Large straw pulverizer

A straw pulverizer, a large-scale technology, is used in agricultural machinery and implements, solid separation, filter screens, etc. It can solve the problems of low degree of automation, affecting production efficiency, straw blocking, etc., achieving high degree of automation, reasonable structure, and preventing blocking. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the purpose, technical solution and advantages of the present invention clearer, the embodiments of the present invention will be described in detail below with reference to the accompanying drawings. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined arbitrarily with each other.

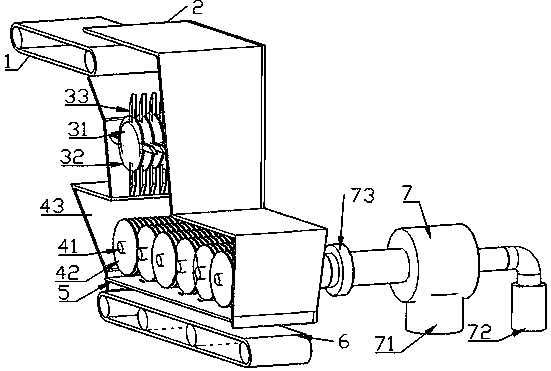

[0016] Such as figure 1 As shown, a large-scale straw pulverizer according to the embodiment of the present invention includes a feeding conveyor belt 1, a first pulverizing device 3, a second pulverizing device 4, a discharge conveyor belt 6 and a dust removal device 7, and the feeding conveyor belt 1 is installed on the straw Above the pulverizer, one end extends into the feed inlet 2, and the first pulverizer 3 is arranged below the feed inlet 2. The first pulverizer 3 includes a main shaft 31, a flange 32 and a cutter 33. The flange The disk 32 is installed on the main shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com