Auxiliary crushing and screening machine for PVC tube production

A PVC pipe and screening machine technology, applied in grain processing and other directions, can solve problems such as single function, low screening efficiency, and easy blockage, and achieve the effect of improving screening efficiency, ensuring secondary filtering effect, and preventing filter screen blocking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

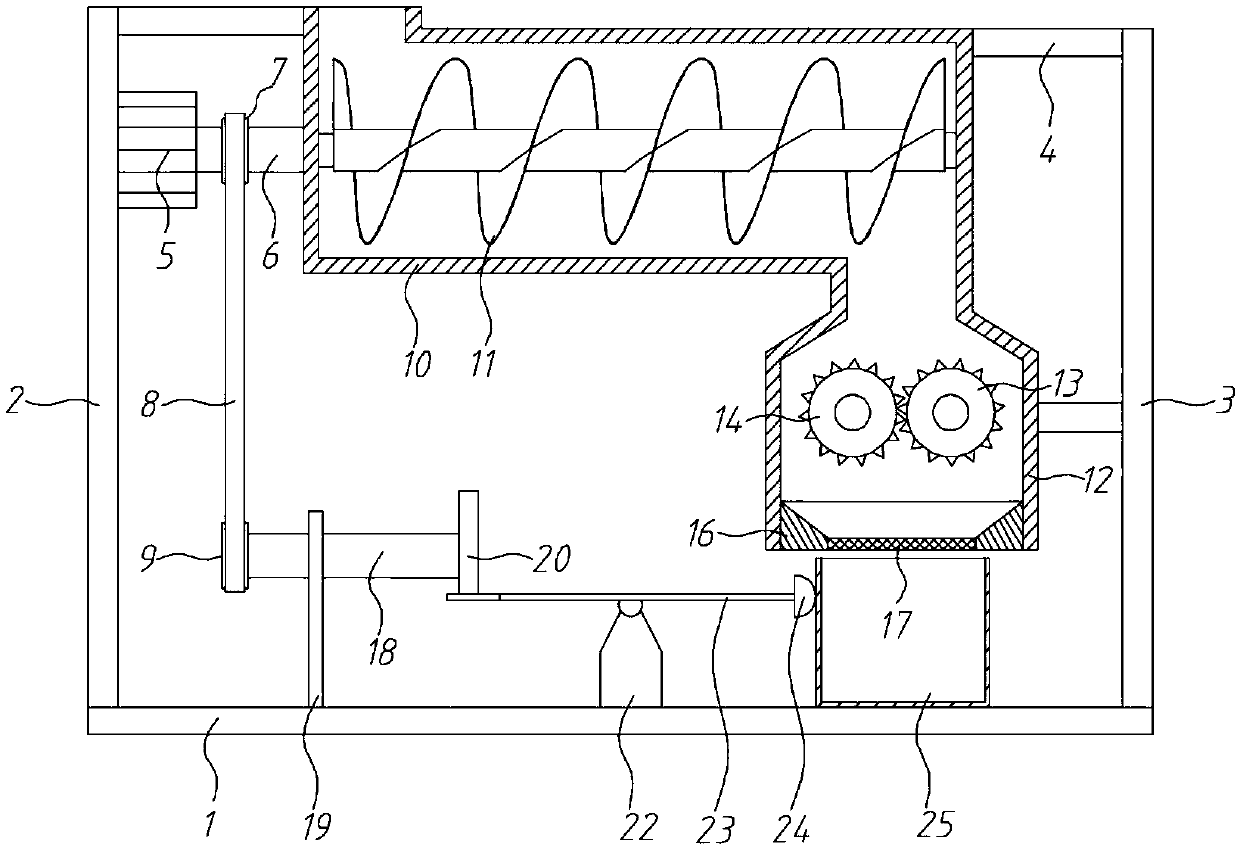

[0039] An additive crushing and screening machine for PVC pipe production, including a support frame, a crushing component and a vibrating component,

[0040] The support frame includes a base 1, a left vertical plate 2 and a right vertical plate 3 fixedly connected to both ends of the base 1, and a drive motor 5 is installed on the inner side of the left vertical plate 2;

[0041]The crushing assembly includes a primary crushing tube 10 and a No. 2 crushing tube 12. The primary crushing tube 10 is horizontally arranged between the left and right vertical plates. The two ends of the primary crushing tube 10 are sealed and fixed to the left vertical plate 2 and the right Vertical plate 3; the upper left end of the primary crushing cylinder 10 has a feed port; the output end of the driving motor 5 extends to the right and is connected with the driving shaft 6, and the driving shaft 6 extends into the primary crushing cylinder 10 and is equipped with a screw twister. The dragon 1...

