Patents

Literature

34results about How to "Uniform bearing surface" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

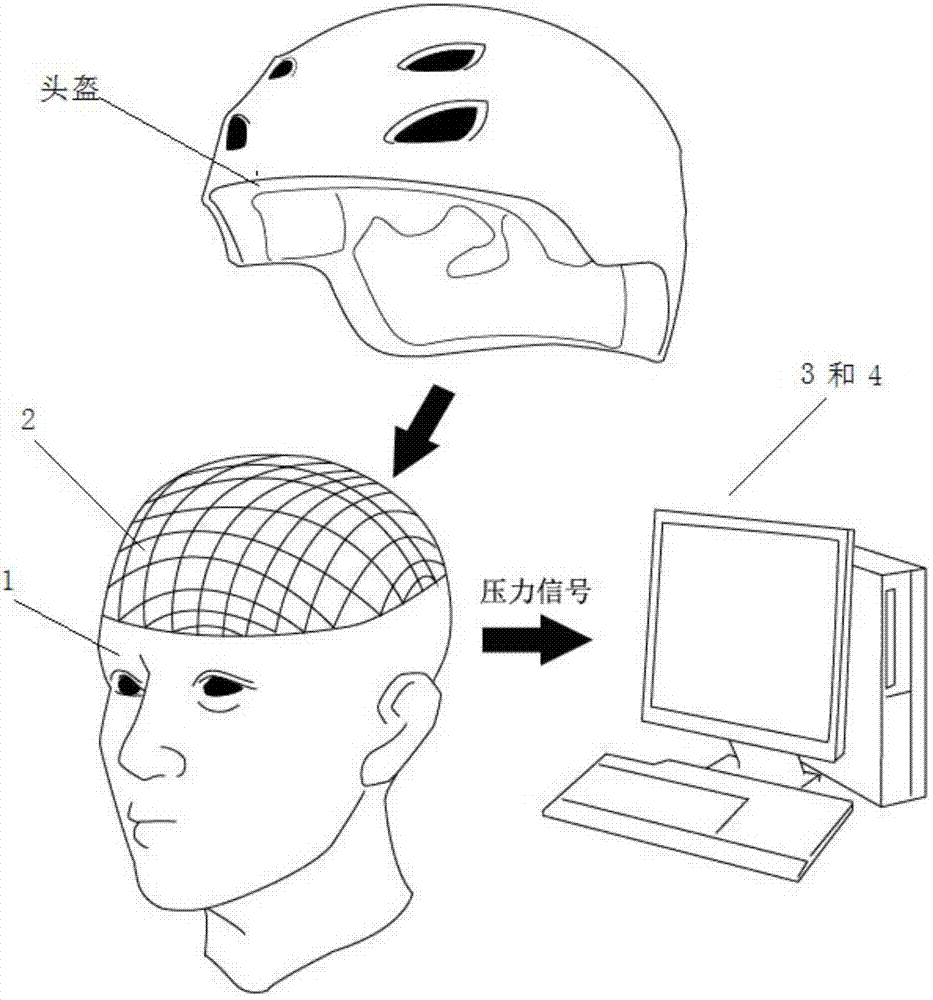

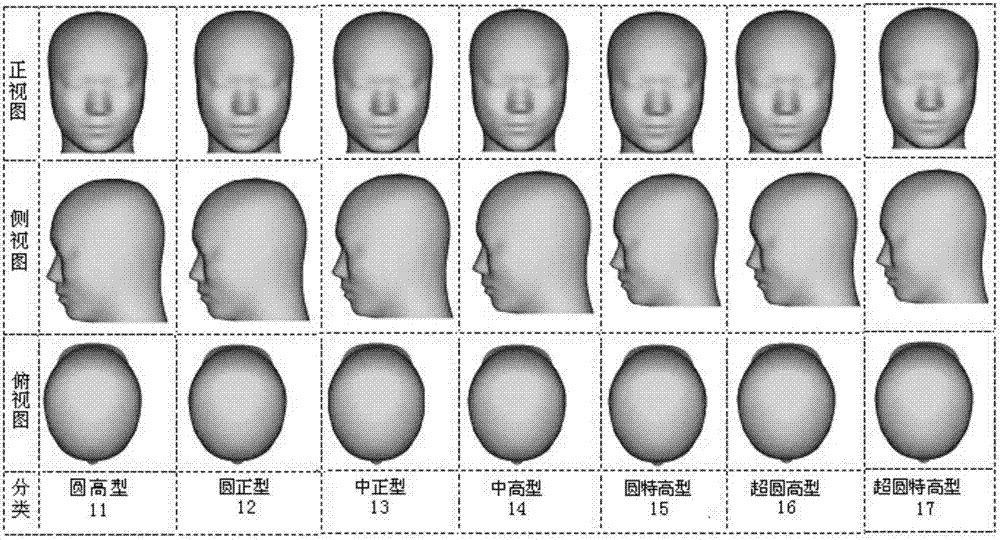

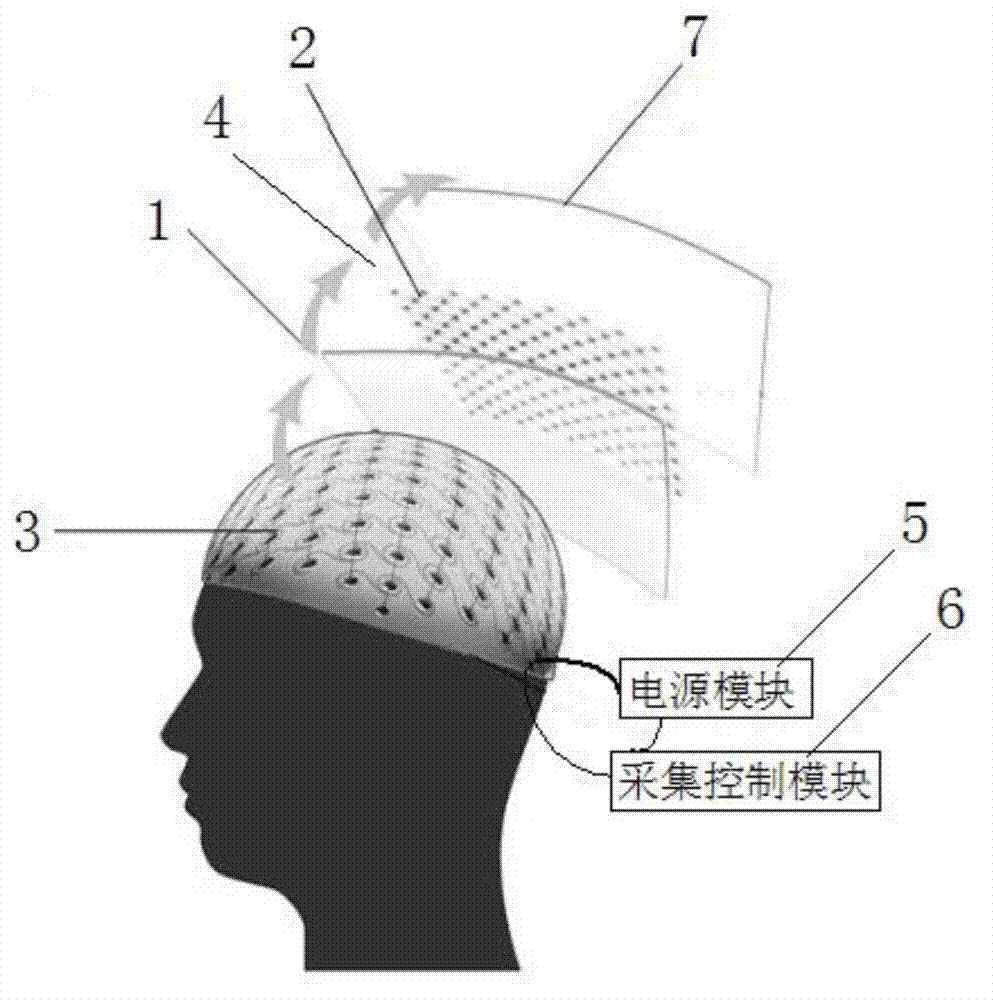

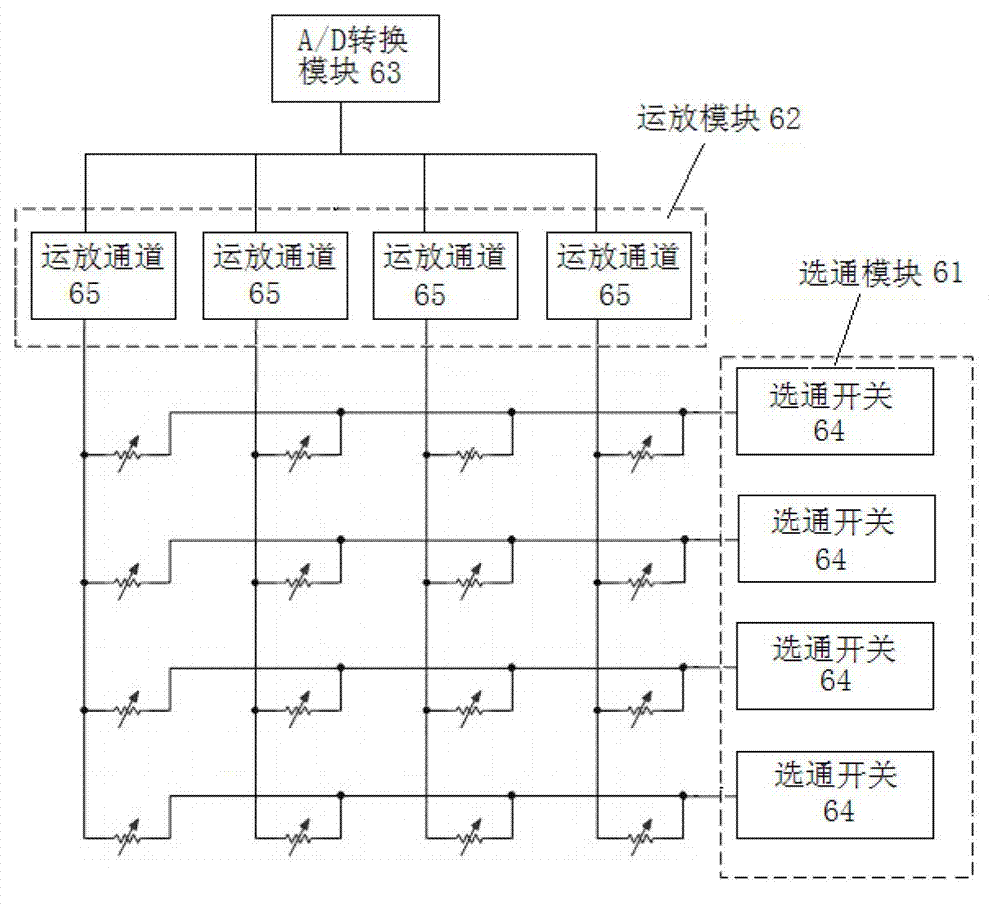

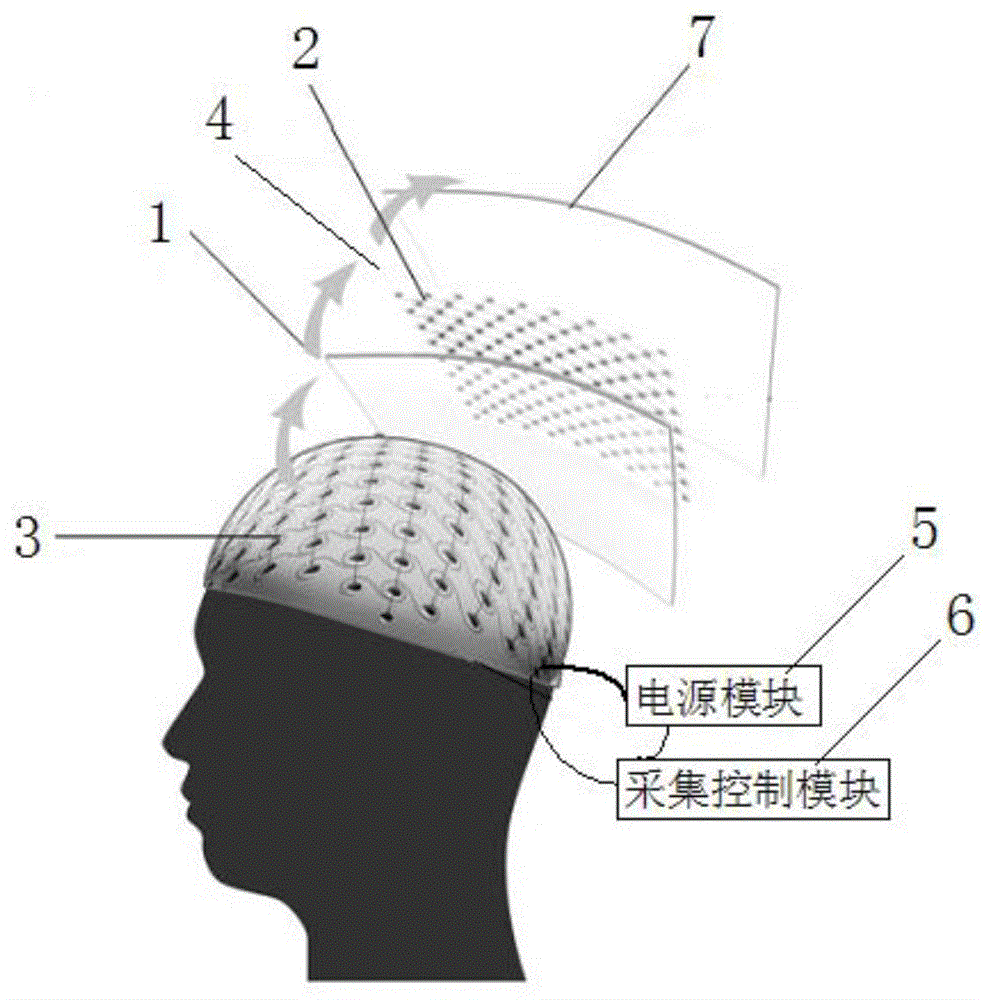

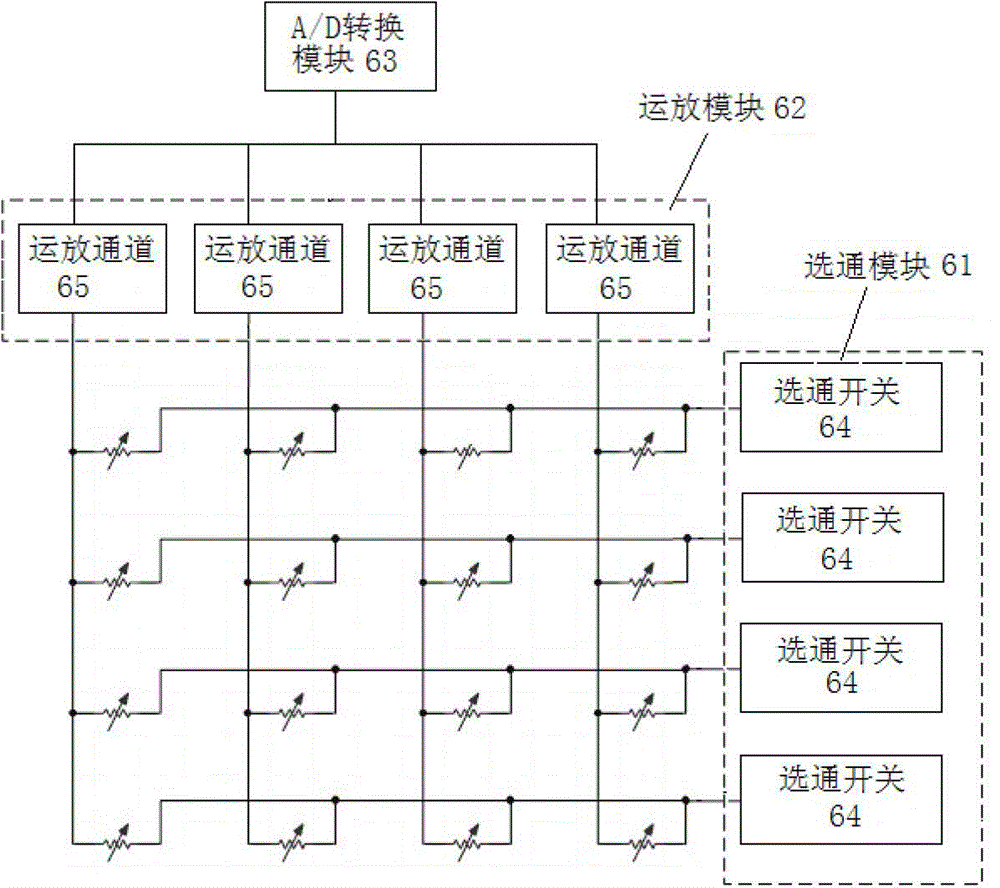

Testing and evaluation system for wear comfortableness of helmet

The invention relates to a testing and evaluation system for wear comfortableness of a helmet. The testing and evaluation system for the wear comfortableness of the helmet comprises a head modular matrix, a sensing device and a data analysis system, wherein the data analysis system is arranged in a computer; the sensing device comprises an undersurface silica gel layer which can be fitted with the curve shape of a head; the upper surface of the undersurface silica gel layer is provided with a matrix network which consists of a plurality of pressure sensors and a lead vertically and horizontally connected with all the pressure sensors; the exterior of the matrix network is connected with a power module and an acquisition control module through leads; the data analysis system comprises a data management unit, a data storage unit and a work efficiency performance analysis unit; the data management unit comprises an open module and a sampling module; and the work efficiency performance analysis unit comprises a pressure mode module, a pressure peak module, a pressure mean value module, a pressure center module, a pressure variance module and a pressure standard deviation module. The testing and evaluation system for the wear comfortableness of the helmet can be widely used for evaluating the wear comfortableness of products, such as various military helmets, helmets for polices, civil helmets, safety helmets, sports helmets and the like.

