Flash drying method for fish meal

A flash drying and fishmeal technology, which is applied in the directions of drying solid materials, drying cargo handling, and drying gas arrangement, can solve the problems of fishmeal being easily deteriorated by heat, affecting the effect of flash drying, etc., to ensure product particle size and moisture requirements, reduce Heat loss, good drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

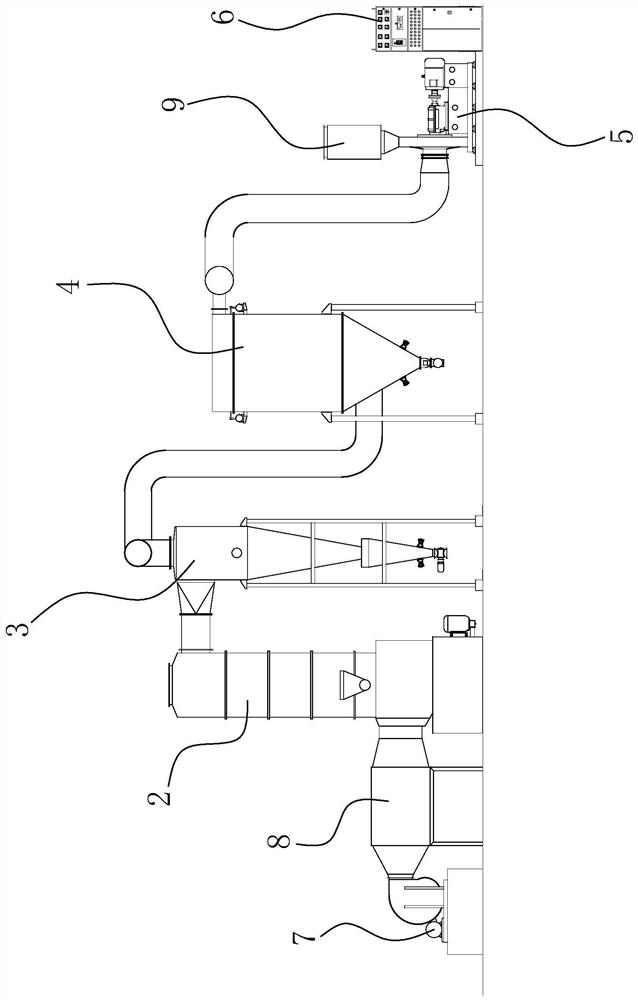

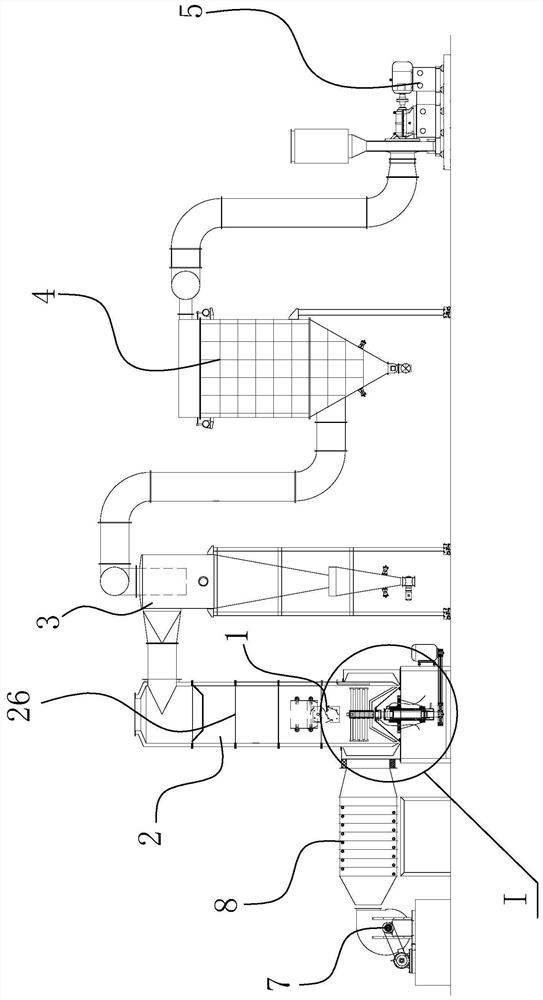

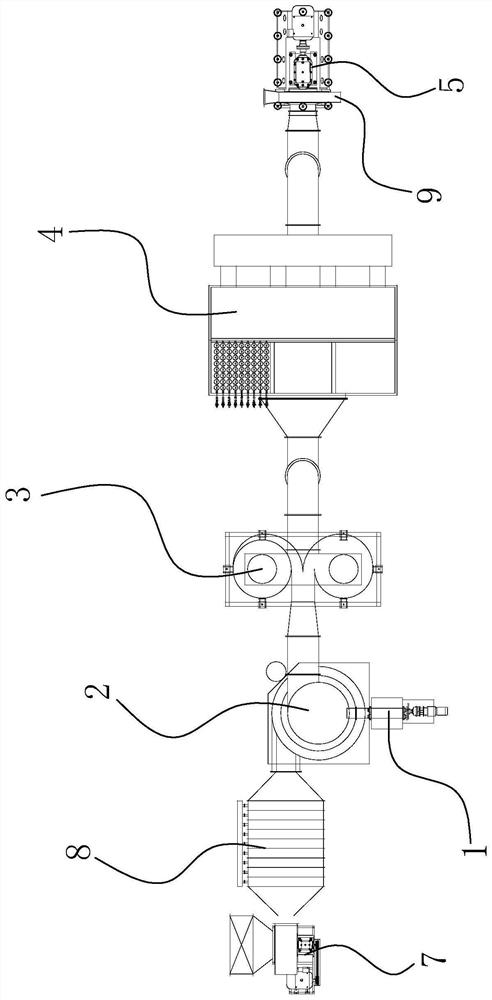

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0033] Such as Figure 1 to Figure 4 Shown, the flash drying method of the fishmeal of the present embodiment comprises the following steps,

[0034] 1. Send the fish meal to be dried into the lower inner cavity of the crushing and drying part 2 through the feeding part 1, and at the same time, the blower 7 sends hot air into the lower inner cavity of the crushing and drying part 2, and the hot air heats and dries the fish meal;

[0035] 2. The crushing mechanism of the crushing and drying part 2 crushes and screens the fish meal so that the fish meal is fully contacted with hot air and dried. During the drying process, the fish meal enters the upper cavity of the crushing and drying part 2 with the cyclone;

[0036] 3. The small and medium-sized fishmeal fishmeal entering the upper chamber continues to rise and enter the cyclone separation p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com