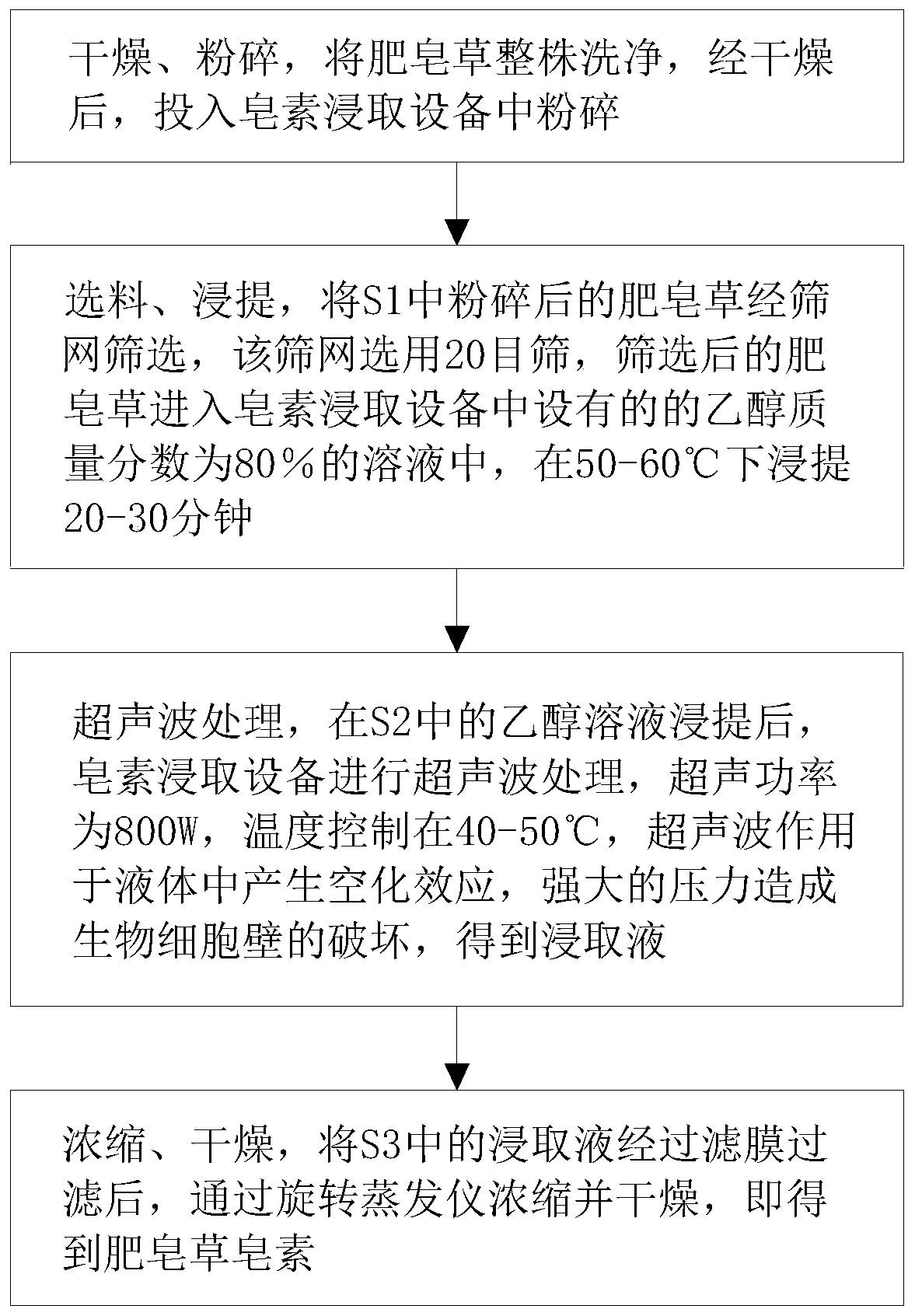

Extraction method of saponaria officinalis saponin

An extraction method and a technology of oxalin, applied in chemical instruments and methods, preparation of sugar derivatives, filtration and screening, etc., can solve problems such as process dispersion, long process cycle, and incomplete crushing, so as to improve work efficiency and improve extraction Efficiency, the effect of maintaining crushing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