Embodiment 2

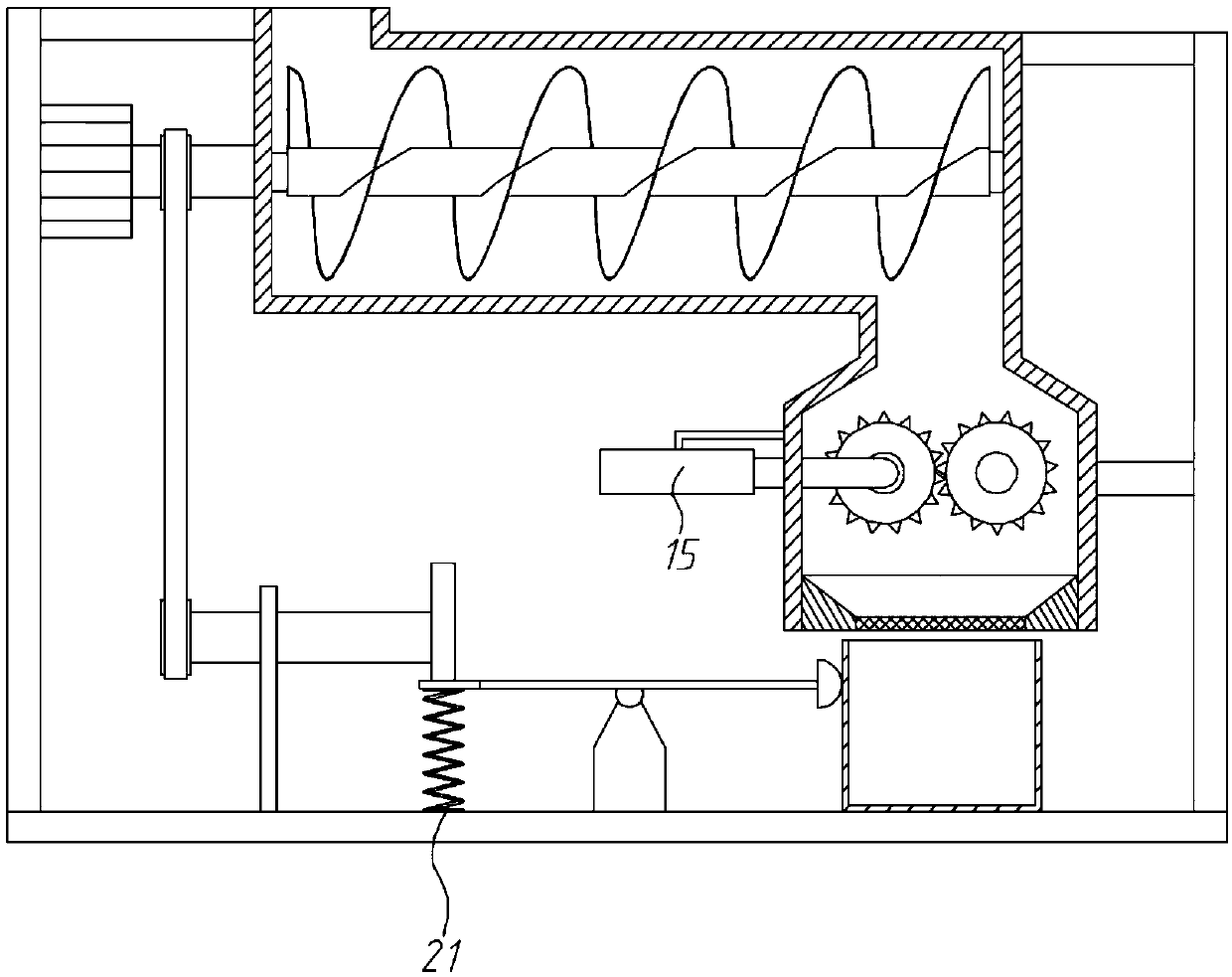

[0047] An additive crushing and screening machine for PVC pipe production, including a support frame, a crushing component and a vibrating component,

[0048] The support frame includes a base 1, a left vertical plate 2 and a right vertical plate 3 fixedly connected to both ends of the base 1, and a drive motor 5 is installed on the inner side of the left vertical plate 2;

[0049] The crushing assembly includes a primary crushing tube 10 and a No. 2 crushing tube 12. The primary crushing tube 10 is horizontally arranged between the left and right vertical plates. The two ends of the primary crushing tube 10 are sealed and fixed to the left vertical plate 2 and the right Vertical plate 3; the upper left end of the primary crushing cylinder 10 has a feed port; the output end of the driving motor 5 extends to the right and is connected with the driving shaft 6, and the driving shaft 6 extends into the primary crushing cylinder 10 and is equipped with a screw twister. The dragon ...