Owner:THE QUARTERMASTER EQUIPMENT RESEARCH INSTITUTE OF THE GENERAL LOGISITIC DEPARTME

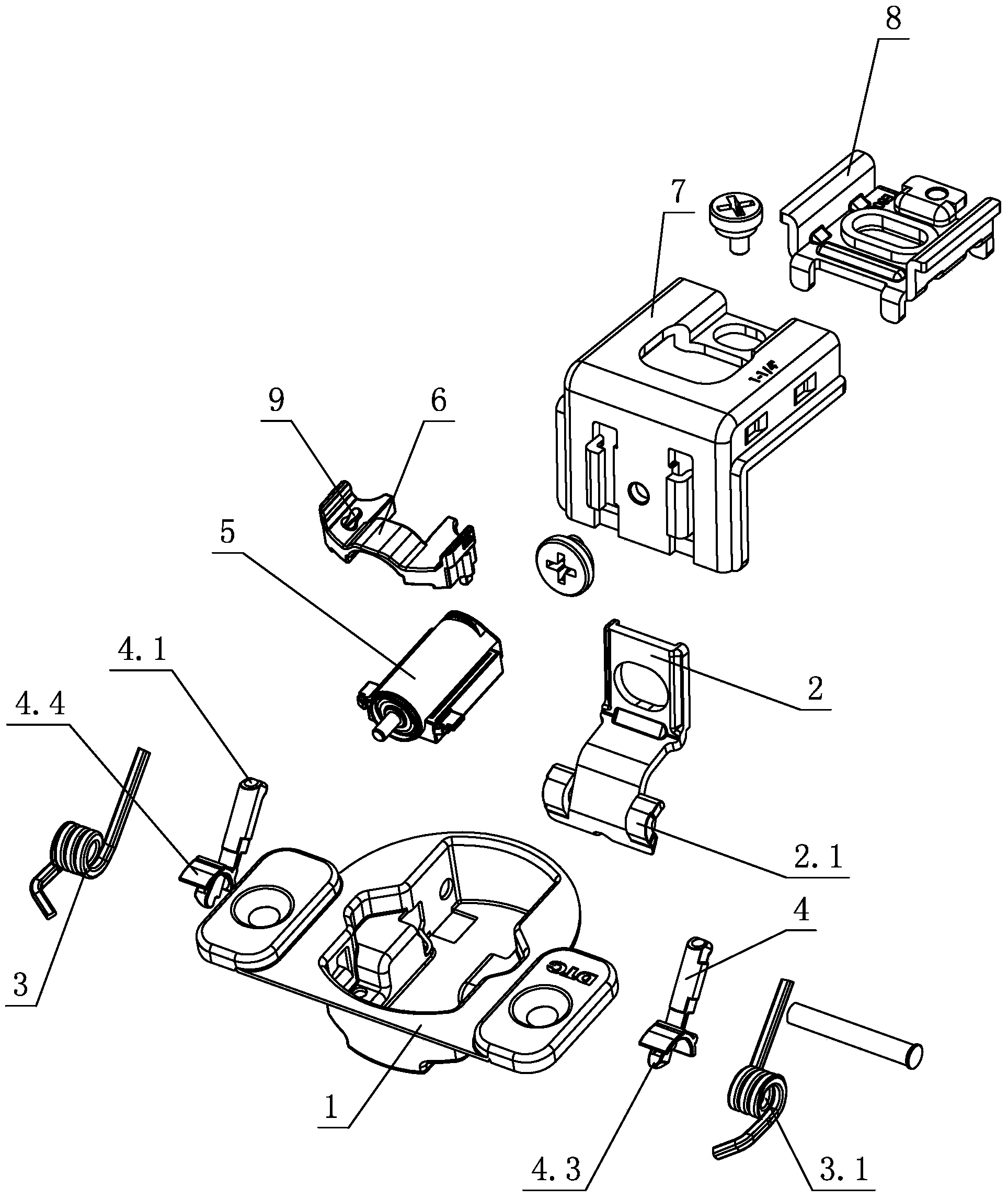

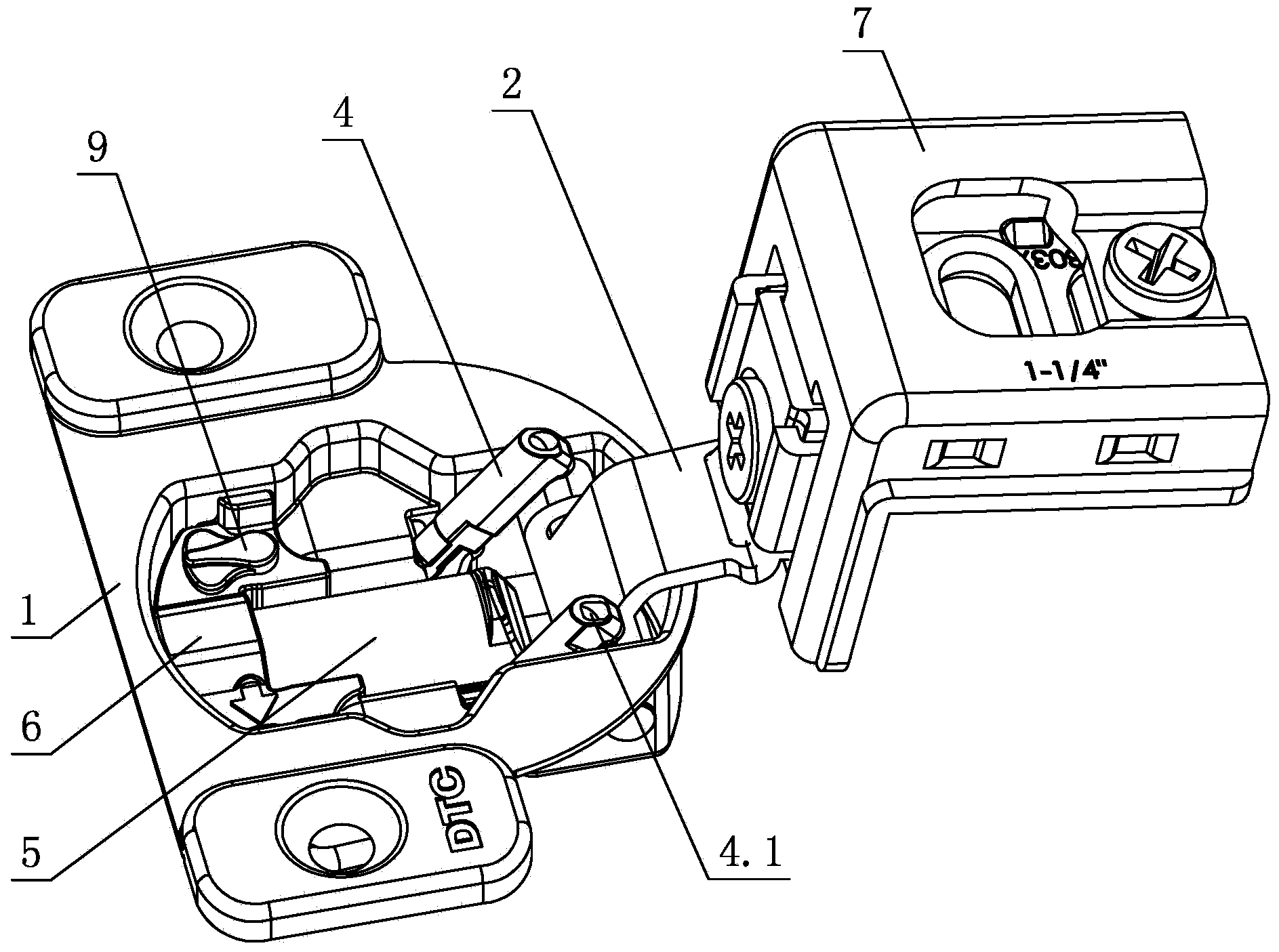

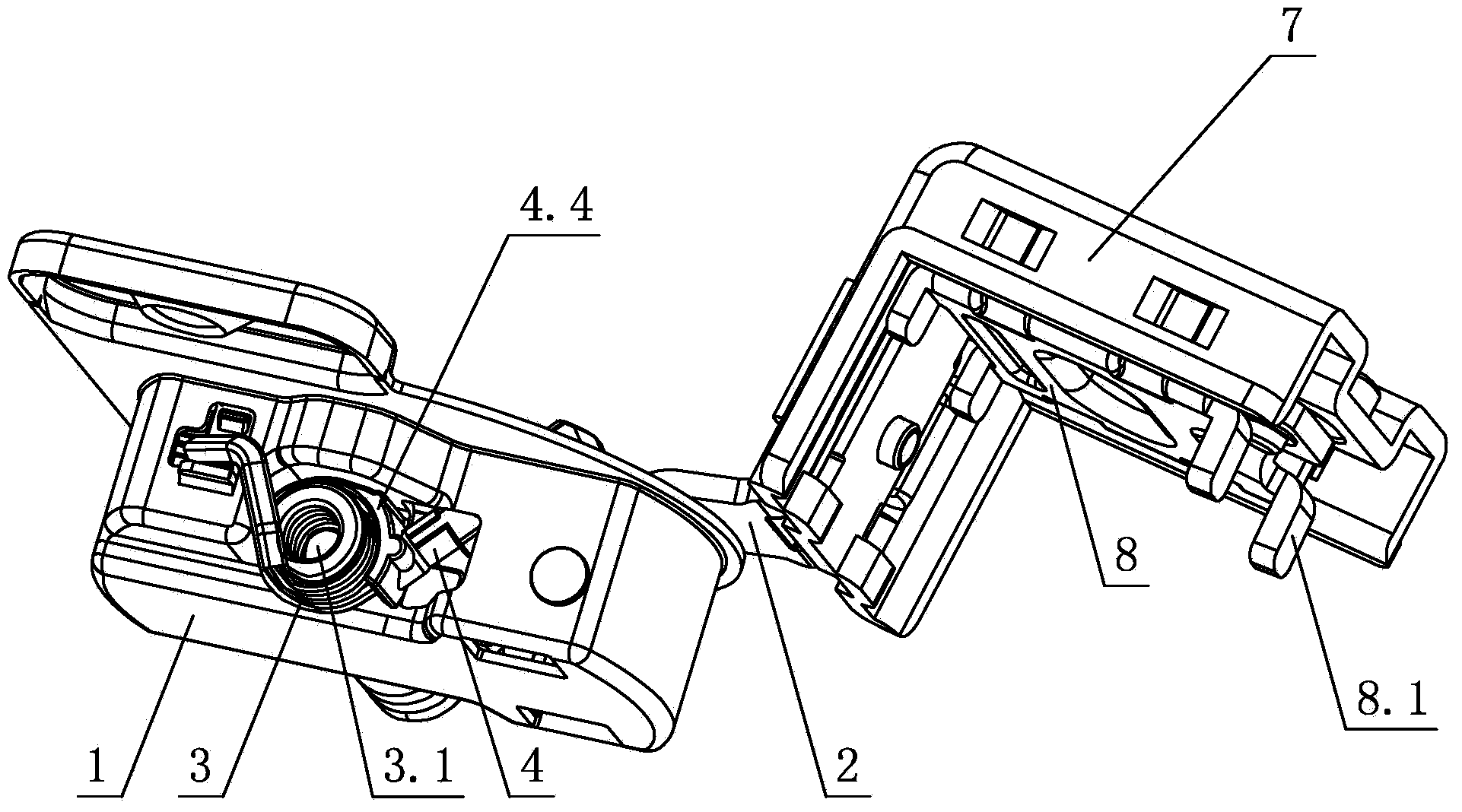

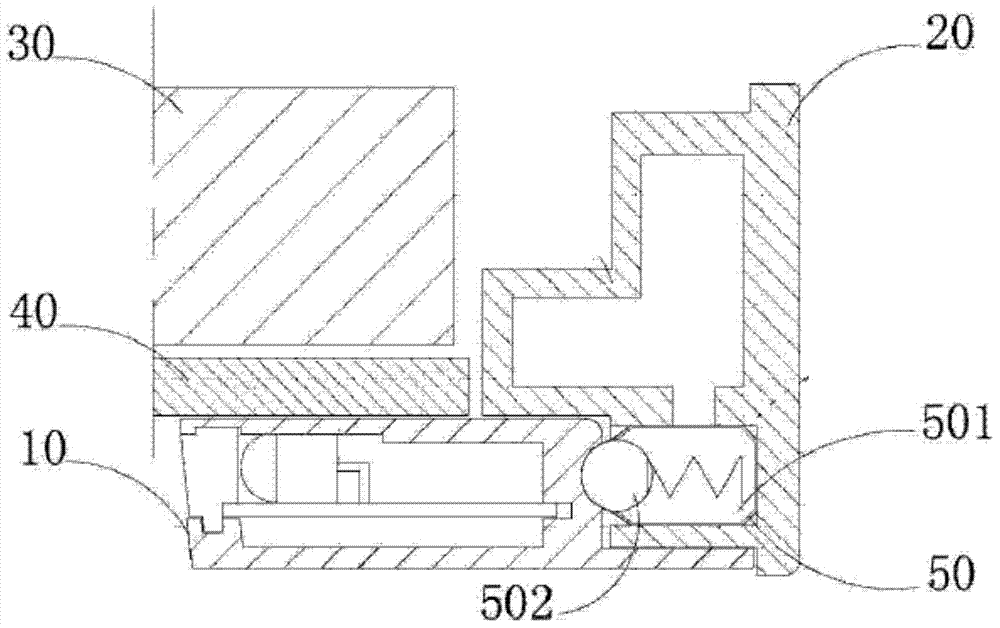

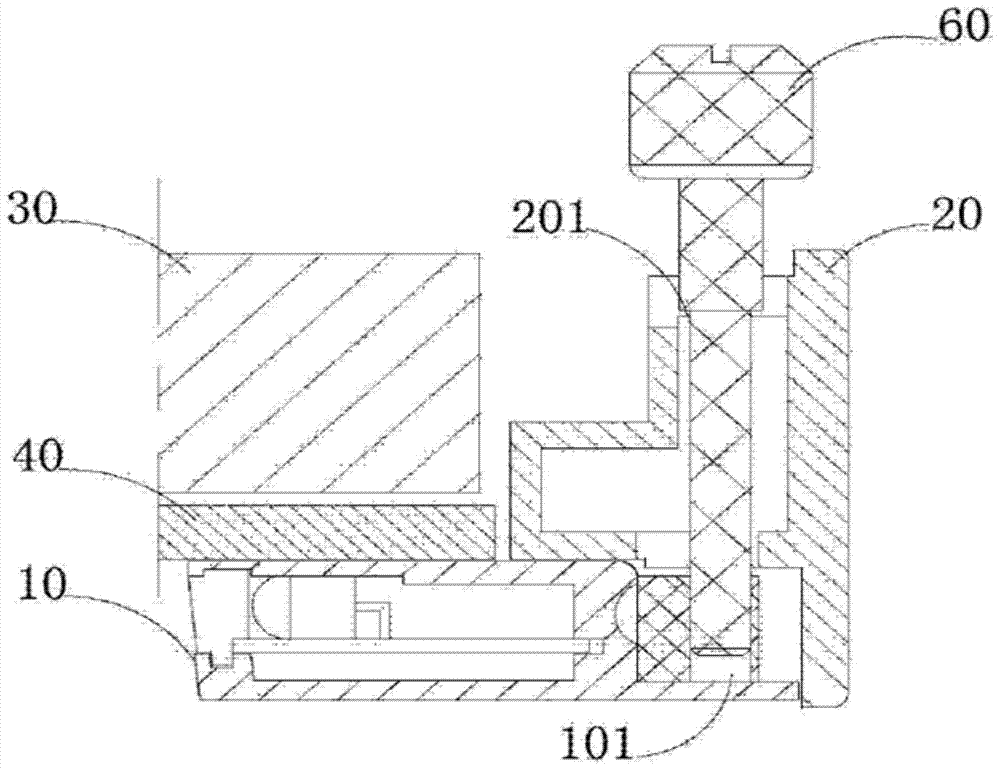

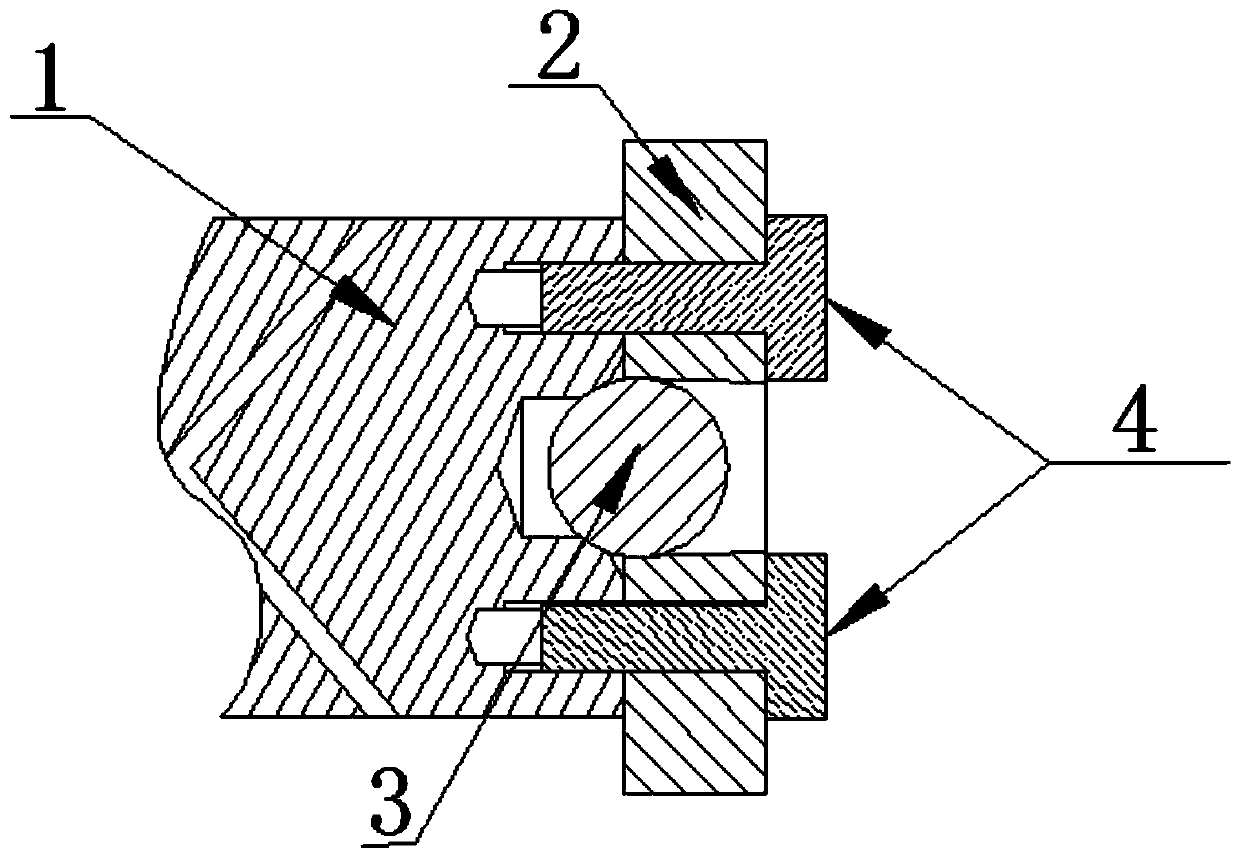

Silent hinge for furniture

InactiveCN103953236AReduce noiseOpen and close smoothlyBuilding braking devicesPin hingesEngineeringMechanical engineering

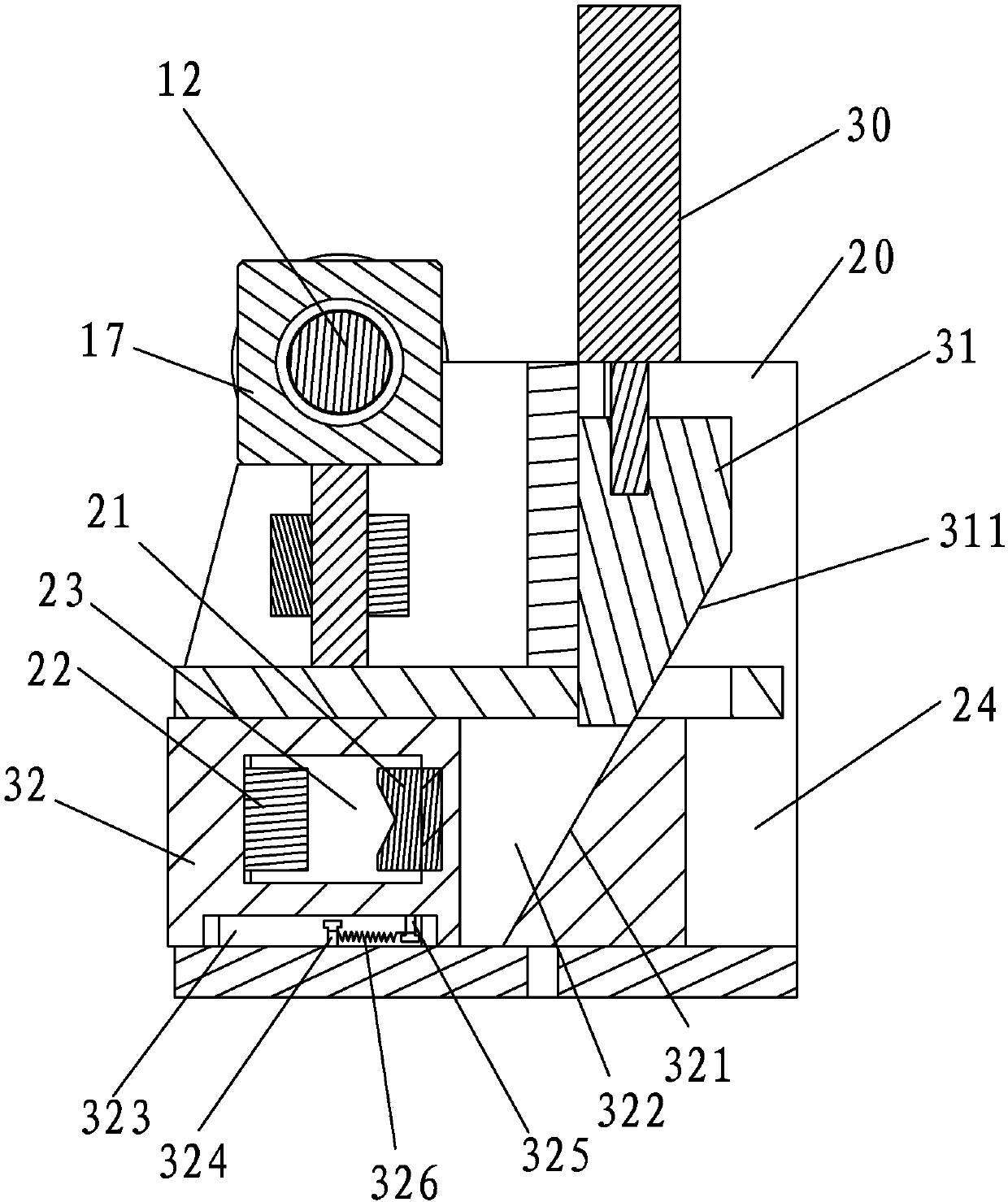

The invention relates to a silent hinge for furniture, which comprises a movable hinged cup connected with a door plate, a fixed piece connected with a wall plate and a hinged arm connected with the movable hinged cup and the fixed piece; a damper is arranged on the movable hinged cup and at least acts on the hinged arm when the hinge is closed, springs which can generate opening and closing action force to the movable hinged cup at least is arranged on the hinge, and one end of the hinged arm is hinged with the movable hinged cup through a connecting unit; the cross section of at least one ends of the springs are non-circular, a sliding piece is arranged on the spring; a concave cavity is formed in the sliding piece, and at least one end of the spring is arranged in the concave cavity; the bottom surface of the sliding piece acts on a rotating part of the hinged arm through the elasticity of the springs, and the sliding piece moves relative to the rotating part when the hinge is opened and / or closed and generates an opening force or a closing force. Through an improved structure, the silent hinge has the characteristics of simple and reasonable structure, reliable performance, flexibility in operation, long service life, stable and smooth opening and closing process, less effort, low noise and the like, thereby having high practicability.

Owner:伍志勇

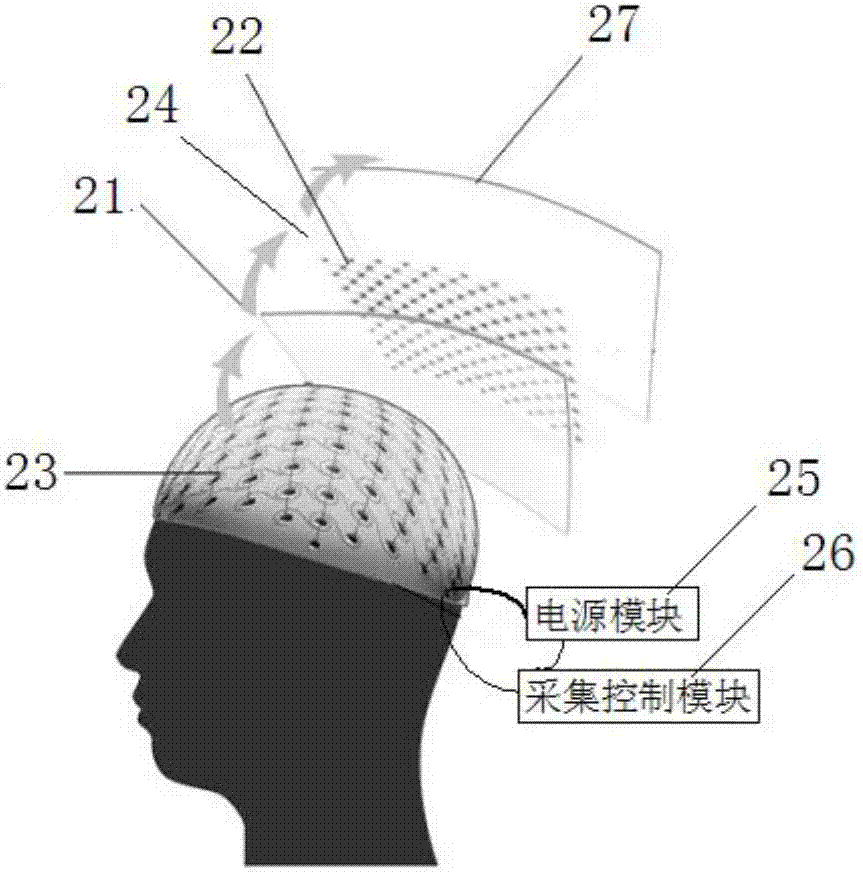

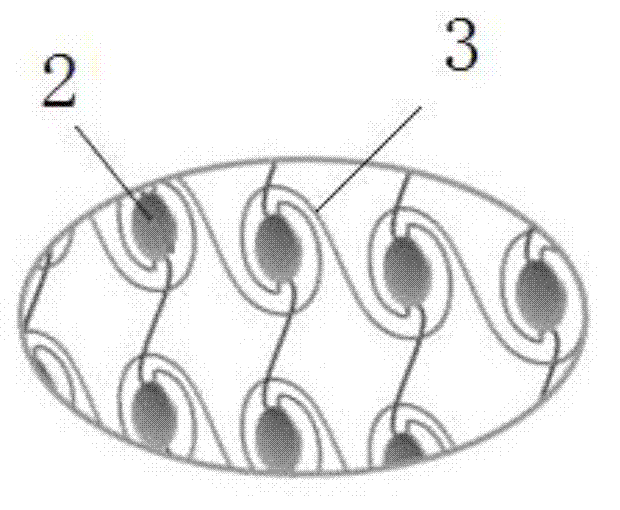

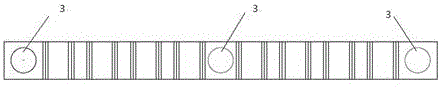

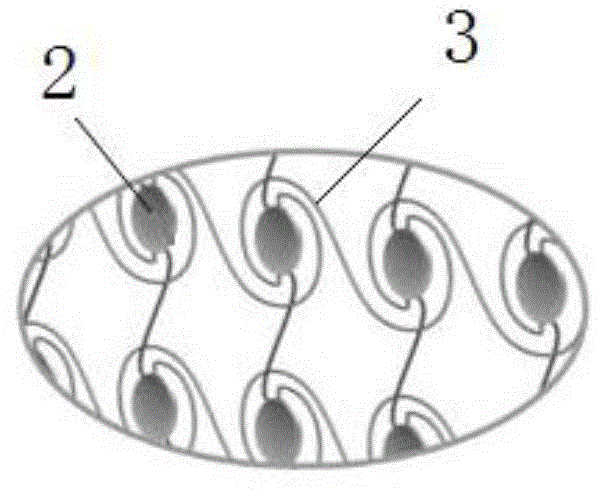

Flexible sensing device for measuring head pressure and manufacture method thereof

The invention relates to a flexible sensing device for measuring a head pressure and a manufacture method thereof. The flexible sensing device comprises a bottom silicon layer which can be fit to the curve shape of a head, the upper surface of the bottom silicon layer is provided with a matrix network which is formed by a plurality of pressure sensors and wires which are vertically and horizontally connected with the pressure sensors, and a power supply module for supplying electricity and an acquisition control module for outputting information of the pressure sensors are connected outside the matrix network through wires. The flexible sensing device has better flexibility, can be tightly clung to the curve face of the head, and is particularly suitable for measuring the pressures born on points of the head when a person wears protective articles such as a helmet and a safety helmet.

