Composite large-area crusher cavity

A crusher, large-area technology, applied in grain processing and other directions, can solve the problems of poor forming degree of crushed materials, reduce crushing efficiency, and affect crushing effect, etc., to strengthen crushing and trimming, improve crushing efficiency, and avoid chaos hit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be further elaborated below in conjunction with the accompanying drawings.

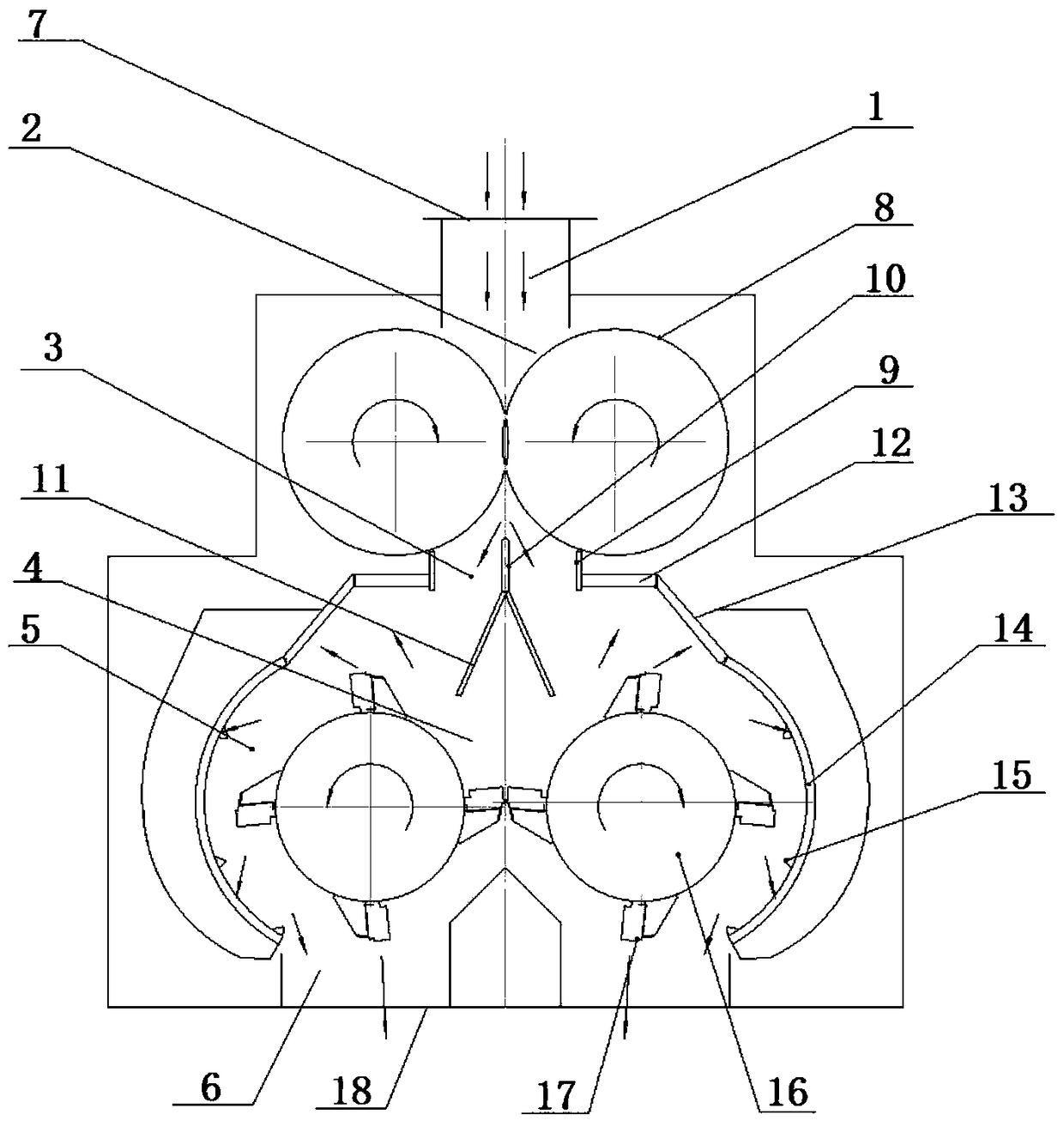

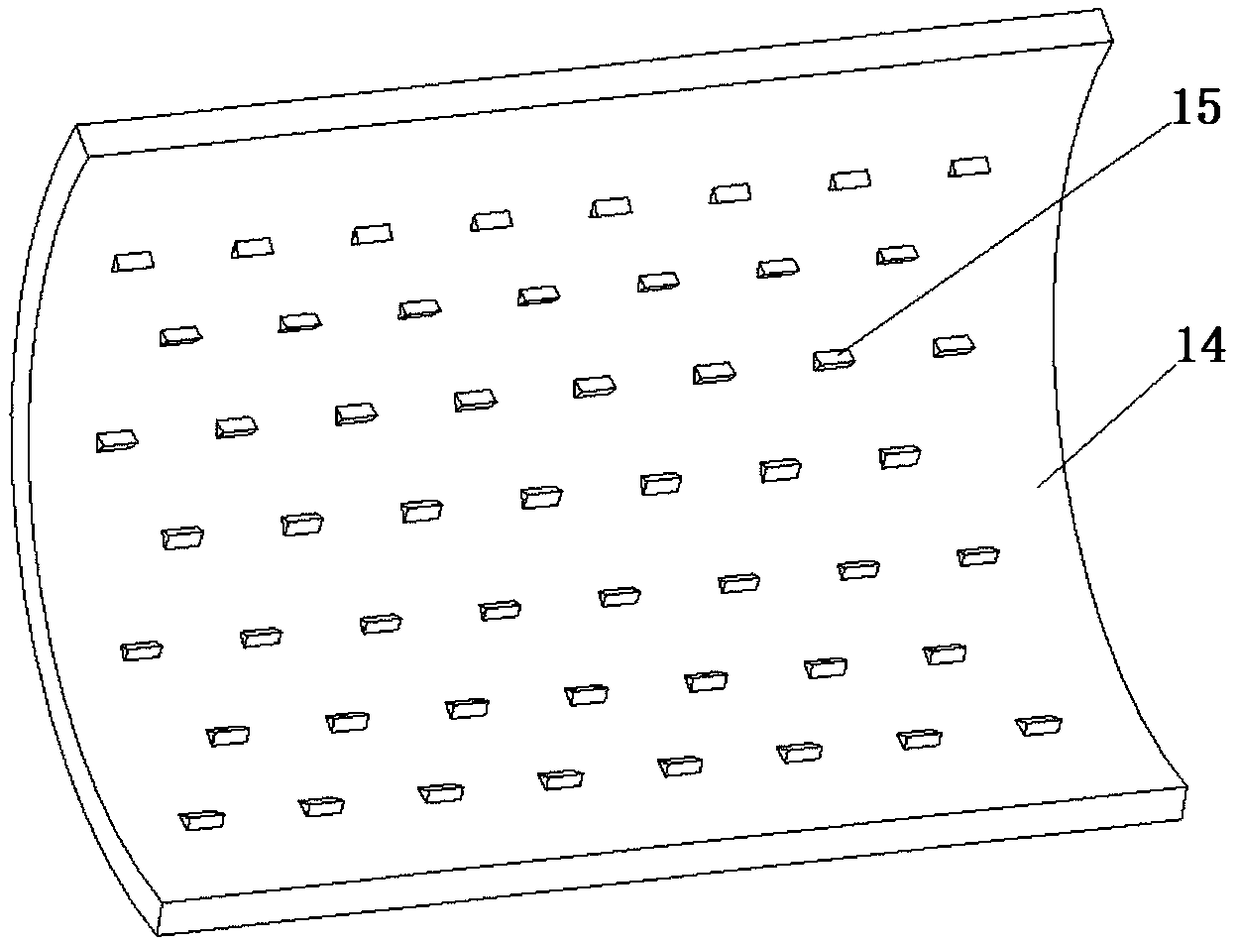

[0025] In this example, if figure 1 and 2 As shown, a composite large-area crusher cavity, the cavity includes a feed cavity 1, an acceleration cavity 2, a diversion cavity 3, a crushing cavity 4, a finishing cavity 5 and a discharge cavity 6 from top to bottom. , the accelerating chamber 2 includes two horizontally arranged accelerating rollers 8, the crushing chamber 4 includes two horizontally arranged crushing rollers 16, and the finishing chamber 5 is between the two crushing rollers 16 and the side wall of the chamber;

[0026] The top of the feeding chamber 1 is provided with a feeding port 7, and the bottom of the two accelerating rollers 8 is provided with a material guide plate 9, and the middle of the two material guide plates 9 is provided with a material dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com