Embodiment 3

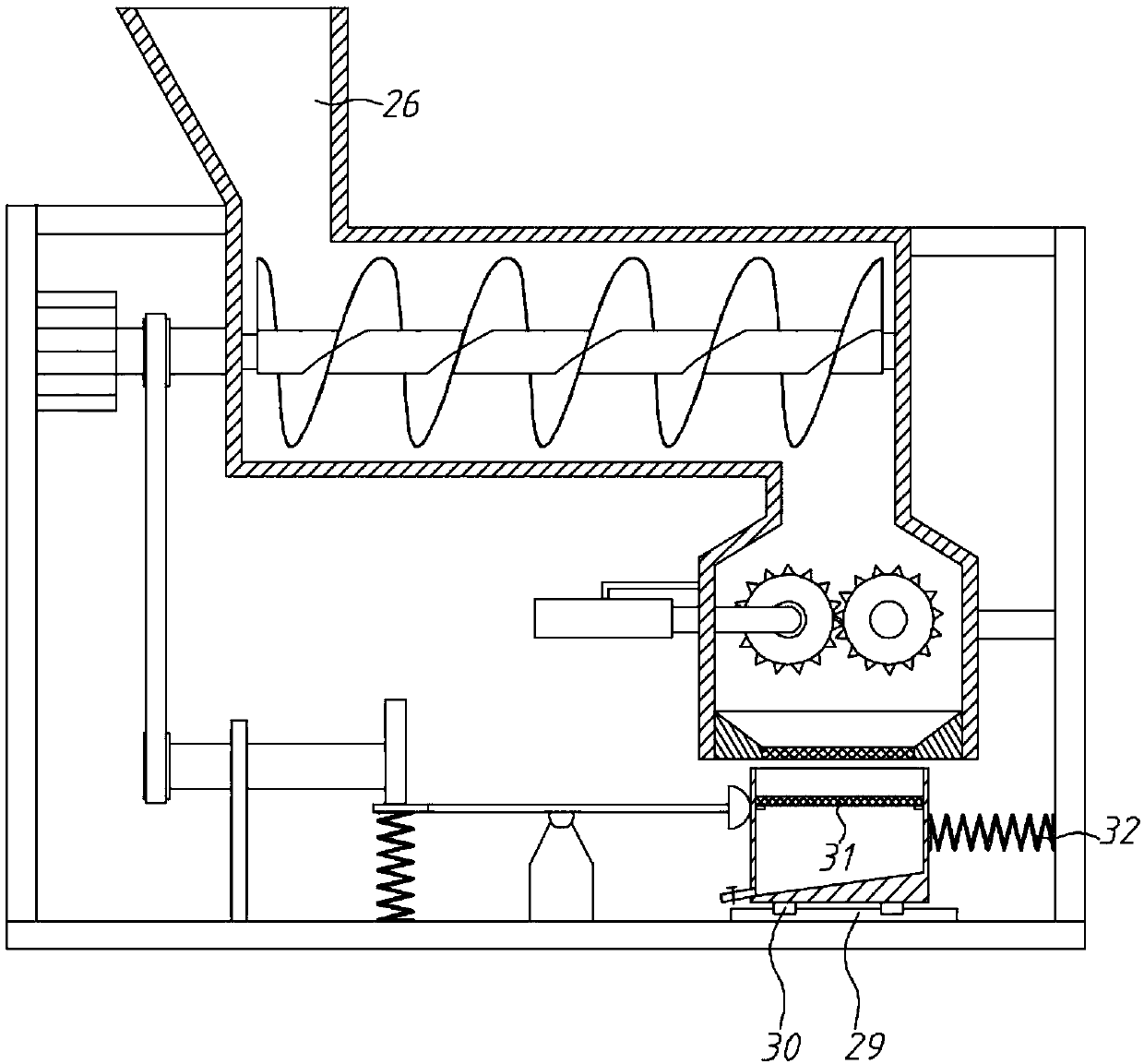

[0054] An additive crushing and screening machine for PVC pipe production, including a support frame, a crushing component and a vibrating component,

[0055] The support frame includes a base 1, a left vertical plate 2 and a right vertical plate 3 fixedly connected to both ends of the base 1, and a drive motor 5 is installed on the inner side of the left vertical plate 2;

[0056] The crushing assembly includes a primary crushing tube 10 and a No. 2 crushing tube 12. The primary crushing tube 10 is horizontally arranged between the left and right vertical plates. The two ends of the primary crushing tube 10 are sealed and fixed to the left vertical plate 2 and the right Vertical plate 3; the upper left end of the primary crushing cylinder 10 has a feed port; the output end of the driving motor 5 extends to the right and is connected with the driving shaft 6, and the driving shaft 6 extends into the primary crushing cylinder 10 and is equipped with a screw twister. The dragon ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com