Owner:THE QUARTERMASTER EQUIPMENT RESEARCH INSTITUTE OF THE GENERAL LOGISITIC DEPARTME

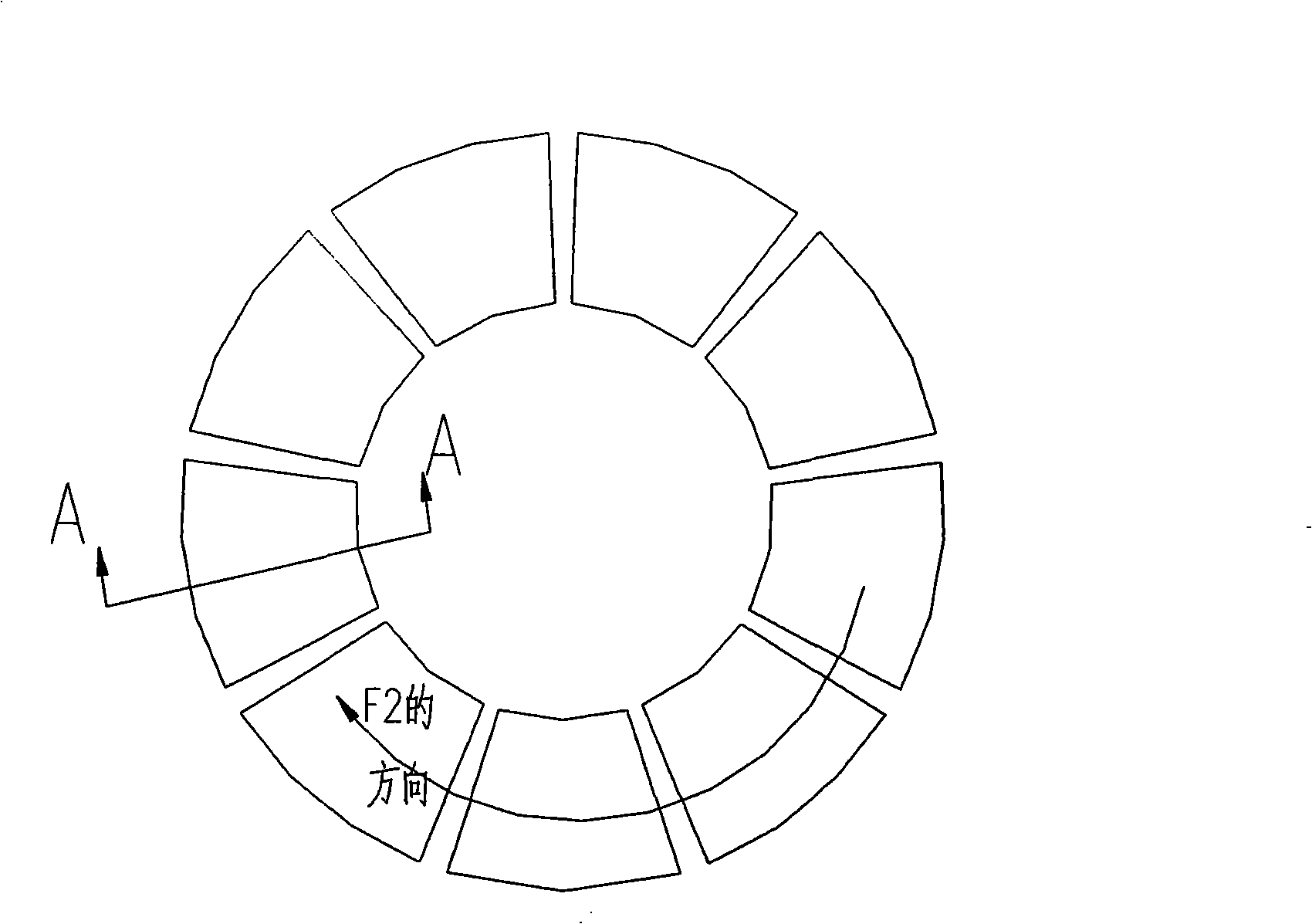

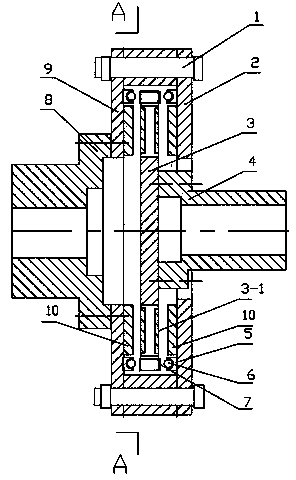

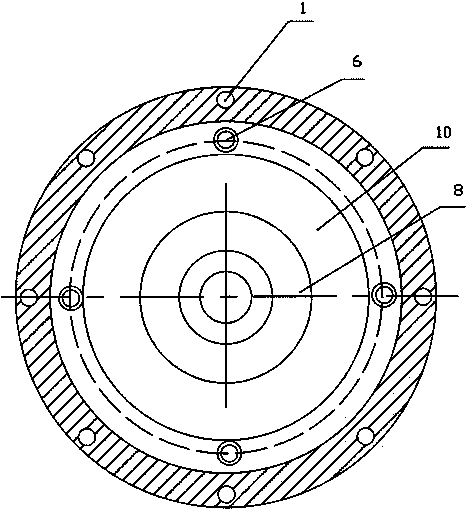

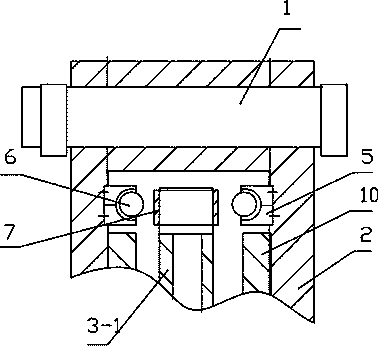

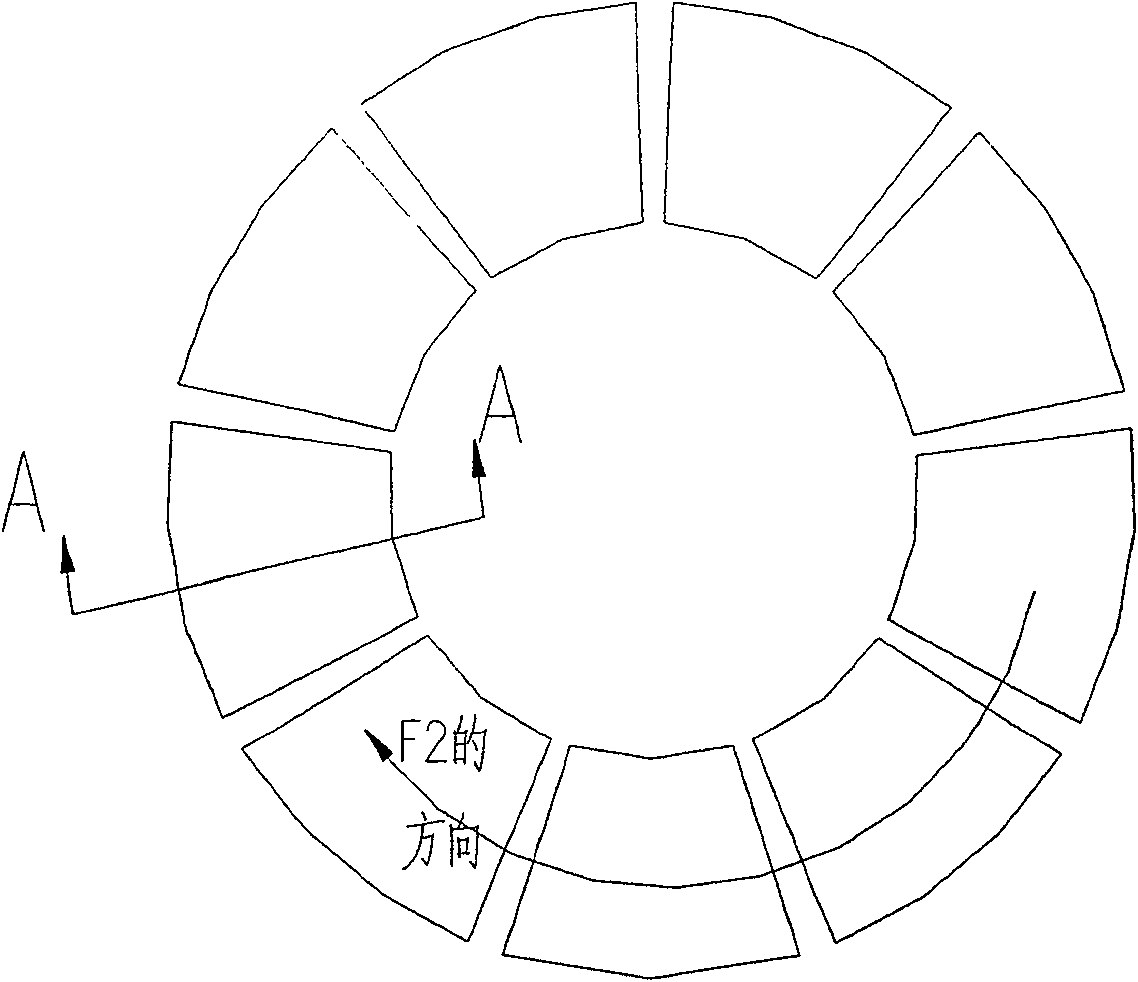

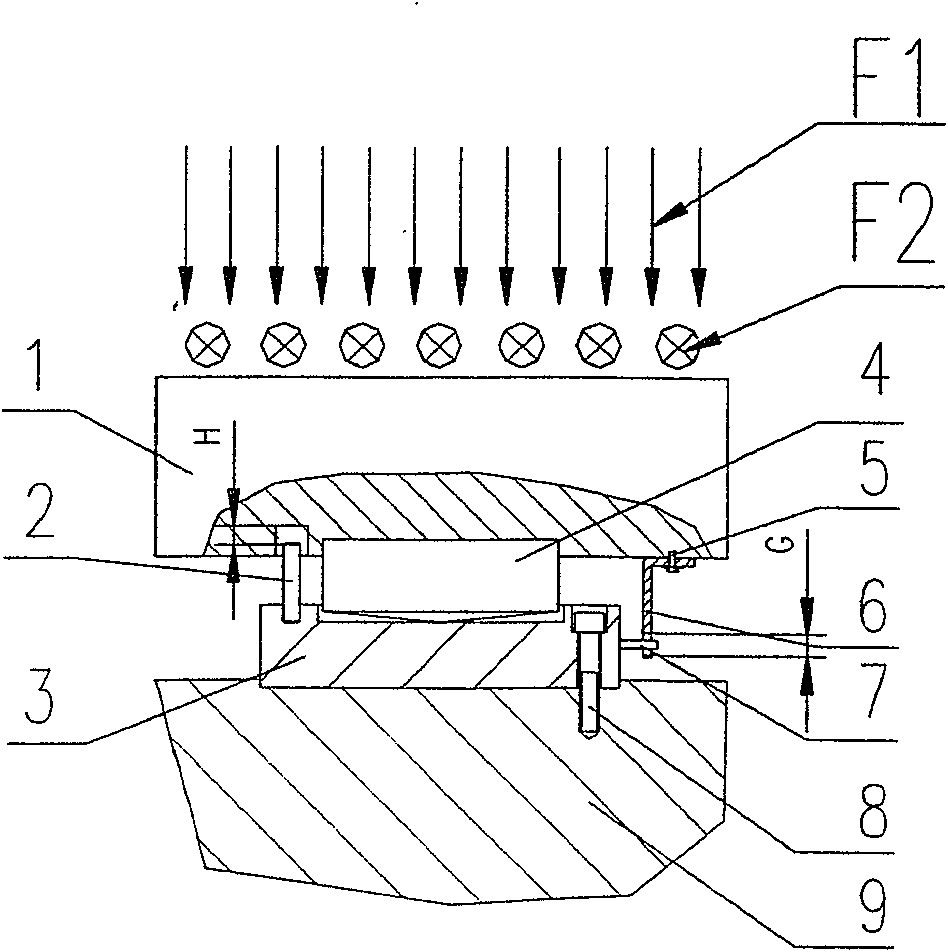

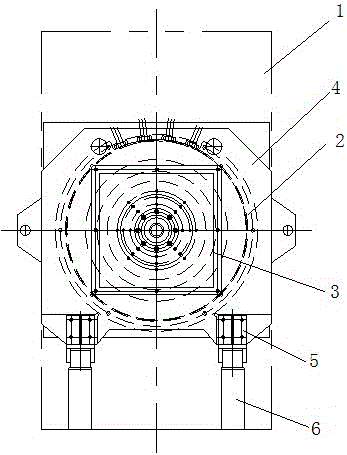

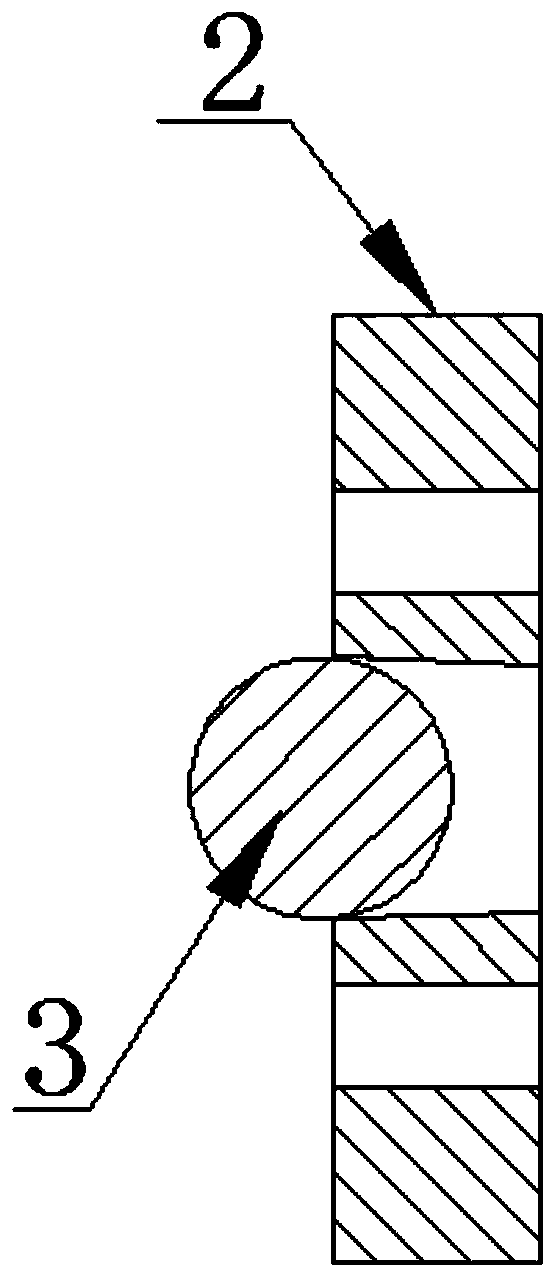

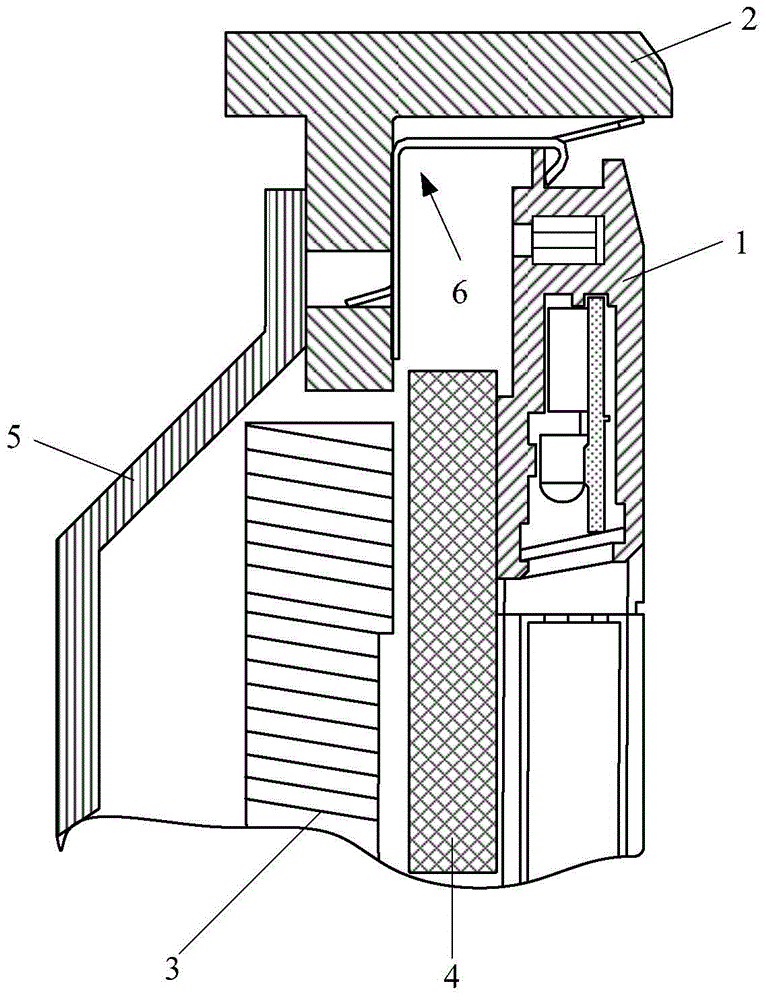

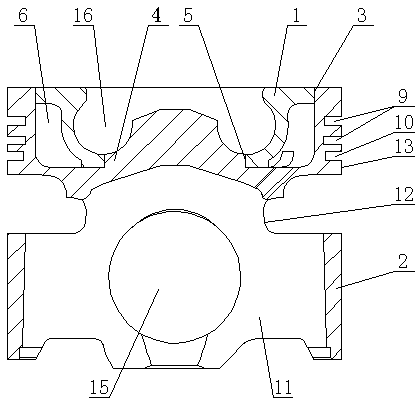

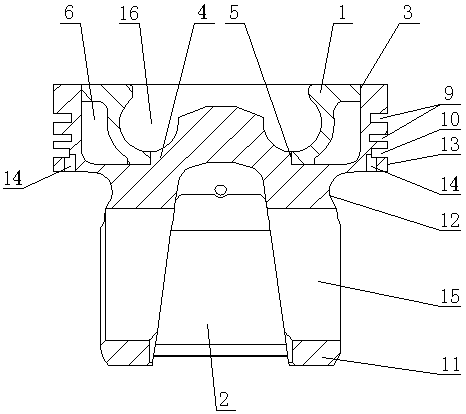

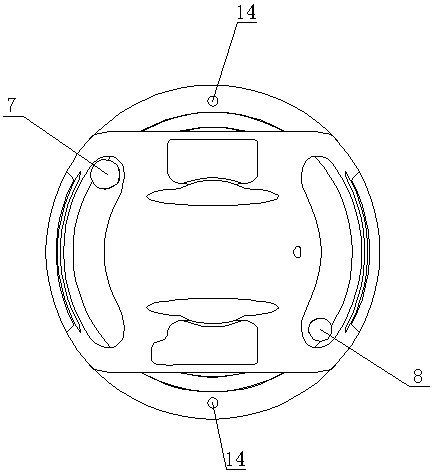

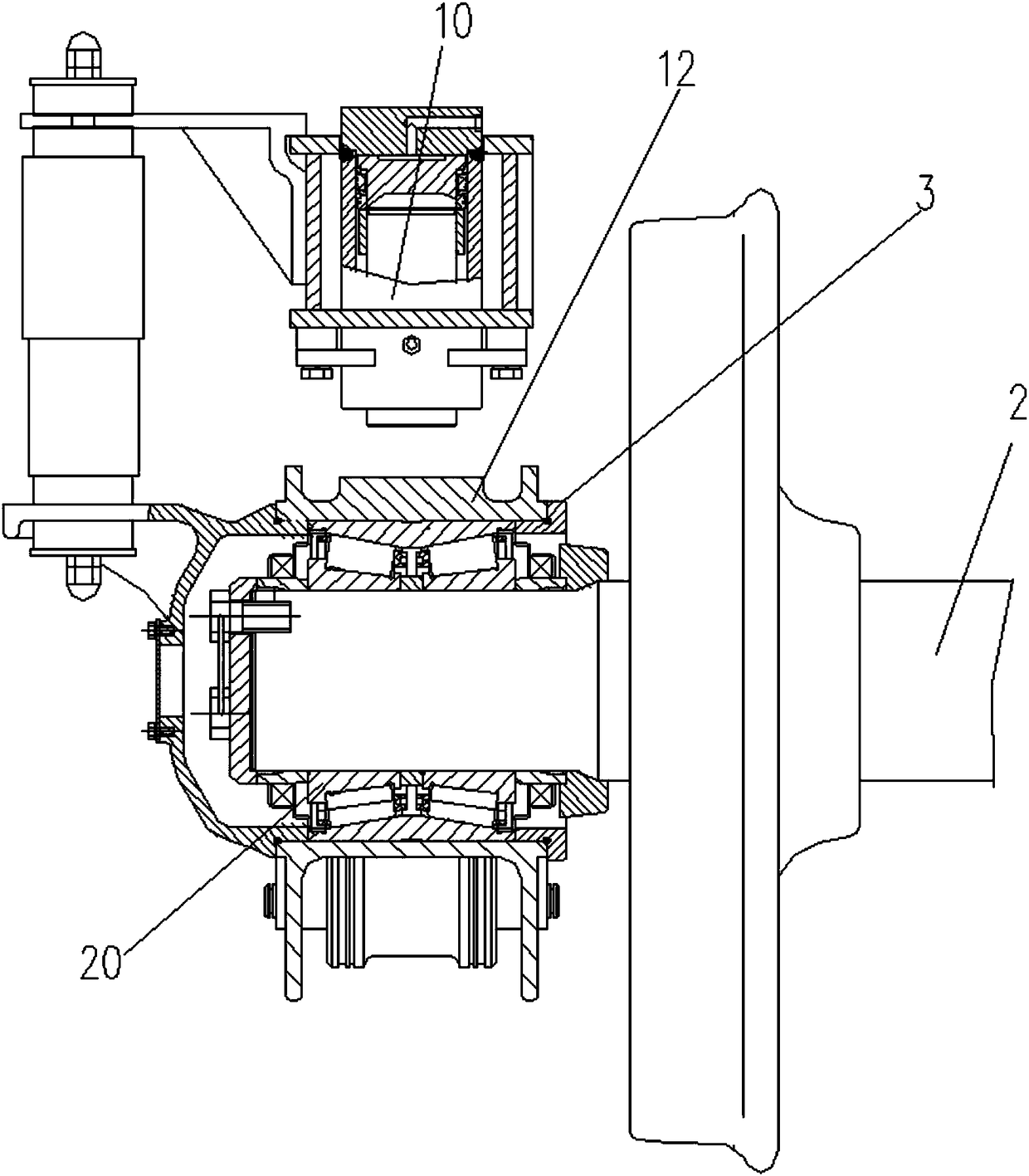

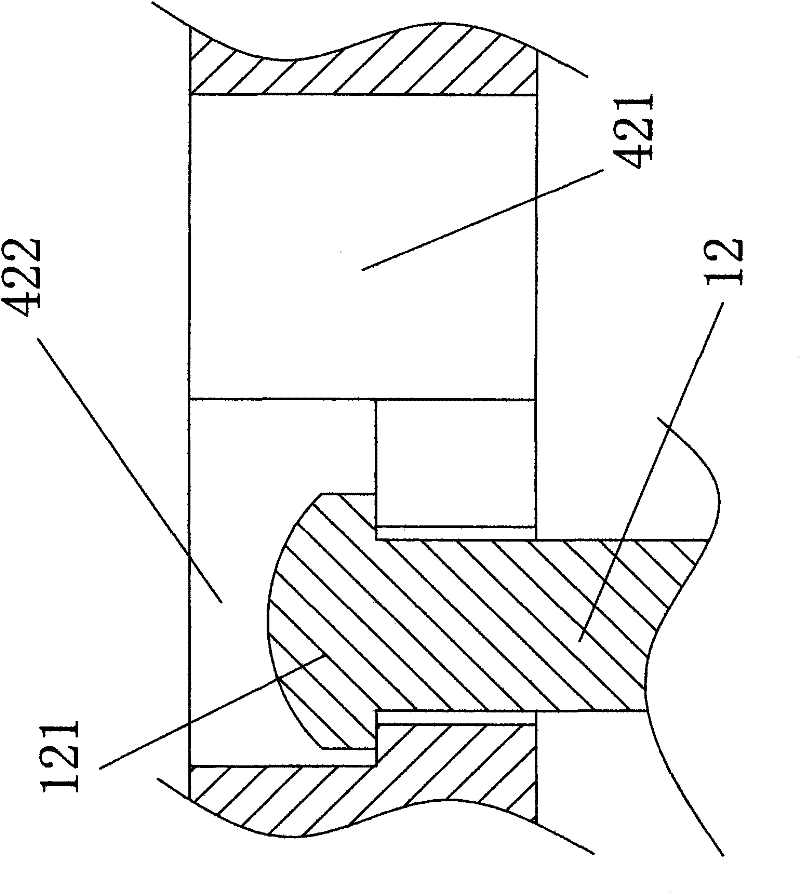

Thrust bearing

ActiveCN101403411AUniform bearing surfaceControl radial swing amplitudeBearing componentsSliding contact bearingsAerospace engineeringOil film

The invention relates to a thrust bearing, which is characterized by comprising 6 to 24 thrust bearing pad groups; each thrust bearing pad group comprises thrust bearing pads and a supporting pad; the independent thrust bearing pad groups are evenly distributed on a same ring-shaped plane; a supporting block is arranged between the thrust bearing pads and the supporting pad; the lower-part end surface of the supporting pad is a spherical cambered surface; and the radial central line of each supporting block lags behind the geometric central line of the corresponding thrust bearing pads. The thrust bearing has the advantages that as a plurality of groups of thrust bearing pads and the supporting block of the spherical cambered surface are adopted, the stress surfaces of the thrust bearings are even; stop pins effectively control the radial swinging width of the thrust bearing pads; as the radial central line of the supporting block lags behind the geometric central line of the thrust bearing pads, and due to wedge-shaped lubricating oil inlets, oil films are easily formed on the surface of the thrust bearing pads so as to reduce the temperature of touching surfaces; both the supporting block and the stop pins can prevent the thrust bearing pads and the supporting pad from being deviated; among a plurality of independent thrust bearing pads, individual thrust bearing pad can be replaced separately, and therefore the maintenance cost is reduced.

Owner:NANJING HIGH SPEED & ACCURATE GEAR GRP

Permanent magnet coupler limiting structure

ActiveCN103812306AAvoid mechanical frictionLimit Axial MisalignmentDynamo-electric gearsPermanent magnet rotorElectrical conductor

The invention relates to a permanent magnet coupler limiting structure which comprises a conductor rotor disc and a permanent magnet rotor disc. The conductor rotor disc comprises a driving side conductor disc and a driven side conductor disc which are fixedly connected through a bolt, the permanent magnet rotor disc is arranged between the two conductor discs and provided with a permanent magnet, the conductor rotor disc is provided with a conductor plate, and a fixed air gap is reserved between the permanent magnet and the conductor plate. The permanent magnet coupler limiting structure is characterized in that limiting blocks are symmetrically arranged on the inner side of the driving side conductor disc and the inner side of the driven side conductor disc, roll balls are embedded on the limiting blocks in a rolling mode, limiting slideways are arranged at the positions of two sides of the permanent magnet rotor disc corresponding to the limiting blocks, fixed intervals are reserved between the limiting slideways and the roll balls, and the fixed air gap is larger than the fixed intervals. The limiting blocks are provided with spherical grooves, and the roll balls are embedded in the spherical grooves. The permanent magnet coupler limiting structure has the advantage that direct mechanical friction between the conductor discs and a permanent magnet disc is avoided.

Owner:山东东朋自控仪表有限公司

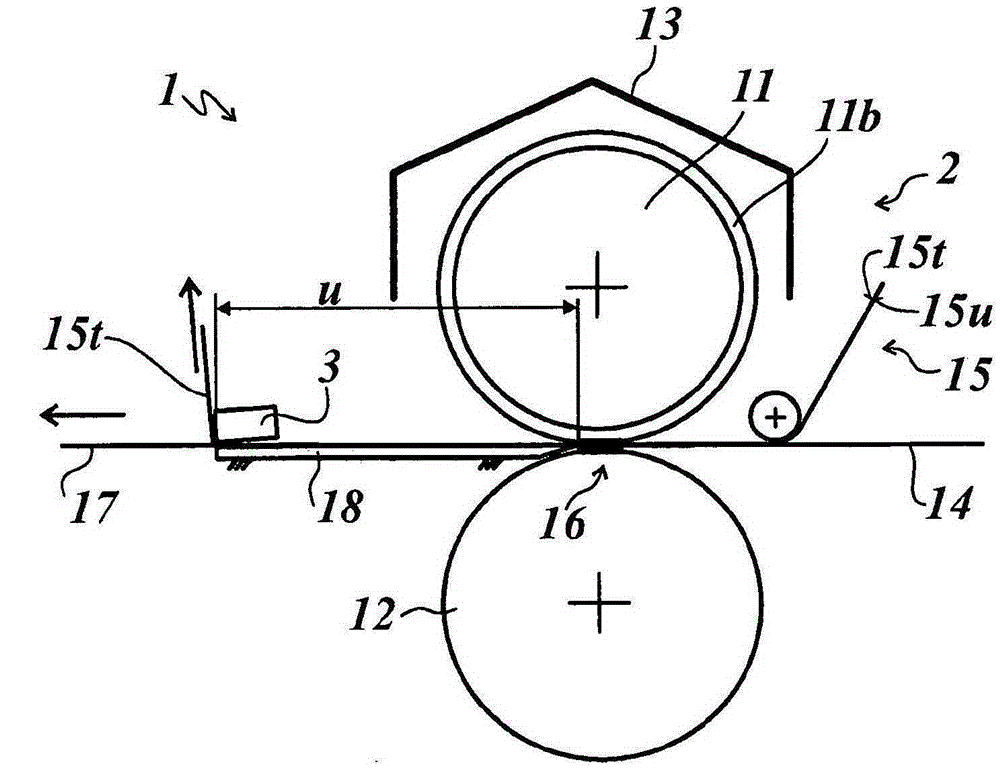

Hot stamping machine

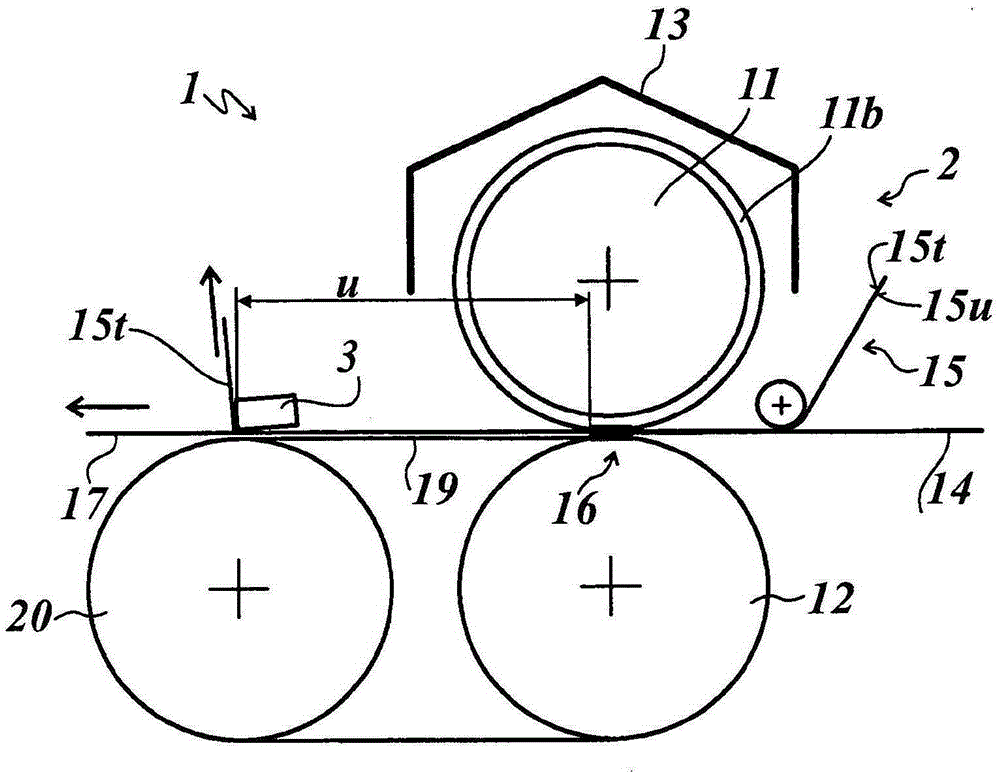

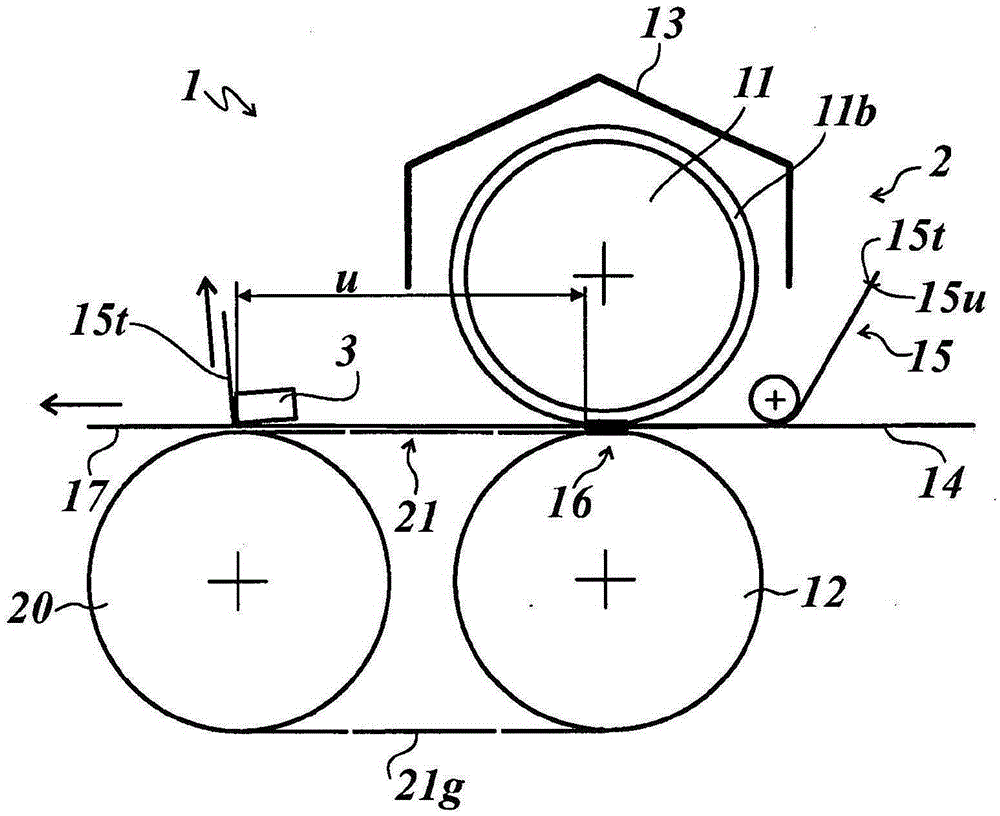

ActiveCN105283321APrevent peelingHigh resolutionTransfer printingDecorative surface effectsHot stampingCounter pressure

The invention relates to a hot stamping machine (1), comprising a stamping device (2) for transferring a transfer layer (15u) arranged on a carrier layer (15t) of a hot stamping foil (15) onto a substrate (14). The hot stamping machine comprises a heatable stamping roller (11) and a counter-pressure roller (12) between which is stamping gap (16) is defined, and a downstream releasing device (3) for releasing the carrier layer (15t) from the transfer layer (15u) transferred onto the substrate (14). Between the stamping gap (16) and the releasing device (3) a flat contact element (18) is arranged below the stamped substrate (17), which contact element is directly contiguous to the stamping gap (16) or is spaced apart from the stamping gap (16) by less than 1mm or is arranged to overlap the stamping gap (16).

