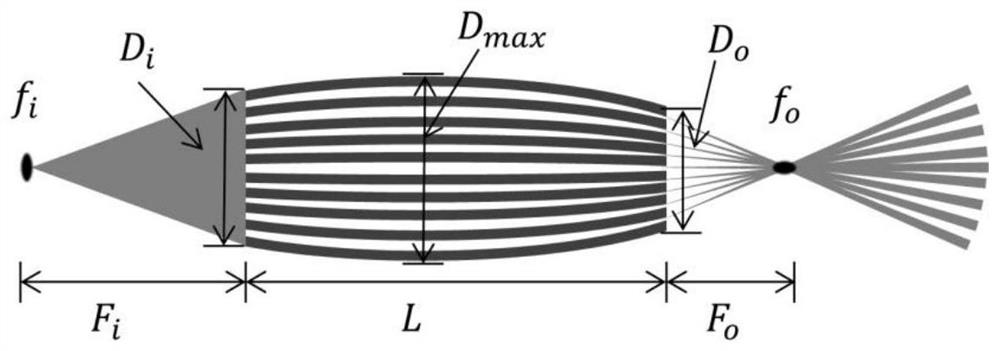

[0043] X-ray generator 1 can be combined with laboratory point focal spot X-ray tube and beam splitter 8, the focus of the light tube is placed at the front focal spot of the beam splitter, and the beam splitter 8 scatters the received X-ray tube The X-ray beams are converted into respective independent narrow cone beams, and the cone beams are converged at the rear focal point of the beam splitter 8 . The X-ray generator 1 is a rotating anode molybdenum target light source, the focal spot diameter is 300 microns, and the power is 3 kilowatts. The inner diameter of the sub-tube of the beam splitter 8 is 1 micron, the outer diameter is 30 microns, the working distance of the beam splitter 8 is 15 mm, and the focal spot size 30 microns. The sample 5 is adjusted and placed at the focal spot of the beam splitter 8 through the precision displacement platform 9 , and the imaging detector 5 is placed behind it, and the projection images of the sample 3 at various angles can be obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com