Thrust bearing

A thrust bearing and thrust bearing pad technology, applied in the field of thrust bearings, can solve the problems of poor cooling effect, difficult to form oil film, burning of thrust bearings, etc., and achieve the effect of controlling radial swing amplitude, prolonging service life and uniform force surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The accompanying drawing discloses the specific structure of an embodiment of the present invention without limitation, and the present invention will be further described below in conjunction with the accompanying drawings.

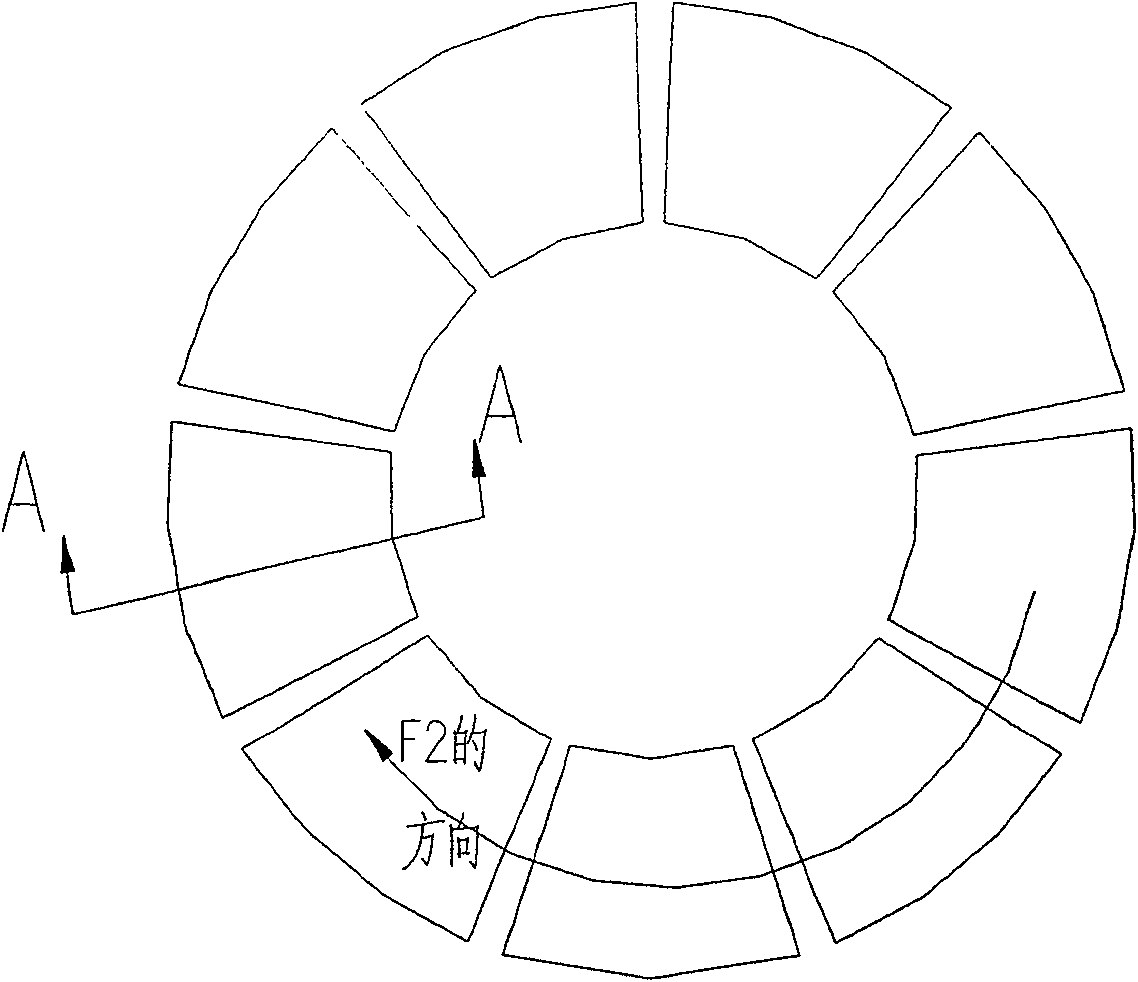

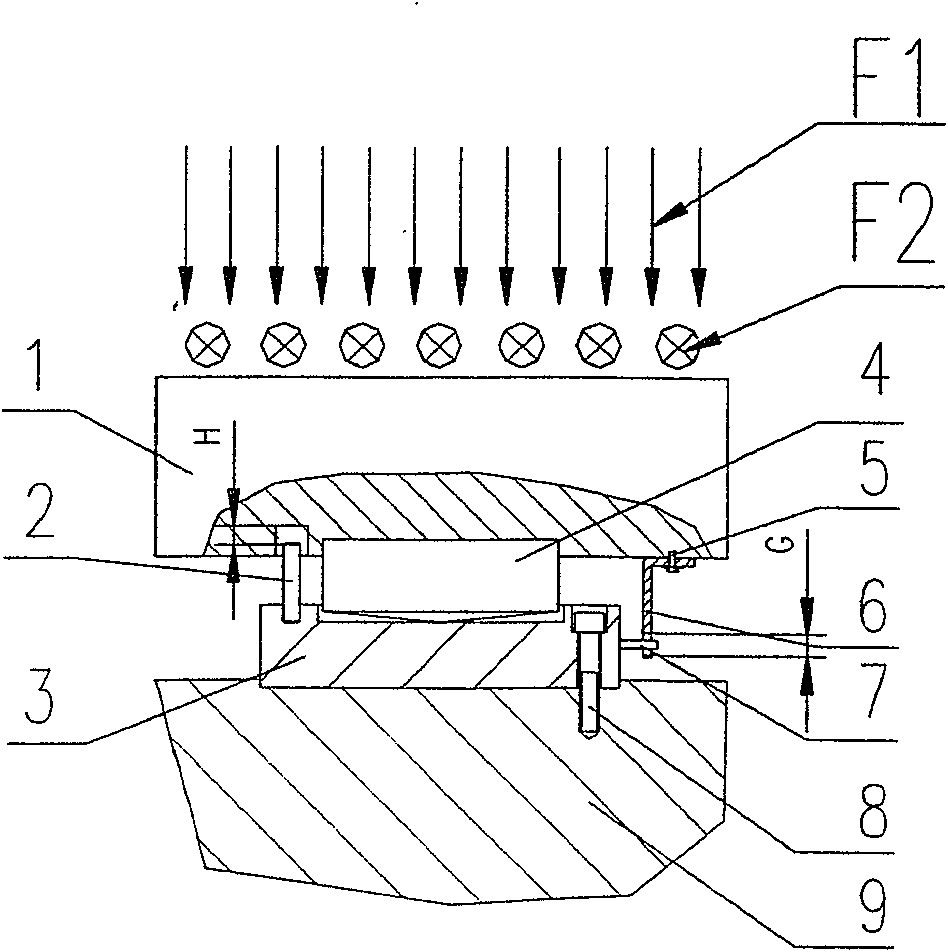

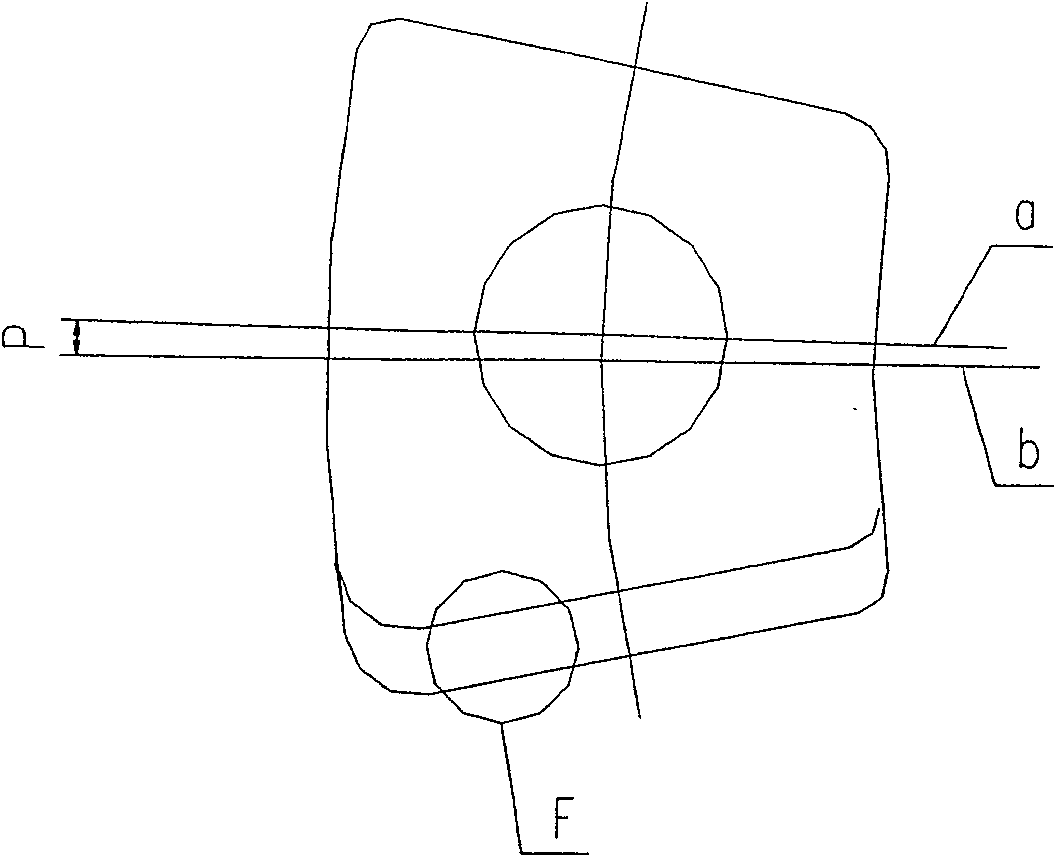

[0022] Depend on figure 1 figure 2 combine image 3 It can be seen that the present invention includes 6 to 24 independent thrust bearing pad groups, each set of thrust bearing pads contains corresponding thrust bearing pads 1 and support pads 3, the upper surface of the thrust bearing pad 1 is covered with a Babbitt alloy layer, and the independent thrust pads The bearing pad groups are evenly distributed on the same circular plane. A support block 4 is provided between the thrust bearing pad 1 and the support pad 3. The lower end surface of the support block 4 is a spherical arc surface; the horizontal force direction F2 of the thrust bearing pad is used as a reference , in the ring with thrust bearing pads 1 evenly distributed, the radial ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com