Owner:LEONHARD KURZ STIFTUNG & CO KG

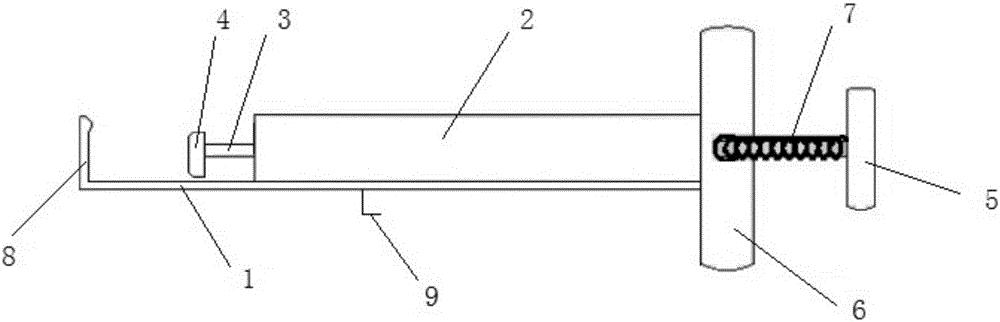

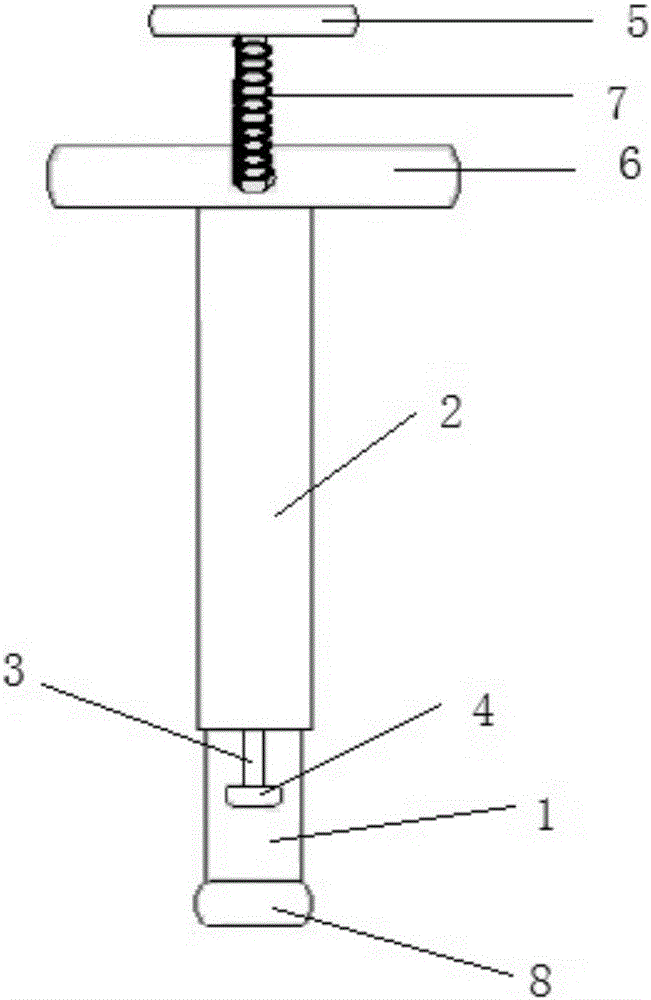

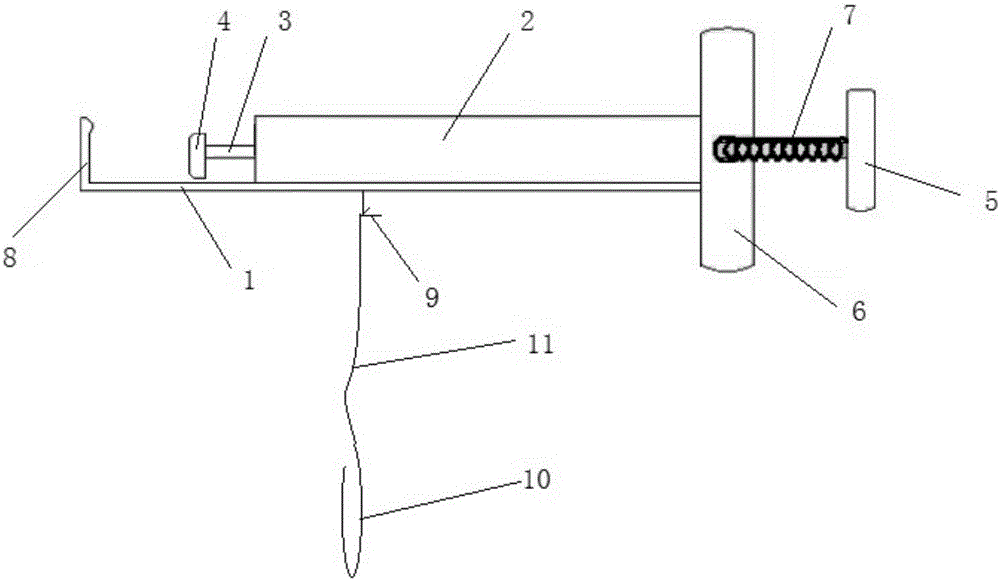

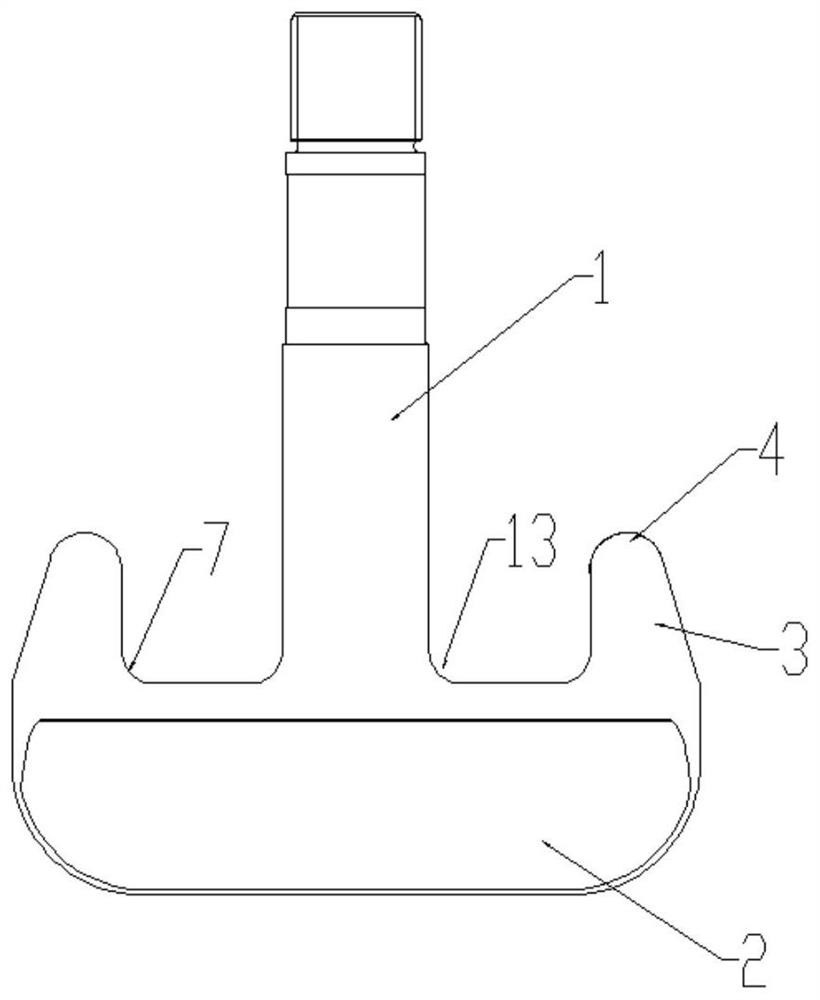

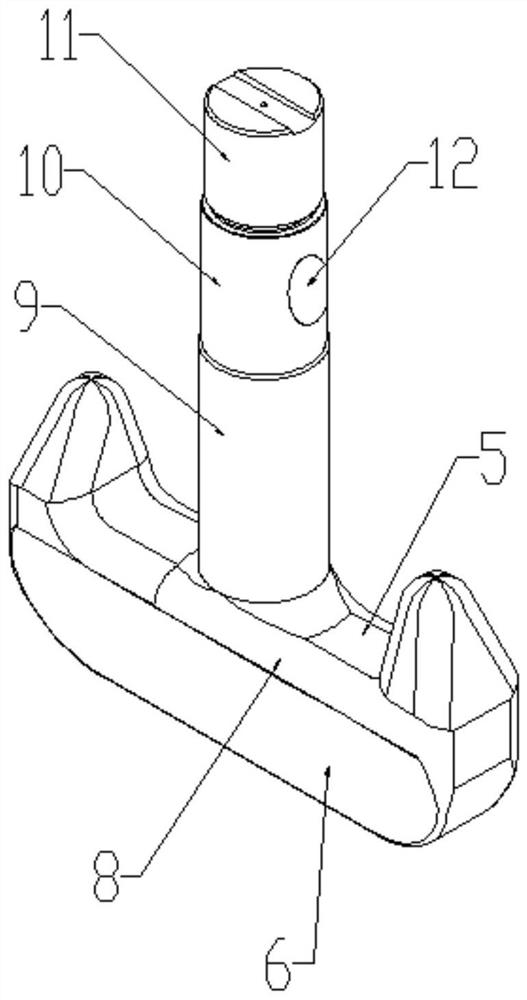

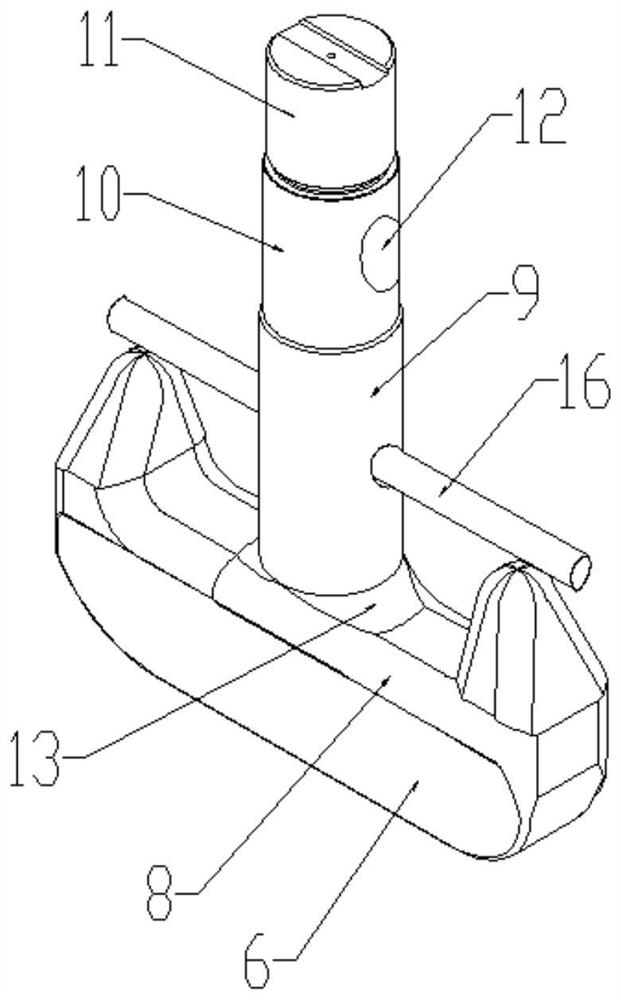

Slidable simple tarsal gland duct massager

InactiveCN106137695AUniform bearing surfaceImprove treatment efficiencyEye treatmentSuction-kneading massageConjunctivaMassage

The invention relates to a slidable simple tarsal gland duct massager. The massager comprises a push rod sleeve, a conjunctiva end support, a push rod, a skin end massage cake and a conjunctiva end massage portion. The push rod is movably arranged in the push rod sleeve, one end of the push rod is fixedly connected with the skin end massage cake while a push handle is arranged at the other end of the push rod, and a spring is arranged between the push handle and the push rod sleeve and sleeves the push rod. The conjunctiva end support is fixedly connected with the push rod sleeve, one end of the conjunctiva end support is fixedly connected with the conjunctiva end massage portion, and the skin end massage cake is positioned between the conjunctiva end massage portion and the push rod and opposite to the conjunctiva end massage portion. The slidable simple tarsal gland duct massager has advantages of simplicity, safety, labor saving, high uniformity of tarsal plate stress surface, improvement of treatment efficiency, simplicity and reliability in operation, availability for autonomous operations of patients or family members and avoidance of troubles of frequent hospitalization.

Owner:SICHUAN PROVINCIAL PEOPLES HOSPITAL

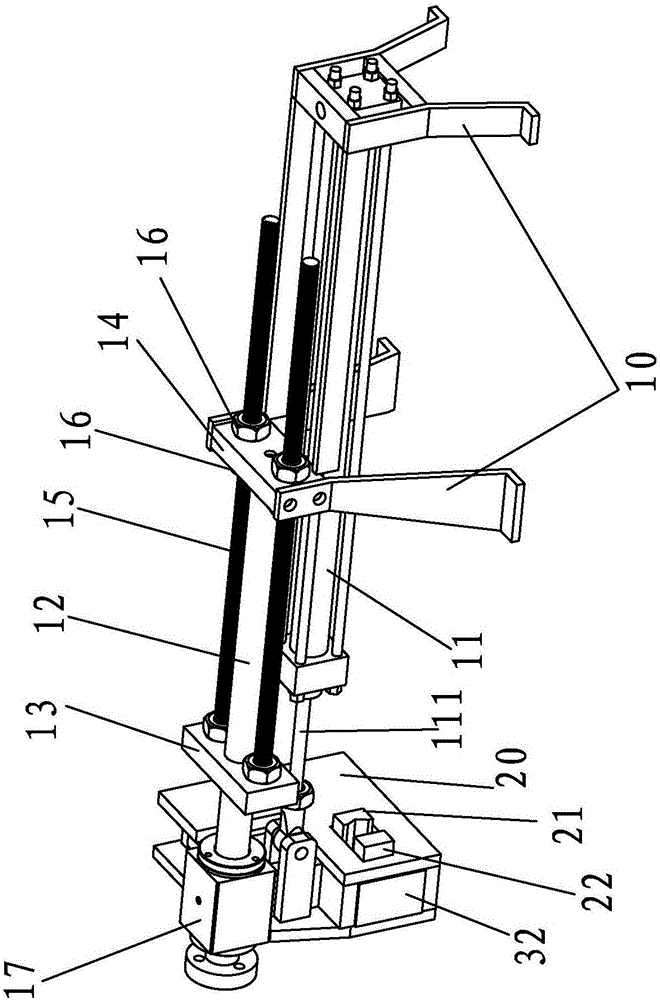

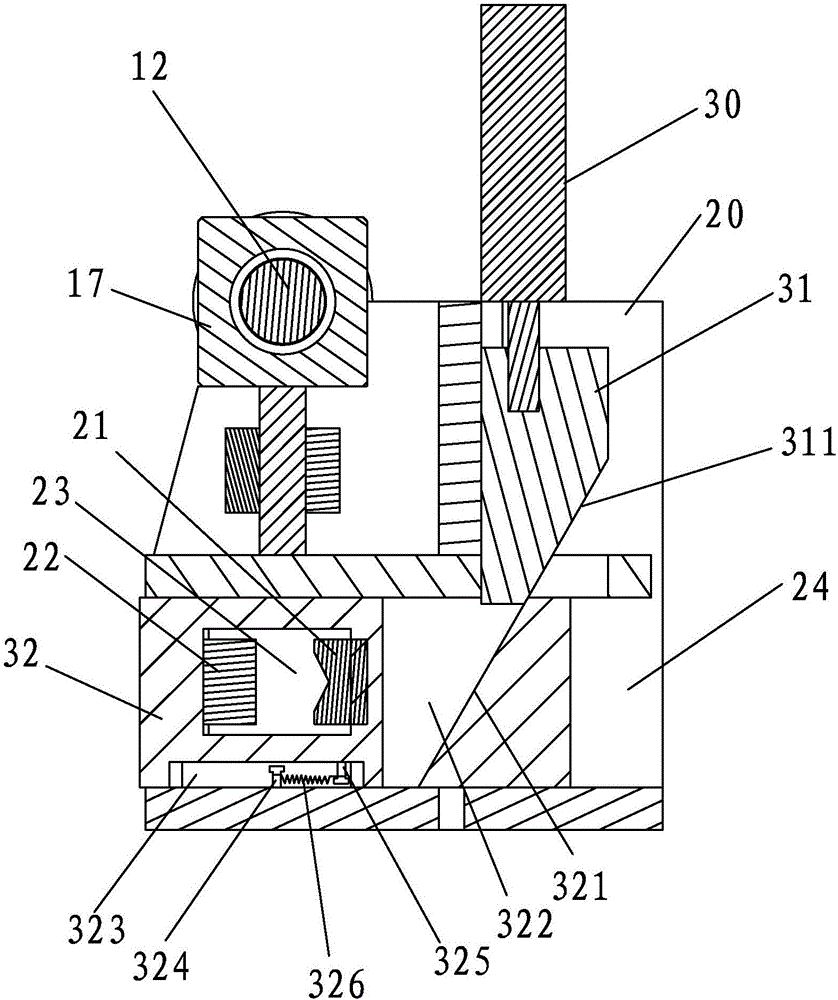

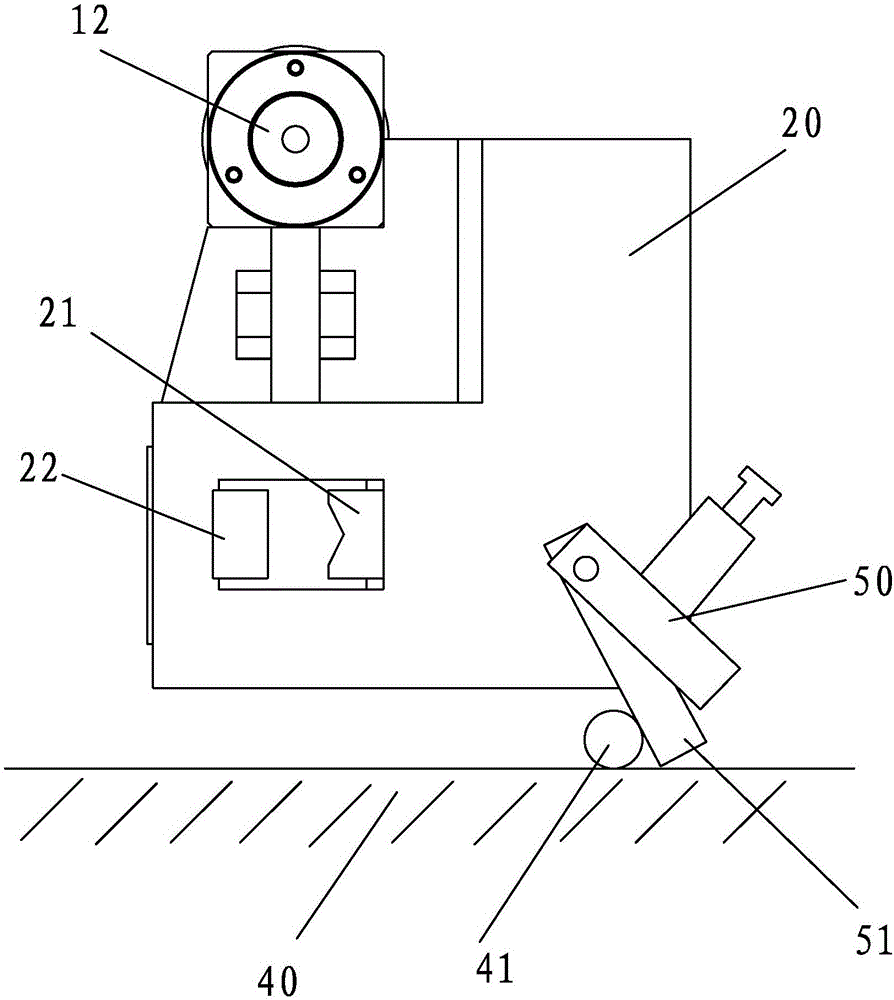

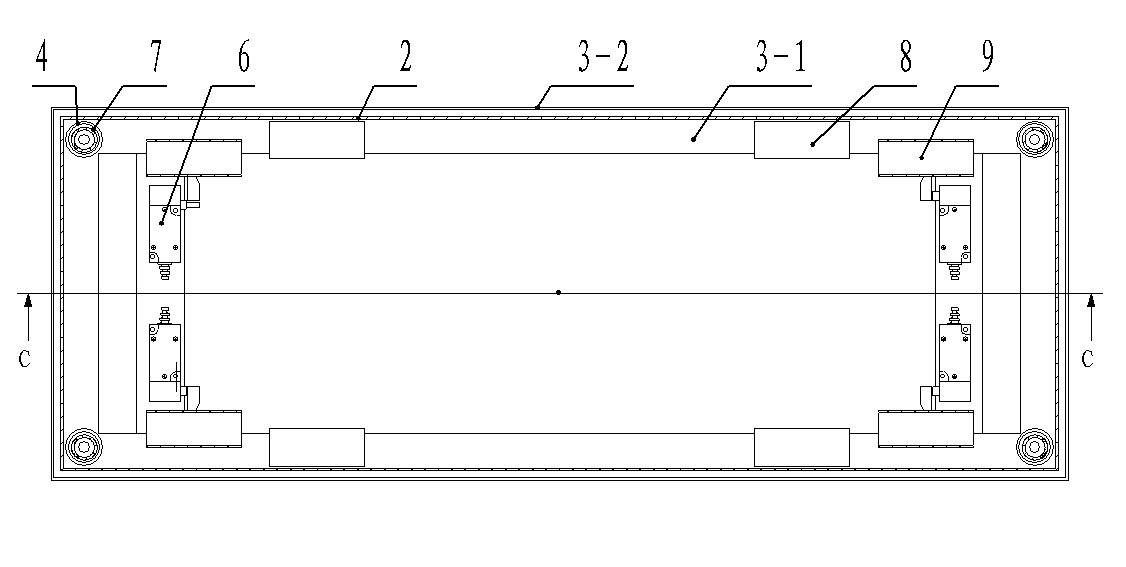

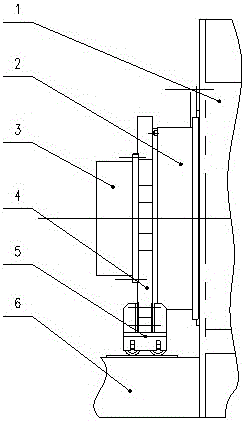

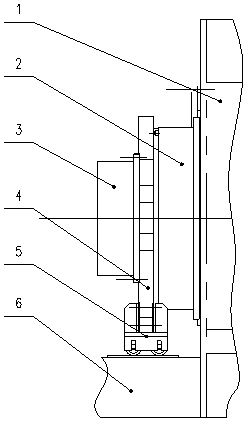

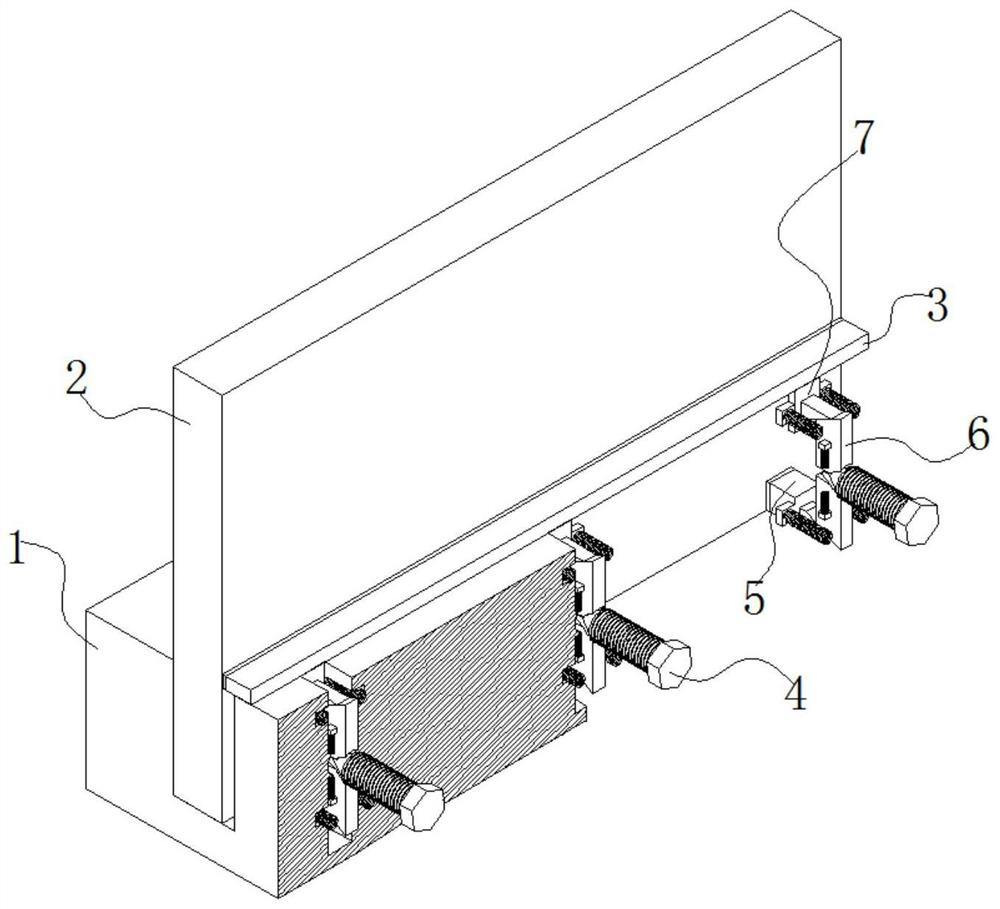

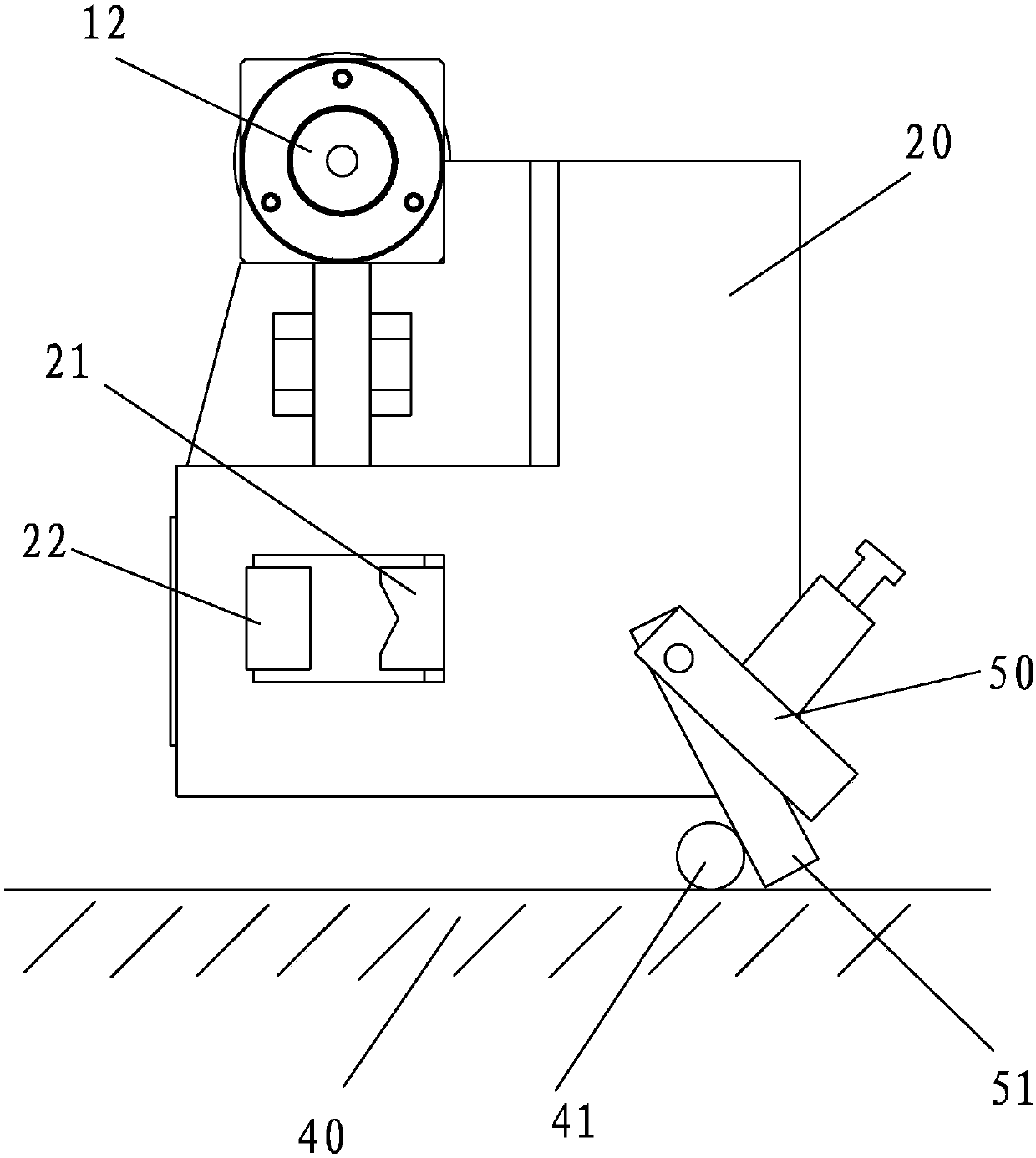

Feeding device of shearing machine

InactiveCN106346072AStable jobReduce failureShearing machine accessoriesMechanical engineeringEngineering

The invention relates to a feeding device of a shearing machine. The feeding device comprises a clamping mechanism for clamping a bar and a feeding mechanism for feeding the bar to a shearing system of the shearing machine. The feeding mechanism comprises a support and a feeding cylinder for driving the clamping mechanism to move back and forth. The feeding cylinder is connected to the support. The feeding device further comprises a guiding bearing bar. The clamping mechanism is erected on the guiding bearing bar in the mode of sliding relative to the guiding bearing bar. The clamping mechanism is improved, stable clamping is ensured, and meanwhile an adjusting device is added, so that bar conveying abrasion is avoided. The feeding device has the advantages of being simple in structure and capable of improving the product quality and prolonging the service life of a machine table.

