Novel efficient oil sand crushing machine

A crusher and oil sand technology, applied in grain processing, etc., can solve the problems of oil sand crushing failure, high cost, difficult maintenance and repair, etc., and achieve good crushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

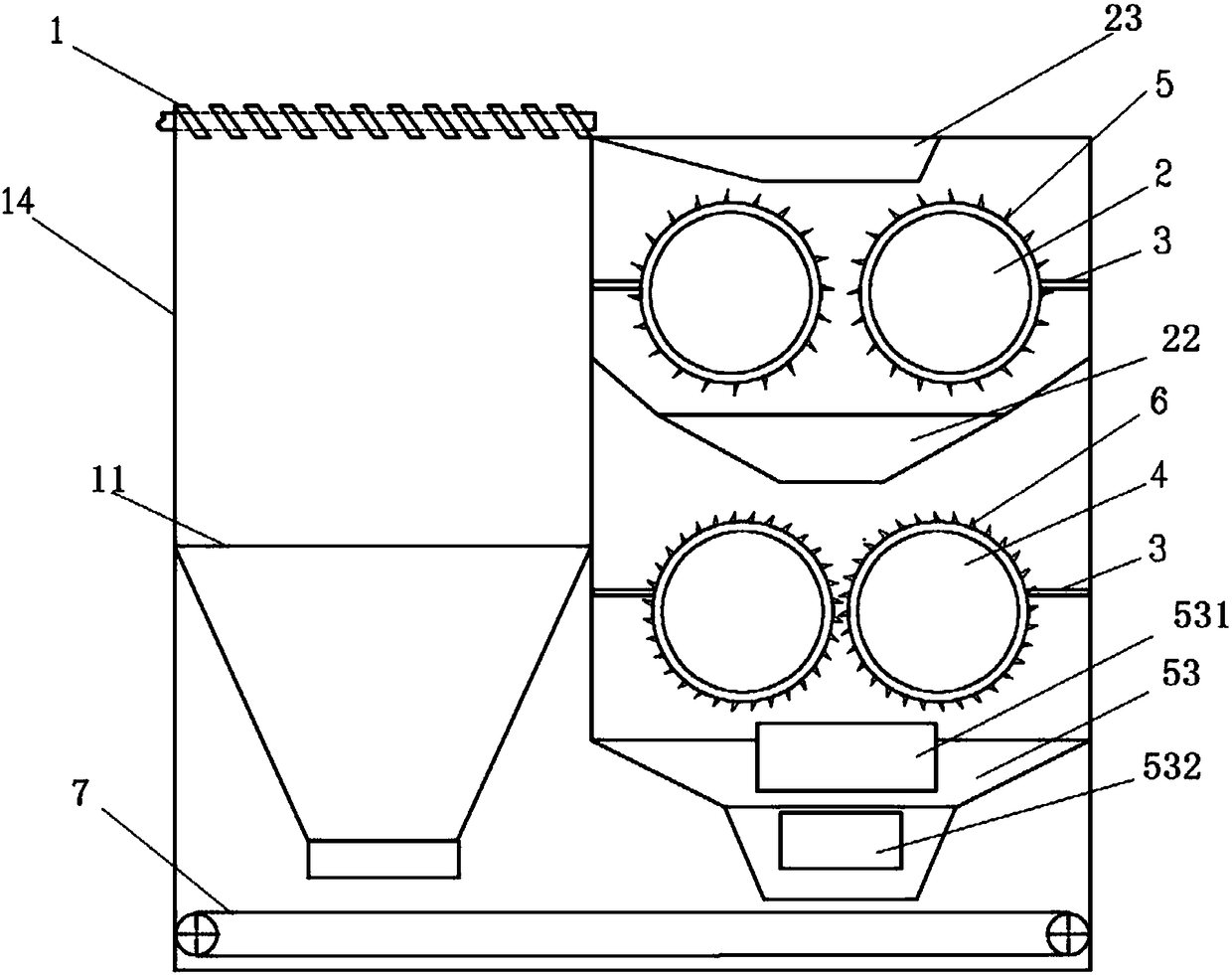

[0069] The new high-efficiency oil sand crusher of the present invention has a sorting propulsion device 1, a primary crushing device 2, a roller surface cleaning device 3, a secondary crushing device 4, and a conveying device 7.

[0070] The sorting propulsion device is used to screen the oil sand. The first discharge port 11 is provided under the sorting propulsion device. The oil sand that meets the requirements is discharged through the first discharge port 11 through the gap of the sorting propulsion device. , the oil sand that does not meet the requirements enters the primary crushing device 2;

[0071] The primary crushing device 2 is arranged near the outlet end of the sorting propulsion device to further crush the oil sand from the sorting propulsion device to obtain coarsely crushed oil sand. The discharge port 22 , the coarsely crushed oil sand flows into the secondary crushing device 4 through the second discharge port 22 .

[0072] The secondary crushing device 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com