Raw material crushing device for machining

A technology of mechanical processing and crushing device, applied in the field of mechanical processing, can solve the problems of unable to adjust the crushing components, insufficient crushing of raw materials, poor quality of finished products, etc., to achieve the effect of improving the refining effect, preventing the splashing of raw materials, and improving the crushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

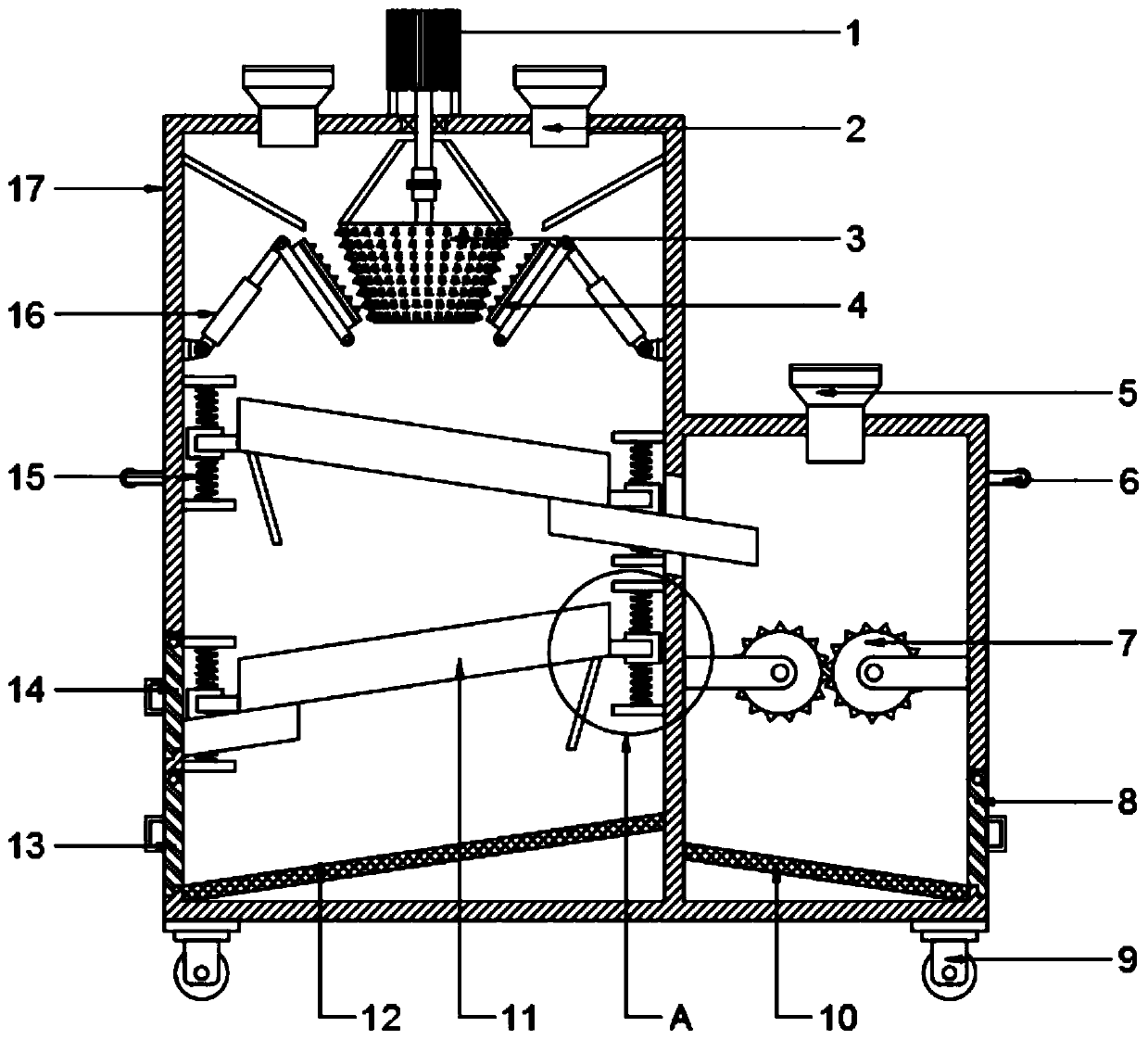

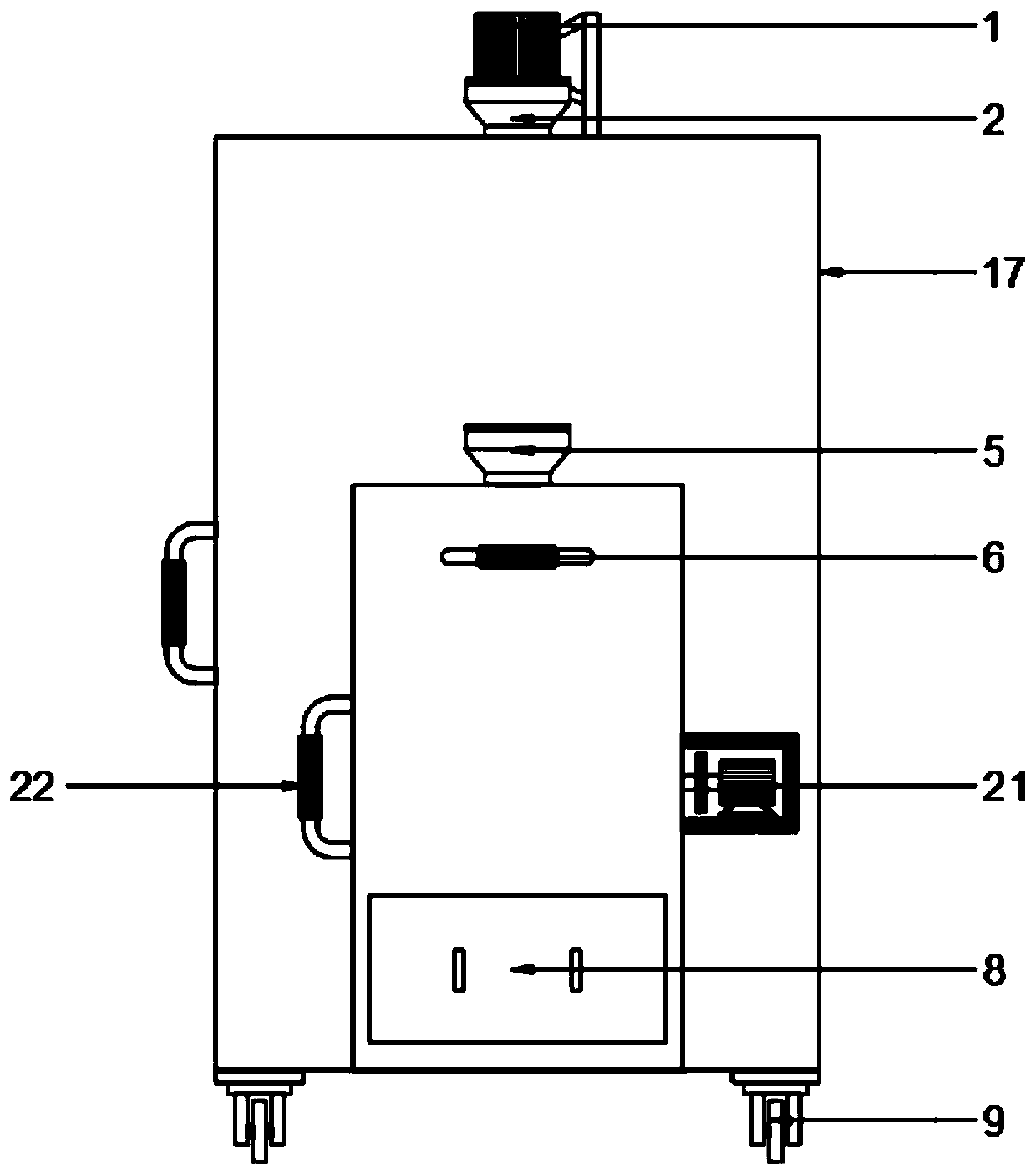

[0027] see Figure 1~6 , in an embodiment of the present invention, a raw material crushing device for mechanical processing, including a box body 17 and a crushing assembly and a screening assembly arranged in the box body, a crushing chamber is provided inside the box body 17, and the top of the crushing chamber is connected with a Two groups of first feed hoppers 2, the discharge port of the first feed hopper 2 is located above the crushing assembly and a material guide plate is also arranged between the two, and the material guide plate is used to feed the first feed hopper The raw materials in 2 are guided to the crushing assembly to prevent waste from being spilled; the crushing assembly includes a crushing hammer 3, a crushing plate 4 and an electric telescopic rod 16. The crushing hammer 3 is rotatably installed inside the crushing chamber and its shaft passes through The crushing chamber is set in linkage with the crushing motor 1 fixedly installed on the top of the c...