Owner:泉州鹏宜机械有限公司

Detachable touch frame structure and display device

ActiveCN103927055ARealize narrowingSmall footprintInput/output processes for data processingDisplay deviceEngineering

The invention provides a detachable touch frame structure and a display device and relates to the technical field of display screens. The touch frame structure can be assembled and disassembled conveniently and rapidly, and a side frame is narrowed. The detachable touch frame structure is characterized by comprising the side frame, a snap spring sheet and a touch frame; the snap spring sheet comprises a fixed portion, an elastic portion and a protruding portion; the fixing portion is fixedly connected with the inner wall of the side frame; the elastic portion is connected with the fixed portion; the protruding portion is arranged on the elastic portion; the touch frame is arranged on the inner side of the side frame; a protruding clamping rib is arranged on the outer side wall of the touch frame; the protruding clamping rib is clamped with the protruding portion; a gap is reserved between the protruding clamping rib and the inner wall of the side frame. The elastic portion can drive the protruding portion to move to the gap when compressed, and consequently the protruding portion is separated from the protruding clamping rib.

Owner:HISENSE VISUAL TECH CO LTD

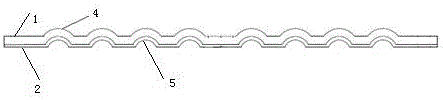

Metal fixing support capable of being embedded with multiple optical cables

PendingCN106019519AEven by forceUniform bearing surfaceOptical fibre/cable installationEngineeringMetal

The invention discloses a metal fixing support capable of being embedded with multiple optical cables, which comprises a metal outer layer and a rubber inner wall, wherein the metal outer layer and the rubber inner wall are bonded together; the rubber inner wall is convex towards the metal outer layer direction to form inner-wall circular arcs; and outer arcs are arranged at positions, corresponding to the inner-wall circular arcs, on the metal outer layer. The problem that the optical cables are likely to fall is solved.

Owner:ECONOMIC RES INST OF STATE GRID GANSU ELECTRIC POWER +3

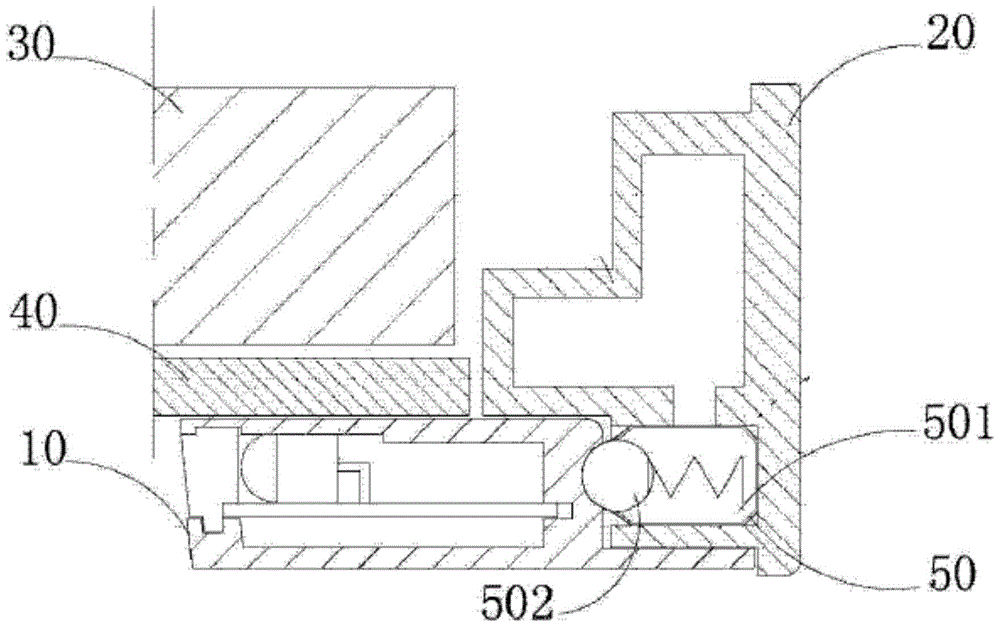

Pedal device for injection molding machine

ActiveCN103252880AImprove reliabilityEliminate potential safety hazardsElectricityInjection molding machine

The invention discloses a pedal device for an injection molding machine, which relates to the technical field of an injection molding machine. The pedal device for the injection molding machine comprises a pedal, wherein a supporting base is arranged below the pedal; a movable sleeve is arranged between the pedal and the supporting base, and is fixedly connected with the pedal through a slab; a plurality of buffer pieces are mounted between the slab and the supporting base in a space defined by the movable sleeve; a limiting switch is arranged on the supporting base, and is electrically connected with a controller for controlling a safety door of the injection molding machine to open and close; and at least one limiting block, which is higher than the limiting switch, is arranged between the slab and the supporting base. With the adoption of the pedal device for the injection molding machine provided by the invention, the potential safety hazard in a working process of the injection molding machine can be avoided.

Owner:广西嘉诚工业有限公司

Thrust bearing

ActiveCN100591932CUniform bearing surfaceControl radial swing amplitudeBearing componentsSliding contact bearingsThrust bearingWedge shape

The invention relates to a thrust bearing, which is characterized by comprising 6 to 24 thrust bearing pad groups; each thrust bearing pad group comprises thrust bearing pads and a supporting pad; theindependent thrust bearing pad groups are evenly distributed on a same ring-shaped plane; a supporting block is arranged between the thrust bearing pads and the supporting pad; the lower-part end surface of the supporting pad is a spherical cambered surface; and the radial central line of each supporting block lags behind the geometric central line of the corresponding thrust bearing pads. The thrust bearing has the advantages that as a plurality of groups of thrust bearing pads and the supporting block of the spherical cambered surface are adopted, the stress surfaces of the thrust bearingsare even; stop pins effectively control the radial swinging width of the thrust bearing pads; as the radial central line of the supporting block lags behind the geometric central line of the thrust bearing pads, and due to wedge-shaped lubricating oil inlets, oil films are easily formed on the surface of the thrust bearing pads so as to reduce the temperature of touching surfaces; both the supporting block and the stop pins can prevent the thrust bearing pads and the supporting pad from being deviated; among a plurality of independent thrust bearing pads, individual thrust bearing pad can be replaced separately, and therefore the maintenance cost is reduced.

