Pretensioned prestressed concrete polygonal pile and production method thereof

A production method and polygonal technology, applied in sheet pile walls, ceramic forming machines, manufacturing tools, etc., can solve the problems of low bending resistance of thin-walled pipe piles, low bearing capacity of single pile foundations, and uneven distribution of steel bars. Achieve the effect of good concrete compactness, high bearing capacity of single pile, and not easy to local fatigue damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with accompanying drawing description and specific embodiment:

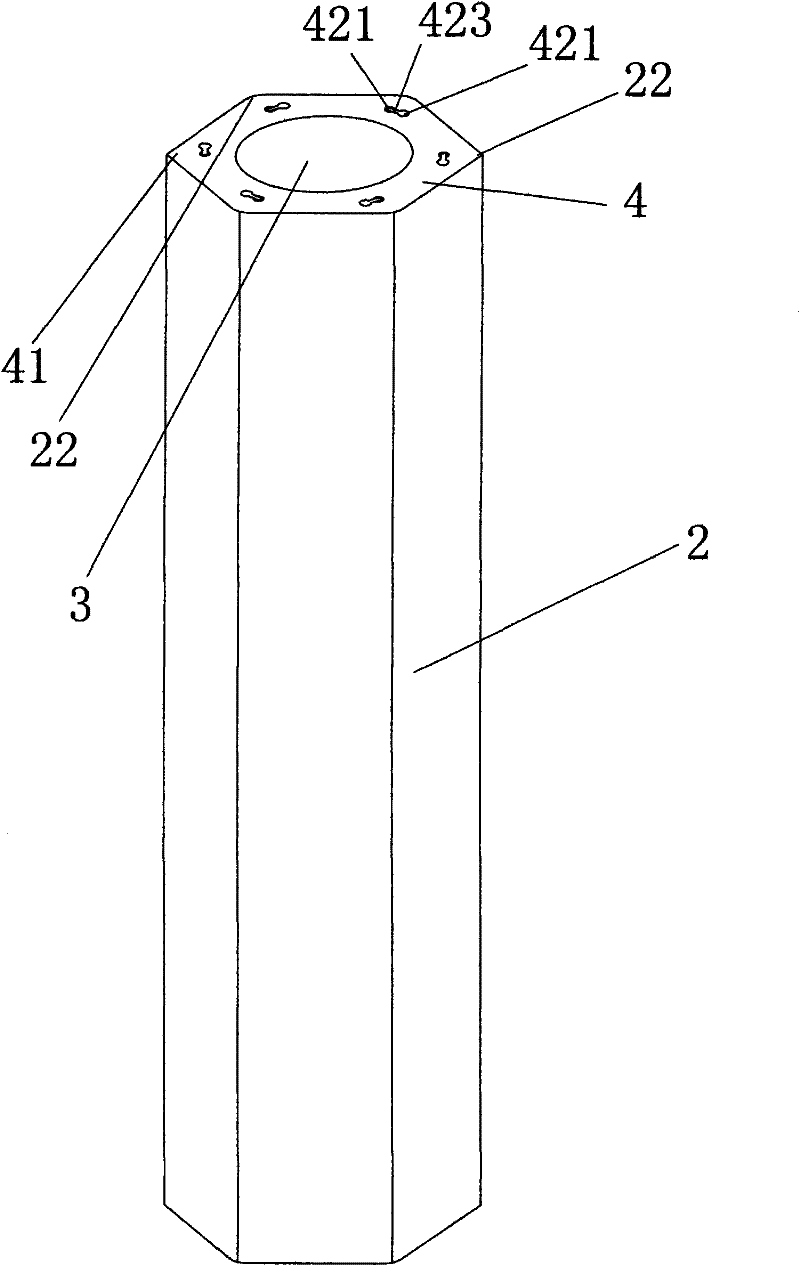

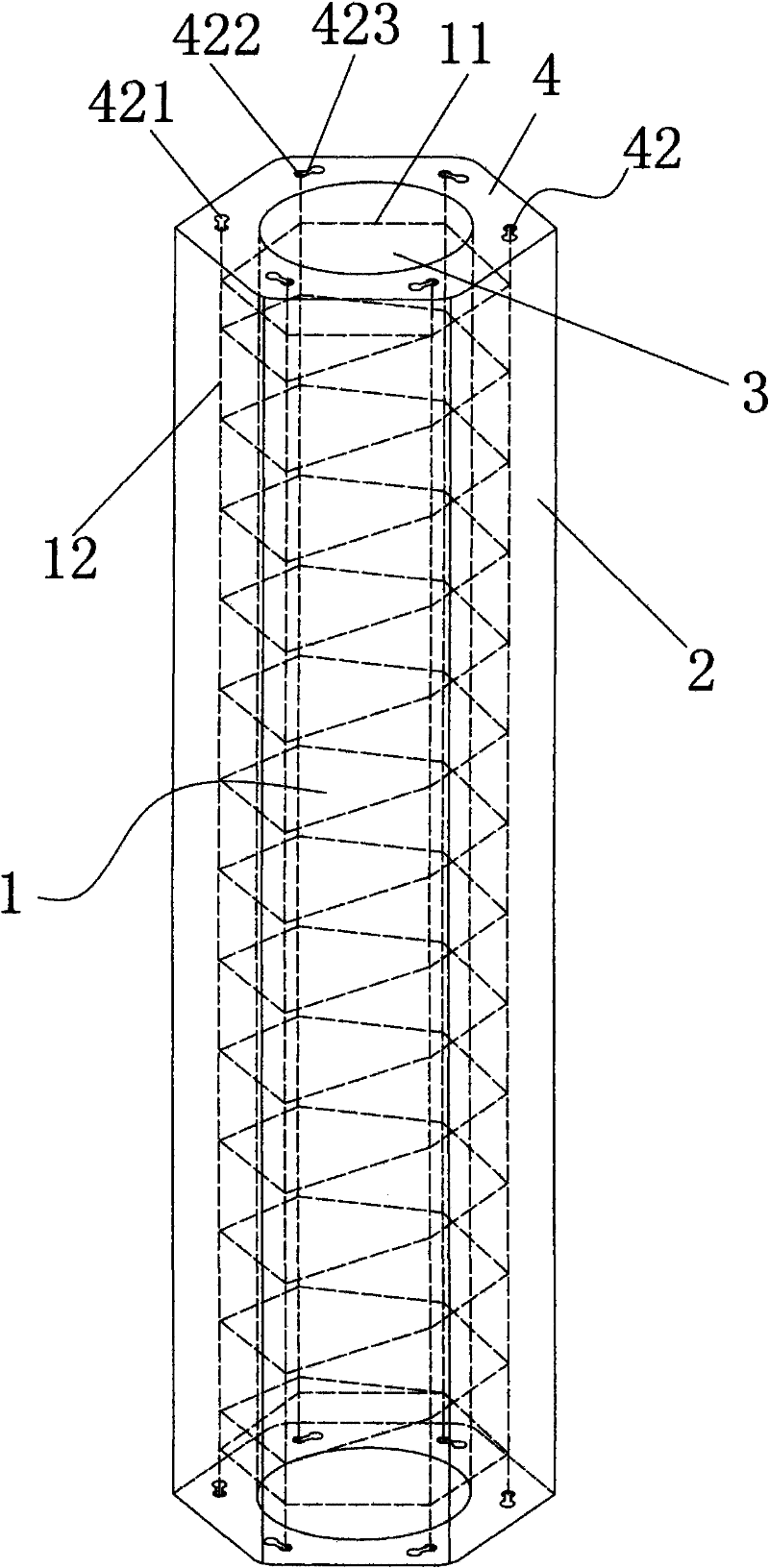

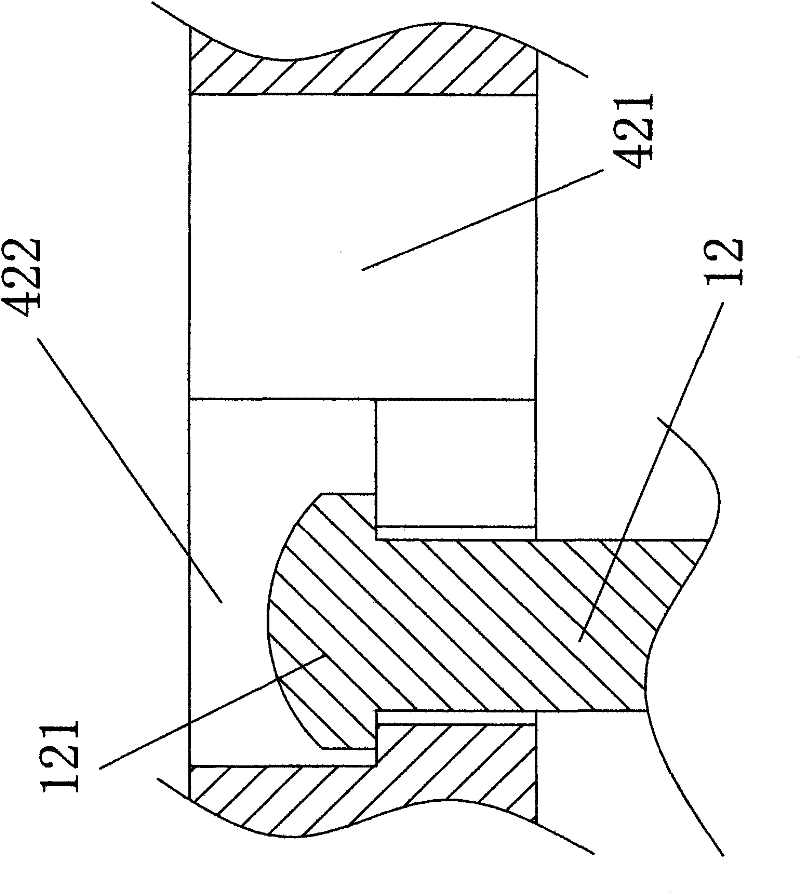

[0036] like Figures 1 to 4 A kind of pre-tensioned prestressed concrete polygonal pile shown, comprises reinforcement cage frame 1, and described reinforcement cage frame 1 comprises a plurality of main steel bars 12, is welded with spiral stirrup 11 on described main steel bars 12, so The head of the main steel bar 12 is larger than the diameter of the main steel bar 12, and the polygonal pile body 2 formed by pouring concrete and integrated with the steel bar cage 1 is arranged outside the steel bar 12. The pile body 2 has at least five sides, and the center of the polygonal pile body 2 is provided with a central circular hole 3 that runs through the entire polygonal pile body 2, and polygonal end plates 4 are respectively provided on both ends of the polygonal pile body 2, Both ends of the reinforcement cage 1 are fixedly connected w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com