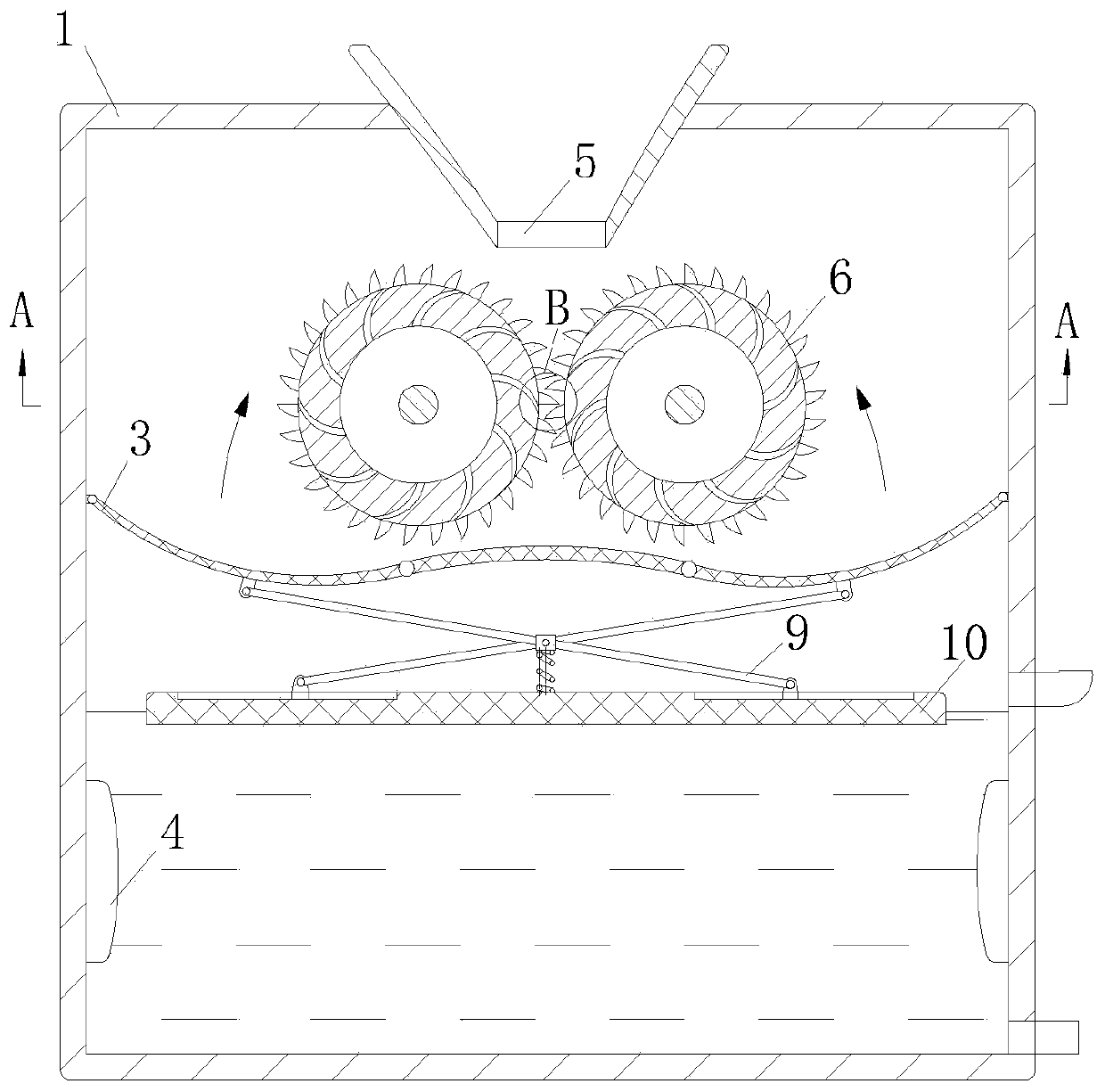

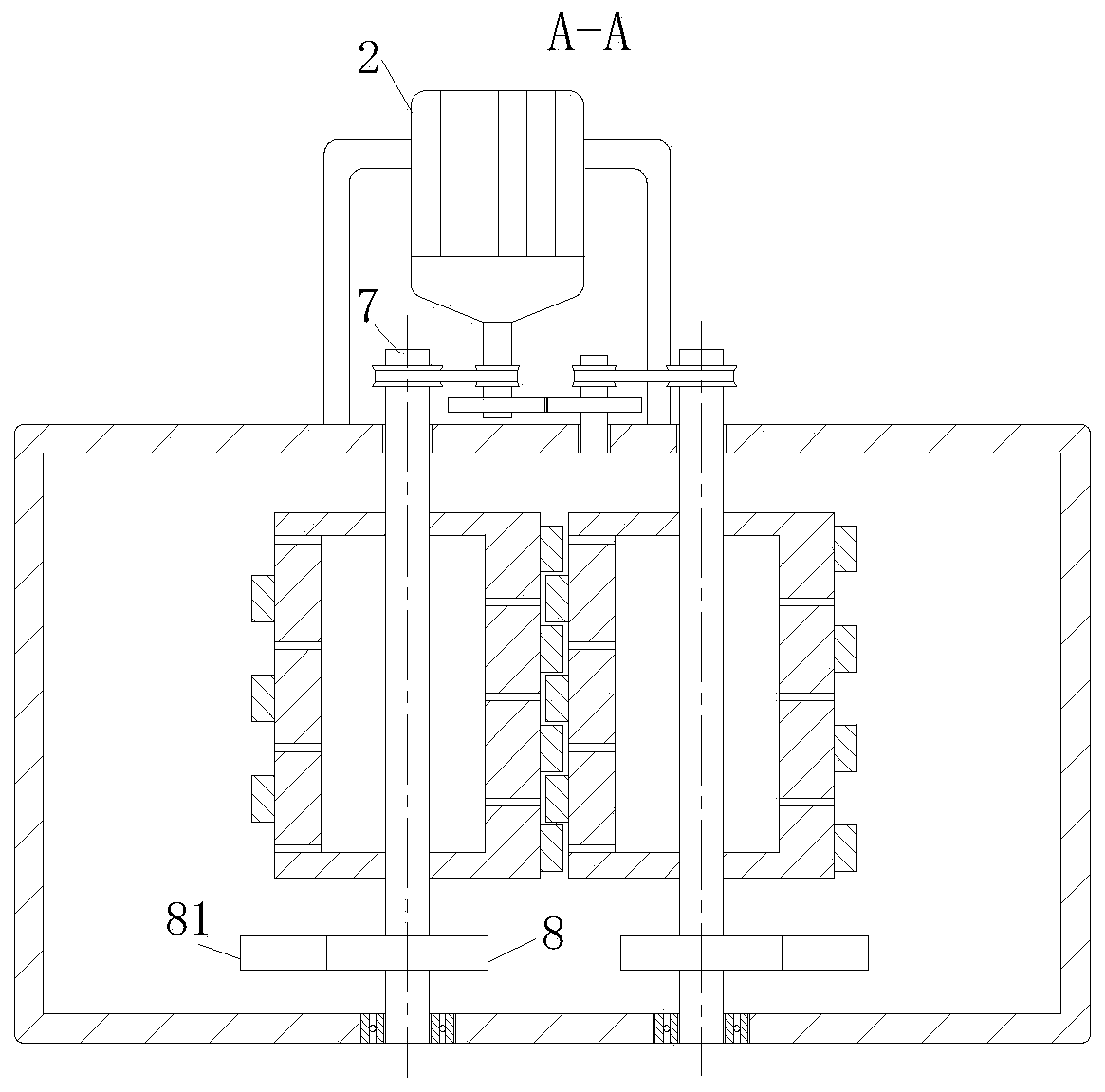

Embodiment approach

[0035] As an embodiment of the present invention, the screen 3 includes a middle screen 31 and an end screen 32; the end screen 32 is symmetrically distributed with respect to the middle screen 31; the middle screen 31 is slightly raised The shape of the end screen 32 is concave; the middle screen 31 is a rigid body; the end screen 32 is soft; the middle screen 31 is connected to the end screen 32 by hinges, and the end The other side of the screen 32 is hinged and fixed on the inner wall of the casing 1; during use, the soapwort particles that have not passed the screening fall into the recess of the end screen 32, and the end screen 3 is bounced and deformed by the elastic telescopic frame 9 , the soapwort particles in the recess are bounced, and it is impossible to ensure that the soapwort particles bounce to the crushing roller 6 and break again, and by setting the hinged end screen 32, the deformation of the end screen 32 is controlled, and the end The soapwort particles ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com