Owner:NANJING HIGH SPEED & ACCURATE GEAR GRP

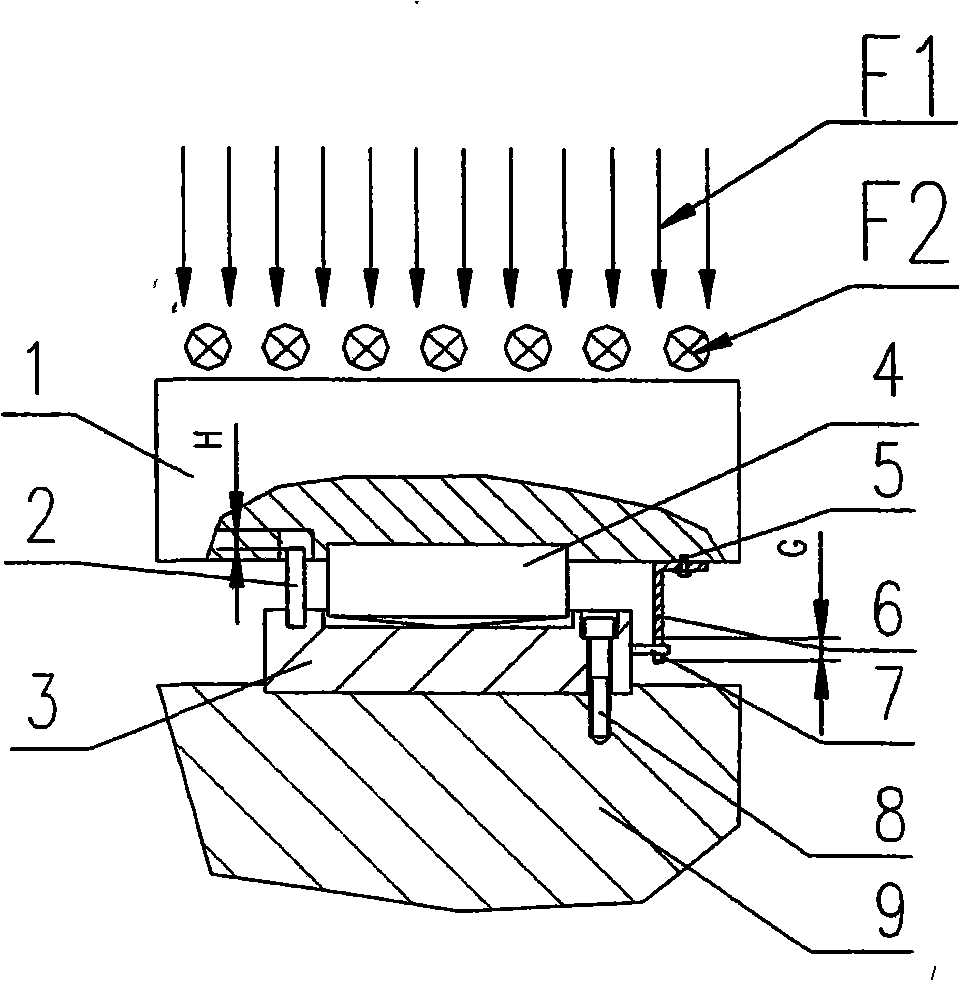

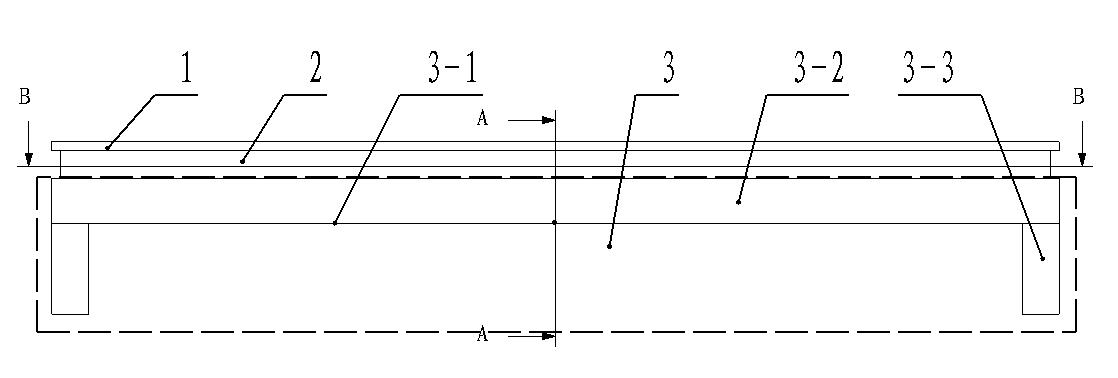

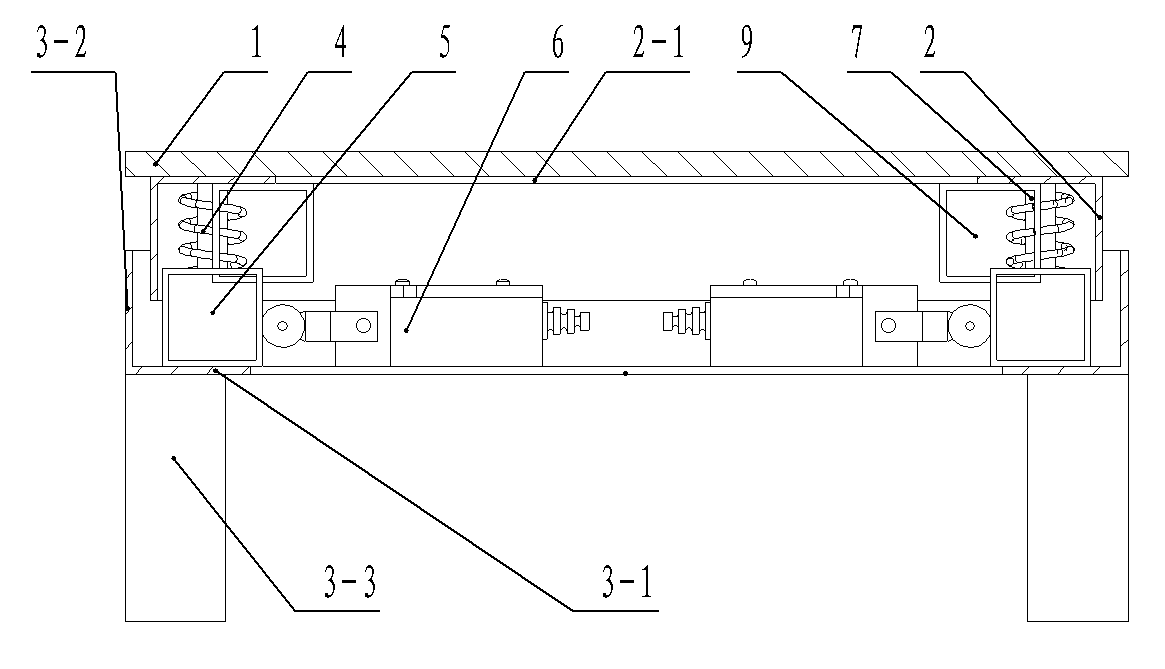

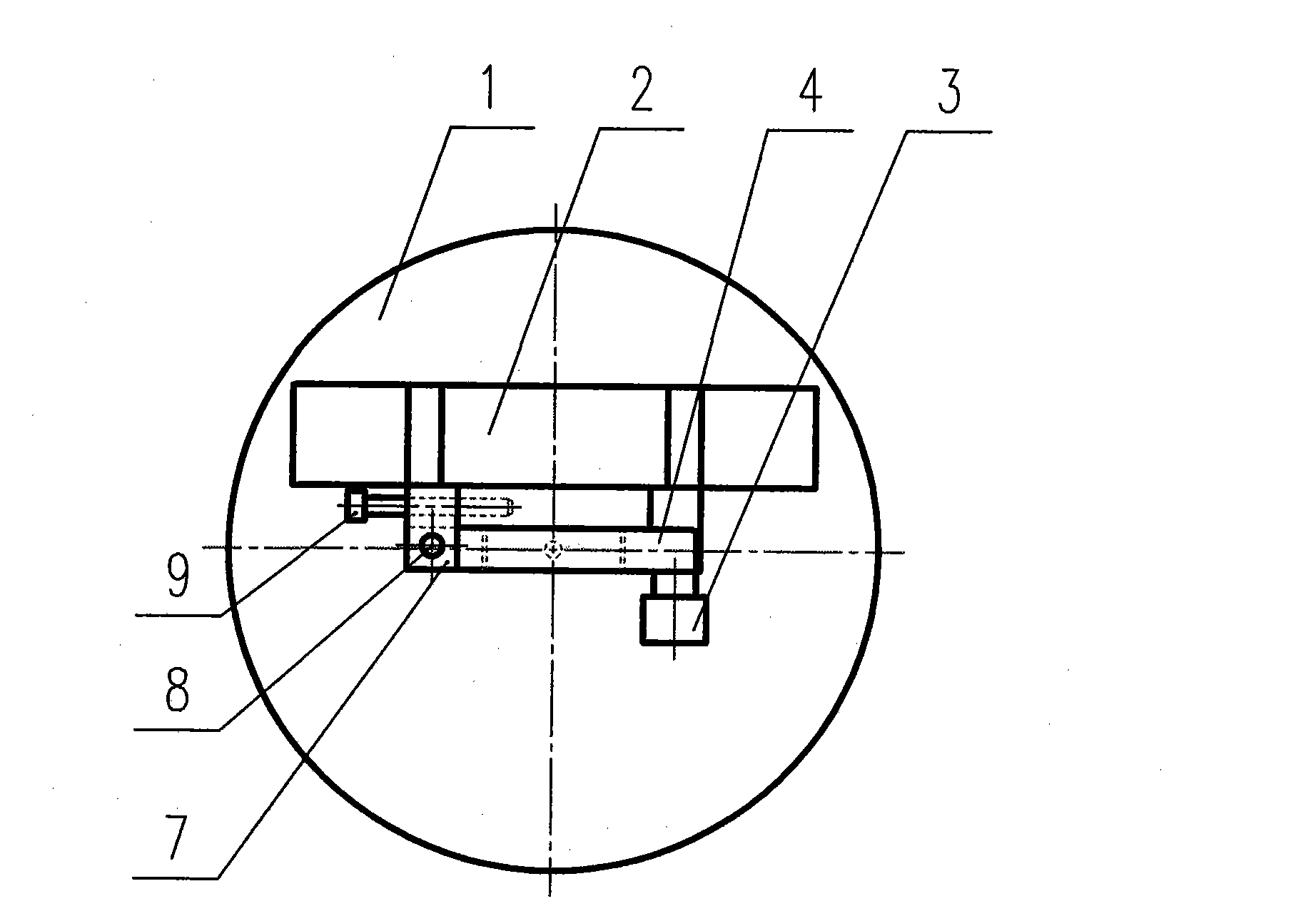

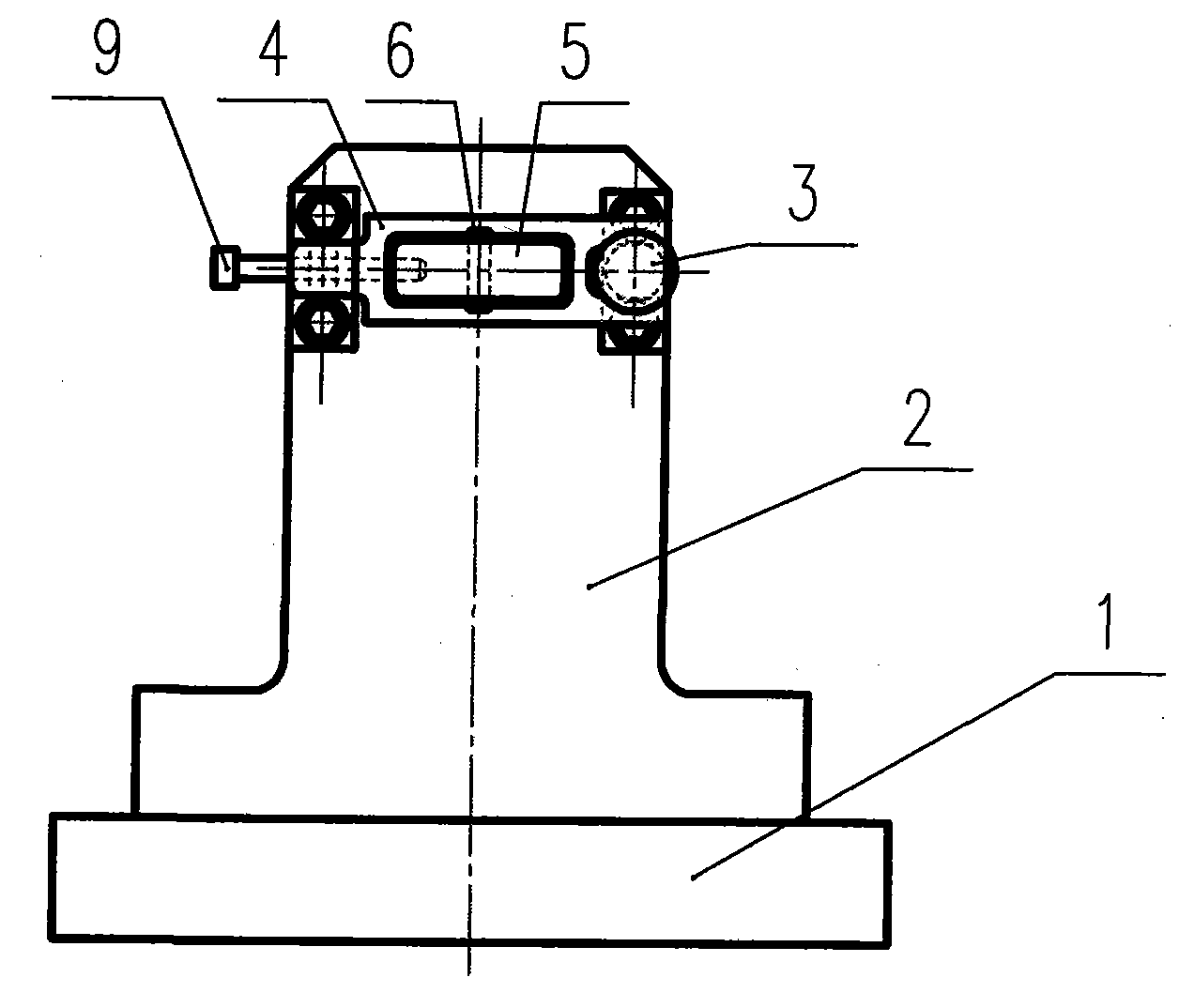

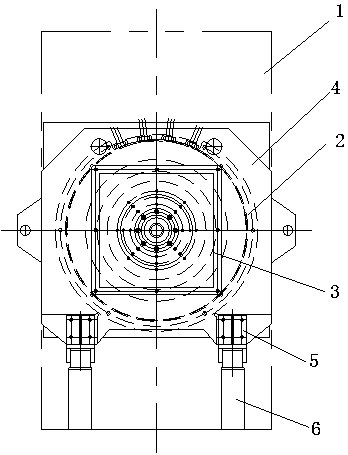

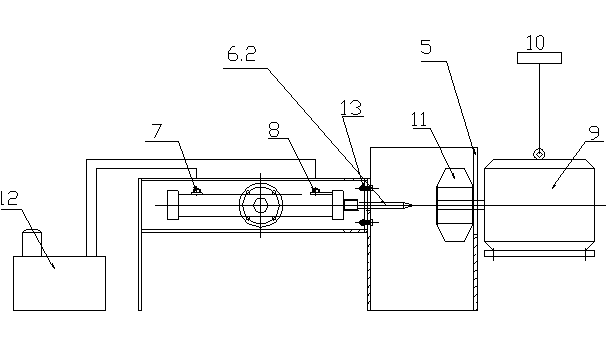

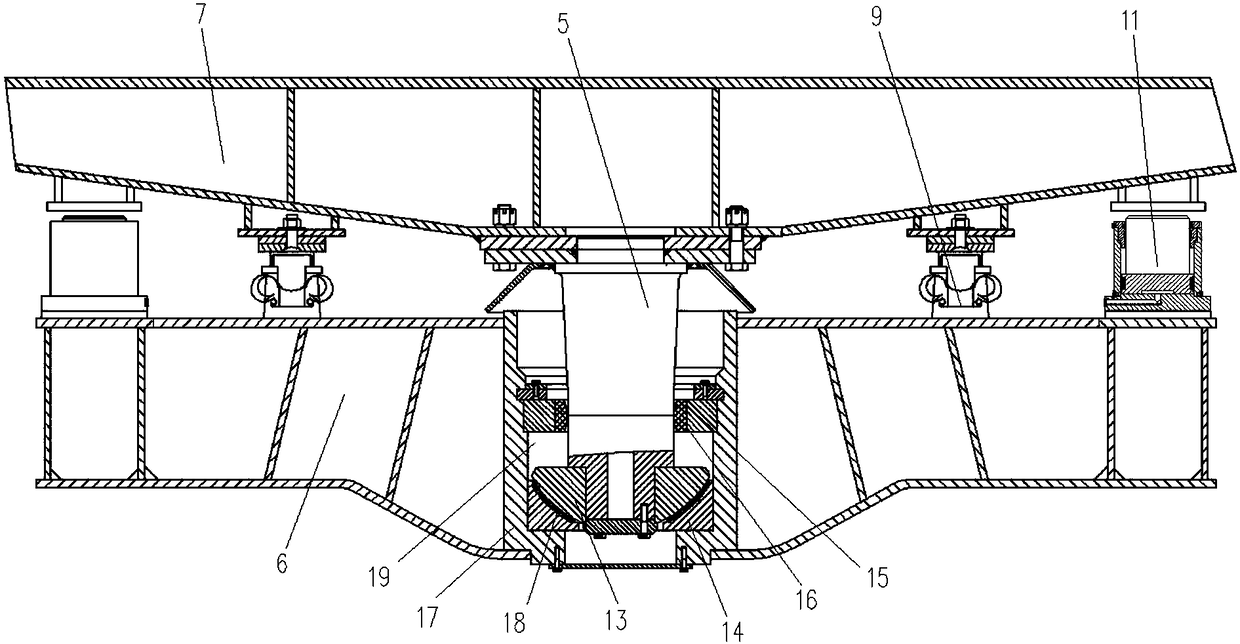

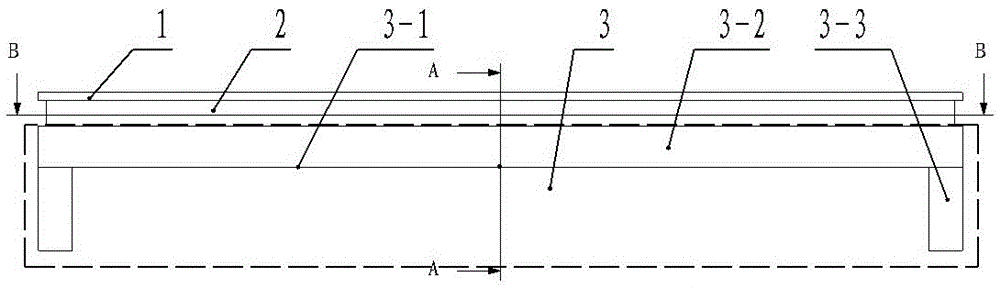

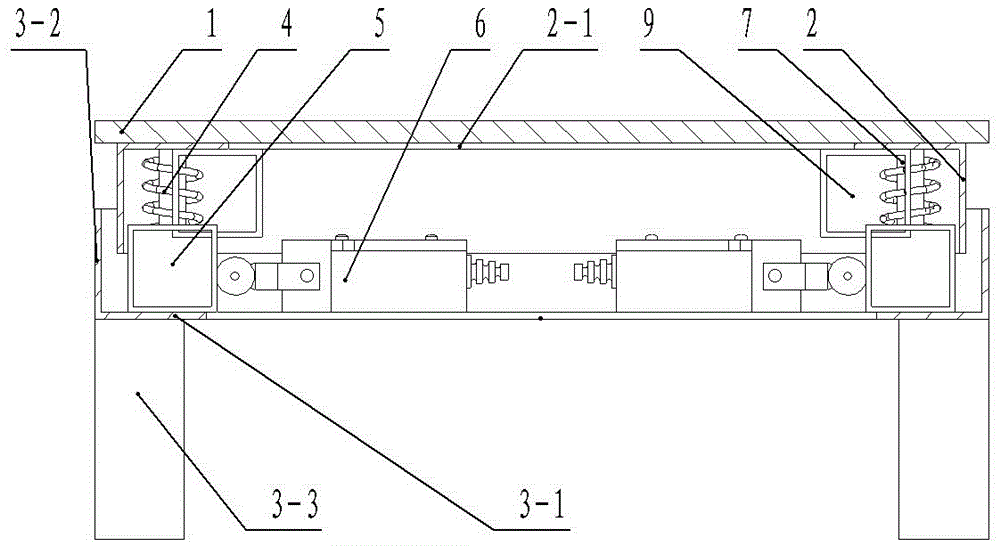

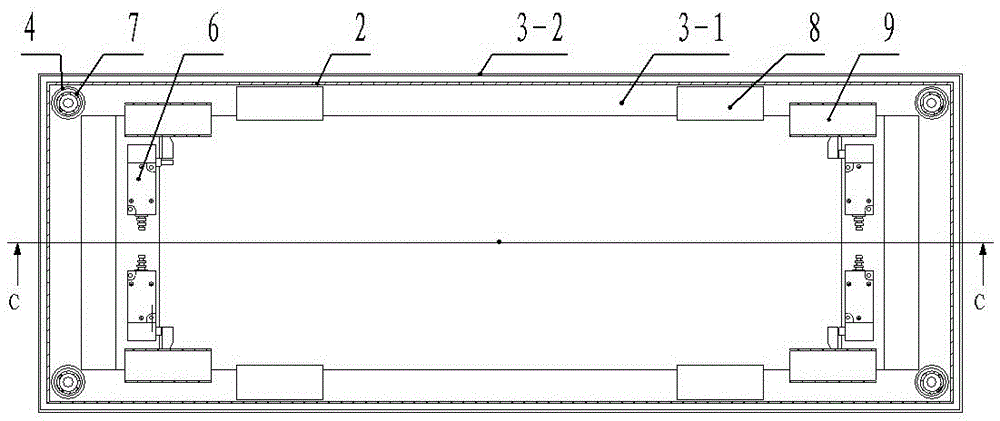

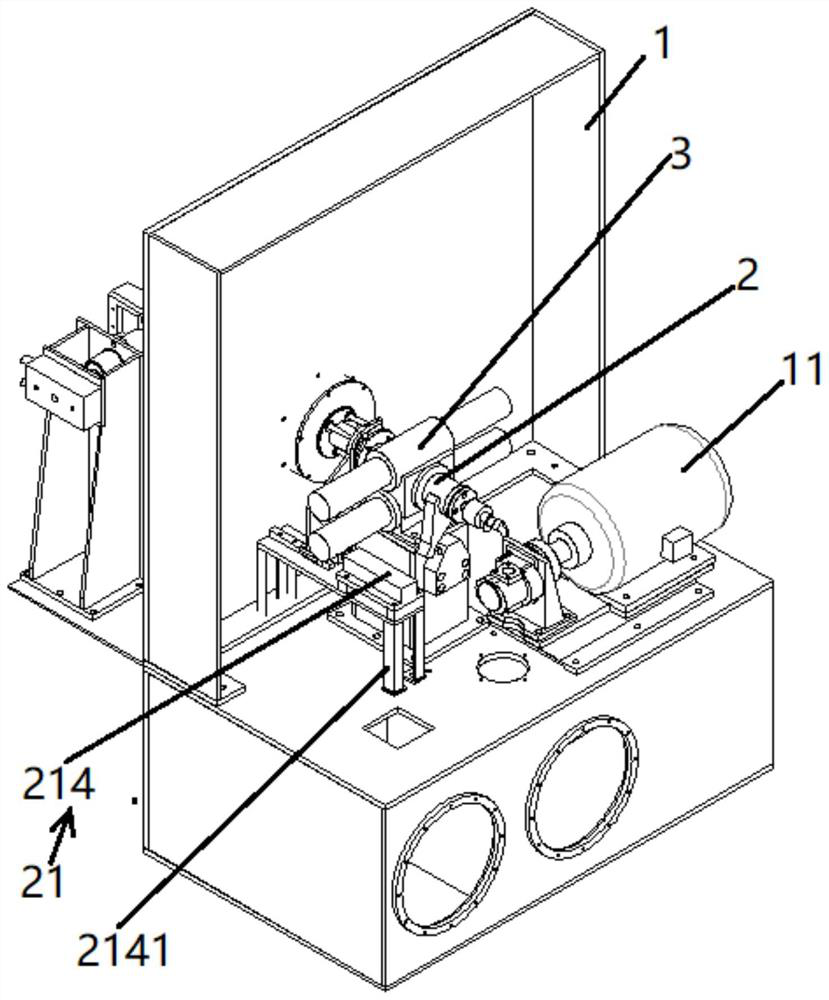

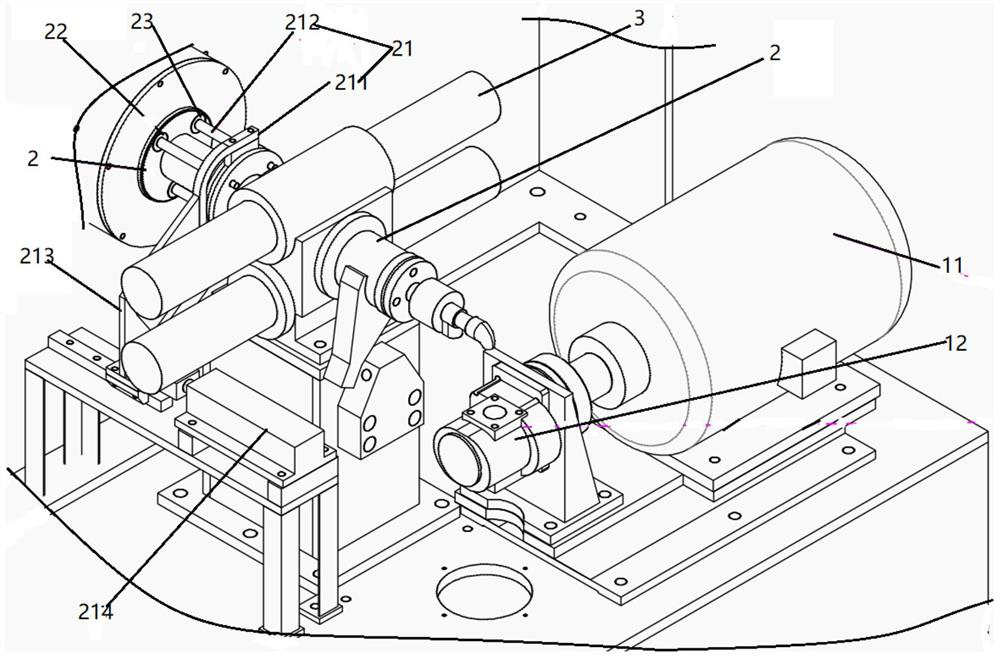

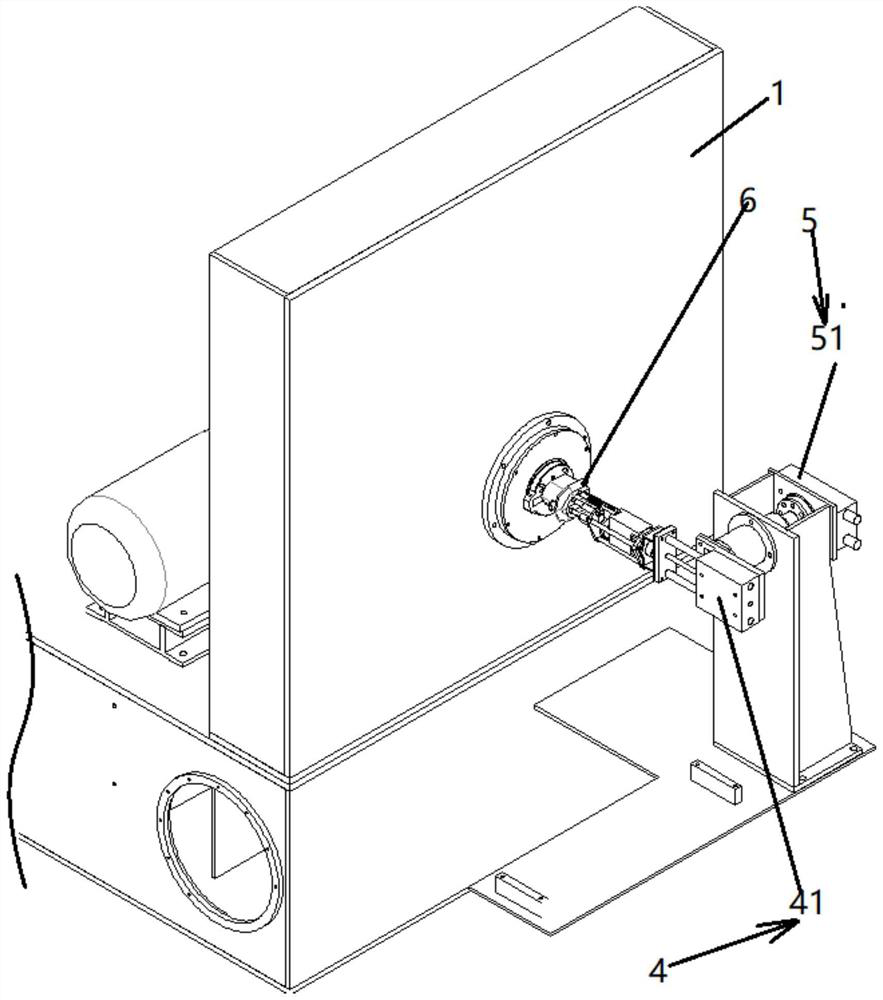

Automatic-following pressure balance ring-shaped drive device and application method thereof

The invention provides an automatic-following pressure balance ring-shaped drive device and an application method thereof. The automatic-following pressure balance ring-shaped drive device comprises a rack, wherein a ring-shaped drive device is mounted on the rack through a hydraulic nut; the ring-shaped drive device is connected with a water inlet valve body through a connecting device; a supporting device is connected below the connecting device; the supporting device is in sliding connection with a rail below the supporting device; and the ring-shaped drive device is further connected with an industrial controller. The automatic-following pressure balance ring-shaped drive device makes up the control precision defects and the structural defects caused by simultaneous movement of a plurality of cylinders in the past, and has the advantages of being simple in structure, high in working efficiency, easy to realize automatic control and the like. Especially, the automatic-following balance pressure ring-shaped drive device adopts an independent ring-shaped drive device; only one drive device is provided, so that control is simple, and synchronous following pressure balance performances are good, and therefore, the problem that the conventional structure cannot be used for placing large-diameter cylinders, and a plurality of small cylinders cannot meet high-precision synchronization requirements is solved.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

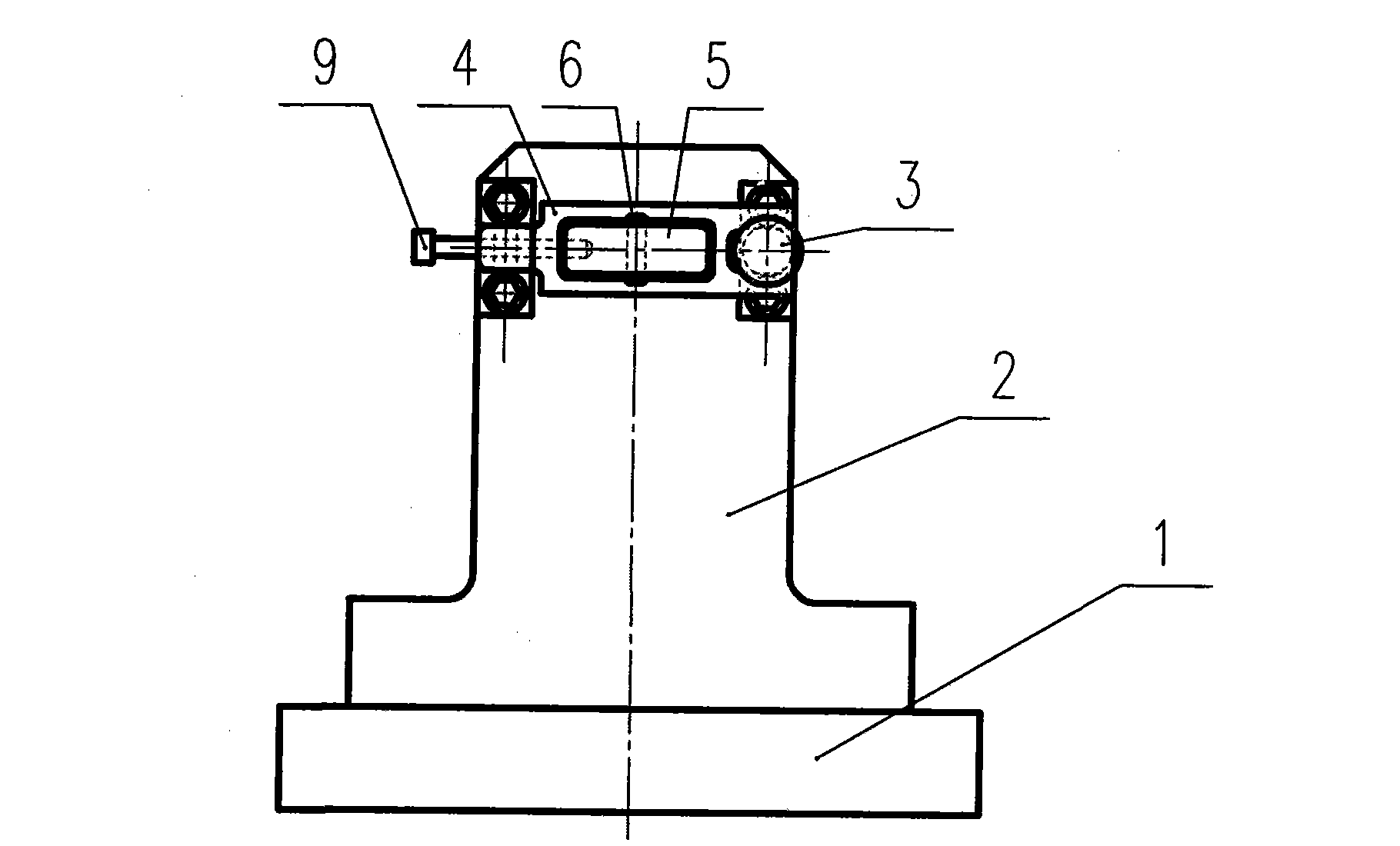

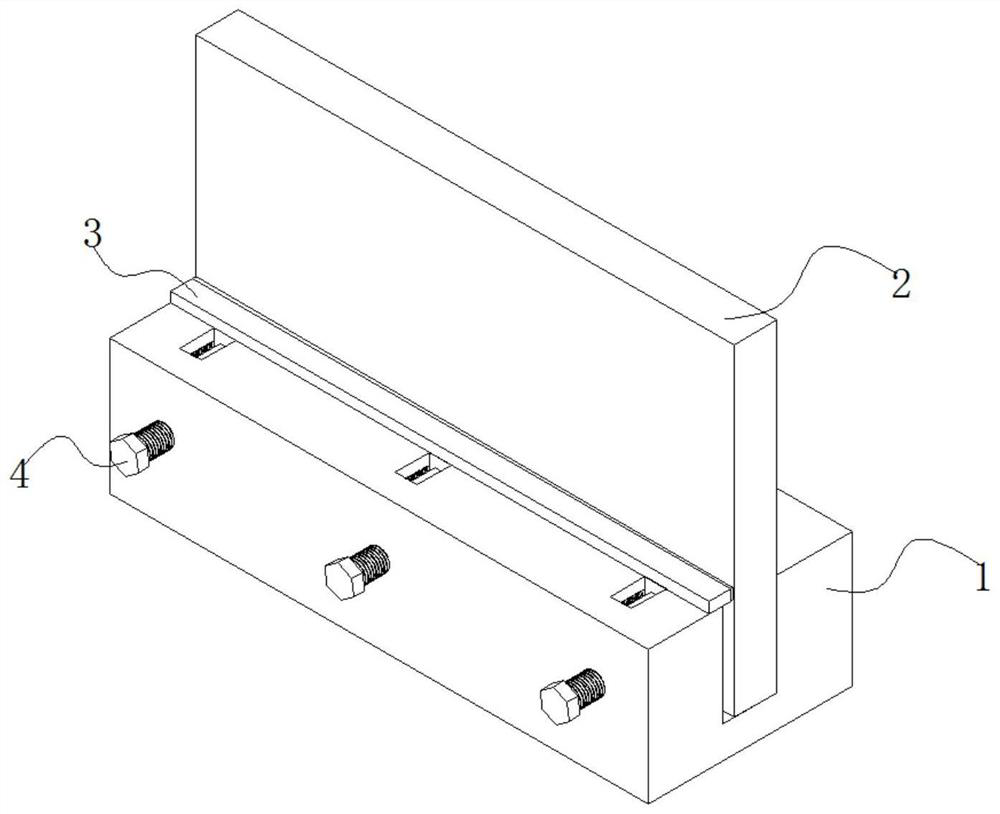

High-precision positioning fixture

InactiveCN102107401AGuaranteed accuracyGuaranteed stabilityWork holdersMechanical engineeringEngineering

Owner:TIANJIN JINLAI PRECISION MACHINERY

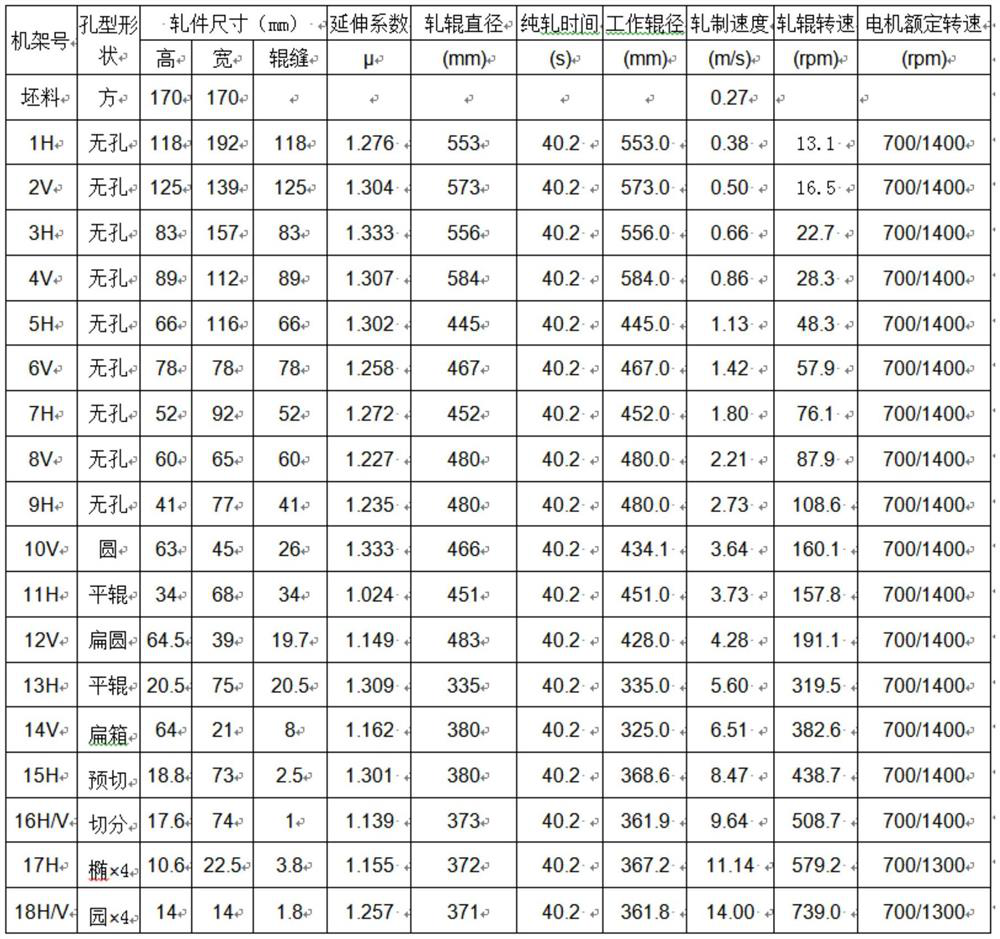

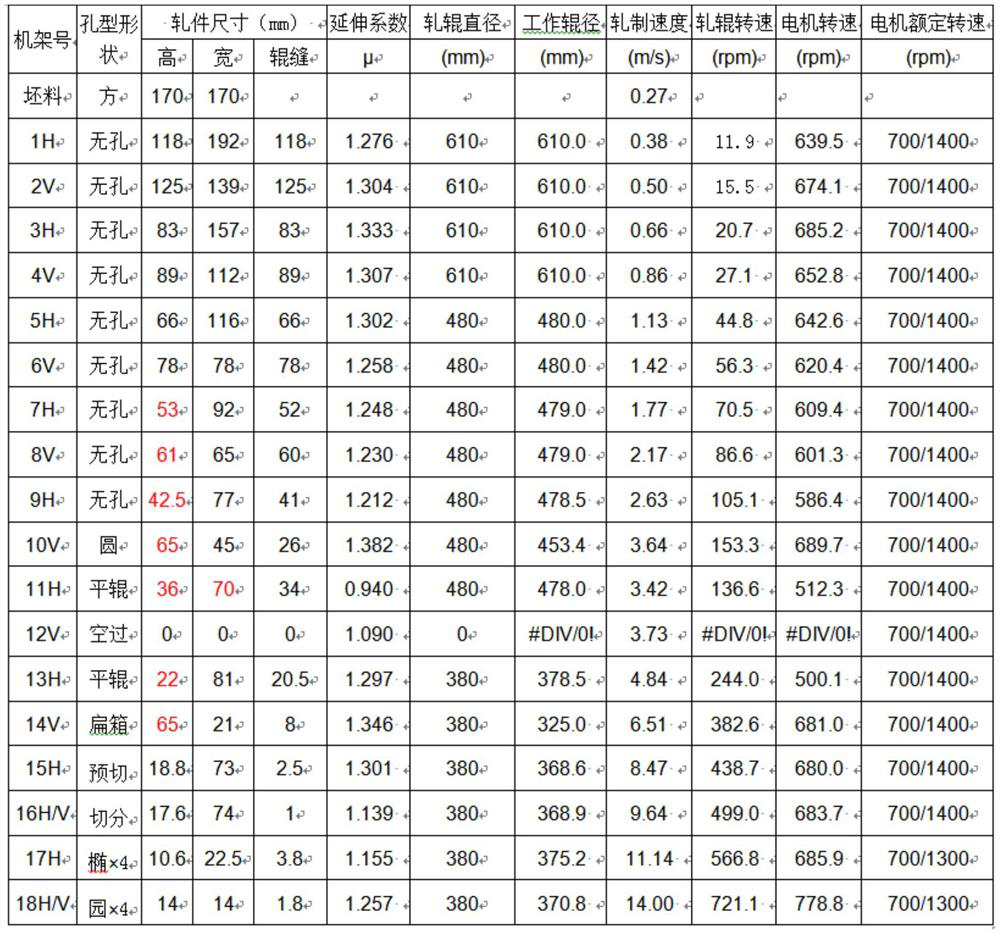

A method for optimizing pass pattern of φ14mm steel bars

The invention relates to the technical field of rebar production and machining, and discloses a groove optimization method of a rebar of specification of phi 14 mm. The method comprises the followingmethod of 1), preparation work; 2), rough machining; 3), middle machining; and 4), finish machining. According to the groove optimization method of the rebar of the specification of phi 14 mm, an existing eighteen rolling mills are adjusted to be seventeen rolling mills through the above mentioned steps, so that the requirement for energy sources is reduced, and then a large amount of energy is saved; through a rough rolling unit, a middle rolling unit and a finishing rolling unit, the same roller diameter is adopted, so that the vibration of the rebar in the rolling process is conveniently reduced, and the stability of the rebar in the rolling process is improved; and by reducing the rolling speed of rollers in the rough rolling unit, the medium rolling unit and the finish rolling unit, the stress surface of the reinforcing rebar in the rolling process is more uniform, so that the final quality of a product is ensured, the quality of the product is prevented from fluctuating, and thepurposes of good stability, outstanding quality of the finished product and energy conservation are achieved.

Owner:CHENGYU VANADIUM TITANIUM TECH CO LTD

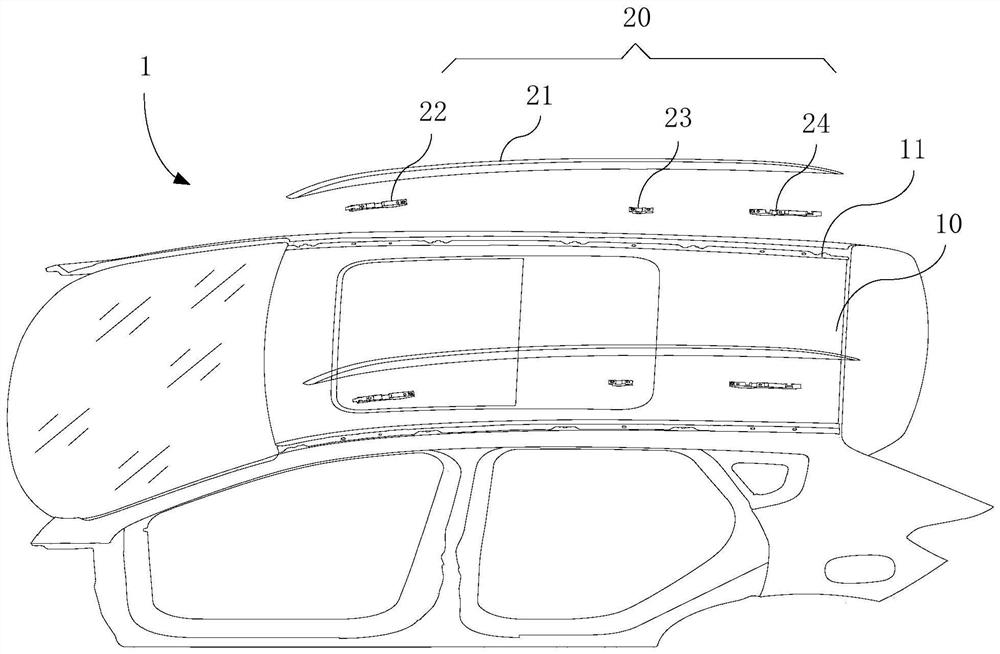

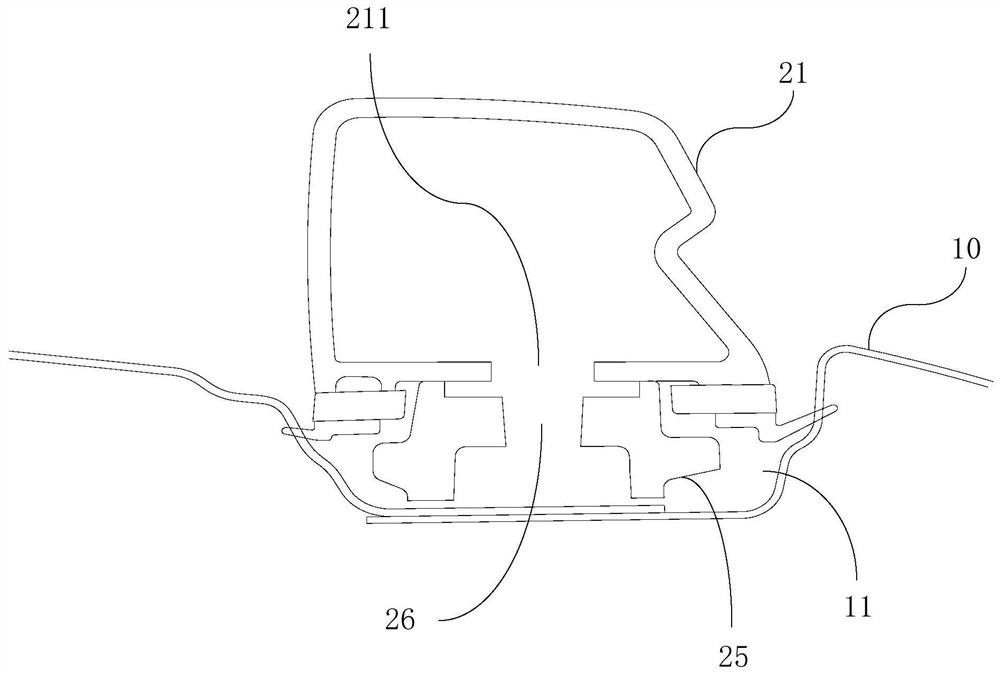

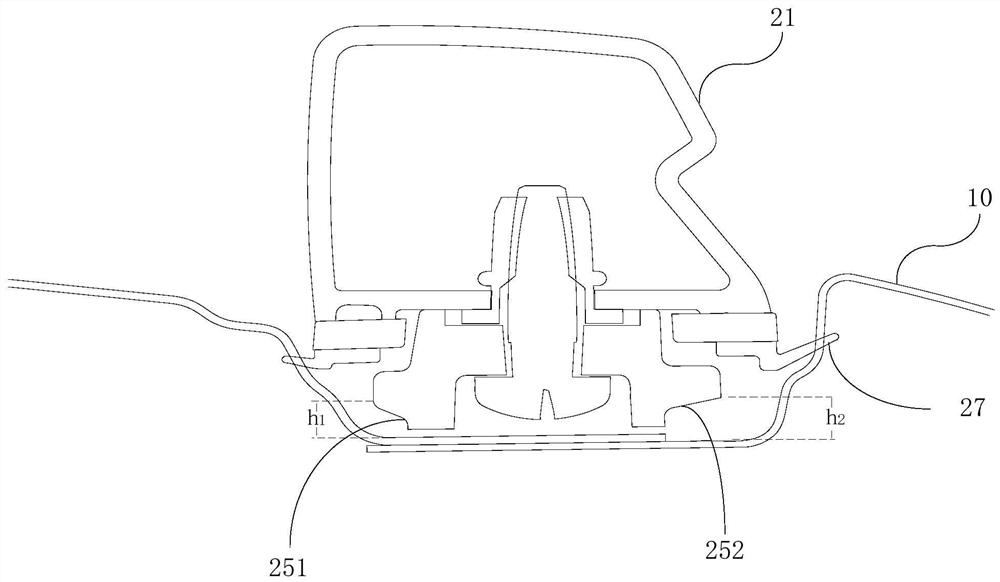

Automobile roof and automobile

ActiveCN112224138ASolve the problem of sheet metal springbackAvoid the problem of sheet metal springbackSupplementary fittingsStructural engineeringMechanical engineering

The invention provides an automobile roof and an automobile. The automobile roof comprises a top cover and luggage rack assemblies symmetrically arranged on the two sides of the top cover, an assembling groove is formed in the end face, facing the outer side, of the top cover, the luggage rack assemblies are connected with the top cover through the assembling groove, and receding parts are arranged on the end faces, connected with the assembling groove, of the luggage rack assemblies. According to the automobile roof provided by the invention, the technical problems that the luggage rack assembly is insufficient in bearing capacity and easy to break due to the fact that the roof and the luggage rack assembly are not tightly connected and the roof is prone to sheet metal springback are solved.