Embodiment 2

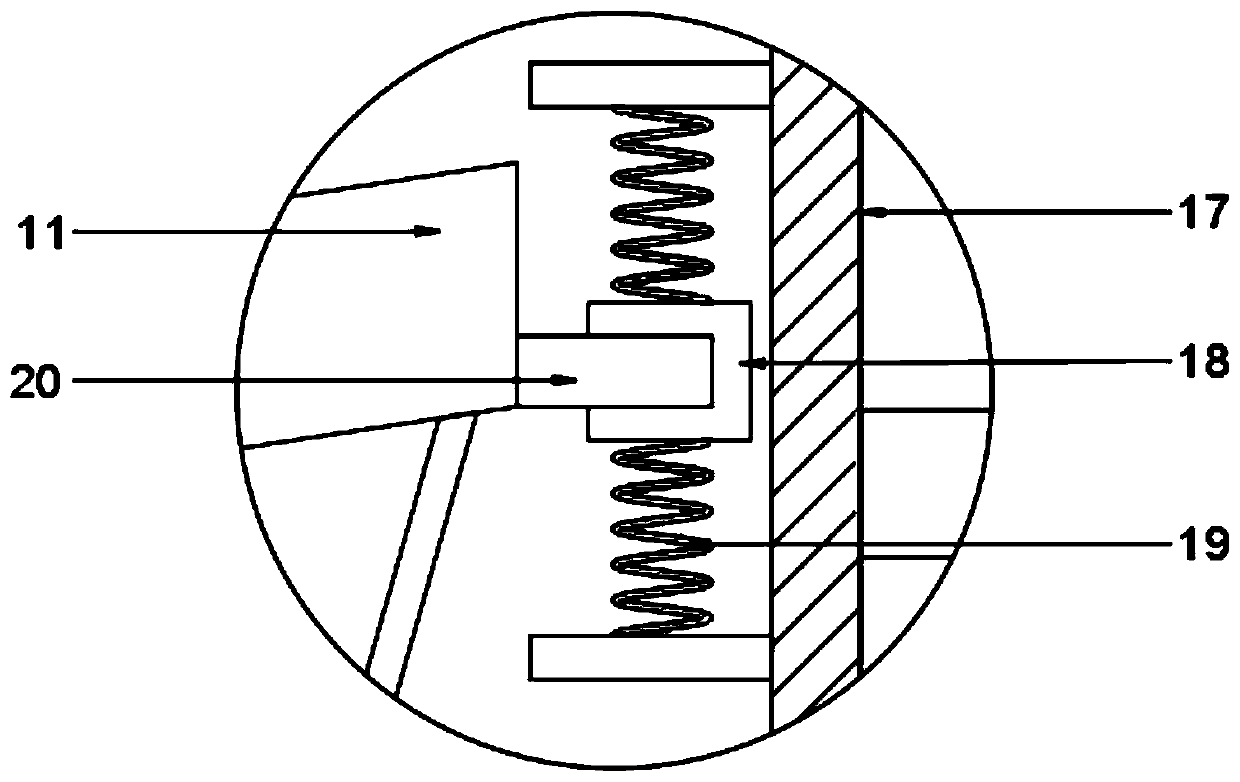

[0034] see Figure 1~2 , in the embodiment of the present invention, a raw material crushing device for mechanical processing, on the basis of embodiment 1, the elastic assembly 15 includes an elastic slot 18 and a compression spring 19, and the elastic slot 18 is in a "C" shape And its upper and lower ends are all provided with compression spring 19, and the end of described compression spring 19 far away from elastic clamping groove 18 is fixedly installed on the inner wall of crushing box through baffle plate, and described elastic clamping groove 18 and clamping block 20 form movable engagement, It can not only drive the vibrating screen 11 to vibrate when the raw material falls on the vibrating screen 11, but also enhance the effect, and is easy to disassemble. According to actual requirements, the vibrating screen 11 with the corresponding aperture can be replaced according to the distance between the breaking hammer 3 and the crushing plate 4 , enhance the raw material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com