Heat pressing moulding process and equipment for lignite rich in water after drying process

A technology of hot pressing and drying treatment, which is applied in metal processing equipment, petroleum industry, solid fuel, etc. It can solve the problems that the latent heat of water cannot be fully utilized, and it is not suitable for drying lignite rich in water, so as to achieve the phenomenon of reabsorption Reduced, simple construction, increased heat generation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The type selection and main parameters of the lignite drying and forming equipment with an annual output of 250,000 tons of lignite designed by the invention are adopted.

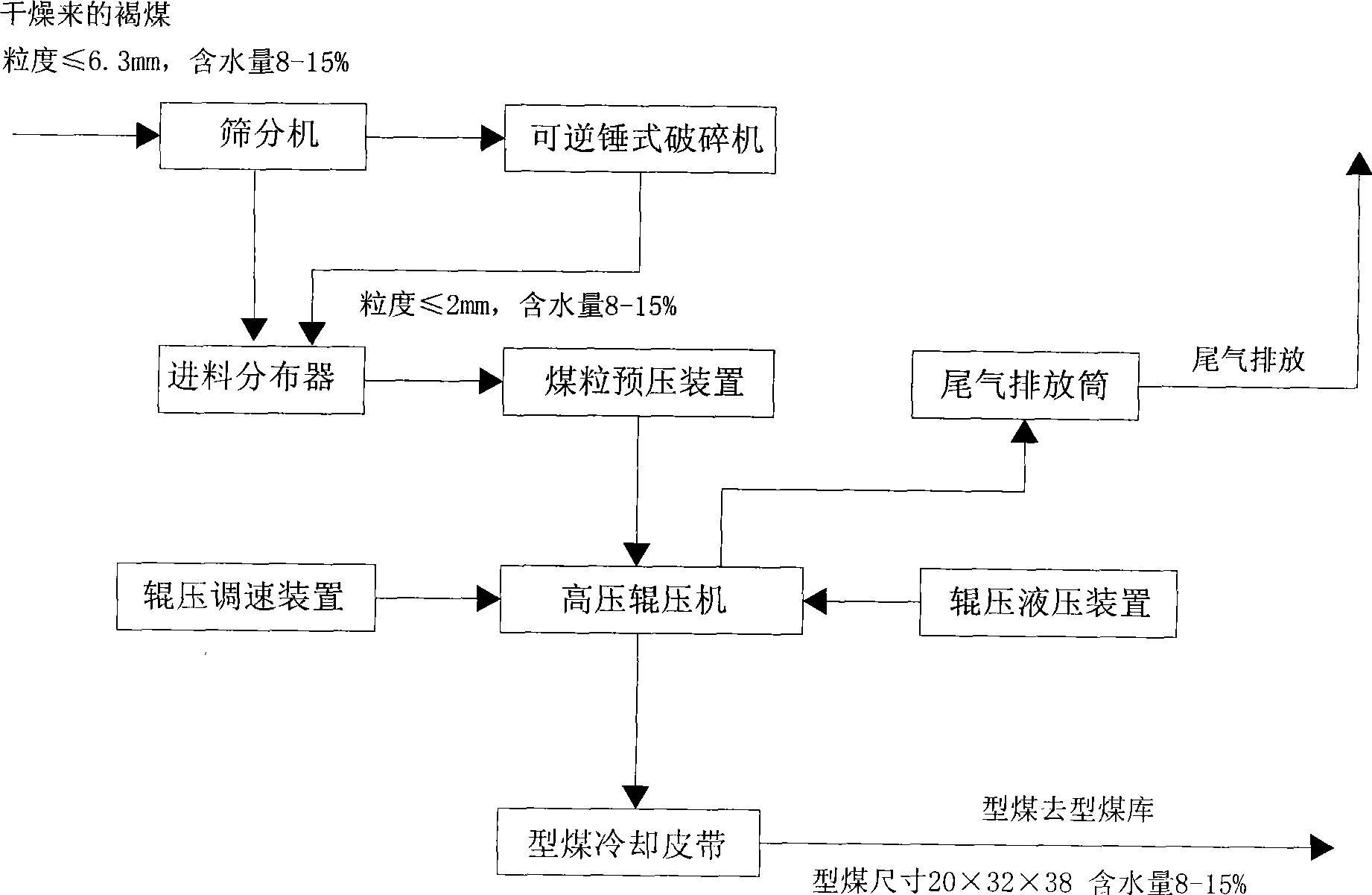

[0032] Process Description( figure 1 ):