Owner:GREAT WALL MOTOR CO LTD

An application method of an automatic follow-up balance pressure ring drive device

The invention provides an automatic-following pressure balance ring-shaped drive device and an application method thereof. The automatic-following pressure balance ring-shaped drive device comprises a rack, wherein a ring-shaped drive device is mounted on the rack through a hydraulic nut; the ring-shaped drive device is connected with a water inlet valve body through a connecting device; a supporting device is connected below the connecting device; the supporting device is in sliding connection with a rail below the supporting device; and the ring-shaped drive device is further connected with an industrial controller. The automatic-following pressure balance ring-shaped drive device makes up the control precision defects and the structural defects caused by simultaneous movement of a plurality of cylinders in the past, and has the advantages of being simple in structure, high in working efficiency, easy to realize automatic control and the like. Especially, the automatic-following balance pressure ring-shaped drive device adopts an independent ring-shaped drive device; only one drive device is provided, so that control is simple, and synchronous following pressure balance performances are good, and therefore, the problem that the conventional structure cannot be used for placing large-diameter cylinders, and a plurality of small cylinders cannot meet high-precision synchronization requirements is solved.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

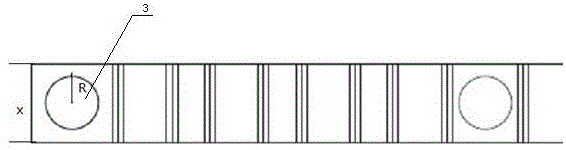

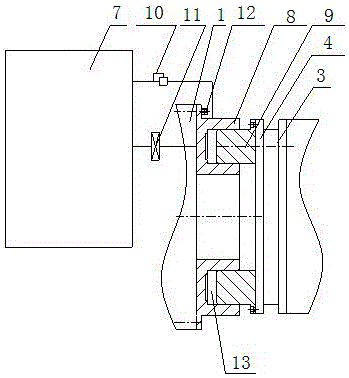

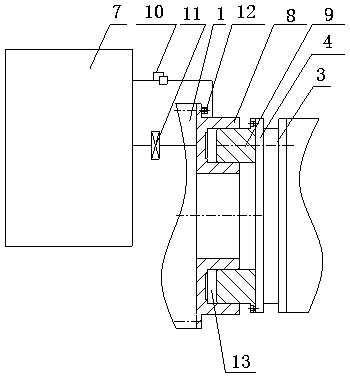

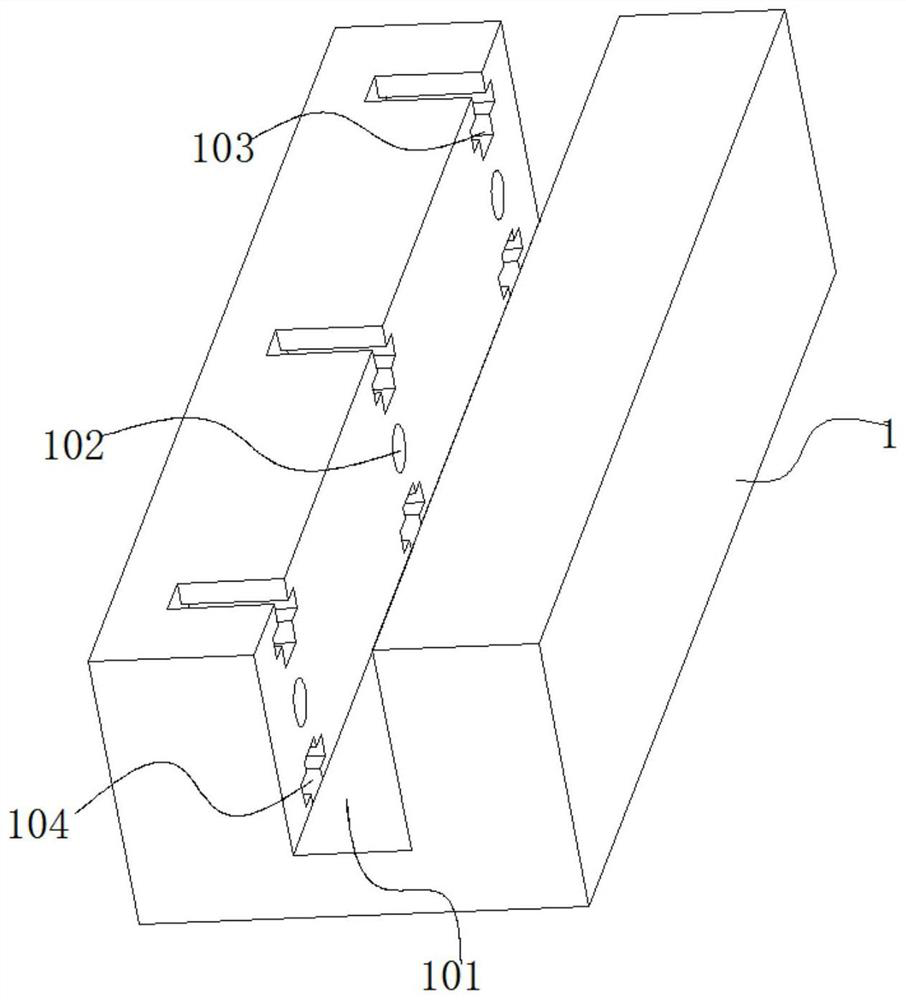

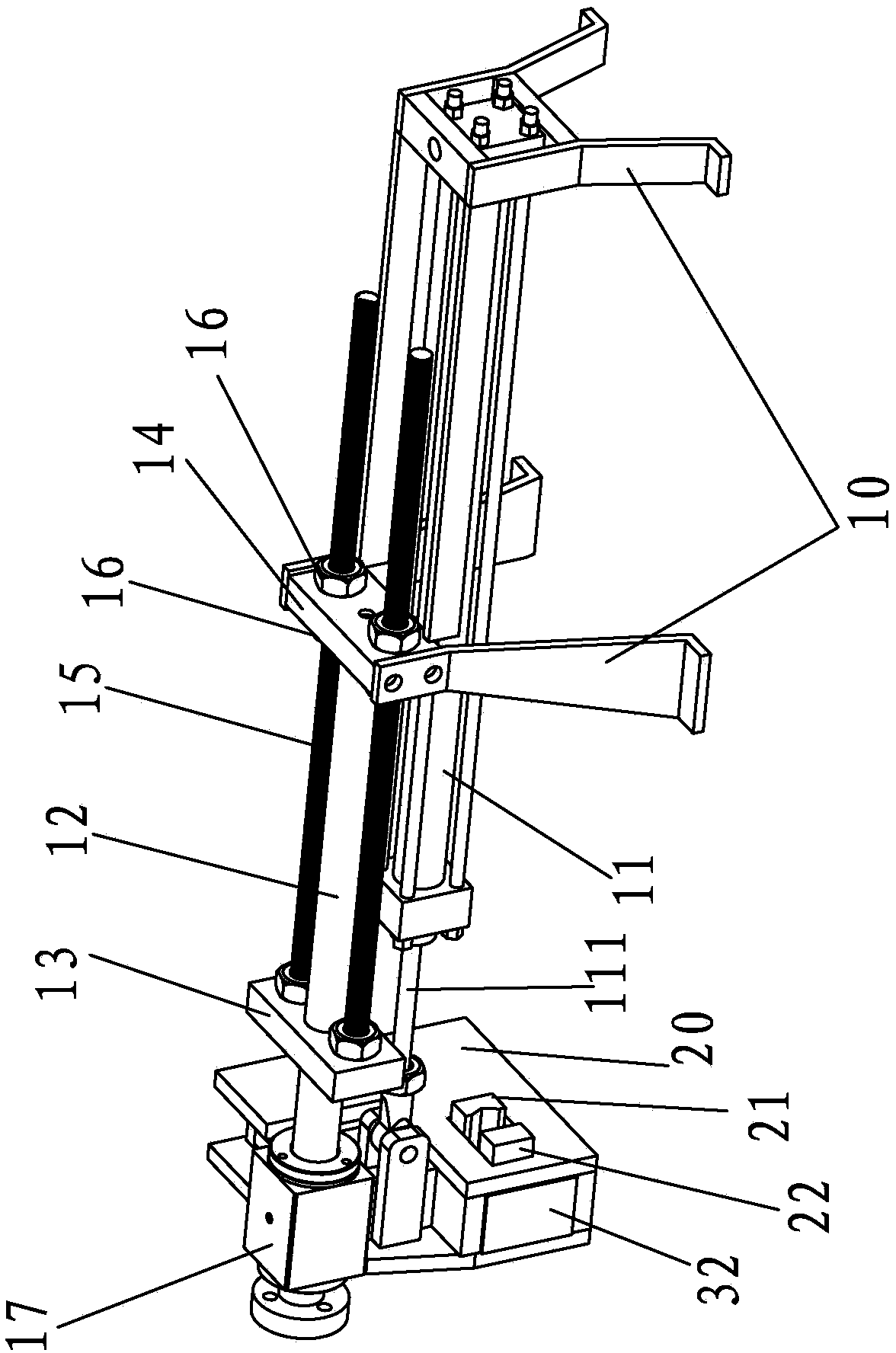

Dismounting device for hydraulic coupler

InactiveCN103317330AUniform bearing surfaceEasy disassembly and separationMetal working apparatusFluid couplingControl engineering

The invention discloses a dismounting device for a hydraulic coupler. The dismounting device comprises a hydraulic coupler dismounting working chamber and a hydraulic cylinder, wherein the hydraulic coupler dismounting working chamber is used for accommodating the hydraulic coupler, the hydraulic cylinder is installed inside a hydraulic cylinder fixing frame, a piston rod of the hydraulic cylinder is connected with the hydraulic coupler dismounting working chamber, and the hydraulic coupler dismounting working chamber is provided with a hydraulic coupler dismounting working chamber working face which is matched with a stressed face of the hydraulic coupler. The dismounting device has the advantages that when the dismounting device is used for dismounting and separating the hydraulic coupler from a transmission shaft of an electric motor, the operation is simple, and the centering performance is good; during dismounting, the stressed face of the hydraulic coupler is uniform, and the hydraulic coupler and the electric motor are separated quickly under the condition that the hydraulic coupler and the electric motor are not damaged; the dismounting device is simple in structure, low in cost, safe and quick.

Owner:JIGANG GRP

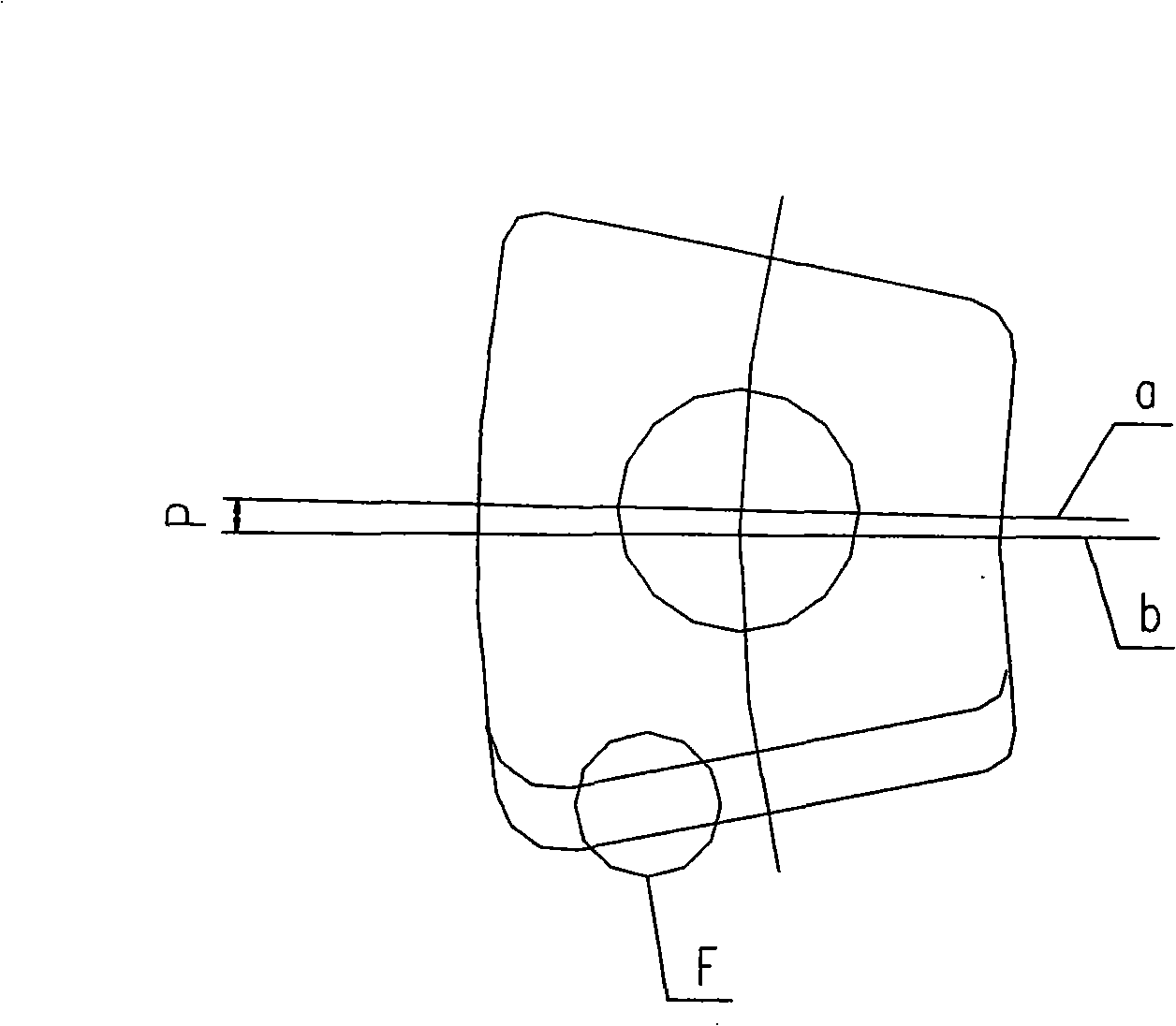

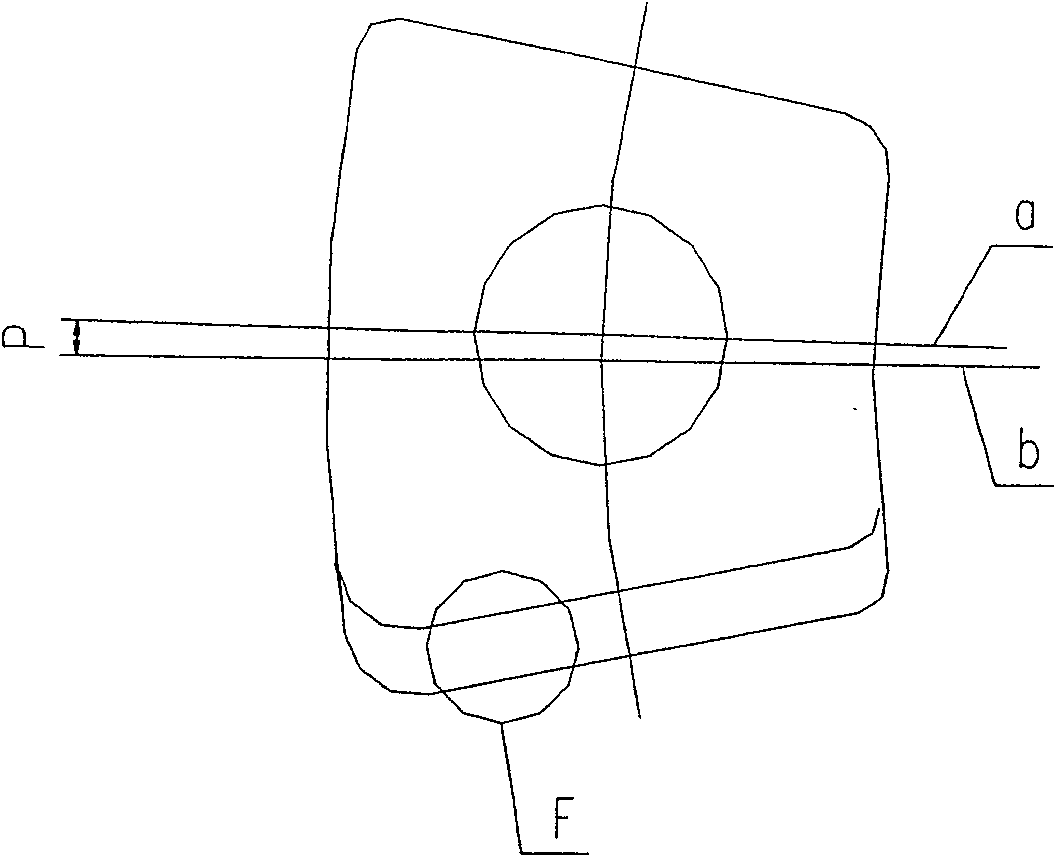

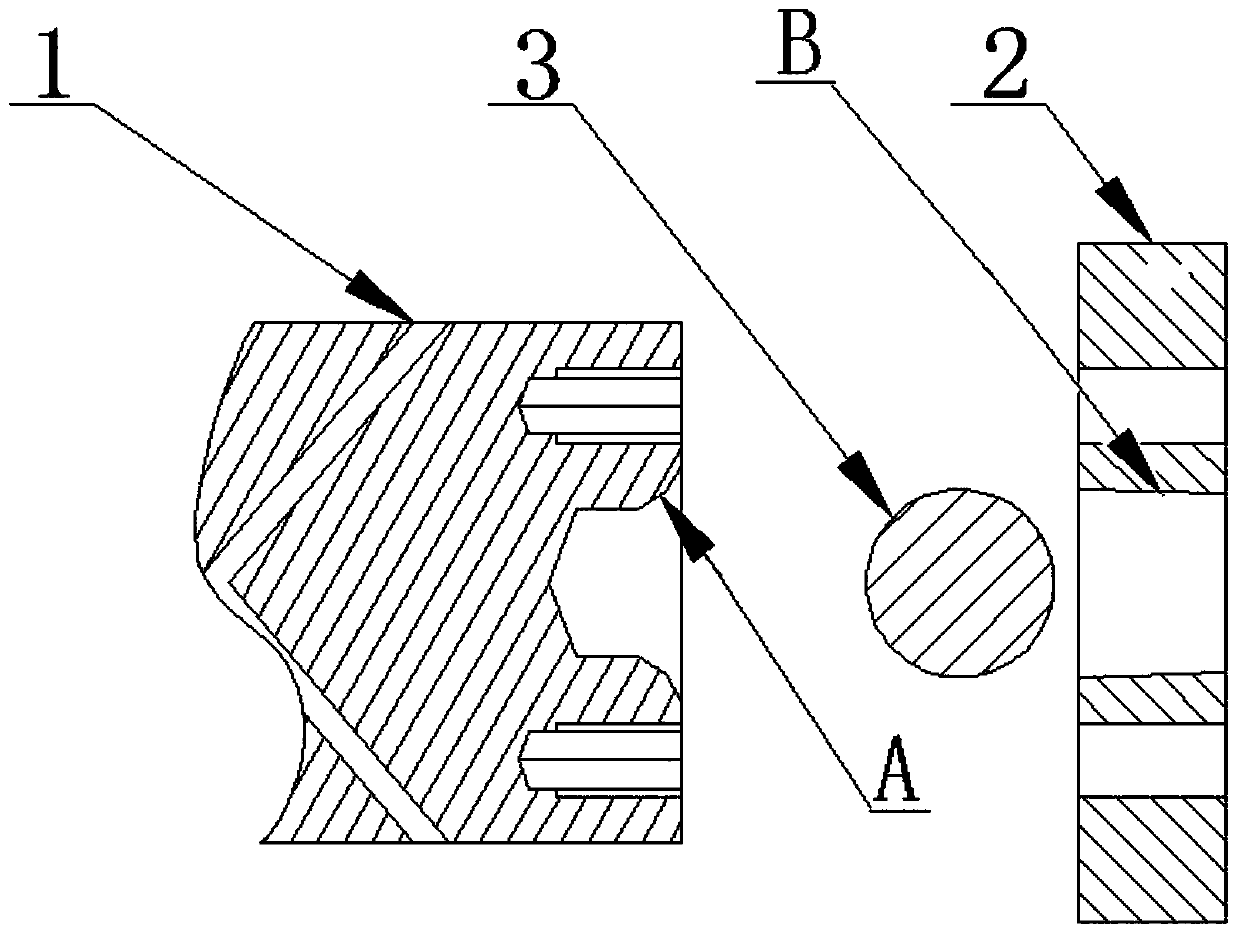

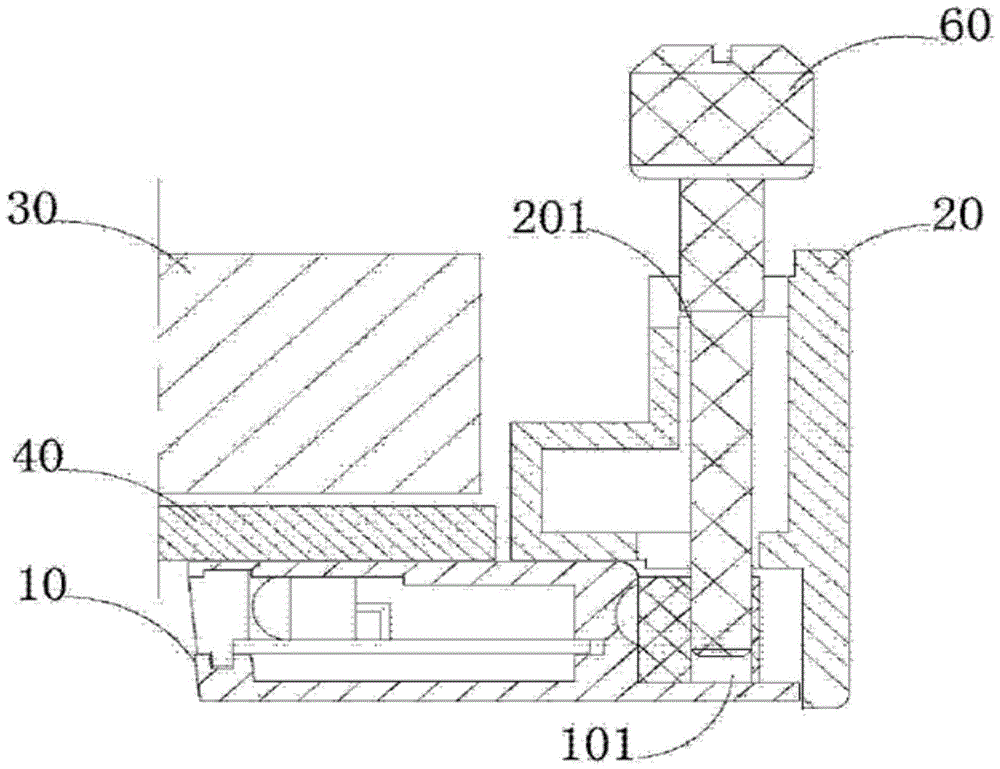

A tool with a replaceable cutter head and the connection method between the replaceable cutter head and the cutter bar

The invention discloses a tool provided with a replaceable tool bit and a connecting manner of the replaceable tool bit and a tool bar of the tool. According to the tool, an inner hole having the conical surface is dug in the center of the connecting surface of the tool bar, an inner hole having the conical surface is also dug in the center of the connecting surface of a replaceable blade, and a steel ball is arranged in the inner hole of the replaceable blade; the angle of the conical surface of the inner hole of the replaceable blade ranges from 1 degree to 8 degrees; the angle of the conical surface of the tool bar ranges from 20 degrees to 80 degrees; and a gap ranging from 0.01 mm to 0.1 mm exists between the tool bar and the replaceable blade. The connecting manner comprises three steps as follows: the steel ball is mounted between the conical surface of the replaceable tool bit and the conical surface of the tool bar, and then fixation is performed by the aid of compression screws. According to the tool and the connecting manner, aligned positioning connection of the tool bar with the replaceable blade is realized, the blade can be always aligned to the cutter bar during repeated blade replacement, aligned positioning connection of the tool bar with the blade is not required to be adjusted repeatedly by wasting a lot of energy, and the runout of the whole tool can be controlled within 0.003 mm.

Owner:CHENGDU QIPING TECH CO LTD

A detachable touch frame structure and display device

ActiveCN103927055BRealize narrowingSmall footprintInput/output processes for data processingDisplay deviceEngineering

Owner:HISENSE VISUAL TECH CO LTD

Fireproof glass mounting structure

PendingCN112523365ADifficult to enterAffect aestheticsWallsFire proofingStructural engineeringMechanical engineering

The invention discloses a fireproof glass mounting structure, and relates to the technical field of fireproof glass mounting. The fireproof glass mounting structure comprises a fixing base; a limitingclamping groove is formed in the top of the fixing base; fireproof glass is slidably connected with the interior of the limiting clamping groove; a limiting plate is slidably connected with the position, located at one side of the limiting clamping groove, of the top of the fixing base; a plurality of threaded holes penetrating through the fixing base are formed in the inner wall of one side of the limiting clamping groove; extrusion bolts are in threaded fit in the threaded holes; a first limiting sliding groove is formed in the position, above the threaded holes, of the inner wall of the limiting clamping groove; a second limiting sliding groove is formed in the position, below the threaded holes, of the inner wall of the limiting clamping groove; and a positioning block is slidably connected with the interior of the second limiting sliding groove. According to the fireproof glass mounting structure, through the cooperative use of the extrusion bolts, extrusion blocks, a limiting sliding block and the positioning block, the problems that in an existing fireproof glass mounting structure, the fireproof glass mounting process is complex, glass mounting is unstable, and glass is inconvenient to replace in the later period are solved.

