Square bundle straw crusher capable of achieving blending cutting and beating secondary crushing

A straw grinder and two-stage crushing technology, applied in cutting equipment, agricultural machinery and tools, grain processing, etc., can solve the problems of manual bulk baling and manual feeding, difficulty in reaching mutton sheep, and inability to subdivide processing, etc., to reduce labor costs Effects of labor intensity, efficiency improvement and processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

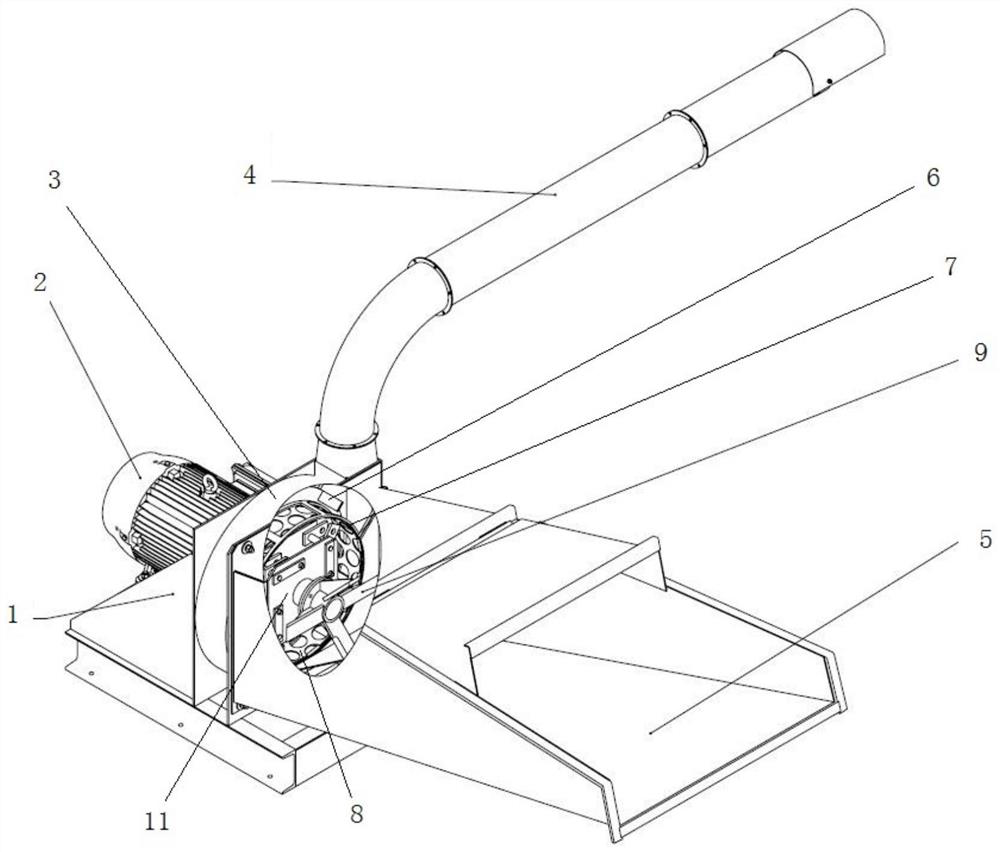

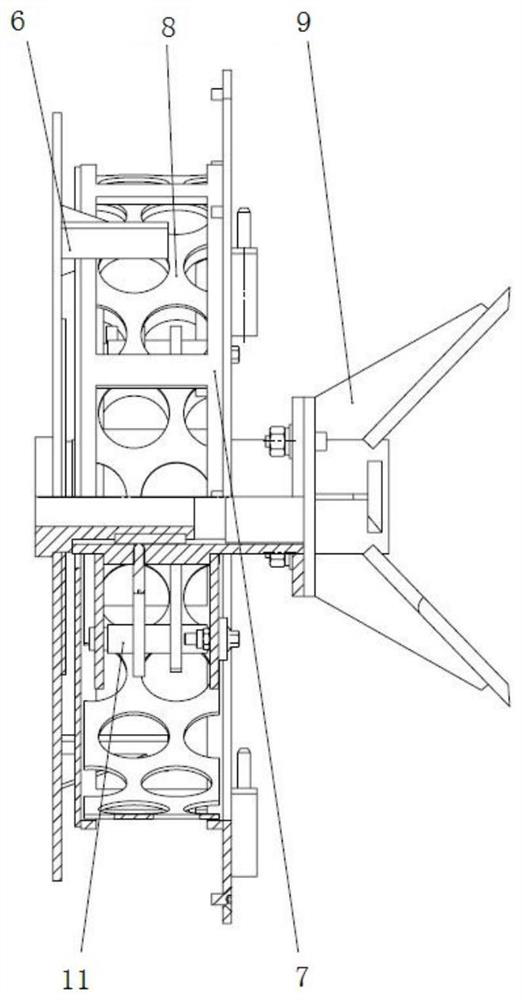

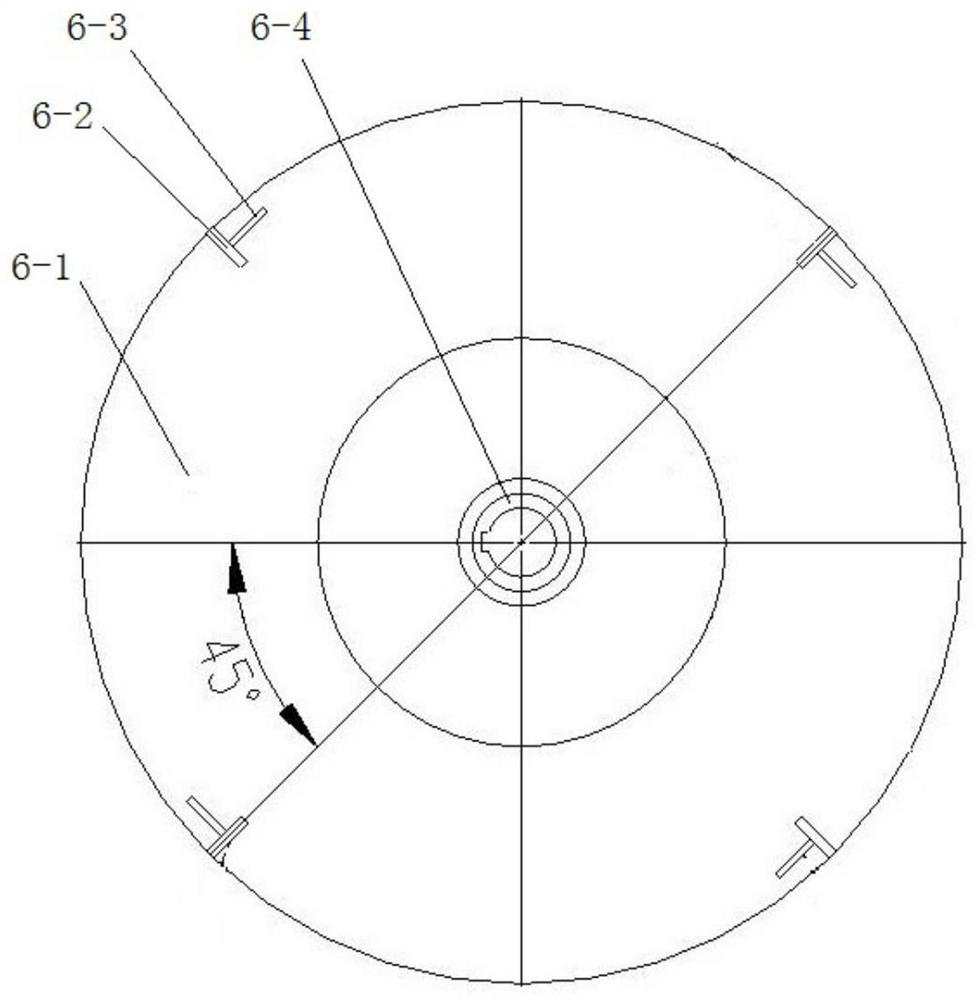

[0033] Reference numerals: machine base 1; motor 2; casing 3; discharge pipe 4; feed port 5; impeller 6 (bottom plate 6-1, blade 6-2, reinforcing rib 6-3, connecting sleeve 6-4) ; Crushing chamber 7; Screen 8; Stirring mechanism 9 (stirring knife flange 9-1, stirring pipe shaft 9-2, oblique stirring knife 9-3, flat stirring knife 9-4); chopping mechanism 10 (chopping knife flange 10-1, chopping pipe shaft 10-2, cutter 10-3); hammer cutting mechanism 11 (hammer cutting flange 11-1, front plate 11-2, hammer blade 11-3, Sleeve 11-4, hammer shaft 11-5, reinforcing lath 11-6, back plate 11-7, hammer cutting pipe shaft 11-8).

[0034] The present invention is a mixing and beating two-stage pulverizing square-bale straw pulverizer, which comprises a machine base on which a motor and a casing are installed, the casing is connected with a discharge pipe and a feeding port, and inside the casing is installed a The crushing mechanism is characterized in that: the crushing mechanism is d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com