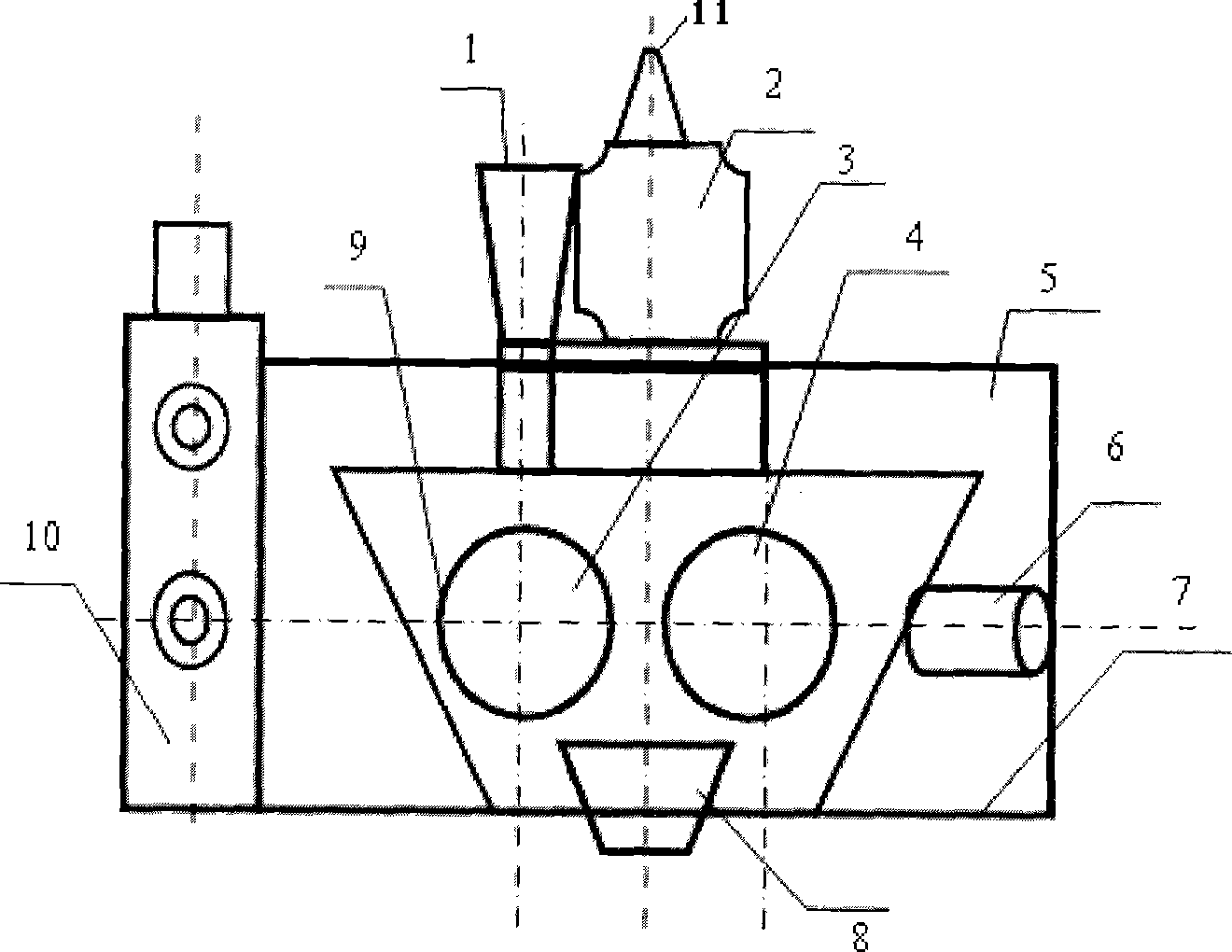

[0033] Dry lignite with a water content of 30wt% to 50wt% and a particle size of ≤6.3mm to about 10wt%. After screening, it enters the reversible hammer crusher. 2mm, as the raw material of the high-pressure roller press, and then enter the coal particle pre-pressing device 2 through the feed inlet and the coal particle distributor 1 for pre-pressing, and pass through two relative rotating forward moving roller shafts 3 and reverse moving rollers Shaft 4, under a certain temperature, moisture, particle size and high pressure, feeds the material into the material mold 9, adjusts the distance between the two moving rollers through the rolling hydraulic device 6, and the hydraulic speed regulating device 5 is used to adjust the speed of the rollers, The mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com