Owner:江苏盛阳消防科技有限公司

A double welded seam welded integral forged steel piston

The invention relates to a double seam welded integral forged steel piston. It consists of a piston head and a piston skirt made of forged steel. The piston head is located in the concave cavity. The outer circle of the end face with a large diameter of the piston head is welded The top surface of the outer circle part of the end face forms the first single-sided weld, and the inner circle part of the end face with the small diameter of the piston head is welded with the outer wall of the boss at the bottom of the cavity, and the inside of the end face with the small diameter of the piston head The top surface of the circular part forms a second single-sided weld, and a gas ring groove and an oil ring groove are sequentially arranged on the peripheral wall of the upper part of the piston skirt from top to bottom. The piston head of the present invention is arranged in the concave cavity on the top of the piston skirt and welded together, the piston head and the piston skirt are firmly connected, and there will be no "top off" phenomenon, and the welding seam is outside the cooling oil chamber, which is easy to clean , avoiding the hard particles of the weld from falling off and causing the engine to scuff.

Owner:BINZHOU DONGHAILONG PISTON

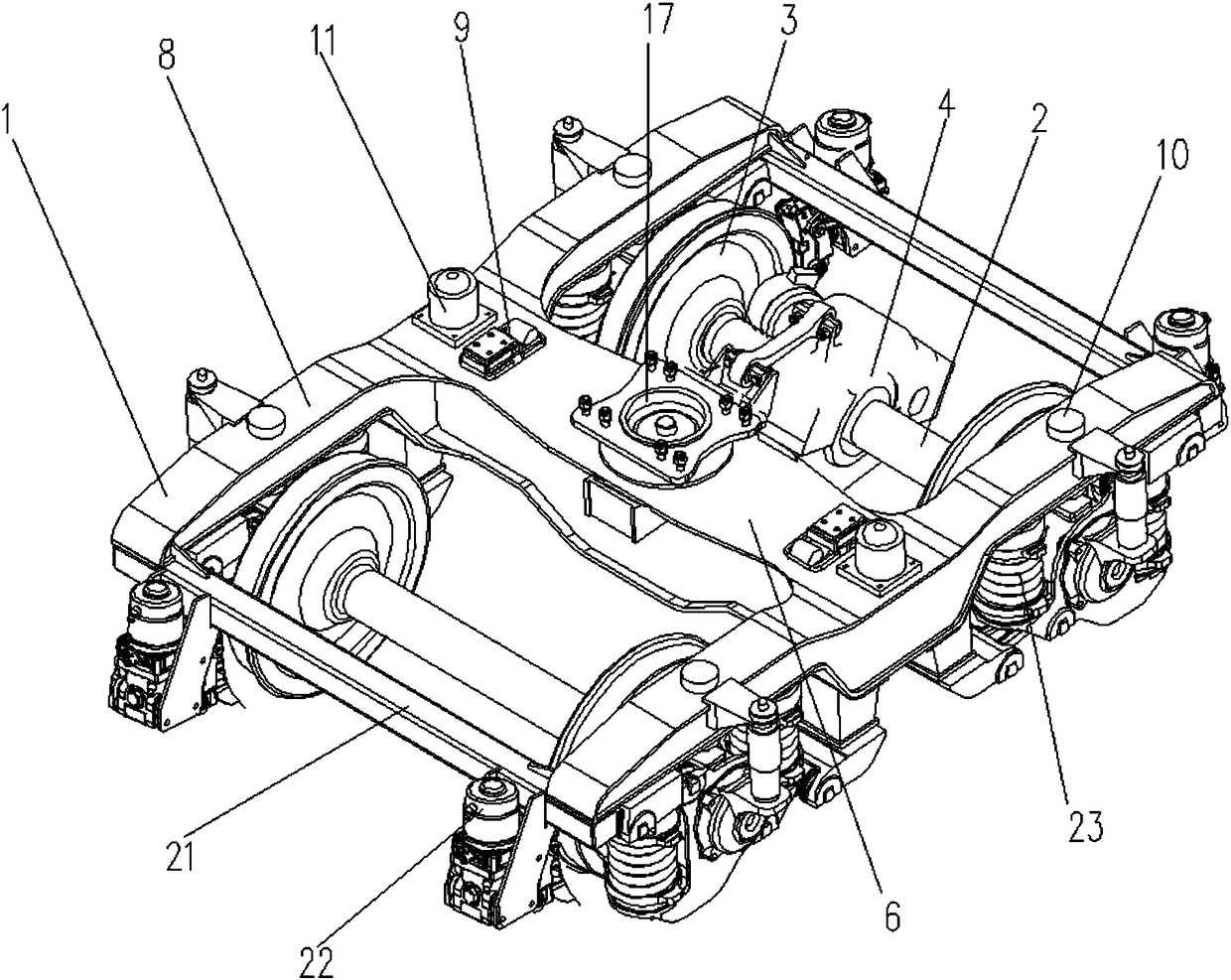

Two-axle bogie with locking function

The invention provides a two-axle bogie with the locking function. The bogie is provided with a framework. A center ball pin traction device is arranged in the middle of a transverse beam of the framework and fixedly connected with a frame located above the framework. A constant contact elastic friction side bearing is supported at the bottom of the frame and matched with the center ball pin traction device to support the frame above the framework, and side beams of the framework are provided with locking devices for enabling the framework and the frame to form rigid supporting and enabling the framework and a wheel set axle box to form rigid supporting. After the framework and the wheel set axle box form rigid supporting, and the framework and the frame form rigid supporting, the phenomenon that the frame swings left and right during vehicle equipment is operated is effectively avoided, the phenomenon that a vehicle tips over is avoided, the traction mode is central traction, and the requirement for low-speed walking of the vehicle is met; when the vehicle is operated at high speed, a center ball pin and the constant contact elastic friction side bearing are matched for use for spherical center plate traction, head shaking snake motion of the bogie is limited, the rolling pendulum motion of the vehicle body is limited, and the anti-dumping safety of the vehicle is promoted.

Owner:BAOJI CSR TIMES ENG MACHINERY

Flexible sensing device for measuring head pressure and manufacture method thereof

The invention relates to a flexible sensing device for measuring a head pressure and a manufacture method thereof. The flexible sensing device comprises a bottom silicon layer which can be fit to the curve shape of a head, the upper surface of the bottom silicon layer is provided with a matrix network which is formed by a plurality of pressure sensors and wires which are vertically and horizontally connected with the pressure sensors, and a power supply module for supplying electricity and an acquisition control module for outputting information of the pressure sensors are connected outside the matrix network through wires. The flexible sensing device has better flexibility, can be tightly clung to the curve face of the head, and is particularly suitable for measuring the pressures born on points of the head when a person wears protective articles such as a helmet and a safety helmet.

Owner:THE QUARTERMASTER EQUIPMENT RESEARCH INSTITUTE OF THE GENERAL LOGISITIC DEPARTME

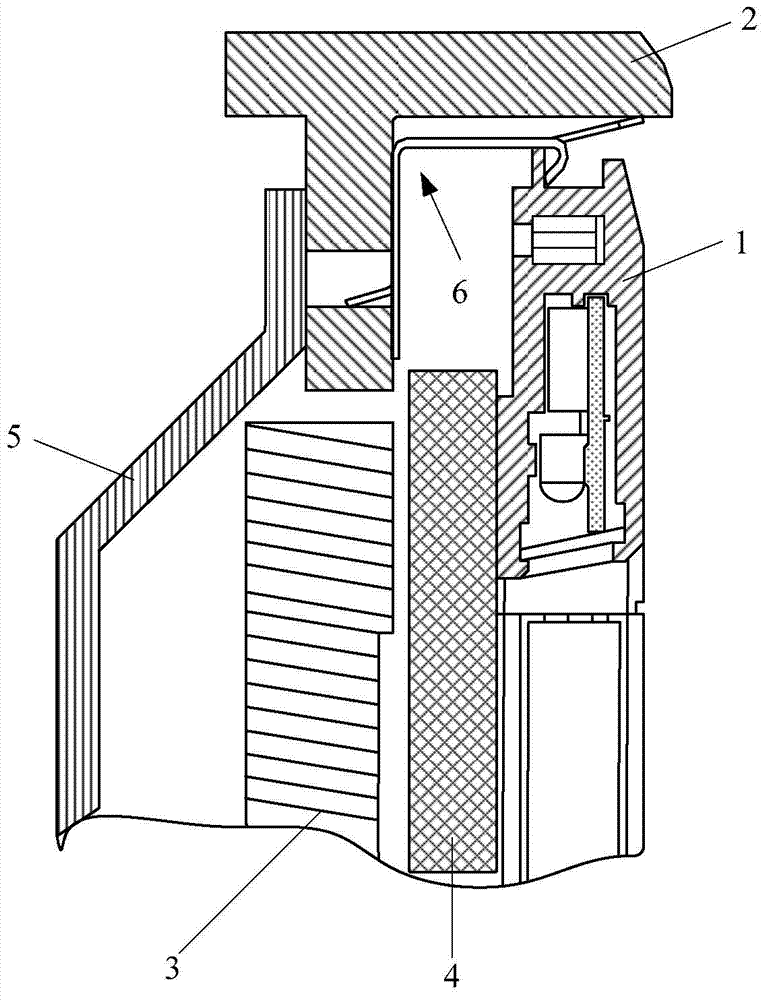

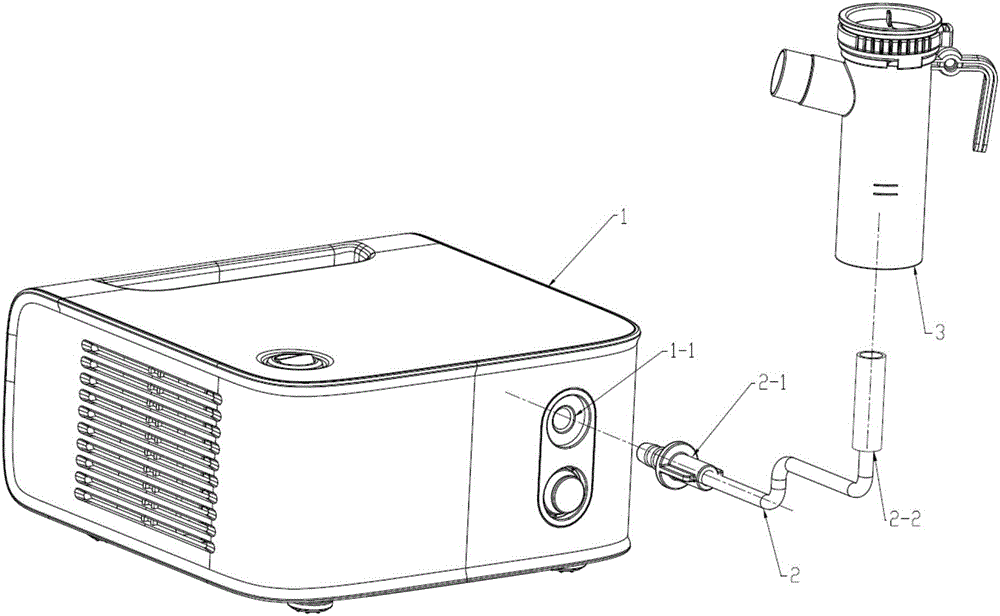

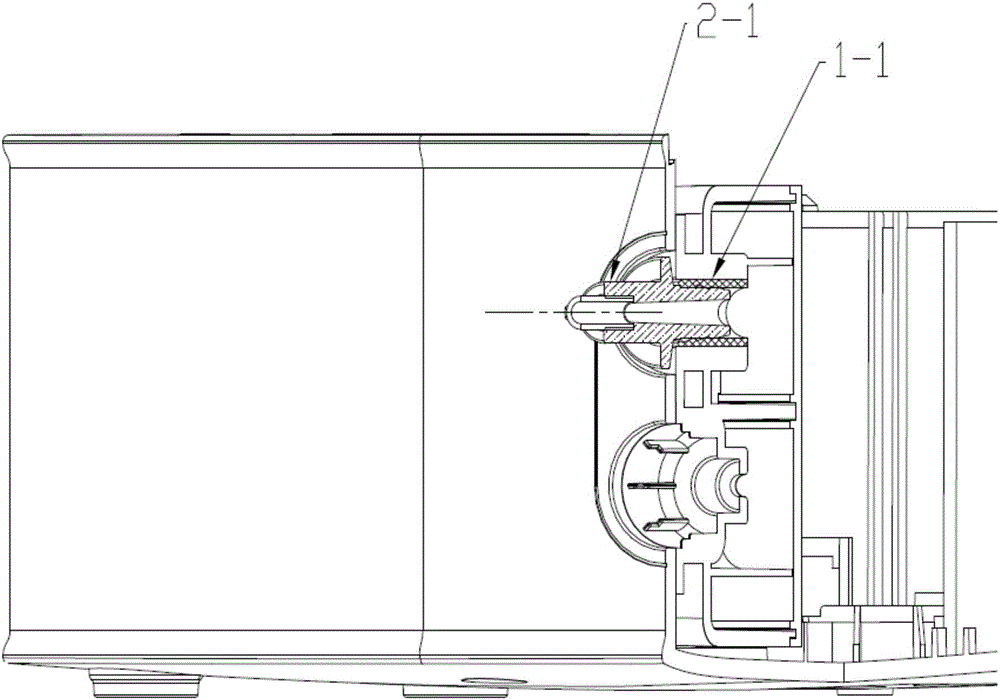

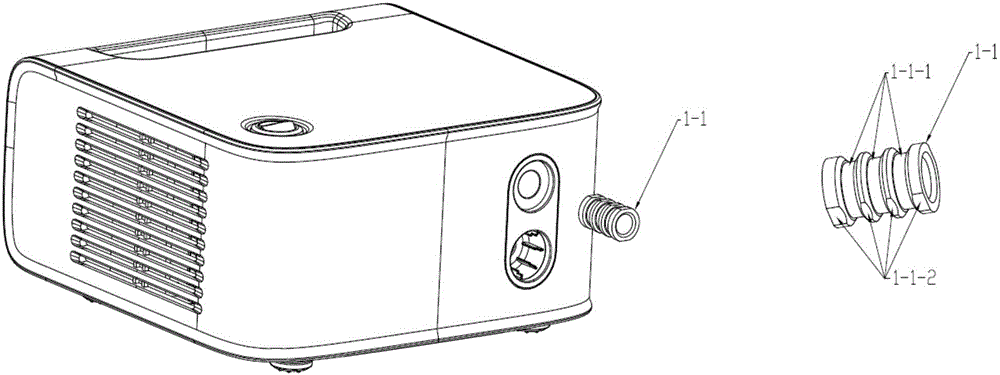

Compressed air atomizer connecting device

InactiveCN106075675AThere will be no problem of breakingUniform bearing surfaceTube connectorsMedical atomisersInhalationElectrical and Electronics engineering

The invention discloses a compressed air atomizer connecting device. The device comprises an atomizer main machine 1, a connecting pipe 2 and an atomizing cup 3, wherein an atomizing nozzle 1-1 is formed in the atomizer main machine 1; the connecting pipe 2 comprises a joint; the atomizing nozzle 1-1 is formed in a body shell of the atomizer main machine 1; the joint comprises a first connector 2-1 and a second connector 2-2; the first connector 2-1 is connected with the atomizing nozzle 1-1; the second connector 2-2 is connected with the external equipment atomizing cup 3; and the atomizing nozzle 1-1 is connected with the first connector 2-1 in an internal wrapping manner. The device has the beneficial effects that the problem of atomizing nozzle rupture caused by inserting and pulling out the joint of the connecting pipe multiple times is solved, thus obviously prolonging the service lives of compressed air atomizers, especially the compressed air atomizers which have high frequency of use and are used in hospitals, and avoiding the problem that atomization inhalation can not be carried out because of atomizing nozzle rupture.

Owner:JIANGSU YUYUE MEDICAL EQUIP&SUPPLY CO LTD +3

Straight-handle double-hook lifting hook suitable for flat sling and lifting equipment

PendingCN112061968AUniform bearing surfaceIncrease the bearing surfaceLoad-engaging elementsContact positionBearing surface

The invention provides a straight-handle double-hook lifting hook suitable for a flat sling. The straight-handle double-hook lifting hook comprises a straight handle and a transverse handle, the lowerend of the straight handle is fixed to the middle of the transverse handle, vertically-upward hook parts are arranged at the two ends of the transverse handle respectively, and ball head structures are arranged at the top ends of the hook parts; the transverse handle is of a flat structure, the upper surface of the transverse handle is a horizontal bearing face, and the two side faces of the transverse handle are vertical faces; the inner surfaces of the hook parts are perpendicular to the bearing surface; the inner surfaces of the hook parts and the bearing surface are in arc transition, andthe bearing surface and the vertical faces are in fillet transition; and the straight handle comprises a fixed section, a matching shaft section and a connecting section, the fixed section is fixed with the transverse handle, and an external thread structure is arranged on the connecting section. According to the lifting hook provided by the invention, the bearing face and the vertical faces makecontact with the sling, the overall stress face of the lifting hook is increased, stress is uniform, the sling is not damaged, the service life of the sling is prolonged, the contact position of thesling and the lifting hook is not prone to deformation, and the lifting stability is high.

Owner:天津重钢机械装备股份有限公司

Feeding device of a shearing machine

InactiveCN106346072BStable jobReduce failureShearing machine accessoriesEngineeringMechanical engineering

The invention relates to a feeding device of a shearing machine. The feeding device comprises a clamping mechanism for clamping a bar and a feeding mechanism for feeding the bar to a shearing system of the shearing machine. The feeding mechanism comprises a support and a feeding cylinder for driving the clamping mechanism to move back and forth. The feeding cylinder is connected to the support. The feeding device further comprises a guiding bearing bar. The clamping mechanism is erected on the guiding bearing bar in the mode of sliding relative to the guiding bearing bar. The clamping mechanism is improved, stable clamping is ensured, and meanwhile an adjusting device is added, so that bar conveying abrasion is avoided. The feeding device has the advantages of being simple in structure and capable of improving the product quality and prolonging the service life of a machine table.

Owner:泉州鹏宜机械有限公司

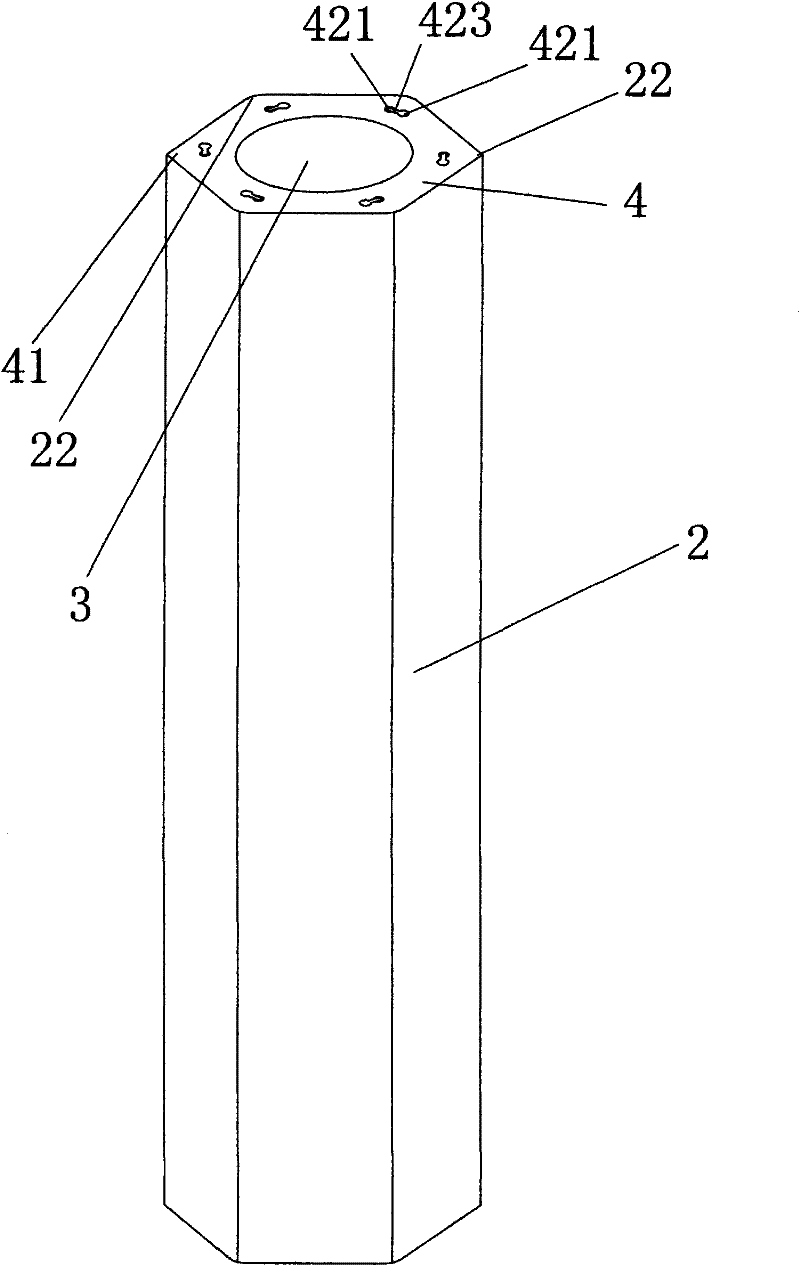

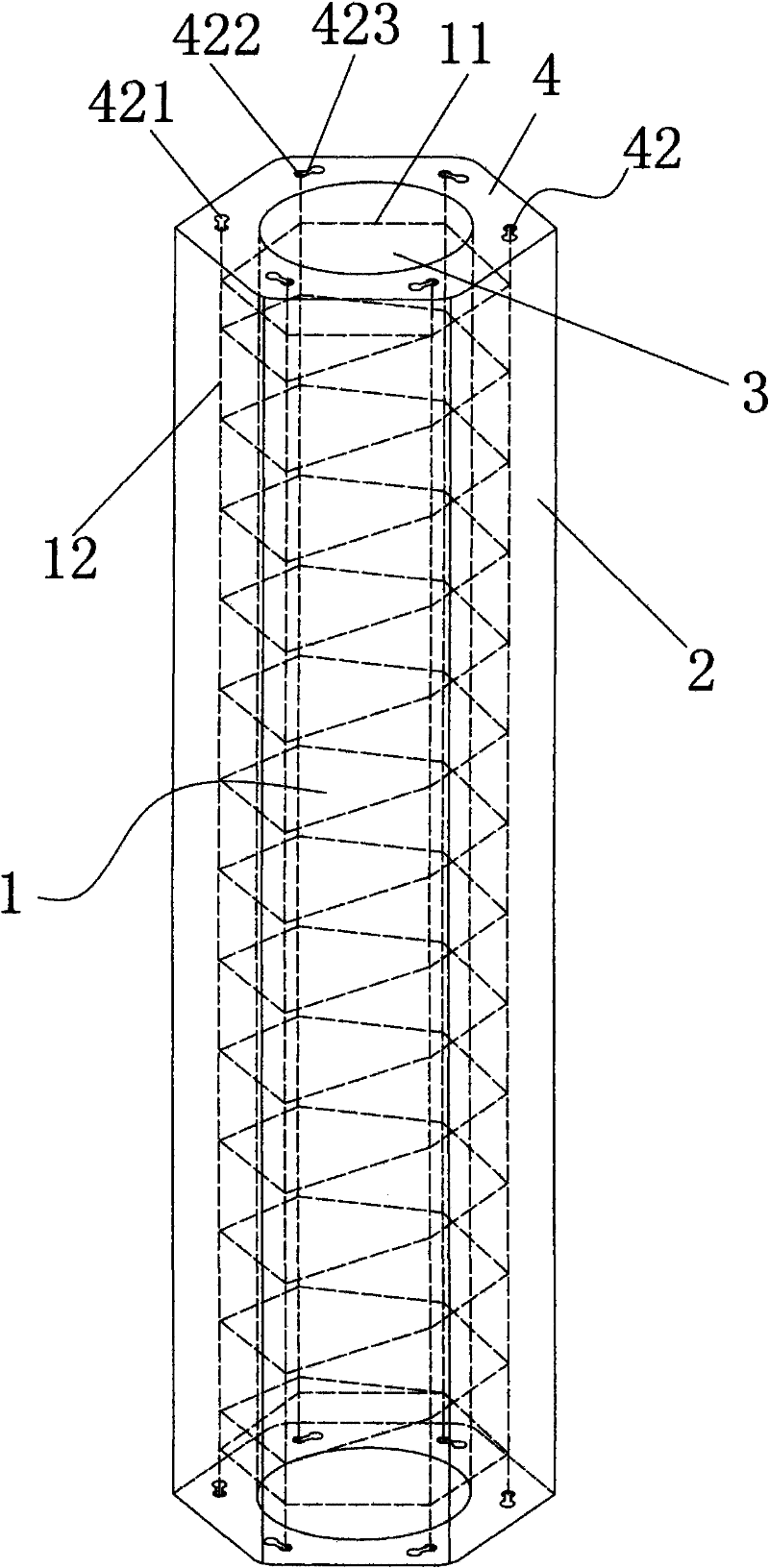

Pretensioned prestressed concrete polygonal pile and production method thereof

ActiveCN101886388BImprove compactnessRaise the intensity levelCeramic shaping apparatusBulkheads/pilesHigh resistancePre stress

The invention discloses a pretensioned prestressed concrete polygonal pile, which is characterized by comprising a reinforcing cage, wherein a polygonal pile body which is poured by concrete and combined with the reinforcing cage into a whole is arranged outside the reinforcing cage; the polygonal pile body is provided with at least five edges; the center of the polygonal pile body is provided with a central round hole which passes through the whole polygonal pile body; the two ends of the polygonal pile are respectively provided with polygonal end plates; and the two ends of the reinforcing cage are fixedly connected with the polygonal end plates. The invention aims to overcome the defects in the prior art, and provides the pretensioned prestressed concrete polygonal pile which has the advantages of high single pile bearing capacity, high horizontal bend-resistant bearing capacity, high shear resistance, high shock resistance, small loss under construction, material saving, light dead weight, convenient stacking, and difficult damage during lifting, transporting and transferring. The invention also aims to provide a method for producing the pretensioned prestressed concrete polygonal pile.

Owner:JIANHUA CONSTR MATERIALS (JIANGSU) CO LTD

Injection molding machine pedal device

ActiveCN103252880BImprove reliabilityEliminate potential safety hazardsInjection molding machineLimit switch

The invention discloses a pedal device for an injection molding machine, which relates to the technical field of an injection molding machine. The pedal device for the injection molding machine comprises a pedal, wherein a supporting base is arranged below the pedal; a movable sleeve is arranged between the pedal and the supporting base, and is fixedly connected with the pedal through a slab; a plurality of buffer pieces are mounted between the slab and the supporting base in a space defined by the movable sleeve; a limiting switch is arranged on the supporting base, and is electrically connected with a controller for controlling a safety door of the injection molding machine to open and close; and at least one limiting block, which is higher than the limiting switch, is arranged between the slab and the supporting base. With the adoption of the pedal device for the injection molding machine provided by the invention, the potential safety hazard in a working process of the injection molding machine can be avoided.

Owner:广西嘉诚工业有限公司

Material returning device of e-shaped elastic strip winding machine

PendingCN114132738ASlide down firmlySteady and precise slide downConveyor partsWinding machinePillow block bearing

The invention discloses a material returning device of an e-shaped elastic strip winding machine. The material returning device comprises a material returning rack, a bearing seat is assembled and connected to the material returning rack, a pivotal bearing is assembled and connected to the bearing seat, a main shaft is rotationally connected to the pivotal bearing, the pivotal bearing is installed on the main shaft, and a forming mold is fixedly assembled and connected to the left side of the main shaft; the main shaft is assembled and connected with a material returning mechanism; the material returning mechanism comprises a material returning disc slidably connected to the forming die, and the right side of the main shaft is slidably connected with a material pushing disc corresponding to the material returning disc. A plurality of material pushing rods are assembled and connected between the material pushing disc and the material returning disc, and the material pushing rods penetrate through the rotary bearing; the material returning mechanism further comprises a material returning oil cylinder assembled and connected to the right side of the top of the material returning rack, a piston rod of the material returning oil cylinder is assembled and connected with a shifting fork plate, and the shifting fork plate is arranged on the right side of the material pushing disc. The device further comprises a material receiving mechanism arranged on the right side of the top of the material returning rack. By means of the design of the parts of the device, even material returning of the e-shaped elastic strips is achieved, the material taking and positioning precision is higher after material returning, and next-step forming is facilitated.

Owner:ANHUI CHAOHU CASTING FACTORY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com